High-thixotropy water-based double-component high-glossiness automotive topcoat and preparation method thereof

A technology of automobile topcoat and thixotropy, which is applied in the field of coatings, can solve the problems of slow drying speed of water-based automobile topcoat, easy generation of prickly heat and dark bubbles in the paint layer, easy sagging during construction, etc., and achieves moderate viscosity, good construction performance, avoid sagging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

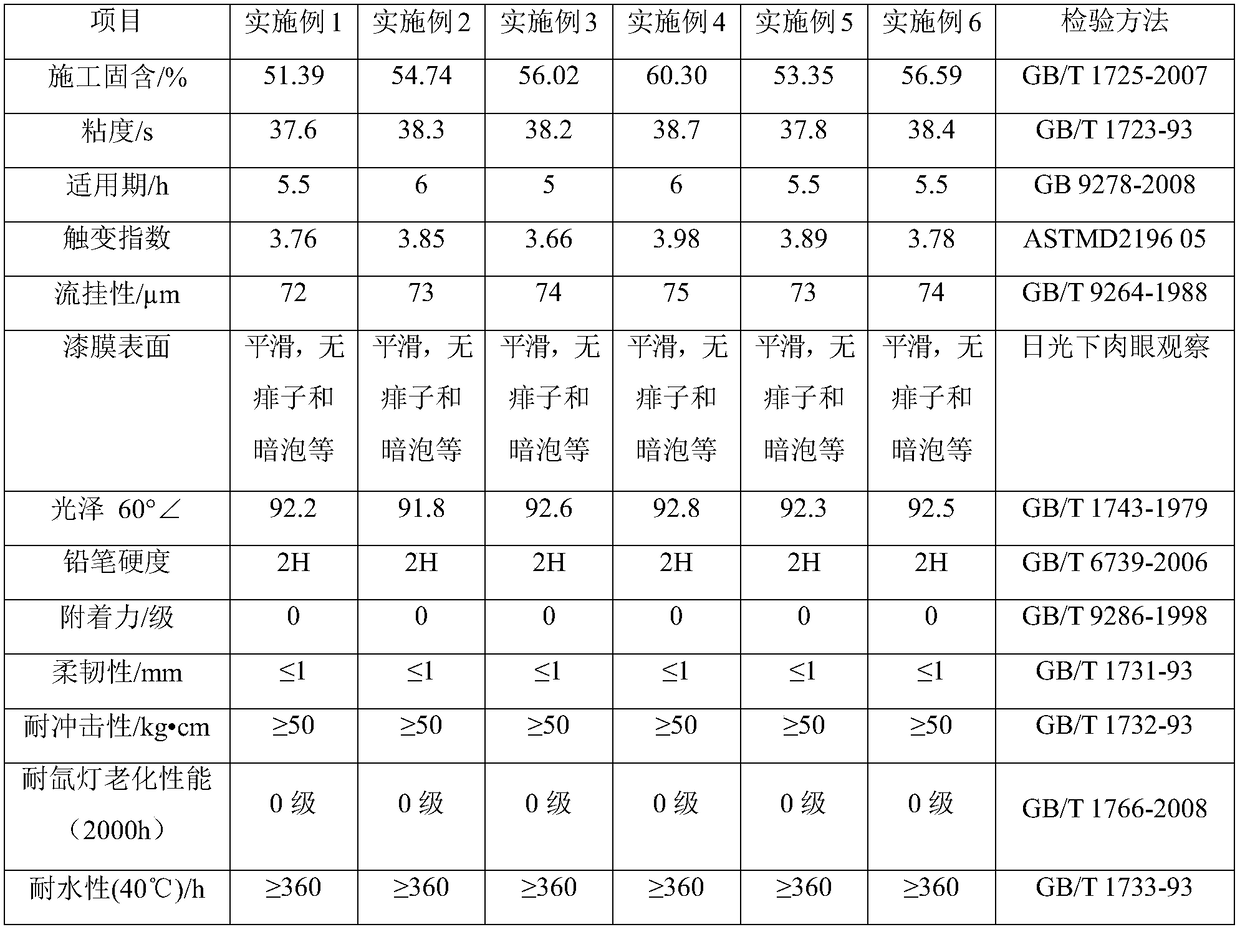

Examples

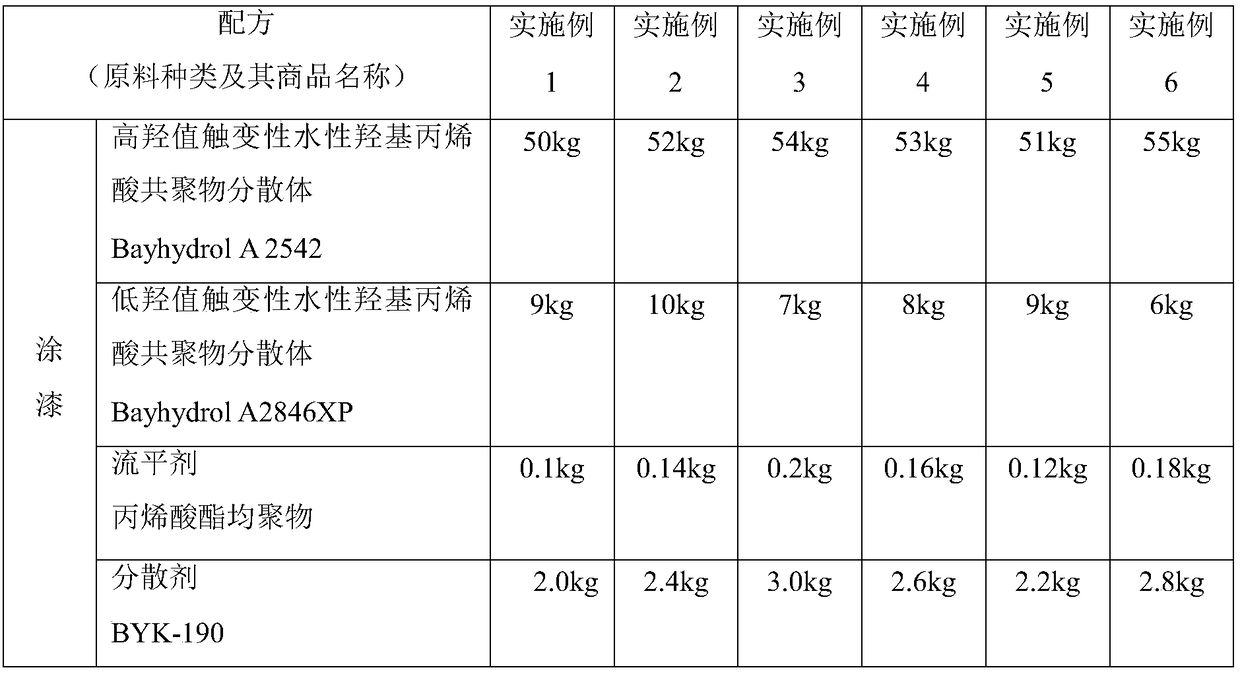

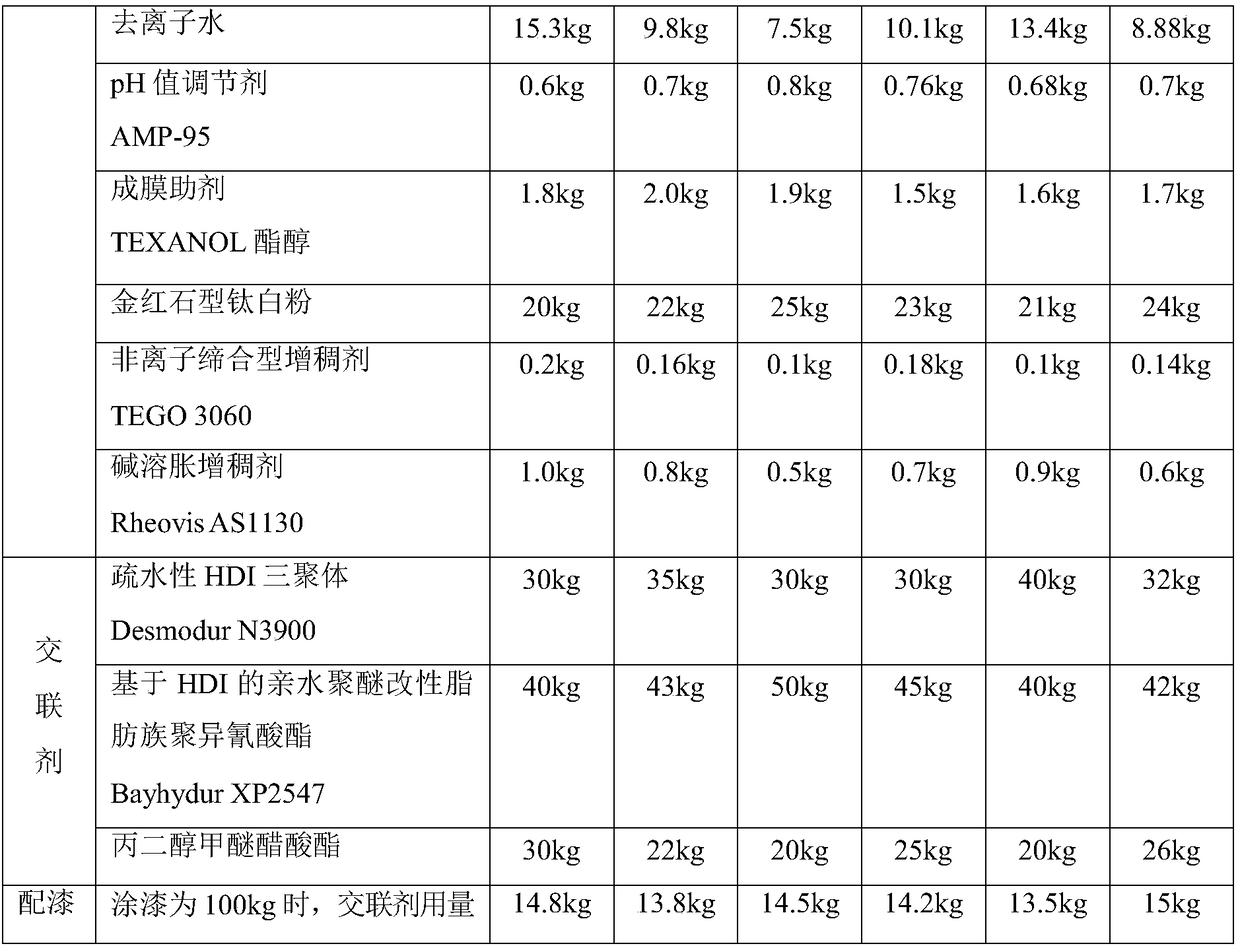

Embodiment 1~6

[0037] The preparation method of embodiment 1~6 is as follows:

[0038] S1. Add the formulated amount of deionized water, dispersant BYK-190 and pH adjuster into the dispersion cylinder to disperse evenly, then slowly add titanium dioxide, pre-disperse at 800rpm for 20min, and then use a sand mill to pre-disperse The final mixture is ground to less than 10 μm to obtain a color paste;

[0039] S2. Add high hydroxyl value thixotropic waterborne hydroxyacrylic copolymer dispersion, low hydroxyl value thixotropic waterborne hydroxyacrylic copolymer dispersion, leveling agent and film-forming aid TEXANOL ester alcohol to the paint mixing tank, and disperse Evenly, then add the color paste, disperse at 800rpm for 20 minutes, then add the non-ionic associative thickener and alkali-swellable thickener in the formulated amount, and get the paint after filtering;

[0040] S3, take the hydrophobic HDI trimer of formula quantity, the hydrophilic polyether-modified aliphatic polyisocyanat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com