Waterborne hydroxyl acrylic finish paint and preparation method thereof

A technology of hydroxyacrylic acid and water-based isocyanate, which is applied in the field of coatings, can solve the problems of high cost and poor film performance, and achieve the effects of increasing the coating area, high solid content in construction, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

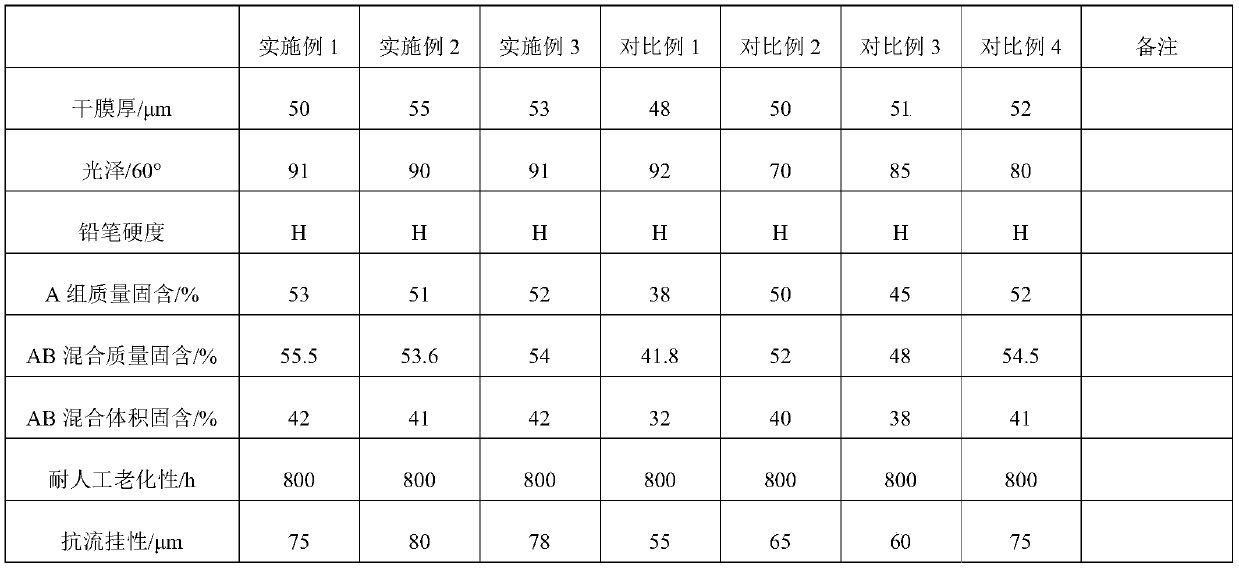

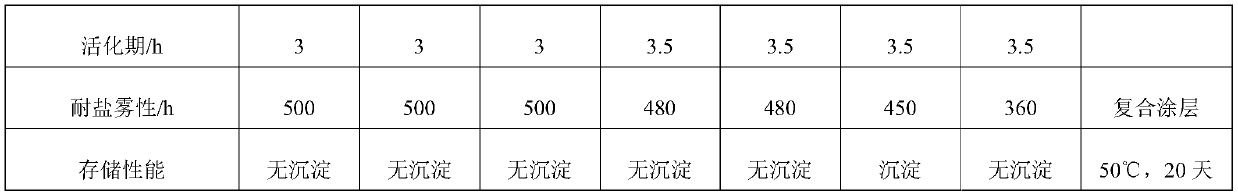

Examples

preparation example Construction

[0040] A preparation method for water-based hydroxyacrylic topcoat, comprising the following steps:

[0041] S1, mix 1 / 2~1 / 3 deionized water and emulsifier evenly, then add brightening agent, disperse evenly, set aside;

[0042] S2, mix the remaining deionized water with pH regulator, defoamer, dispersant, anti-sedimentation agent and 1 / 3~1 / 2 of co-solvent, stir, then add pigments and fillers, stir, and then grind to Fineness ≤ 15μm, that is the stock slurry;

[0043] S3, add the stock preparation slurry to the water-based hydroxyacrylic acid dispersion weight, stir, then add the wetting and leveling agent, thickener and the remaining co-solvent, and stir, which is the A component;

[0044] S4, add the water-based isocyanate curing agent and the environmental protection solvent into the container, and mix evenly, which is the B component;

[0045] S5, mixing component A and component B to obtain a final product.

[0046] The preparation method of described waterborne hydrox...

Embodiment 1

[0053] The following parts are parts by mass.

[0054] S1, mix 4.3 parts of deionized water and 1 part of emulsifier Synperonic PE / F127 evenly, then add 1 part of brightener SP-9512, disperse at 1500r / min for 60min, disperse evenly, and set aside;

[0055] S2, with 4.3 parts of deionized water and 0.2 parts of pH regulator dimethylethanolamine, 0.2 parts of antifoaming agent BYK024, 1.5 parts of dispersant (mass ratio of BYK-190 and BYK-194 of 3:1 Mixture), 3 parts of anti-settling agent (3% DE) and 0.7 part of cosolvent (a mixture of dipropylene glycol methyl ether and dipropylene glycol butyl ether with a mass ratio of 2:3) are mixed uniformly, and the pH is adjusted to be 7-10 , stirred at 800r / min for 15min, then added 21 parts of pigment DuPont R-706 and 10 parts of filler precipitated barium sulfate (1500 mesh), stirred at 1000r / min for 30min, and then ground to a fineness of ≤15μm, namely Stock preparation;

[0056] S3, adding the stock preparation slurry to 50 parts ...

Embodiment 2

[0060] The following parts are parts by mass.

[0061] S1, mix 2.3 parts of deionized water and 1.2 parts of emulsifier Synperonic PE / F127 evenly, then add 1.2 parts of brightener SP-9512, disperse at 1400r / min for 50min, disperse evenly, and set aside;

[0062] S2, 2.4 parts of deionized water and 0.3 parts of pH regulator dimethylethanolamine, 0.4 parts of antifoaming agent BYK024, 0.8 parts of dispersant (a mixture of BYK-190 and BYK-194 with a mass ratio of 2:1 ), 4 parts of anti-sedimentation agent (5% DE) and 1.5 parts of cosolvent (the mixture of dipropylene glycol methyl ether and dipropylene glycol butyl ether with a mass ratio of 3:2) are mixed uniformly, and the pH is adjusted to be 7~10, Stir at 700r / min for 10min, then add 2 parts of pigment carbon black MA100 and 26 parts of filler precipitated barium sulfate (1500 mesh), stir at 1200r / min for 20min, then grind to fineness≤15μm, which is the stock slurry ;

[0063] S3, adding the stock preparation slurry to 55 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com