Water-based double-component thick-coating ultralow-VOC high-solid clear primer and preparation method thereof

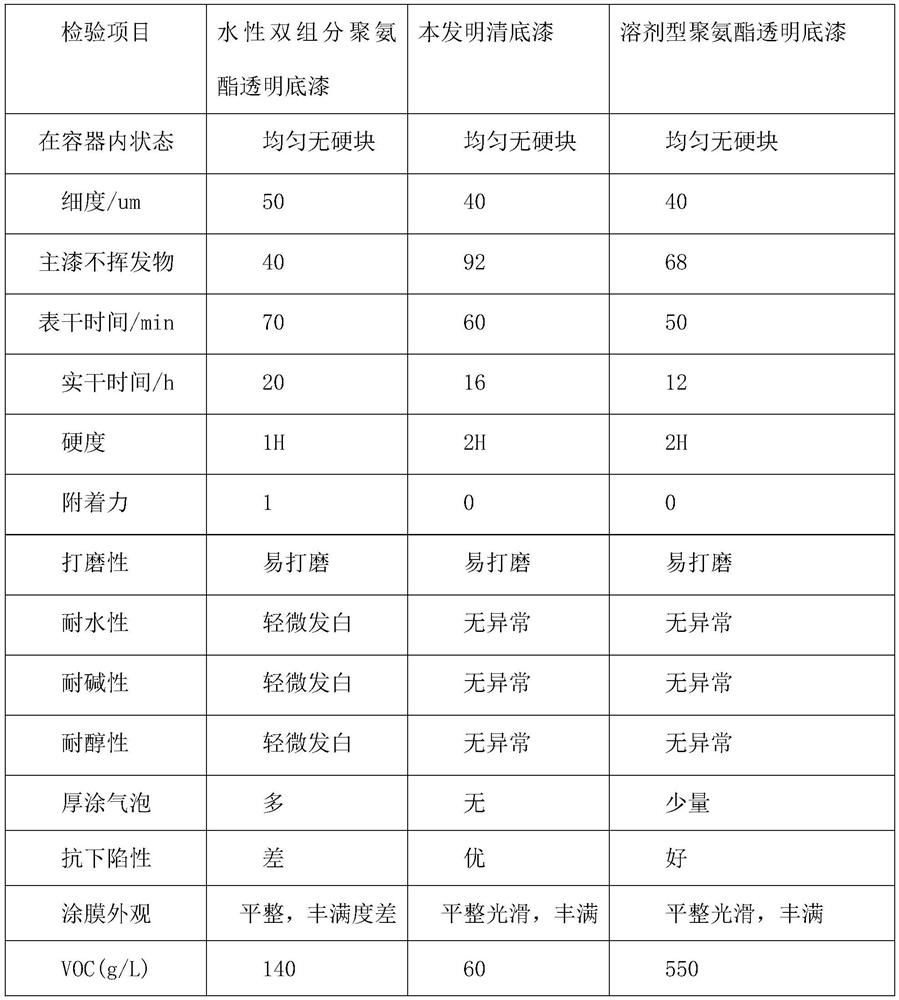

A two-component, high-solid technology, applied in the field of paint, can solve the problems that can not meet the high decorative furniture coating requirements, low solid content of water-based transparent primer, easy to appear dark bubbles, pinholes, heat rash, etc., to achieve the elimination of drums Prevents color bleeding, solves water sensitivity problems, improves transparency and fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare the main paint; weigh 100kg according to the following mass percentages: 56kg liquid epoxy resin, 0.4kg dispersant, 1kg anti-sedimentation agent, 0.2kg defoamer, 0.2kg wetting and leveling agent, 25kg filler, 10kg reactive diluent , co-solvent 7.2kg; put liquid epoxy resin, reactive diluent and part of co-solvent into the container, disperse at 600-800 rpm for 5 minutes; then disperse at 600-800 rpm while adding dispersion Agent, anti-settling agent and filler, disperse at 1200-1500 rpm for 20 minutes until the fineness is acceptable; add the remaining co-solvent and additives and disperse at 600-800 rpm for 10 minutes to obtain the main paint component.

[0028] Coating: Mix the above main paint and curing agent thoroughly, then add water, mix according to the mass ratio of main paint: curing agent: water = 1:0.4:0.5~1; after mixing evenly, spray or brush On the wood surface, dry naturally or bake at low temperature, and the effective period of construction is ...

Embodiment 2

[0030] Prepare the main paint; weigh 100kg according to the following mass percentages: 63kg liquid epoxy resin, 0.3kg dispersant, 0.8kg anti-settling agent, 0.3kg defoamer, 0.3kg wetting and leveling agent, 20kg filler, reactive diluent 11kg, co-solvent 4.3kg; put liquid epoxy resin, reactive diluent and part of co-solvent into the container, disperse at 600-800 rpm for 5 minutes; then add while dispersing at 600-800 rpm Dispersant, anti-sedimentation agent and filler, disperse at 1200-1500 rpm for 20 minutes until the fineness is acceptable; add the remaining co-solvent and additives and disperse at 600-800 rpm for 10 minutes to obtain the main paint component .

[0031] Coating: Mix the above main paint and curing agent thoroughly, then add water, and mix according to the mass ratio of main paint: curing agent: water = 1:0.4:0.5~1; after mixing evenly, spray or brush Apply on the surface of woodware, dry naturally or bake at low temperature, and the effective period of con...

Embodiment 3

[0033] Prepare the main paint; weigh 100kg according to the following mass percentages: 70kg liquid epoxy resin, 0.2kg dispersant, 0.5kg anti-sedimentation agent, 0.3kg defoamer, 0.4kg wetting and leveling agent, 15kg filler, reactive diluent 10kg, co-solvent 3.6kg; put liquid epoxy resin, reactive diluent and part of co-solvent into the container, disperse at 600-800 rpm for 5 minutes; then add while dispersing at 600-800 rpm Dispersant, anti-sedimentation agent and filler, disperse at 1200-1500 rpm for 20 minutes until the fineness is acceptable; add the remaining co-solvent and additives and disperse at 600-800 rpm for 10 minutes to obtain the main paint component .

[0034]Coating: Mix the above main paint and curing agent thoroughly, then add water, and mix according to the mass ratio of main paint: curing agent: water = 1:0.4:0.5~1; after mixing evenly, spray or brush Apply on the surface of woodware, dry naturally or bake at low temperature, and the effective period of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com