Optical coating method and optical film coater using the method

An optical coating machine and optical coating technology, applied in optics, optical components, sputtering coating, etc., can solve the high investment cost of equipment, the inability to meet the requirements of optical thin film and optoelectronic functional multilayer thin film and optoelectronic microsystem preparation, etc. problems, to achieve the effect of reducing equipment investment, reducing equipment investment costs, and improving quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] An optical coating method, which combines cathode vacuum arc coating technology, magnetron sputtering coating technology and thermal evaporation coating technology according to the type of film. convert.

[0021] When used in combination, the parameters still use the well-known parameters when used alone.

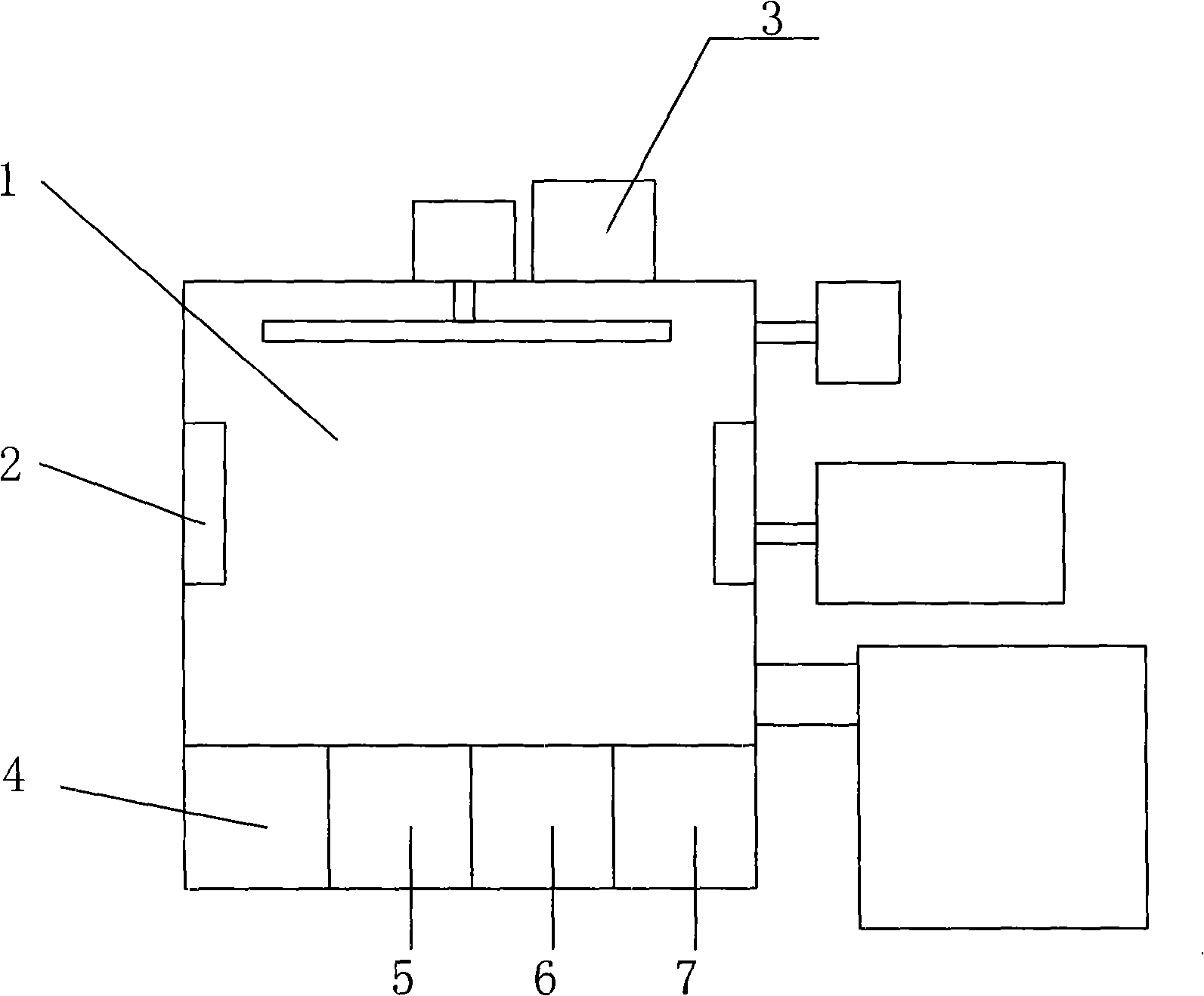

[0022] see figure 1 . An optical coating machine comprises a vacuum coating chamber 1, a temperature control system 2, a film thickness control system 3, a gas flow supply and control system and a thin film evaporation system. Said thin film evaporation system includes cathode vacuum arc emission device 4 , magnetron sputtering device 5 , thermal evaporation device 6 and auxiliary deposition ion source device 7 .

[0023] Use Example 1: Preparation of 3 micron to 5 micron infrared anti-reflection optical film.

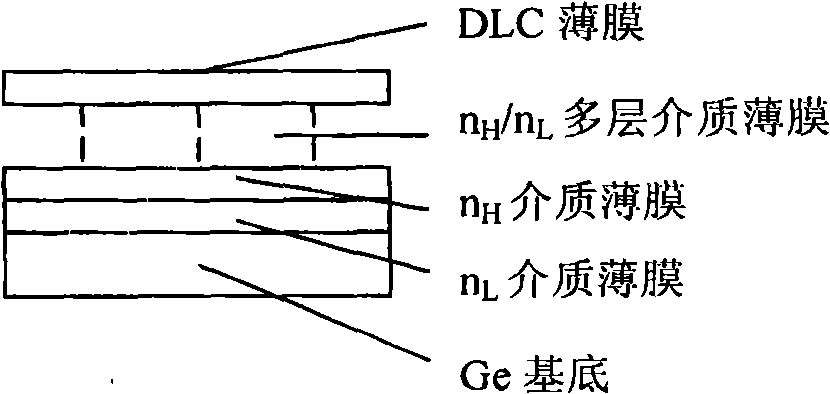

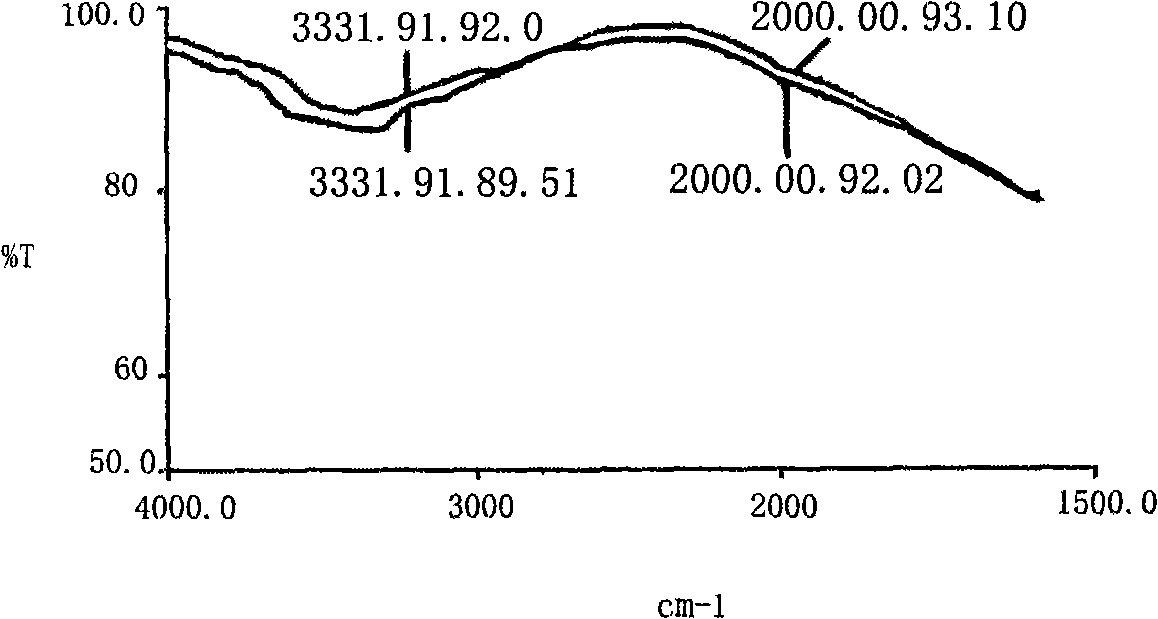

[0024] see figure 2 , where n H =2.4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com