Water-based organic silicon modified cationic acrylic resin and synthesis method thereof

A cationic acrylic and silicone technology, applied in the field of furniture decoration and decoration, which can solve the problems of insufficient hardness, fullness, transparency and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

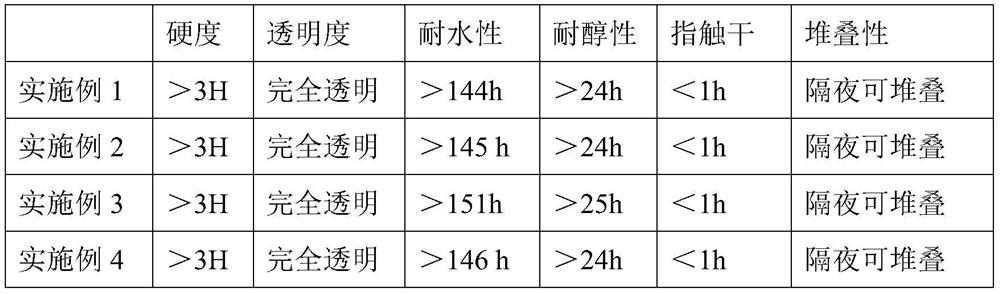

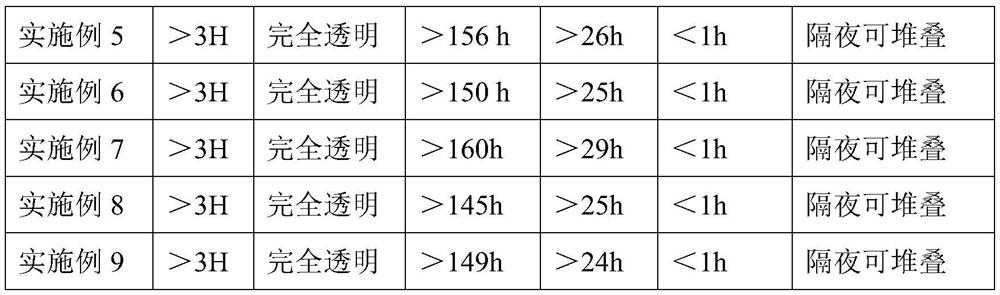

Examples

Embodiment 1

[0037] The preparation method of waterborne organosilicon modified cationic acrylic resin:

[0038] 1) Stir and mix 250kg propylene glycol methyl ether and 50kg absolute ethanol evenly, then heat to 88°C;

[0039] 2) 150kg methyl methacrylate, 40kg butyl acrylate, 200kg styrene, 100kg dimethylaminoethyl methacrylate, 100kg hydroxyethyl acrylate, 30kg vinyltriethoxysilane, 10kg methylstyrene Linear dimer, 50kg N,N-dimethylformamide, 10kg azobisisobutyronitrile were mixed uniformly to obtain a mixed solution;

[0040] 3) Add the mixed solution of step 2) into step 1), and stir while adding dropwise, and the adding time is controlled within 5 hours;

[0041] 4) After step 3), continue to keep warm for 2 hours, and control the temperature at 88°C;

[0042] 5) After step 4), the temperature is lowered, and the temperature is less than 50°C;

[0043] 6) Add 10 kg of lactic acid into step 5), and stir for half an hour to obtain a water-based silicone-modified cationic acrylic resi...

Embodiment 2

[0045] The preparation method of waterborne organosilicon modified cationic acrylic resin:

[0046] 1) Stir and mix 240kg propylene glycol methyl ether and 80kg absolute ethanol evenly, then heat to 90°C;

[0047] 2) 180kg methyl methacrylate, 20kg butyl acrylate, 180kg styrene, 80kg dimethylaminoethyl methacrylate, 60kg hydroxyethyl acrylate, 40kg vinyltriethoxysilane, 15kg methylstyrene Linear dimer, 60kg N,N-dimethylformamide, 12kg azobisisobutyronitrile were mixed uniformly to obtain a mixed solution;

[0048] 3) Add the mixed solution of step 2) into step 1), and stir while adding dropwise, and the adding time is controlled within 5 hours;

[0049] 4) After step 3), continue to keep warm for 2 hours, and keep the temperature at 90°C;

[0050] 5) After step 4), the temperature is lowered, and the temperature is less than 50°C;

[0051] 6) Add 15kg of lactic acid into step 5), and stir for half an hour to obtain a water-based silicone-modified cationic acrylic resin.

Embodiment 3

[0053] The preparation method of waterborne organosilicon modified cationic acrylic resin:

[0054] 1) Stir and mix 100kg propylene glycol methyl ether and 200kg absolute ethanol, then heat to 88°C;

[0055] 2) 150kg methyl methacrylate, 40kg butyl acrylate, 200kg styrene, 100kg dimethylaminoethyl methacrylate, 100kg hydroxyethyl acrylate, 30kg vinyltriethoxysilane, 50kg methylstyrene Linear dimer, 160kg N, N-dimethylformamide, 50kg azobisisobutyronitrile were mixed uniformly to obtain a mixed solution;

[0056] 3) Add the mixed solution of step 2) into step 1), and stir while adding dropwise, and the adding time is controlled within 4 hours;

[0057] 4) After step 3), continue to keep warm for 2 hours, and control the temperature at 88°C;

[0058] 5) After step 4), the temperature is lowered, and the temperature is less than 50°C;

[0059] 6) Add 20kg of lactic acid into step 5), and stir for half an hour to obtain a water-based silicone-modified cationic acrylic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com