Curing-type coating composition and application thereof

A coating composition, a curing-type technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of increasing the emission of volatile substances in the release agent, affecting the appearance integrity of products, affecting production efficiency, etc. Achieve the effect of strong production continuity, excellent mold release performance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0022] 20g of hydrogen-containing silicone oil containing 1.5% hydrogen, 0.1g of Castel catalyst and 20g of toluene were added to the reaction flask, and then 20g of pentafluoropropyl allyl ether (CH 2 =CHCH 2 OCH 2 CF 2 CF 3 ), 2g allyl alcohol (CH 2 =CHCH 2 OH) and 20 g of toluene, after the dropwise addition was completed, the temperature was slowly raised to 85° C. for 6 h, and then the solvent and unreacted monomers were removed in a vacuum to obtain reactive fluorine-containing polysiloxane compound 1.

Synthetic example 2

[0024] Add 20g of hydrogen-containing silicone oil with a hydrogen content of 1.5%, 0.1g of Castel catalyst and 20g of toluene into the reaction flask, then slowly add 20g of hexafluoroisopropyl allyl ether (CH 2 =CHCH 2 OCH(CF 3 ) 2 ), 2g hydroxyethyl acrylate (CH 2 =CHCOOCH 2 CH 2 OH) and 20 g of toluene, after the dropwise addition was completed, the temperature was slowly raised to 85° C. for 6 h, and then the solvent and unreacted monomers were removed in a vacuum to obtain reactive fluorine-containing polysiloxane compound 2.

Synthetic example 3

[0026] Add 20g of hydrogen-containing silicone oil with a hydrogen content of 1.5%, 0.1g of Castel catalyst and 20g of toluene into the reaction flask, then slowly add 20g of octafluoropentyl allyl ether (CH 2 =CHCH 2 OCH 2 (CF 2 ) 4 H), 2g allyltriethoxysilane (CH 2 =CHCH 2 Si(OCH 3 ) 3 ) and 20 g of toluene, after the dropwise addition was completed, the temperature was slowly raised to 85° C. for 6 h, and then the solvent and unreacted monomers were removed in a vacuum to obtain reactive fluorine-containing polysiloxane compound 3.

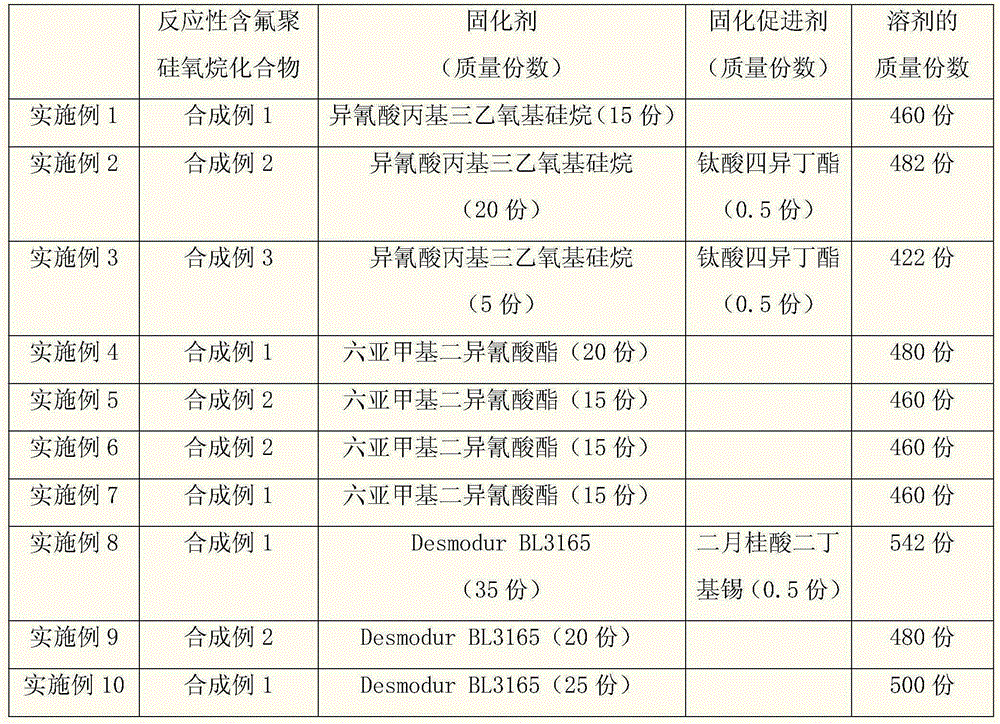

[0027] 2) Compounding of the composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com