Two-component modified heavy-duty-anticorrosion epoxy mortar coating for super-thick membranization construction, and preparation method thereof

An epoxy mortar, two-component technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of demanding drying process, high-power mixing equipment, complex construction technology, etc., and achieve excellent compatibility , Avoid complex production process and reduce dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

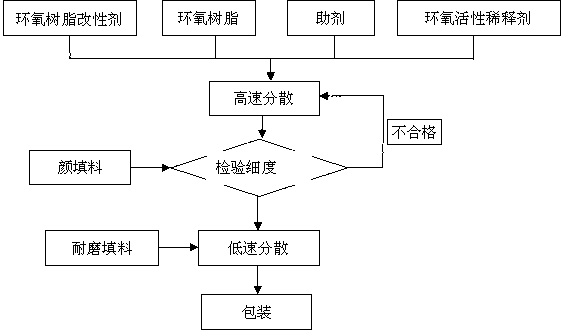

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention is further described, and the present invention is not limited to following embodiment:

[0049] The embodiment of the ultra-thick film construction two-component modified epoxy mortar heavy-duty anti-corrosion coating of the present invention is shown in Table 1:

[0050] Part A raw material name Example 1 Example 2 Example 3 epoxy resin 8 10.5 13 Epoxy Reactive Diluent 7 4.5 2 tricresyl phosphate 2 6 10 liquid indene resin 9 6 3 Wetting and dispersing agent BYK-110 0.1 0.3 0.5 Defoamer BYK-A530 0.5 0.3 0.1 Multifunctional Rheology Additive 4 4.5 5 Wear-resistant filler 10 13 20 Alkaline absorbent 10 7 5 Anti-rust pigments and fillers 15 10 5 Pigments 25 10 16.9 Component B raw material name Example 1 Example 2 Example 3 Phenalkamine curing agent 5 7 10

[0051] The main indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com