Preparation method of NiCrAlYSi powder spraying material

A technology for spraying materials and powders, applied in metal material coating process, coating, melt spraying and other directions, can solve problems such as high temperature oxidation and corrosion, achieve good quality, reduce manufacturing costs, and achieve the effect of engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Put the prepared raw materials into a magnesia crucible and adopt vacuum induction melting. The chemical composition ratio of the raw materials is weight percentage: Cr: 20.0; Al: 9.0; Si: 0.6; Y: 0.5; O: ≤0.050; N : ≤0.020; Ni balance.

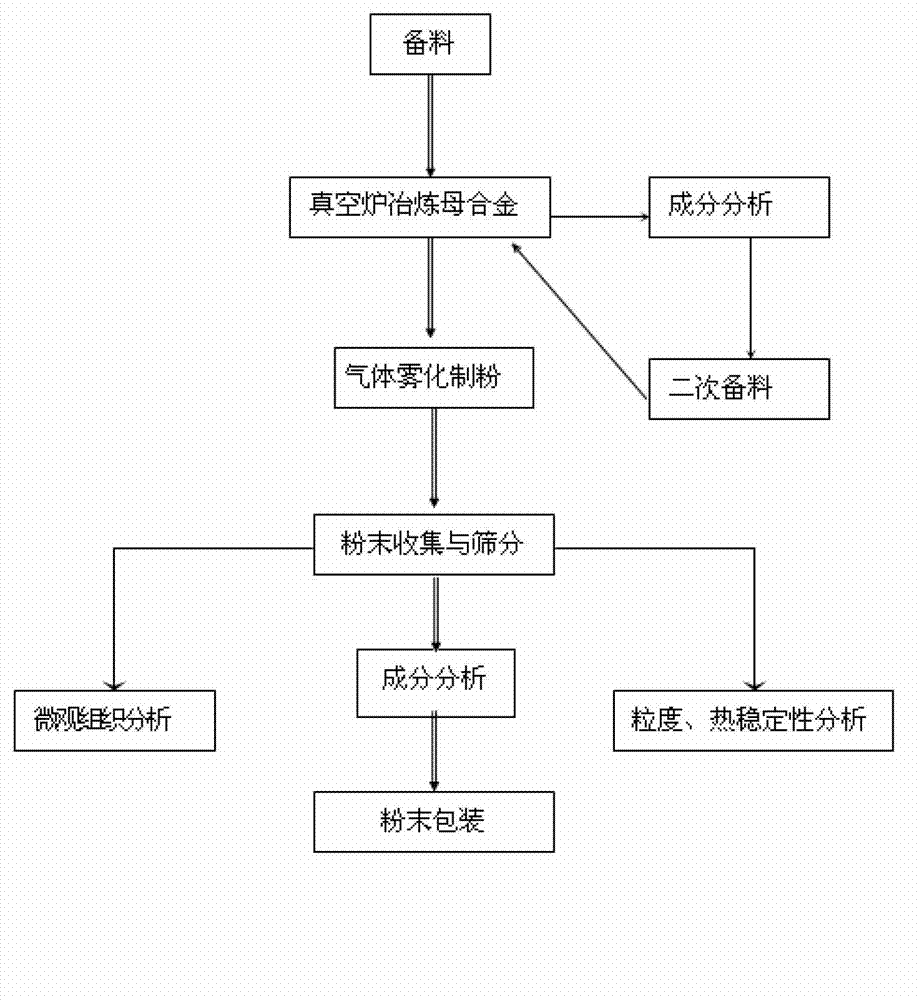

[0035] The specific process flow is:

[0036] (1) Prefabricated master alloy: The master alloy is prepared by vacuum induction heating, the raw material is placed in a magnesia crucible, the pre-vacuum degree is higher than 2Pa, the refining temperature is 1410°C±20°C, the refining time is 15min, and casting The temperature is 1440℃±20℃, and after cooling, it is cast into an alloy rod with a diameter of 80mm;

[0037] (2) Composition analysis: carry out composition analysis on the obtained master alloy, and the obtained alloy composition does not exceed the chemical composition ratio of the NiCrAlYSi powder, and directly proceed to step (3);

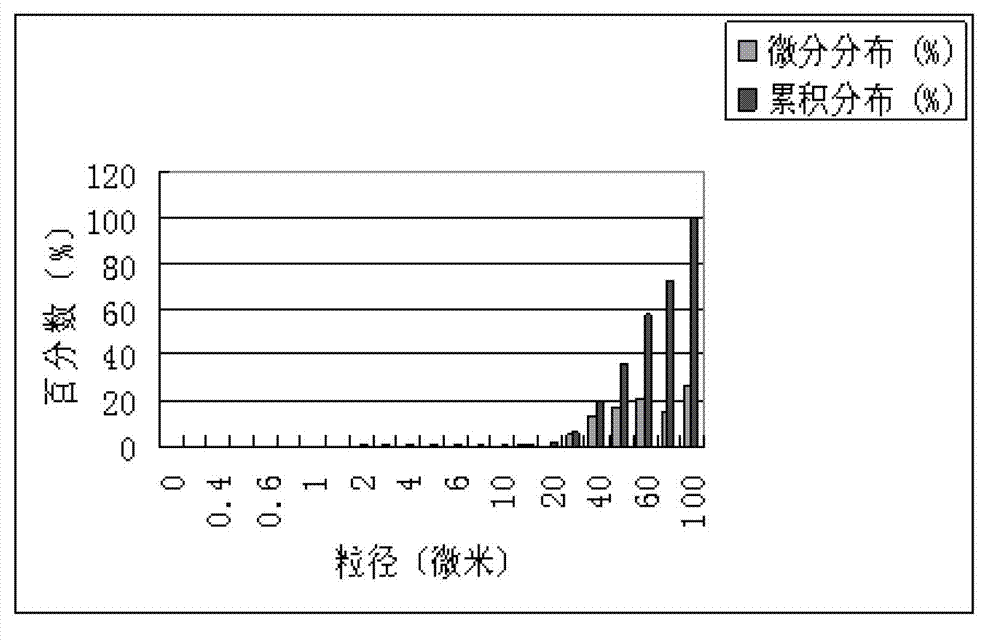

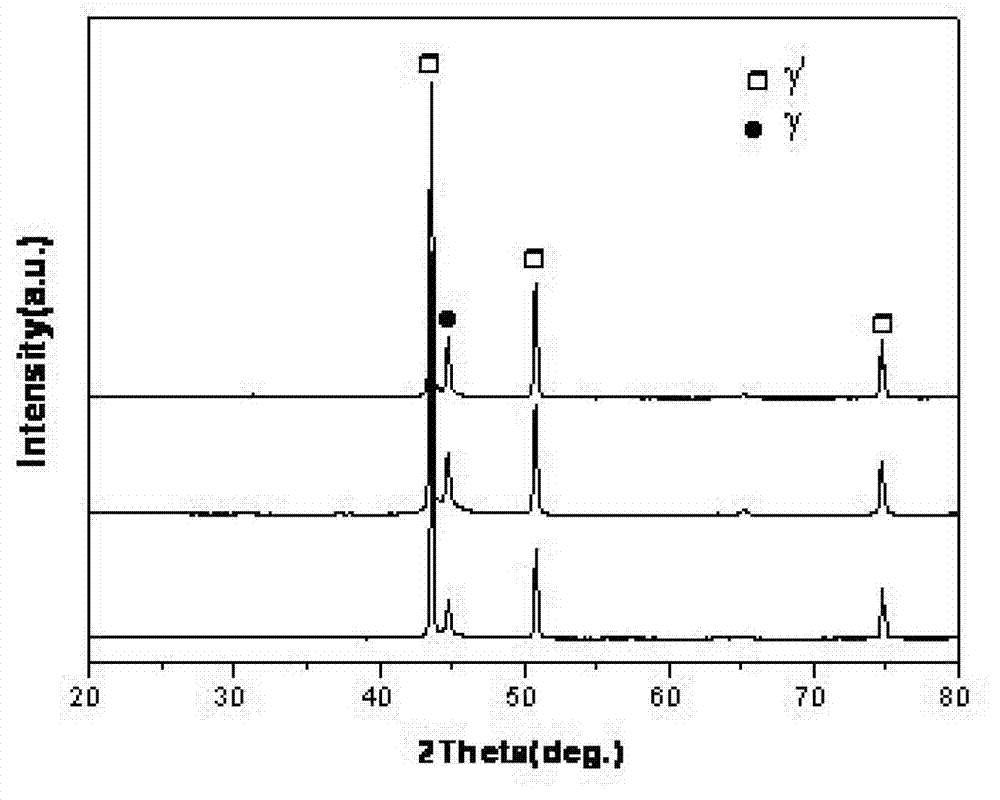

[0038] (3) Gas atomization powder making: powder materials are prepared by ultrasonic gas a...

Embodiment 2

[0052]The difference from Example 1 is that the atomization temperature is 1530°C, the atomization pressure is 8MPa, and the gas flow rate is 10m 3 / min, the alloy liquid flow rate is 3kg / min.

[0053] The obtained NiCrAlSiY alloy powder is uniform in texture, dry, free of foreign impurities and agglomeration. Its bulk density and fluidity meet the requirements of spraying.

Embodiment 3

[0055] The difference from Example 1 is that the atomization temperature is 1510°C, the atomization pressure is 8MPa, and the gas flow rate is 13m 3 / min, the alloy liquid flow rate is 2kg / min.

[0056] The obtained NiCrAlSiY alloy powder is uniform in texture, dry, free of foreign impurities and agglomeration. Its bulk density and fluidity meet the requirements of spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com