PU (polyurethane) high-fullness anti-sinking luster white finish paint

A fullness, anti-sag technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve problems such as general adhesion, general yellowing resistance, and slow drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

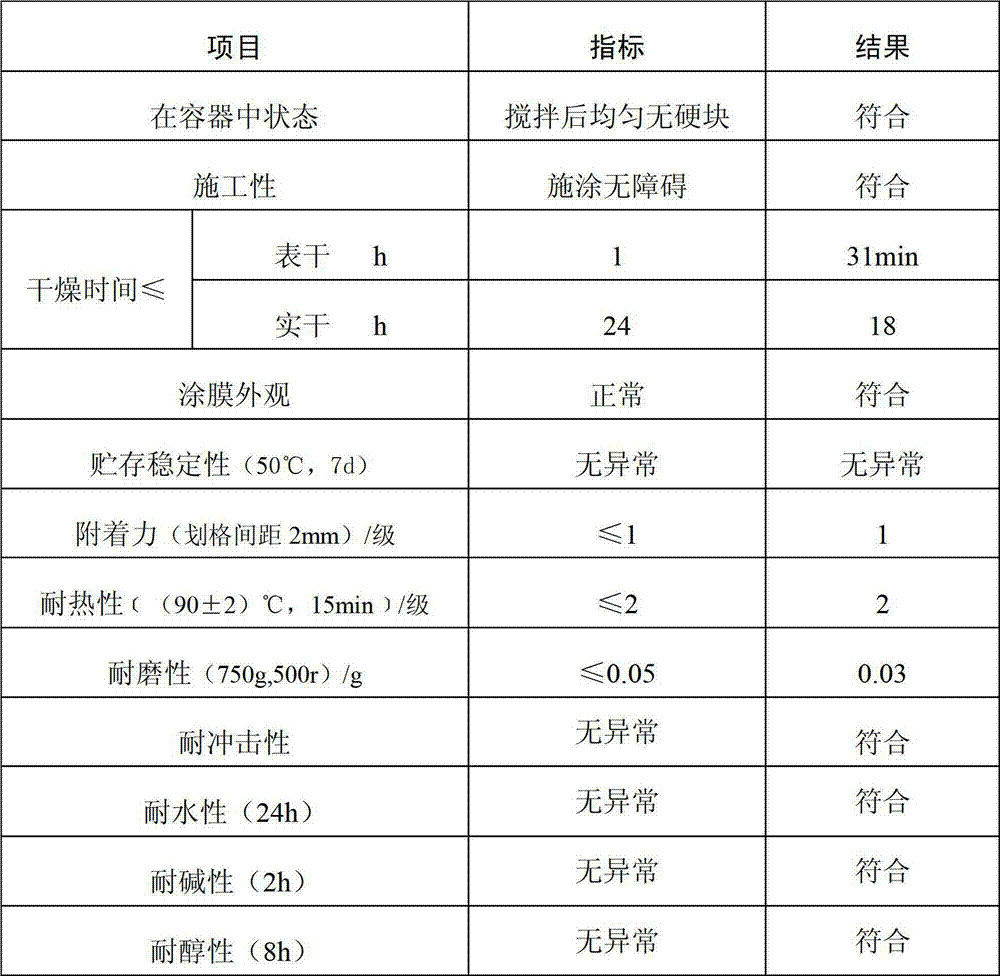

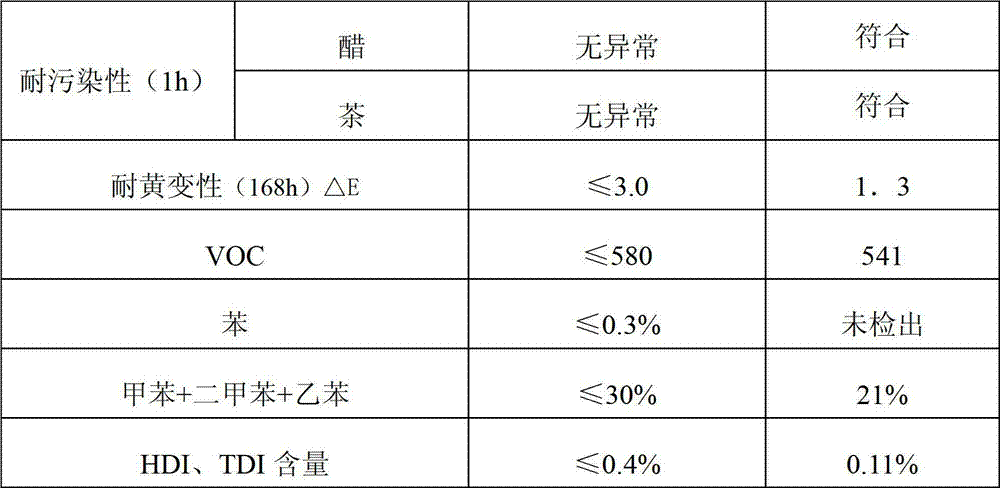

Examples

Embodiment 1

[0023] A kind of PU high-fullness anti-sag bright white finish paint, its weight-to-number ratio is:

[0024] A component 1, B component 0.8, C component 0.5;

[0025] Component C does not participate in chemical reactions, but only plays the role of thinning construction.

[0026] The parts by weight ratio of the first component is as follows:

[0027] Synthetic fatty acid resin 10, saturated polyester resin 10,

[0028] Acrylic resin 15, PU advanced bright white flour paste 60,

[0029] Leveling agent 0.1, defoamer 0.4,

[0030] Additive 0.8, n-butyl acetate 3.4;

[0031] When preparing, add in order to disperse until fully uniform, and control the viscosity at 4500±200cps / 25℃;

[0032] The parts by weight ratio of the B component is as follows:

[0033] n-butyl acetate 50, curing agent 50;

[0034] The parts by weight ratio of the C component is as follows:

[0035] n-butyl acetate 40, toluene 60;

[0036] The parts by weight of the PU high-grade bright white flour...

Embodiment 2

[0052] A kind of PU high-fullness anti-sag bright white finish paint, its weight-to-number ratio is:

[0053] A component 1, B component 0.8, C component 0.5;

[0054] The parts by weight ratio of the first component is as follows:

[0055] Synthetic fatty acid resin 15, saturated polyester resin 15,

[0056] Acrylic resin 20, PU advanced bright white flour paste 65,

[0057] Leveling agent 0.3, defoamer 0.6,

[0058] Additive 1, n-butyl acetate 4;

[0059] When preparing, add in order to disperse until fully uniform, and control the viscosity at 4500±200cps / 25℃;

[0060] The parts by weight ratio of the B component is as follows:

[0061] n-butyl acetate 50, curing agent 50;

[0062] The parts by weight ratio of the C component is as follows:

[0063] n-butyl acetate 60, toluene 40;

[0064] The parts by weight of the PU high-grade bright white flour paste are as follows:

[0065] Synthetic fatty acid resin 55, dispersant 1.2,

[0066] Fumed silica 0.6, titanium dio...

Embodiment 3

[0070] A kind of PU high-fullness anti-sag bright white finish paint, its weight-to-number ratio is:

[0071] A component 1, B component 0.8, C component 0.5;

[0072] The parts by weight ratio of the first component is as follows:

[0073] Synthetic fatty acid resin 13, saturated polyester resin 13,

[0074]Acrylic resin 17, PU advanced bright white flour paste 62,

[0075] Leveling agent 0.2, defoamer 0.5,

[0076] Additive 0.9, n-butyl acetate 3.7;

[0077] When preparing, add in order to disperse until fully uniform, and control the viscosity at 4500±200cps / 25℃;

[0078] The parts by weight ratio of the B component is as follows:

[0079] n-butyl acetate 50, curing agent 50;

[0080] The parts by weight ratio of the C component is as follows:

[0081] n-butyl acetate 45, toluene 50;

[0082] The parts by weight of the PU high-grade bright white flour paste are as follows:

[0083] Synthetic fatty acid resin 47, dispersant 1.1,

[0084] Fumed silica 0.5, titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com