Ultraviolet curing primer for surface of wood and preparation method of ultraviolet curing primer

A wood surface and ultraviolet light technology, which is applied to the field of UV curing primer on wood surface and its preparation, can solve problems such as poor penetration of wood conduits, and achieve the effects of improving filling efficiency, good filling and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

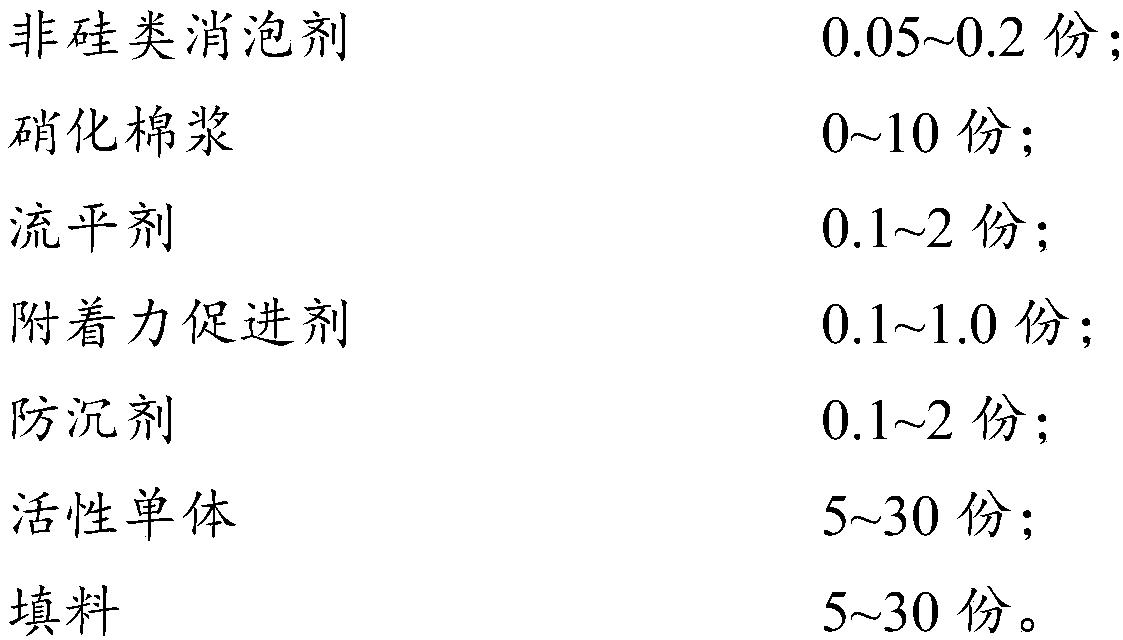

[0043] On the other hand, the embodiment of the present invention also provides a preparation method of an ultraviolet light curing primer for wood surface, comprising:

[0044] S01, weigh each component according to the formula of the above-mentioned UV-curable primer;

[0045] S02, the UV resin, the active monomer, the dispersant, the wetting agent, the non-silicon defoamer, the nitrocellulose pulp, the leveling agent and the anti-sedimentation The agent carries out the first mixed material treatment, obtains the first mixed material;

[0046] S03, adding the filler into the first mixture, performing a second mixing treatment to obtain a second mixture,

[0047] S04. Add the photoinitiator and the adhesion promoter into the second mixture, and perform a third mixture treatment to obtain the UV-curable primer.

[0048] Specifically, in the above step S02, the first mixing process is as follows: the temperature is below 50° C., the speed is 800-1000 rpm, and the stirring is ...

Embodiment 1

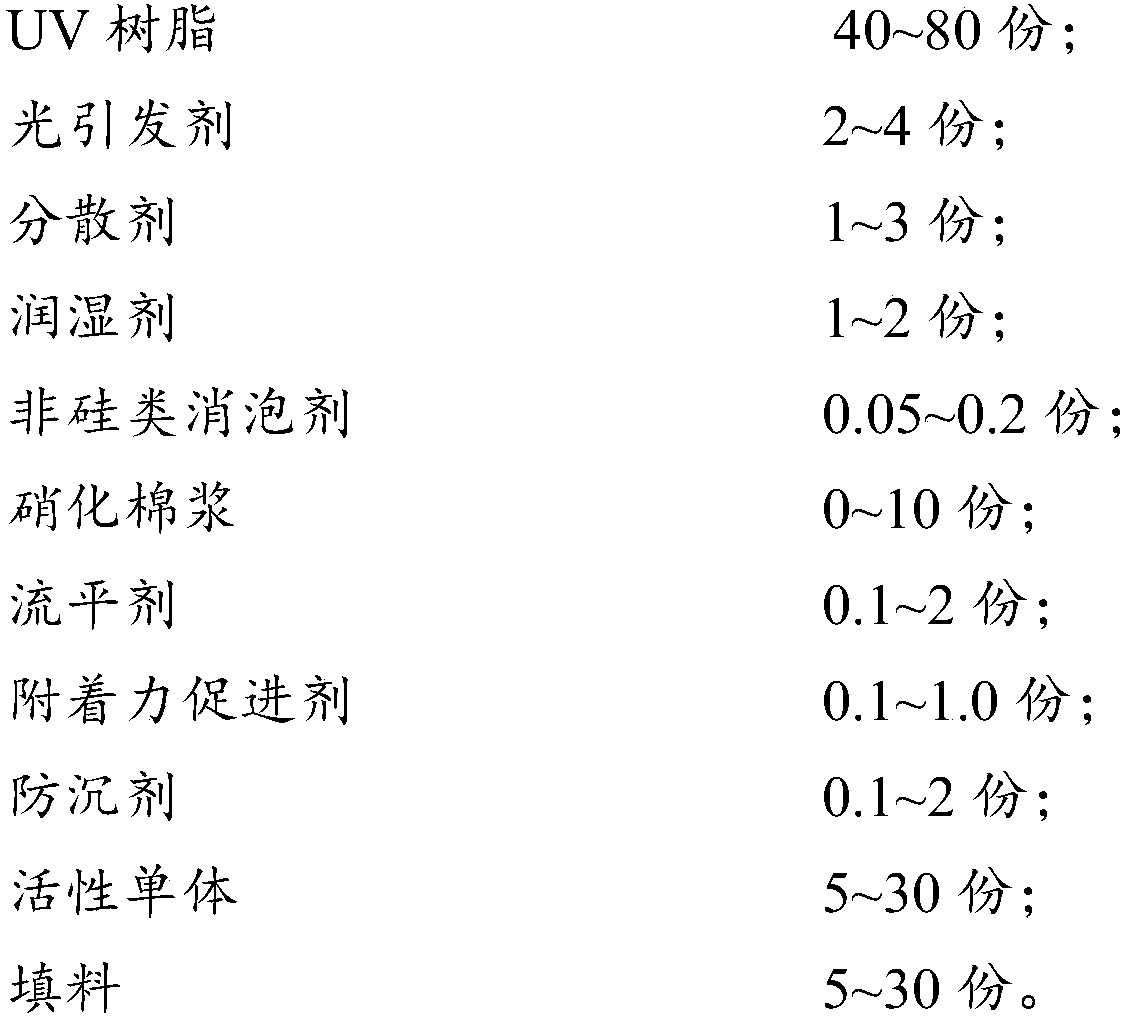

[0054] The content of each component by weight of the UV-curable primer provided in this embodiment is shown in Table 1:

[0055] Table 1

[0056] serial number

[0057] In the above table 1, the 100% UV resin is DSM’s UV resin Agisyn 705; the dispersant is BYK-103; the wetting agent is BYK-190; the non-silicon defoamer is Tego-920; the leveling agent is BYK-358 The anti-settling agent is Degussa brand R-972; the photoinitiator is Ciba company brand 1173; the filler is K brand talcum powder brand TP-3000; the active monomer is polyacrylic acid monomer of Cytec; adhesion promotion The agent is a modified phosphate ester.

[0058] The preparation method of the UV-curable primer provided in this embodiment is as follows:

[0059] S11: Weigh the raw materials of each component according to the components contained in the UV-curable primer in the above Table 1 and their parts by weight;

[0060] S12: Stir the above 100% UV resin, some active monomers, non-silicon defoa...

Embodiment 2

[0070] The content of each component of the UV-curable primer provided in this example is shown in Table 3 (in parts by weight).

[0071] table 3

[0072] serial number

[0073] In the above table 3, the 100% UV resin is DSM’s UV resin; the dispersant is BYK-103; the wetting agent is Rohm and Haas water-based coating wetting and dispersing agent; The leveling agent is BYK-358; the anti-settling agent is Degussa brand R-972; the photoinitiator is Ciba company brand 1173; the filler is K brand talcum powder brand TP-3000; the active monomer is polyacrylic acid of Cytec Monomer; adhesion promoter is a modified phosphate ester.

[0074] The preparation method of the UV-curable primer provided in this embodiment is basically the same as that in Embodiment 1, and will not be repeated here.

[0075] The above-mentioned ultraviolet curing primer is coated on the wood surface by spraying, and the amount of coating can be controlled by adjusting the air pressure of spraying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com