Three-dimensional braided prefab with pre-set thread and manufacturing method thereof

A technology of three-dimensional weaving and manufacturing method, which is applied in the directions of woven fabrics, textiles and papermaking, can solve the problems of low connection strength, low fiber volume content and poor shear resistance, so as to improve the overall mechanical properties and improve the mechanical properties. performance, the effect of meeting manufacturing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

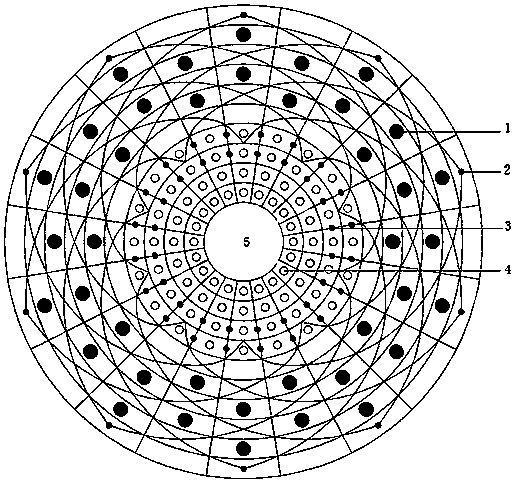

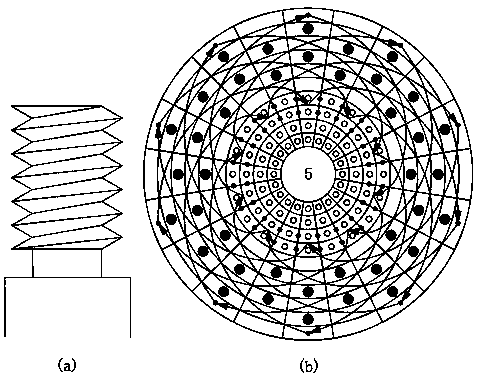

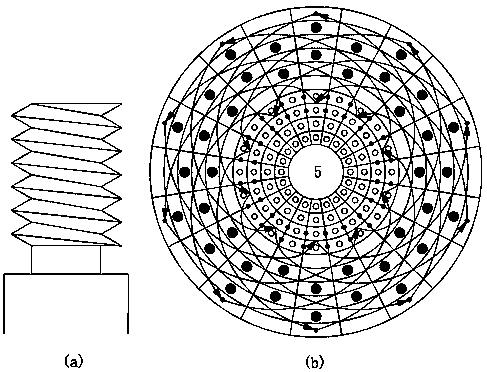

[0021] This embodiment is designed to manufacture three-dimensional braided prefabricated bodies with left-handed pre-threaded threads of M10. The prefabricated bodies are all made of carbon fibers with specifications T300B-3000-40B and T300-1000-50A produced by Toray Corporation of Japan. Woven on a three-dimensional knitting machine. The fineness of the core yarn, the four-step braiding yarn and the carbon fiber for the shaft yarn in the skin-core structure are all 3K, the fineness of the bias three-way braiding yarn is 4K, and the fineness of the bias three-way shaft yarn is 3K and 6K.

[0022] Finished specifications of composite material bolts with thread type M10: nominal diameter 10mm, length 80mm, thread pitch 1.5mm, thread original triangle height 1.3mm. Through calculation, the process design parameters of the prefabricated prefabricated parts are: the diameter of the prefabricated part is 12mm, the outer diameter of the four-step circular three-dimensional braided s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com