High-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through zirconium-strontium composite microalloying and magnesium alloying and preparing method

A casting aluminum alloy and micro-alloying technology, which is applied in the field of aluminum alloy materials, can solve the problems of low hardness, low corrosion resistance, and reduced alloy casting performance, and achieve the effect of increasing corrosion rate and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

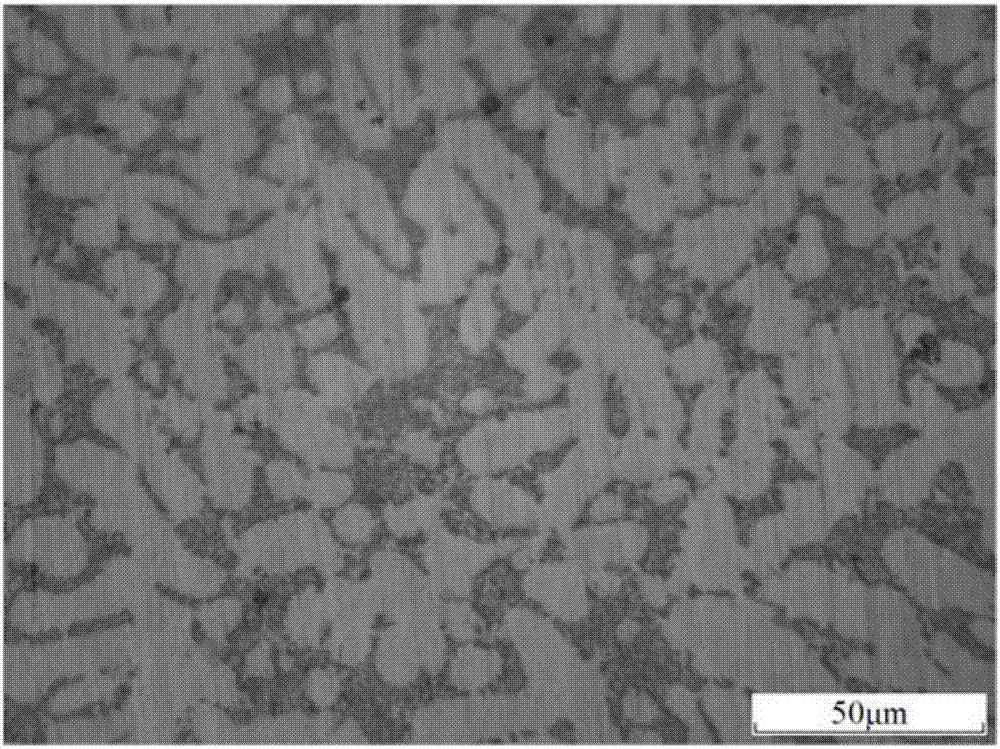

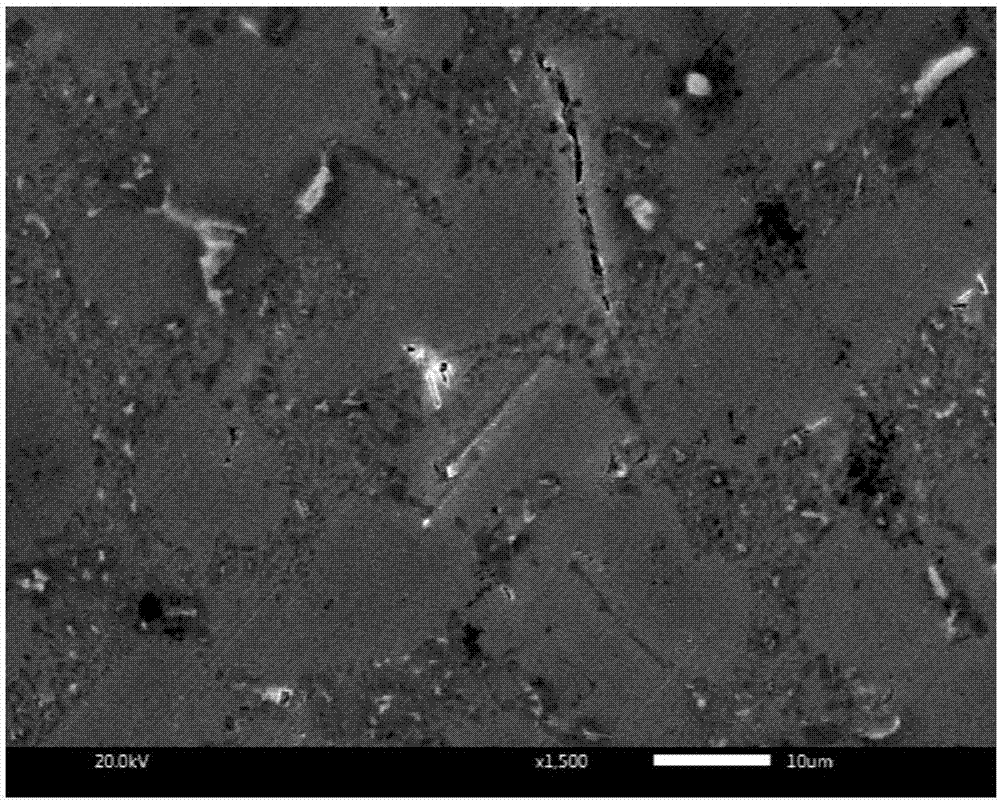

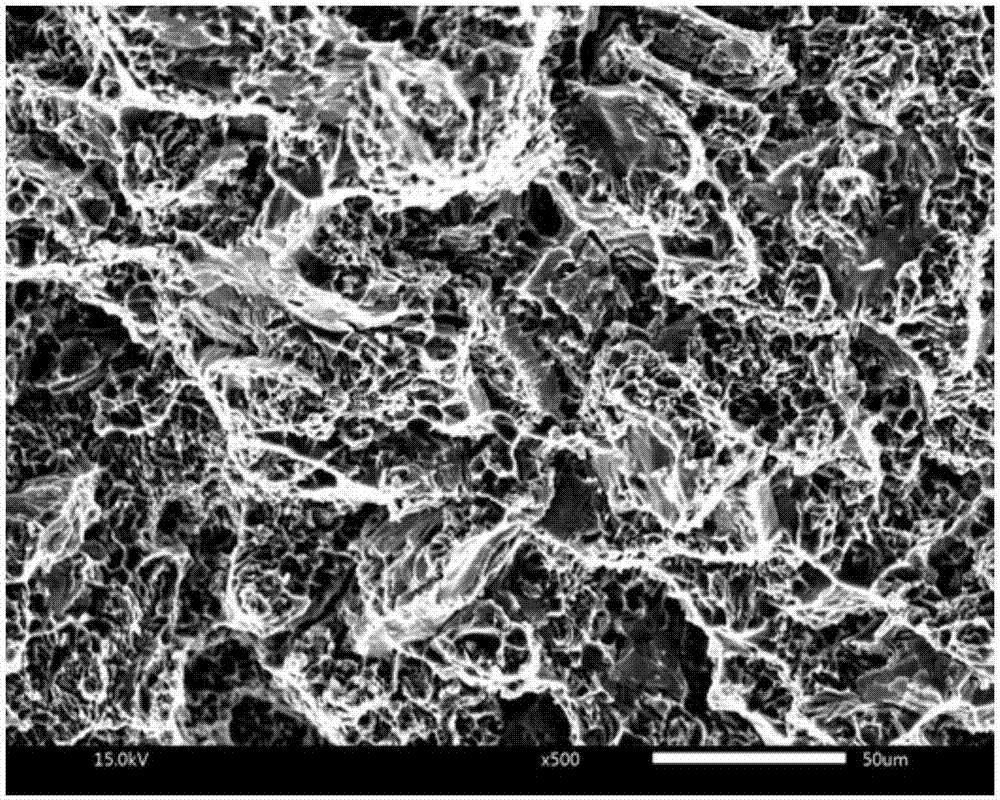

[0032] Such as figure 1 , 2 , 3, 4, and 5.

[0033] A Zr, Sr composite microalloying and Mg alloying high hardness and corrosion resistant Al-Si-Cu cast aluminum alloy, its preparation method:

[0034]First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are represented by mass percentage, the technical Personnel can convert it into weight or mass through conventional calculations, the same below, all components that add up to less than 100% are impurities) After the master alloy is melted, the temperature is raised to 850±10°C, and then Al-Cu (49.62% Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy, Al-Zr (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) master alloy, Al-Sr(89.86%Al, 9.89% Sr, 0.15%Fe, 0.10%Si ) master alloy; after all master alloys and metals are melted, adjust the temperature to 750±10°C, add pure Mg, after it melts, add hexachloroethane to refine and degas until there is no gas After stan...

Embodiment 2

[0038] A Zr, Sr composite microalloying and Mg alloying high hardness and corrosion resistant Al-Si-Cu cast aluminum alloy, its preparation method:

[0039] First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are expressed in mass percentage, the same below, All the components added up to less than 100% are impurities) the master alloy is melted and heated to 850±10°C, and then Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy is added in sequence , Al-Zr (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) master alloy, Al-Sr (89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy; After the alloy and metal are melted, adjust the temperature to 750±10°C, add pure Mg, and after it melts, add hexachloroethane to refine and degas until no gas escapes, keep it for 5 to 10 minutes, then remove the slag and pour it into Preheating to 300±10°C in a metal mold and casting into an ingot; that is, a Zr, Sr composi...

Embodiment 3

[0043] A Zr, Sr composite microalloying and Mg alloying high hardness and corrosion resistant Al-Si-Cu cast aluminum alloy, its preparation method:

[0044] First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are expressed in mass percentage, the same below, All the components added up to less than 100% are impurities) the master alloy is melted and heated to 850±10°C, and then Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy is added in sequence , Al-Zr (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) master alloy, Al-Sr (89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy; After the alloy and metal are melted, adjust the temperature to 750±10°C, add pure Mg, and after it melts, add hexachloroethane to refine and degas until no gas escapes, keep it for 5 to 10 minutes, then remove the slag and pour it into Preheating to 300±10°C in a metal mold and casting into an ingot; that is, a Zr, Sr composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com