Water-based acrylic acid modified saturated polyester resin and preparation method thereof

A water-based acrylic and polyester resin technology, applied in the chemical field, can solve the problems of high VOC content, easy hydrolysis, and low construction solid content, and achieve the effects of increasing construction solid content, reducing viscosity, and improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

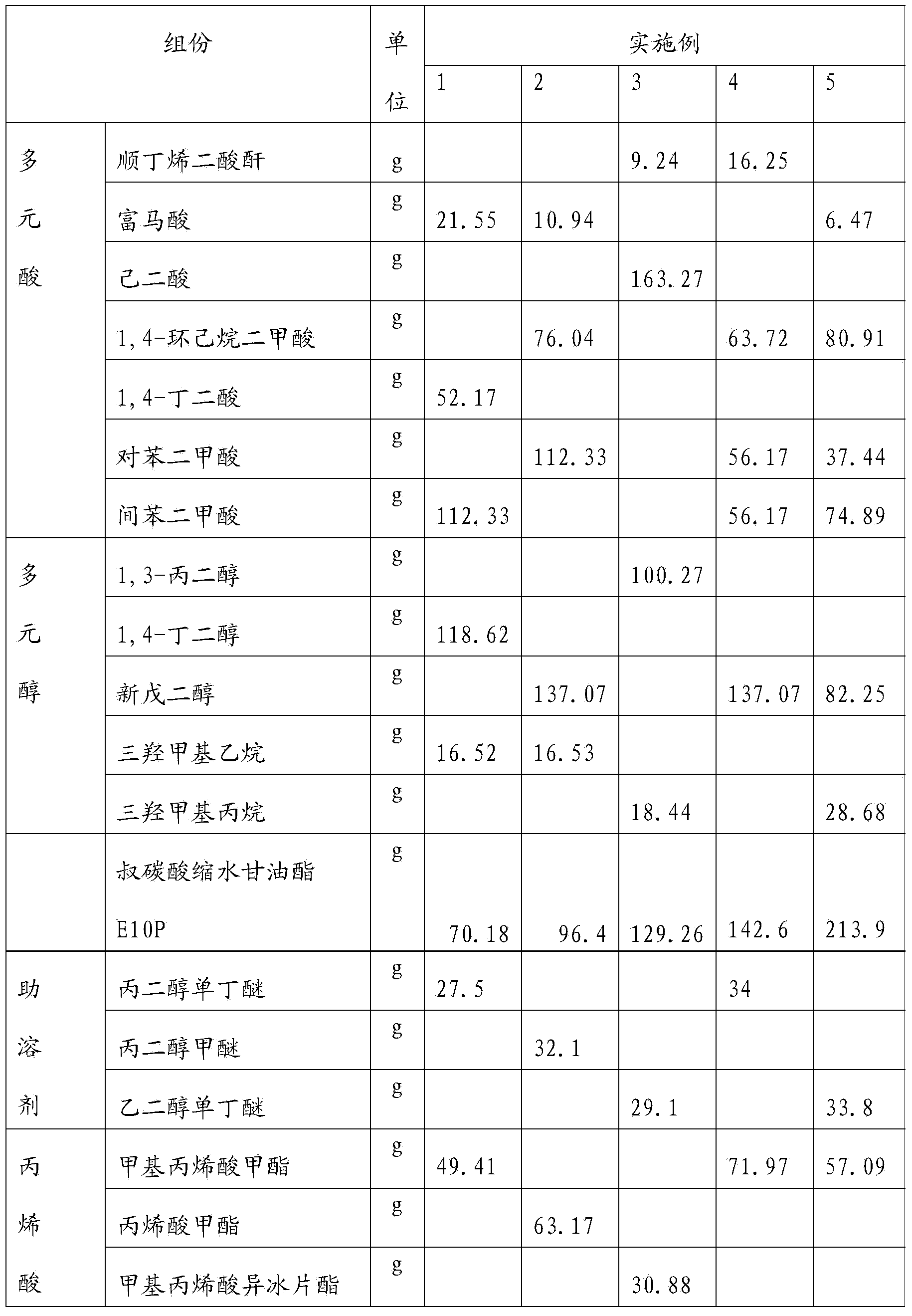

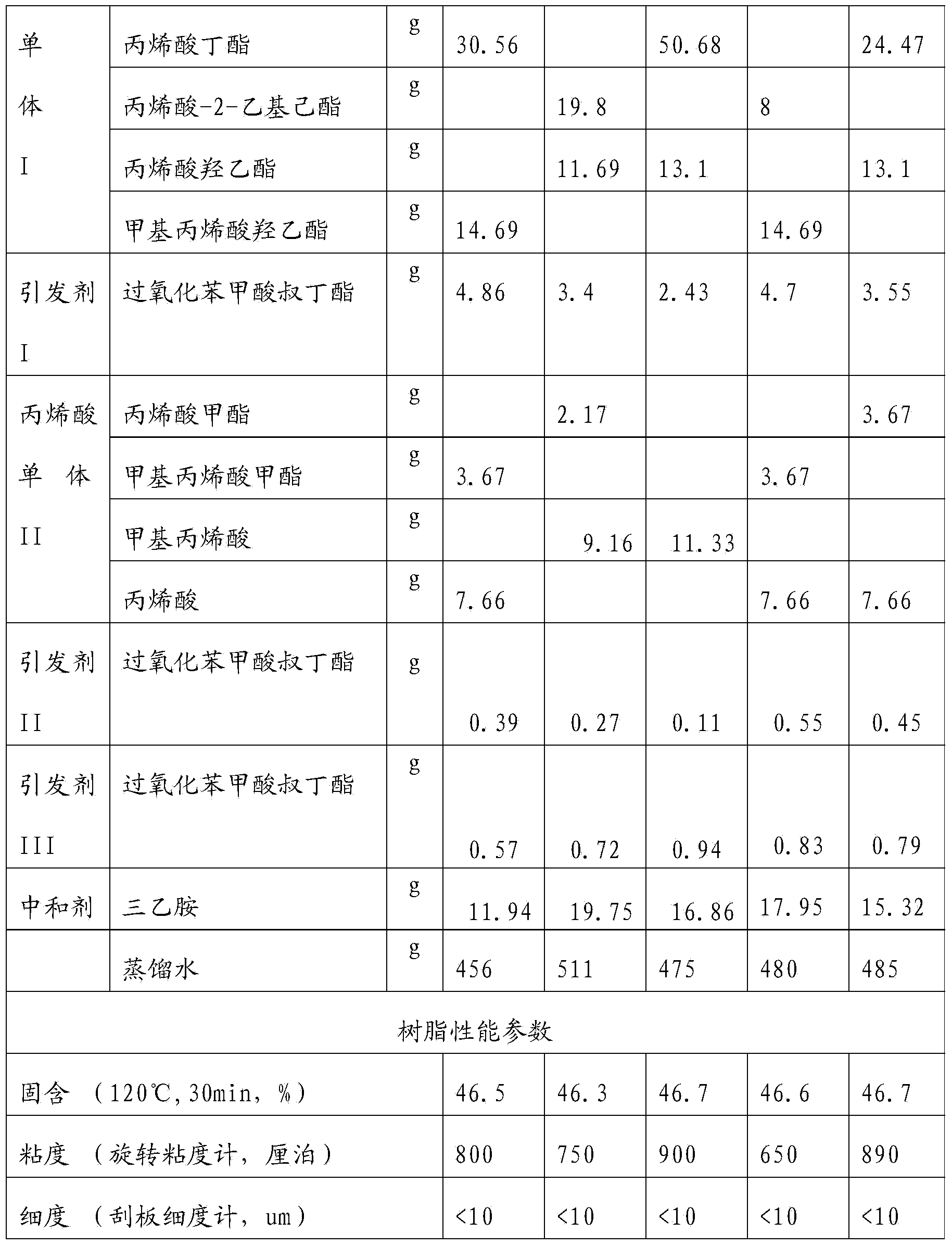

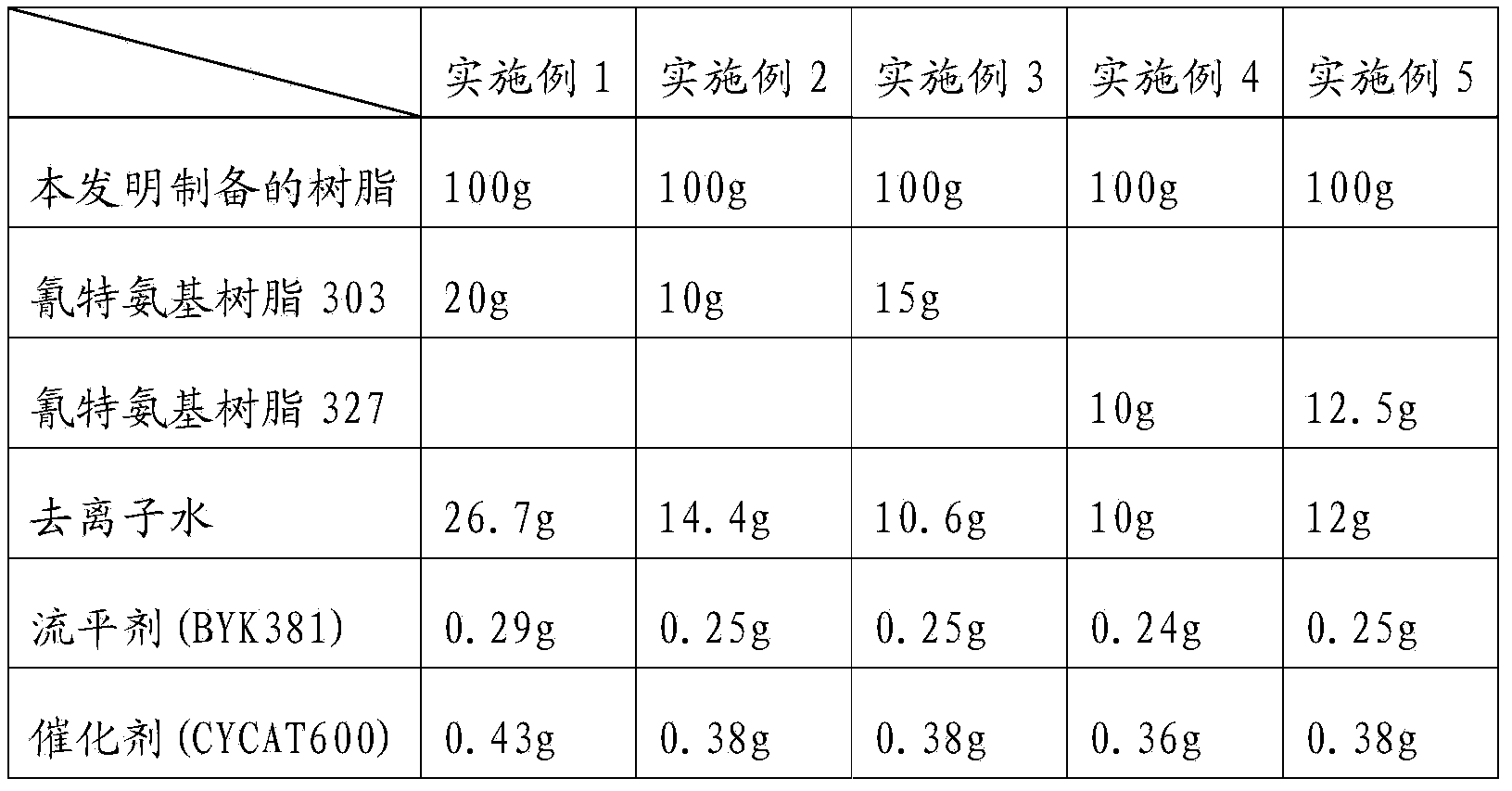

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0028] The specific implementation steps are as follows:

[0029] 1) Put polybasic acid, E10P, and polyol into a 1L reaction flask equipped with stirring device, reflux condensing device, dropping device and temperature control device, feed nitrogen gas, slowly heat to 190°C, keep warm for 1 hour, and slowly heat up to 250°C, keep warm for 6h, add xylene and reflux until the acid value is 20mgKOH / g, control the temperature of the distillation head during the reaction to be less than 100°C;

[0030] 2) Cool down to 110°C and add co-solvent;

[0031] 3) Add the mixture of acrylic acid monomer I and initiator I dropwise at 120°C, and finish dropping in 4 hours;

[0032] 4) Add the mixture of acrylic acid monomer II and initiator II dropwise at 120°C for 1 hour; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com