Damp-heat-resistant acid-resistant paint by using isocyanate for curing novolac epoxy resin

An epoxy resin and isocyanate technology, applied in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of poor acid resistance, poor heat resistance of epoxy resin, good water resistance of chlorinated rubber, etc., to improve the resistance to heat and humidity and acid resistance. , Improve heat and humidity resistance and acid resistance, reduce the effect of coating times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A heat-resistant and acid-resistant paint using isocyanate to cure Norvolac epoxy resin is composed of component A and component B. The component A is composed of the following components by weight: 35 parts of NOVOLAC EPOXY resin, 16 parts of xylene, 4.6 parts of butyl acetate, 0.3 part of dispersant, 15 parts of coloring pigment, 10 parts of ultrafine barium sulfate, 5 parts of sericite, 12 parts of mica iron oxide, 2 parts of chromium oxide green, 1 part of cobalt blue, 0.5 part of anti-settling agent, 0.5 part of catalyst, 0.3 part of leveling agent, and 0.3 part of defoamer. The B component is TMP-TDI adduct. The weight ratio of component A and component B is 2.2:1.

[0034] Above-mentioned NOVOLAC EPOXY resin adopts following steps to make:

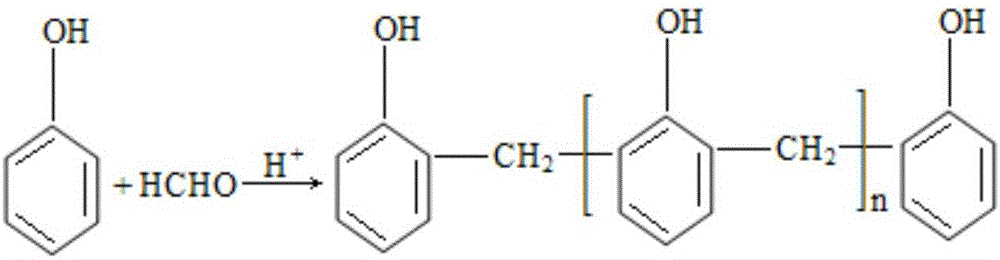

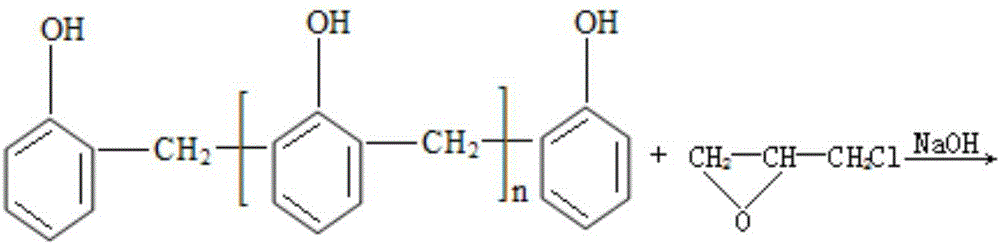

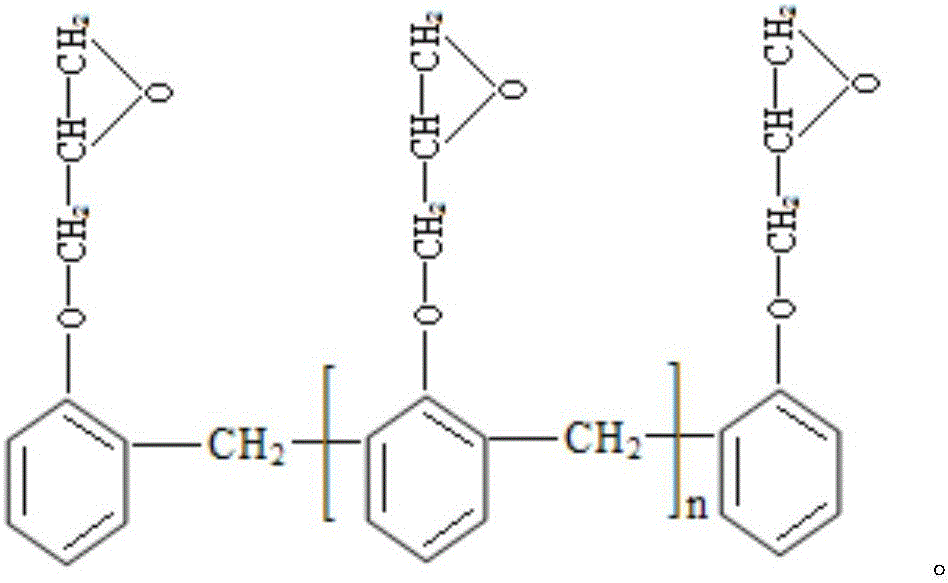

[0035] (1) Synthesis of low-molecular-weight phenolic resin: After heating and melting phenol in advance, add it to the reaction kettle and mix it with formaldehyde. The molar ratio of phenol and formaldehyde is 1:0.5. Aft...

Embodiment 2

[0044] A heat-resistant and acid-resistant paint using isocyanate to cure Norvolac epoxy resin is composed of component A and component B. The component A is composed of the following components by weight: 30 parts of NOVOLAC EPOXY resin, 20 parts of xylene, 4 parts of butyl acetate, 0.4 part of dispersant, 10 parts of coloring pigment, 8 parts of ultrafine barium sulfate, 6 parts of sericite, 10 parts of mica iron oxide, 3 parts of chromium oxide green, 1 part of cobalt blue, 0.4 part of anti-settling agent, 0.6 part of catalyst, 0.7 part of leveling agent, and 0.2 part of defoamer. The B component is HDI trimer (BAYER Desmodur N3300, Germany). The weight ratio of component A and component B is 2:1.

[0045] Above-mentioned NOVOLAC EPOXY resin adopts following steps to make:

[0046] (1) Synthesis of low-molecular-weight phenolic resin: After heating and melting phenol in advance, add it to the reaction kettle and mix it with formaldehyde. The molar ratio of phenol to forma...

Embodiment 3

[0051] A heat-resistant and acid-resistant paint using isocyanate to cure Norvolac epoxy resin is composed of component A and component B. The component A is composed of the following components by weight: 40 parts of NOVOLAC EPOXY resin, 10 parts of xylene, 6 parts of butyl acetate, 0.2 parts of dispersant, 18 parts of coloring pigment, 10 parts of ultrafine barium sulfate, 5 parts of sericite, 12 parts of mica iron oxide, 1 part of chromium oxide green, 2 parts of cobalt blue, 0.7 part of anti-settling agent, 0.3 part of catalyst, 0.2 part of leveling agent, and 0.5 part of defoamer. The B component is HDI trimer (BAYER Desmodur N3300, Germany). The weight ratio of component A and component B is 3:1.

[0052] The preparation method of NOVOLAC EPOXY resin is the same as embodiment 1.

[0053] The above-mentioned dispersant is Tego710. Coloring pigments include carbon black, titanium dioxide, phthalocyanine blue, permanent violet and permanent red F3RK, etc., which can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com