Patents

Literature

127 results about "Pitch length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

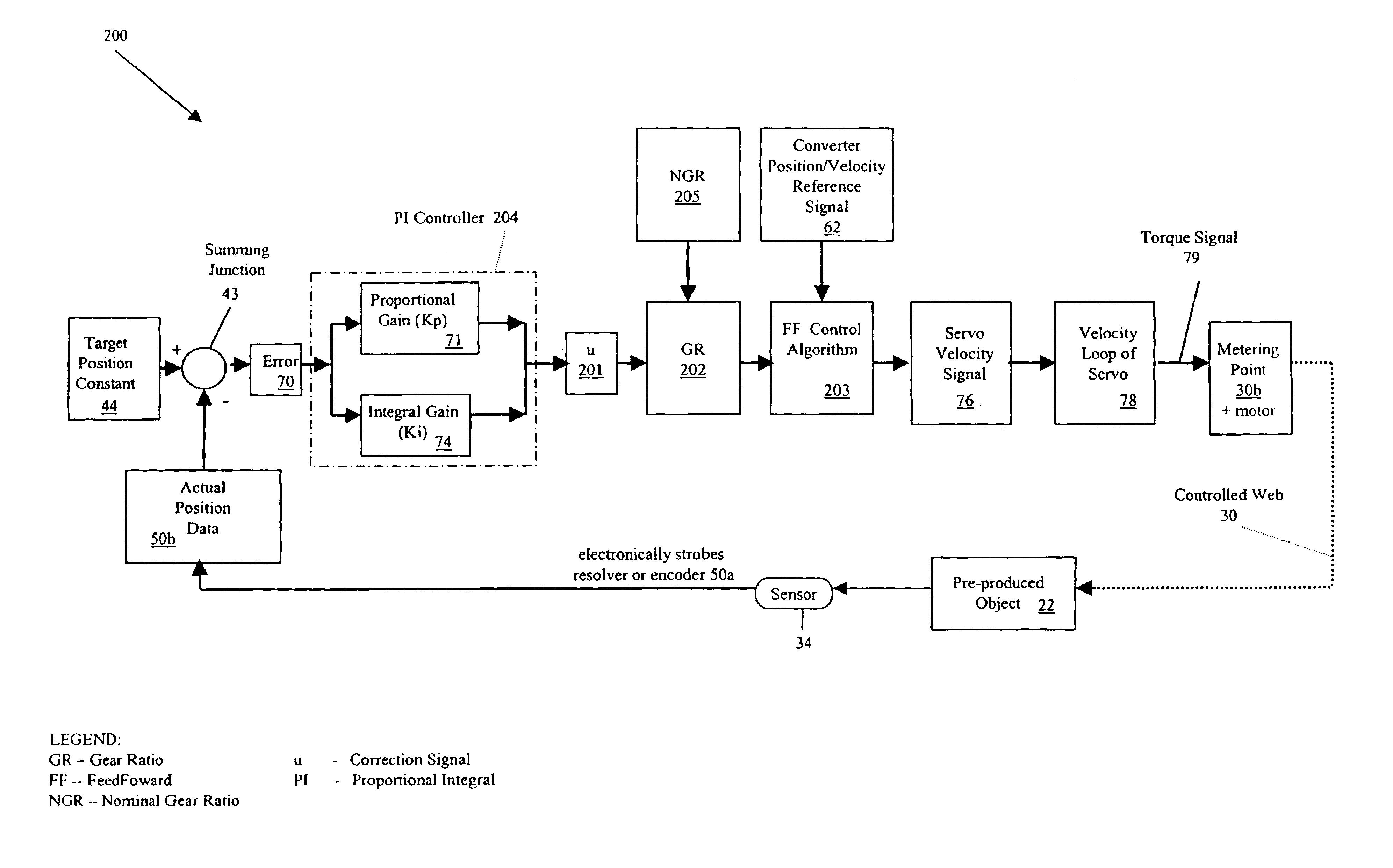

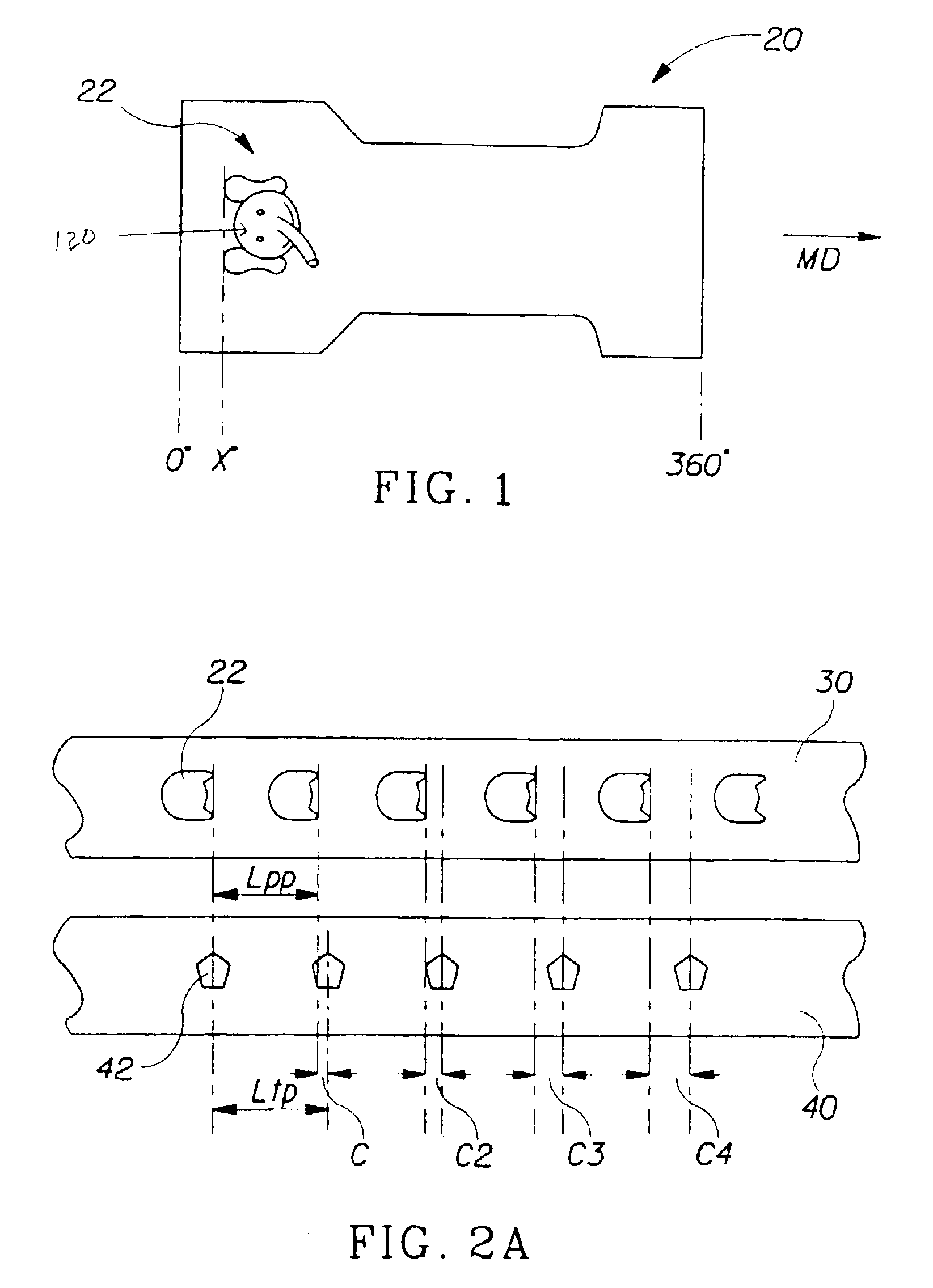

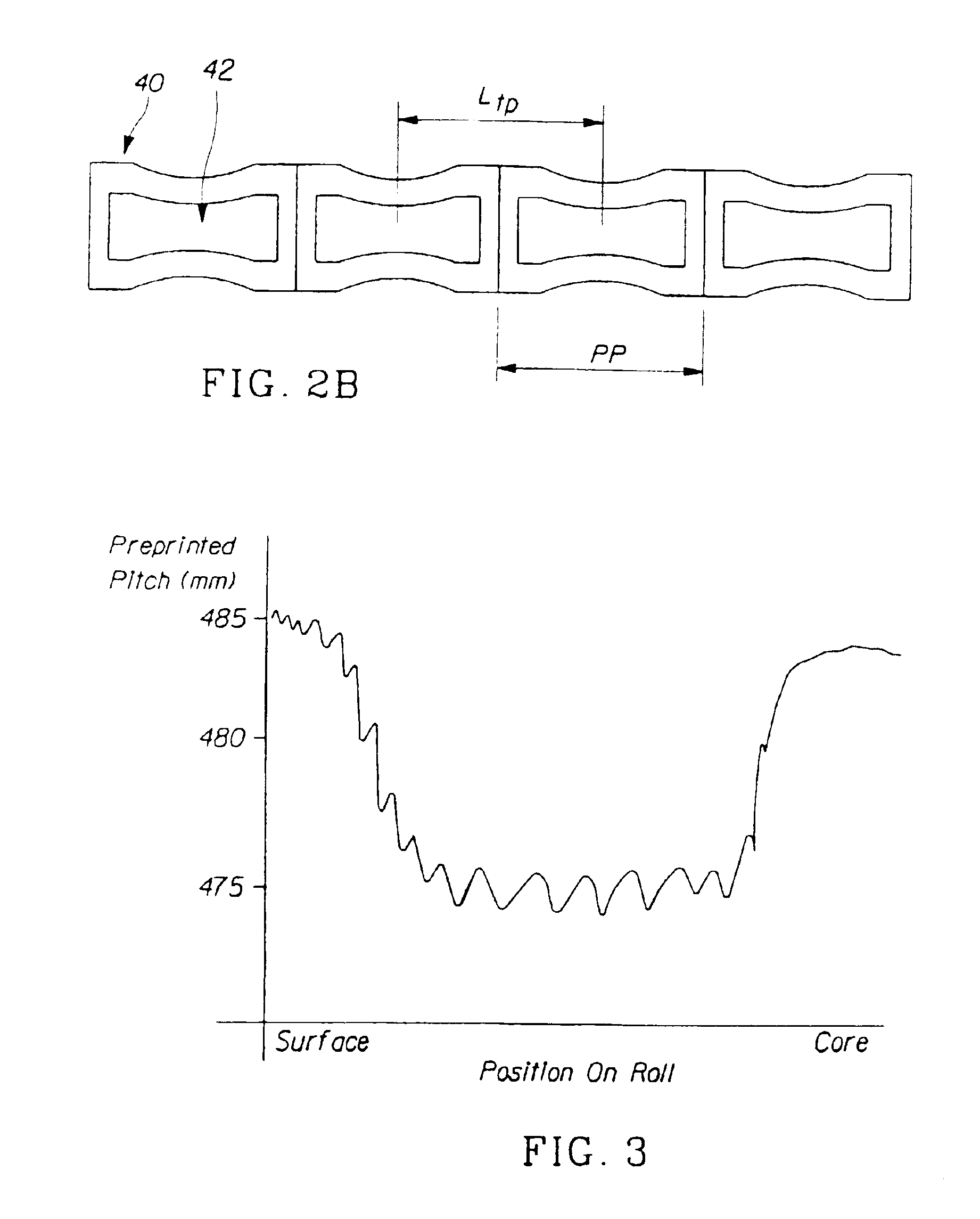

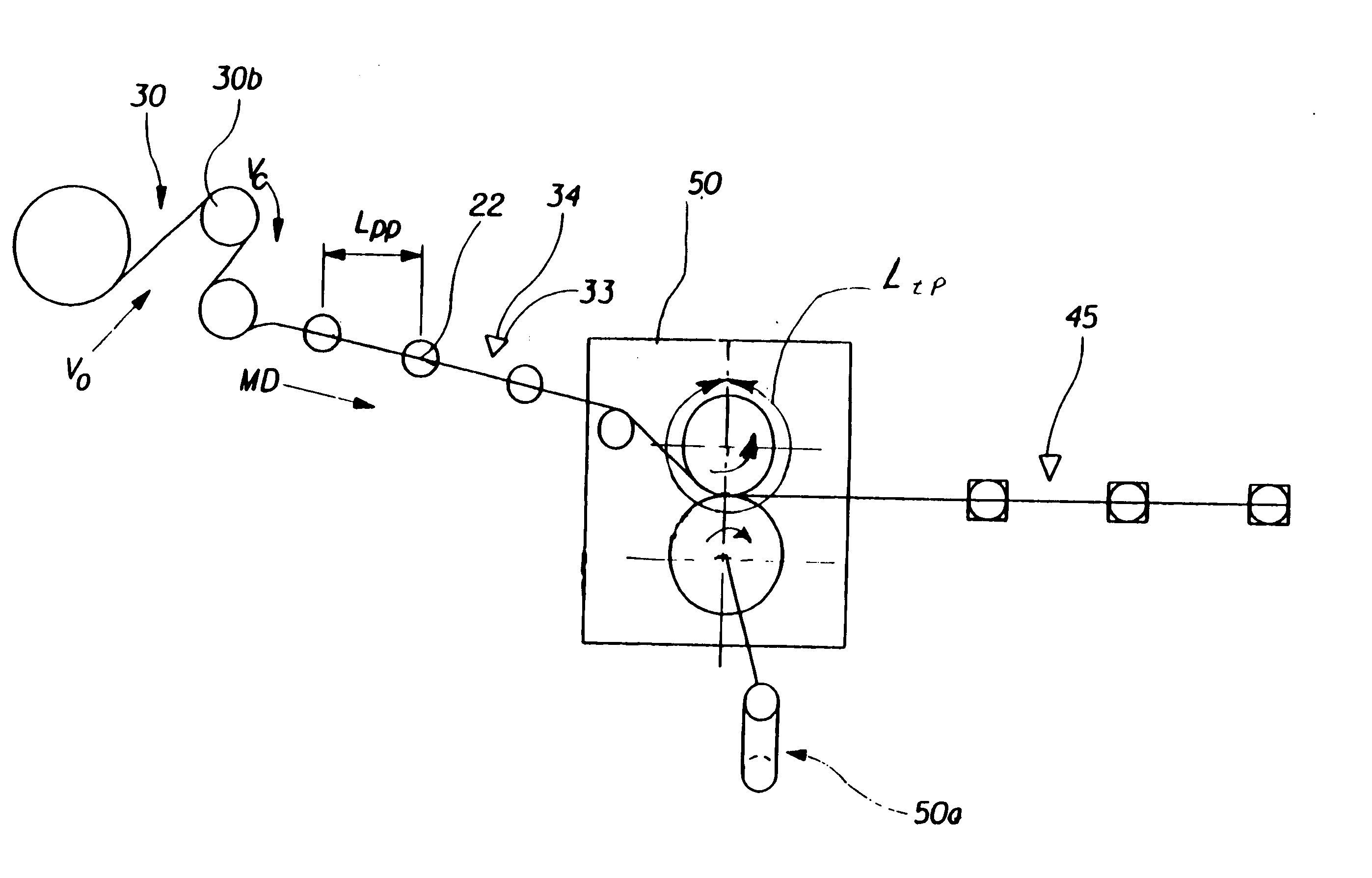

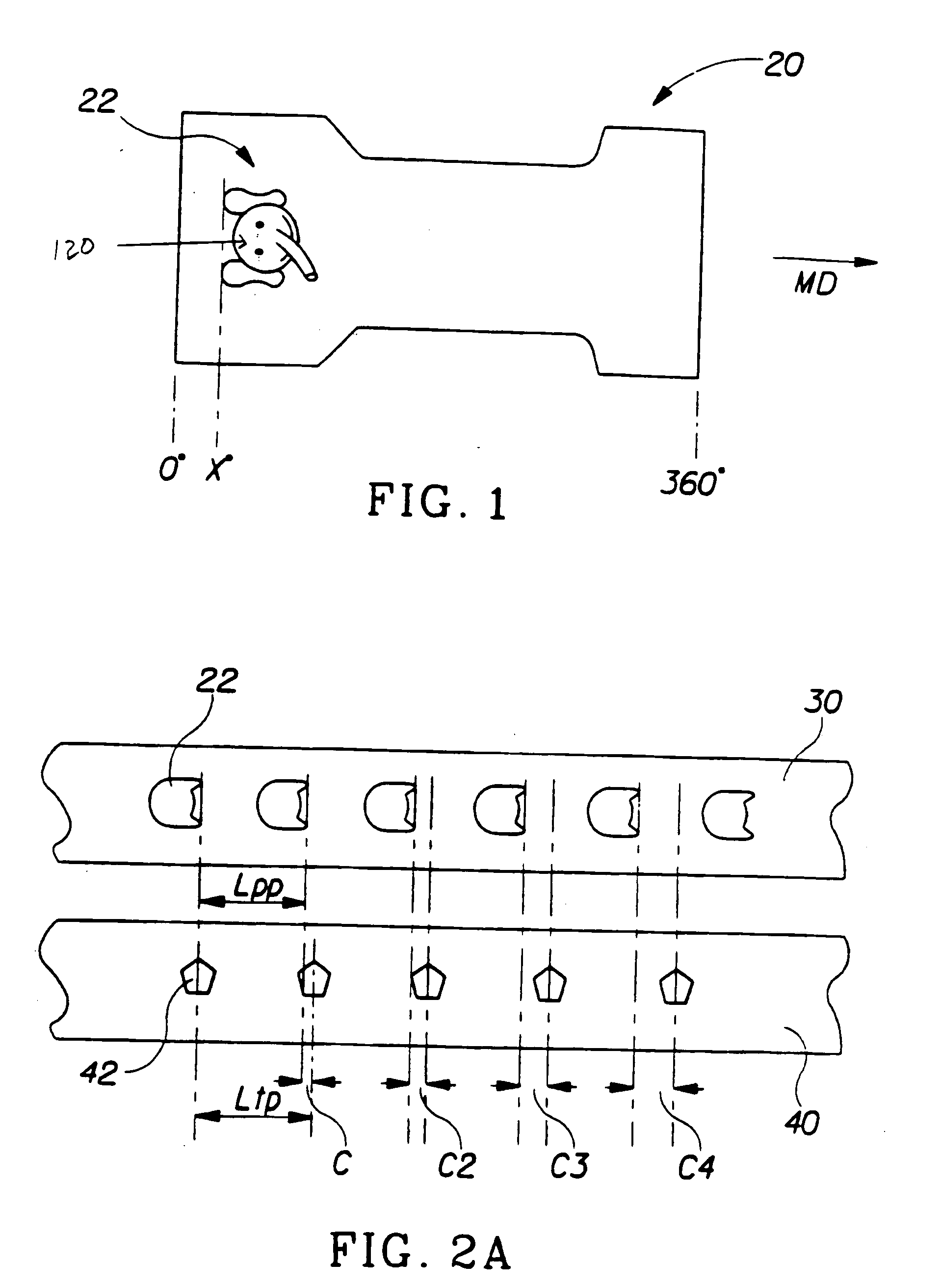

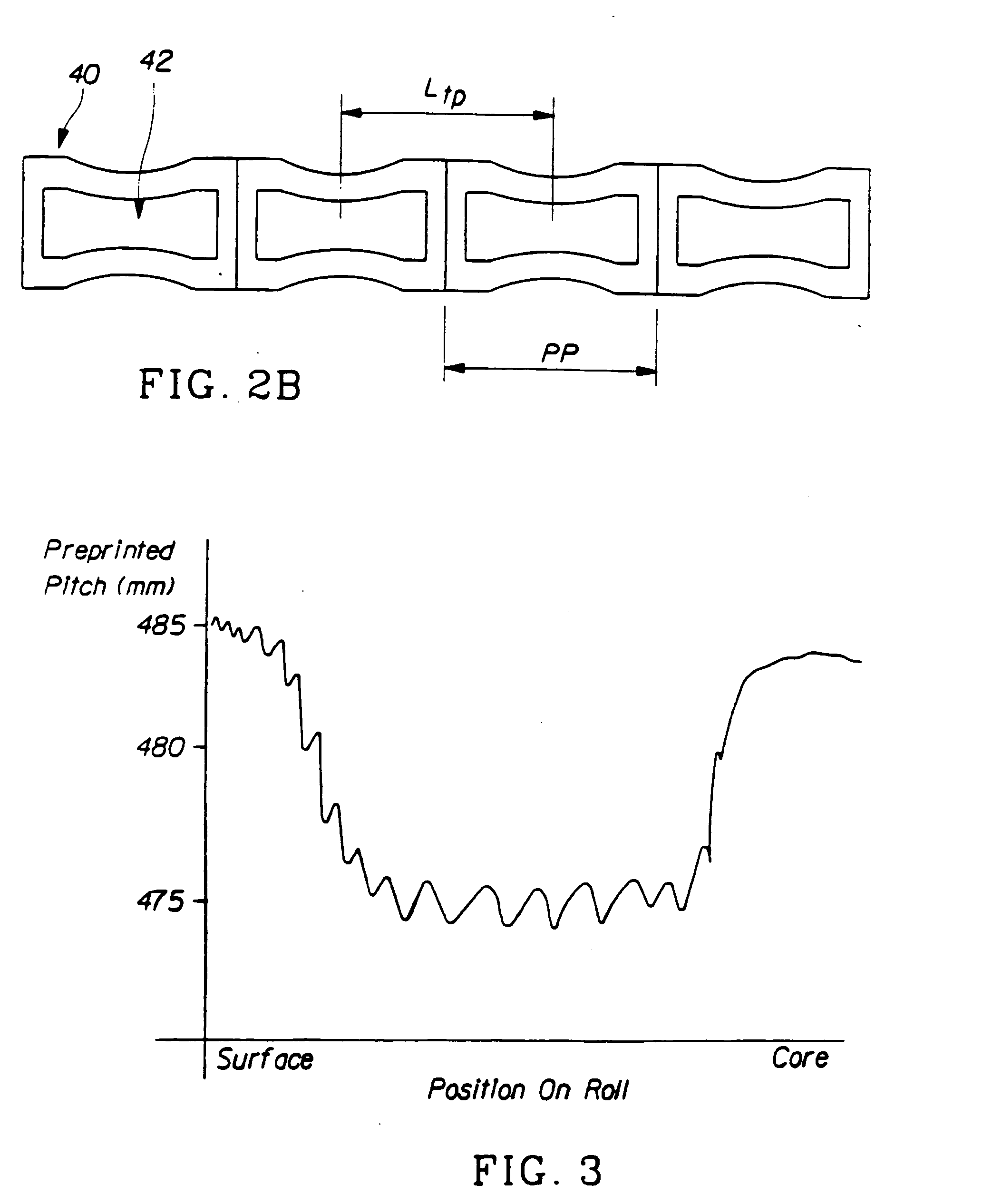

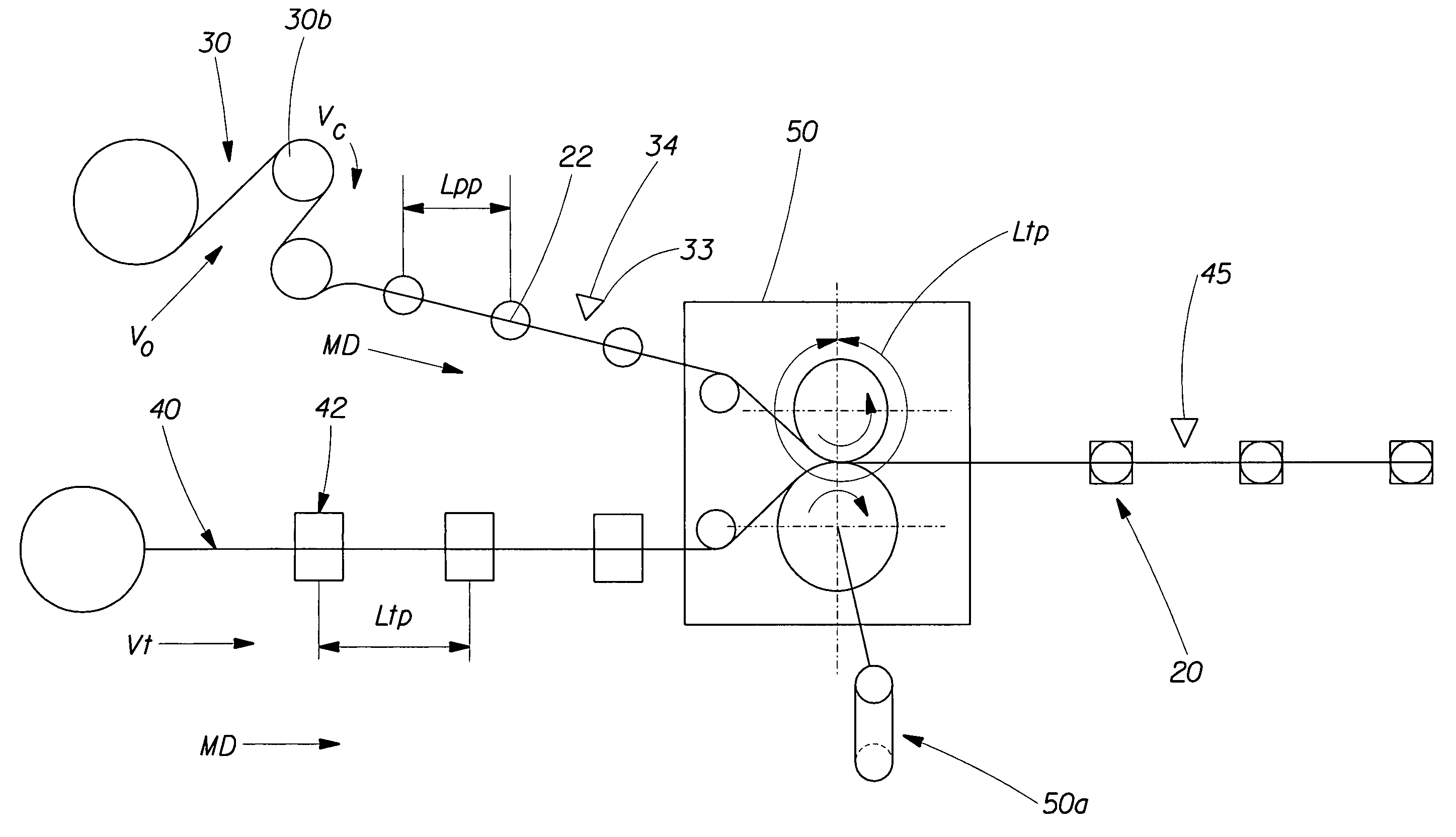

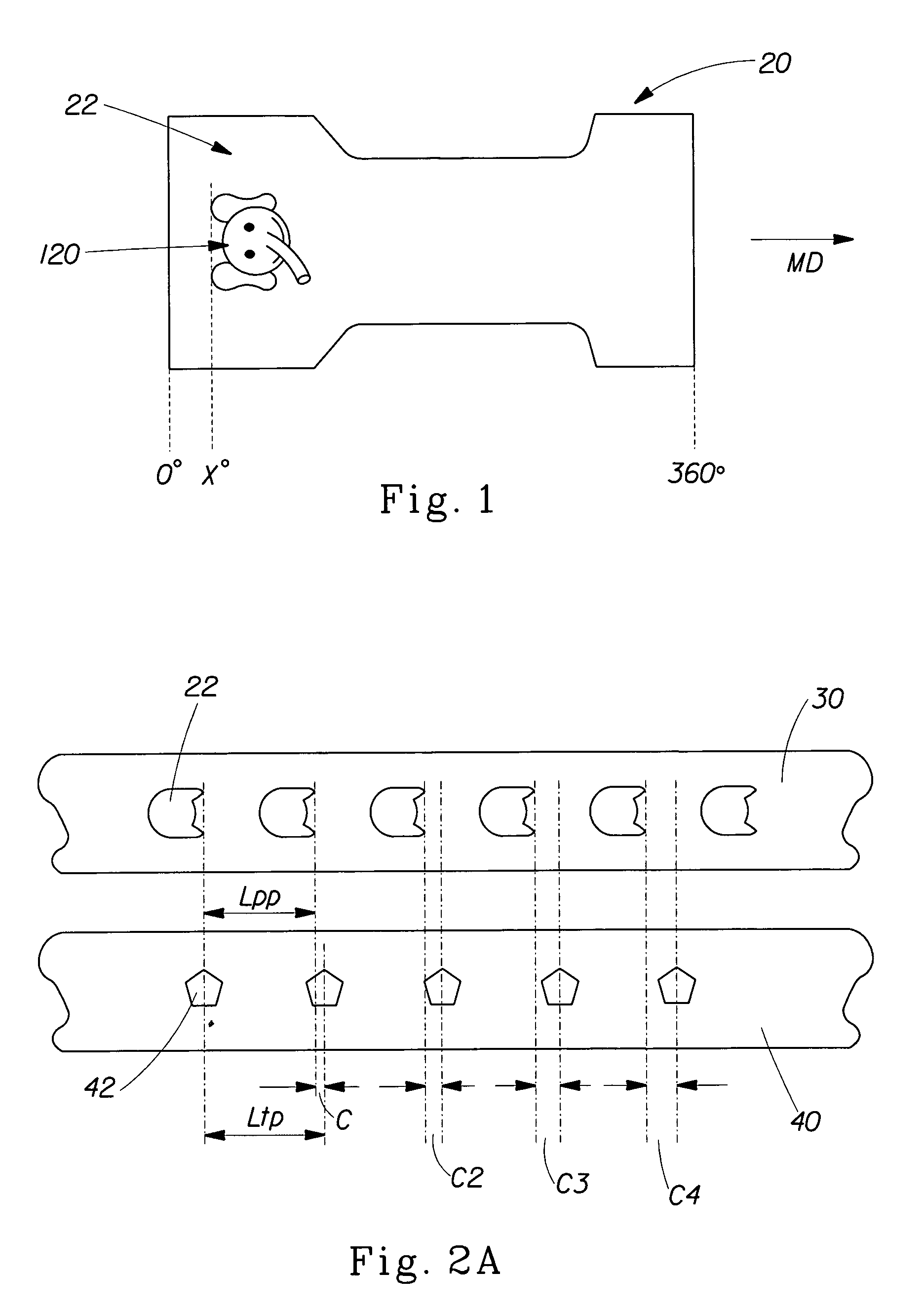

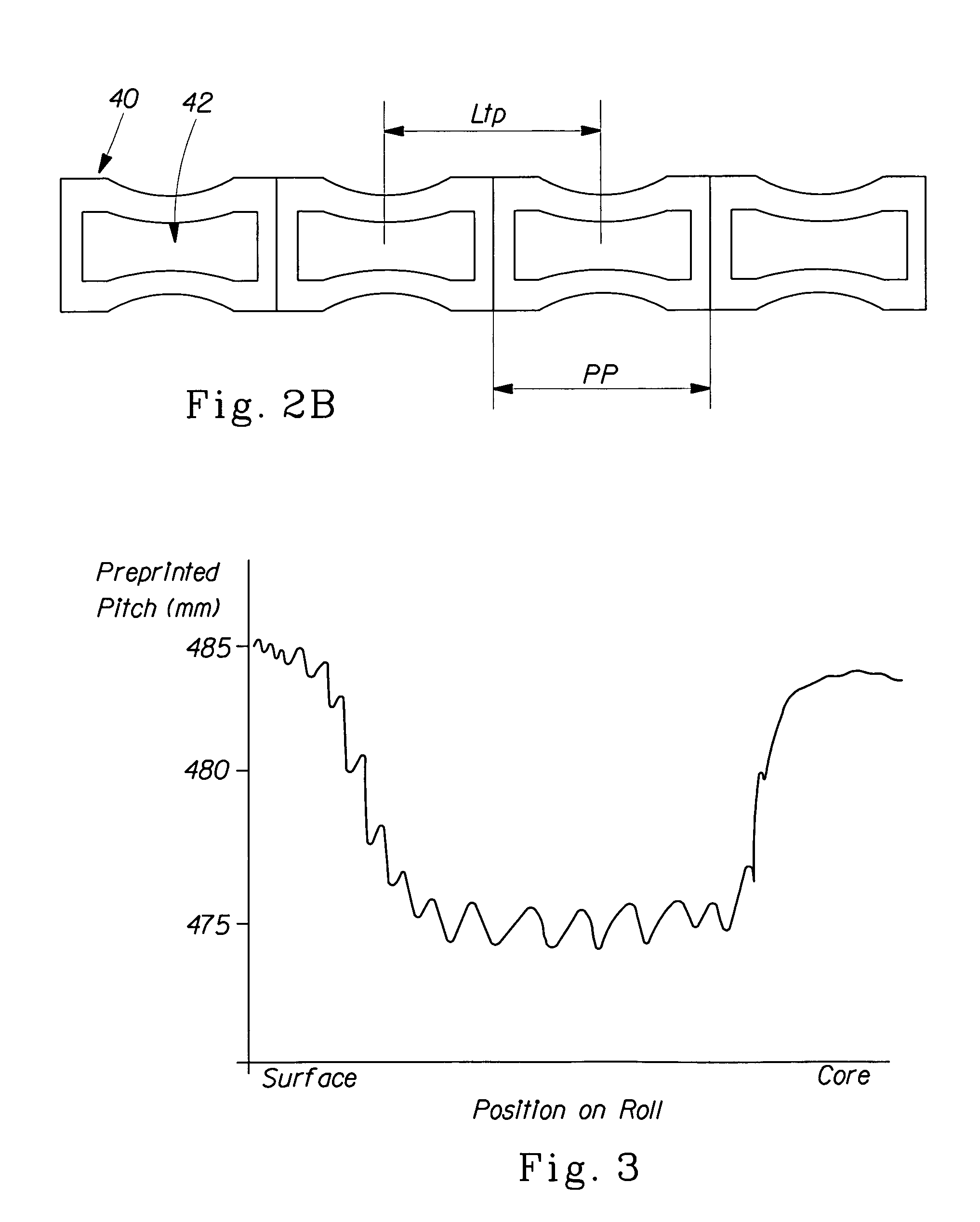

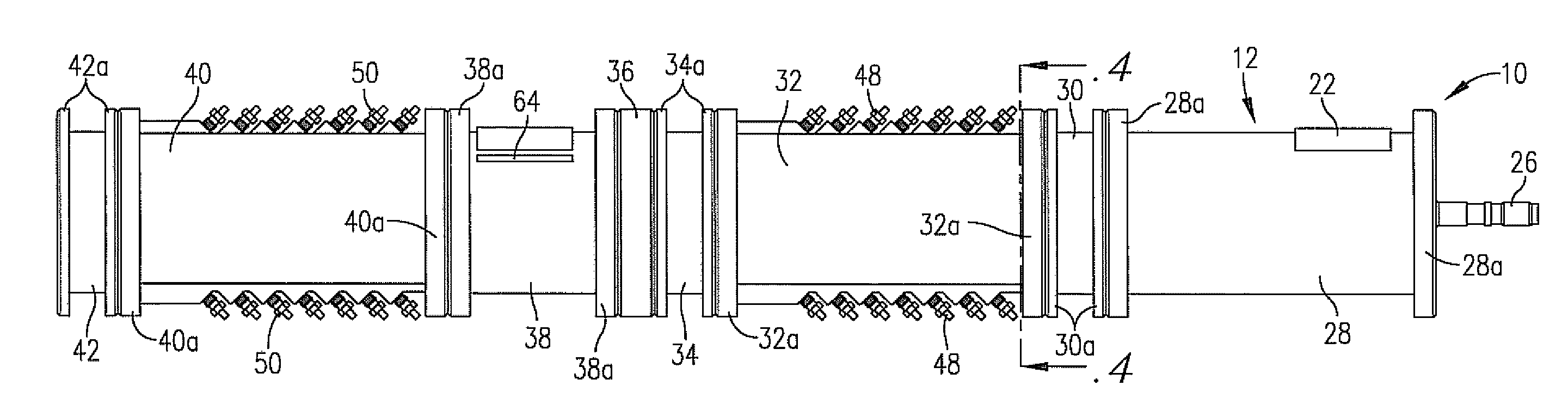

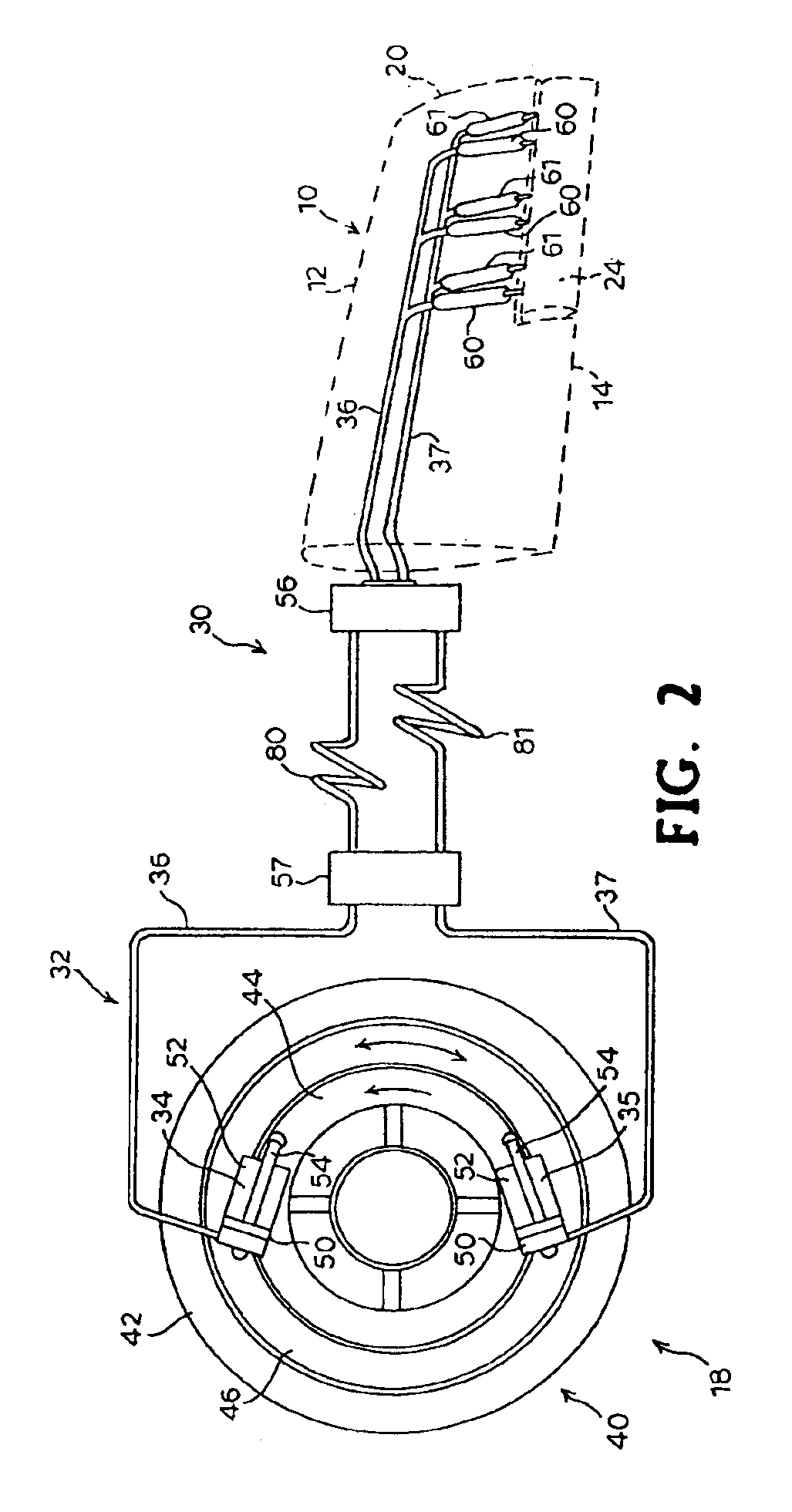

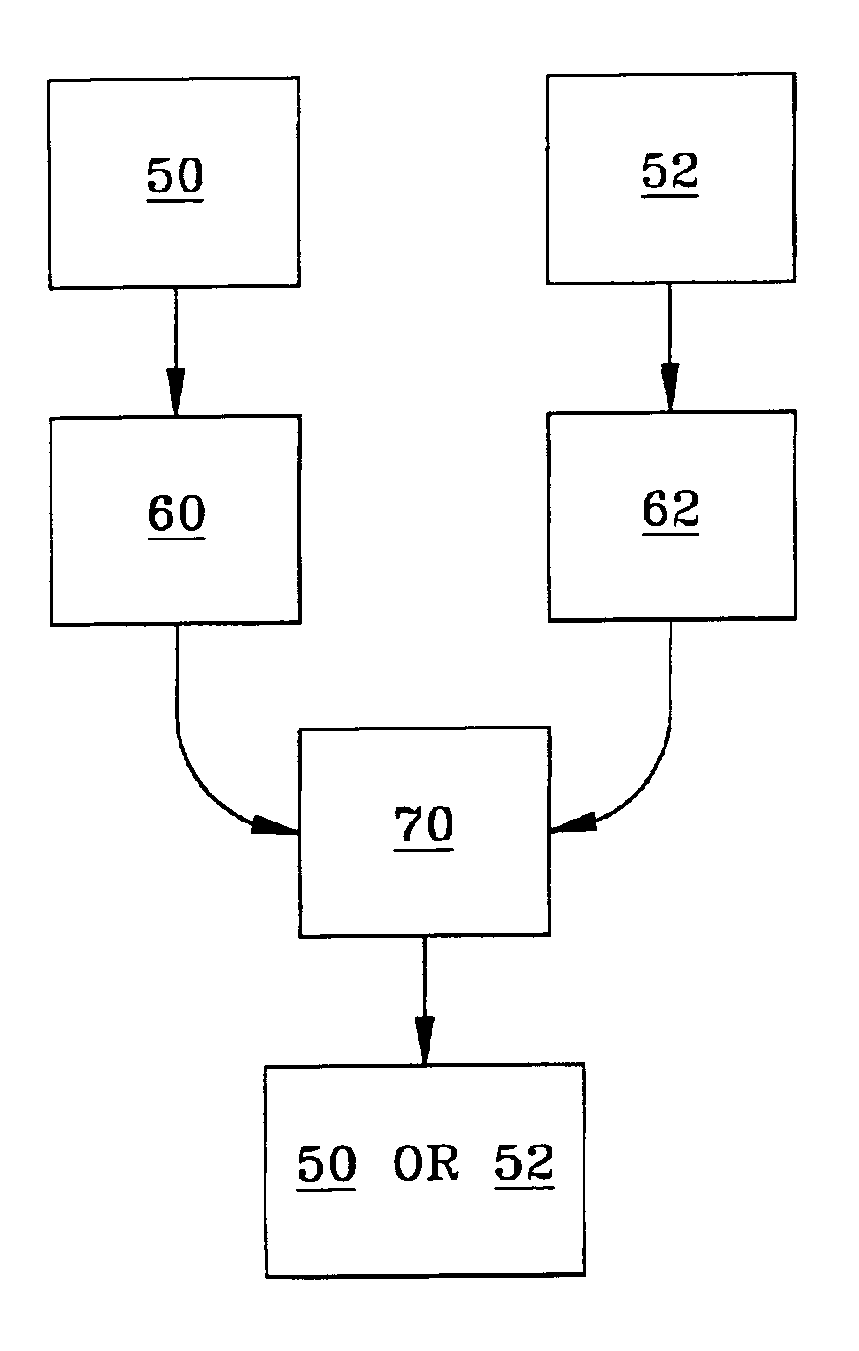

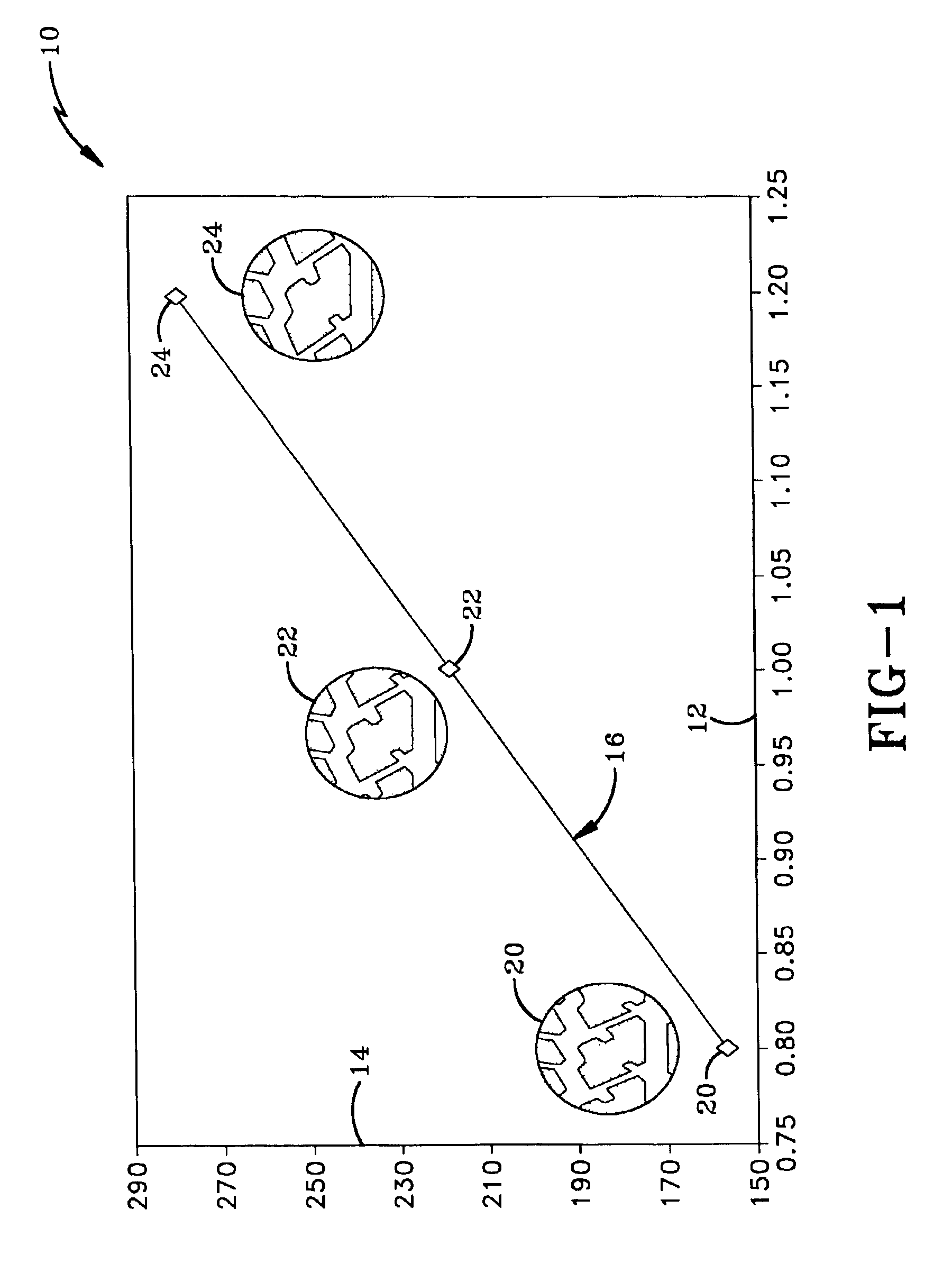

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pre-produced webs into a converting line producing disposable absorbent articles such as diapers, pull-ups, feminine hygiene articles or a component thereof. The pre-produced webs can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position. The present invention includes five embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward control system; the fourth and fifth embodiments, in addition, include an automatic phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pre-produced webs into a converting line producing disposable absorbent articles such as diapers, pull-ups, feminine hygiene articles or a component thereof. The pre-produced webs can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position. The present invention includes five embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward control system; the fourth and fifth embodiments, in addition, include an automatic phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:PROCTER & GAMBLE CO

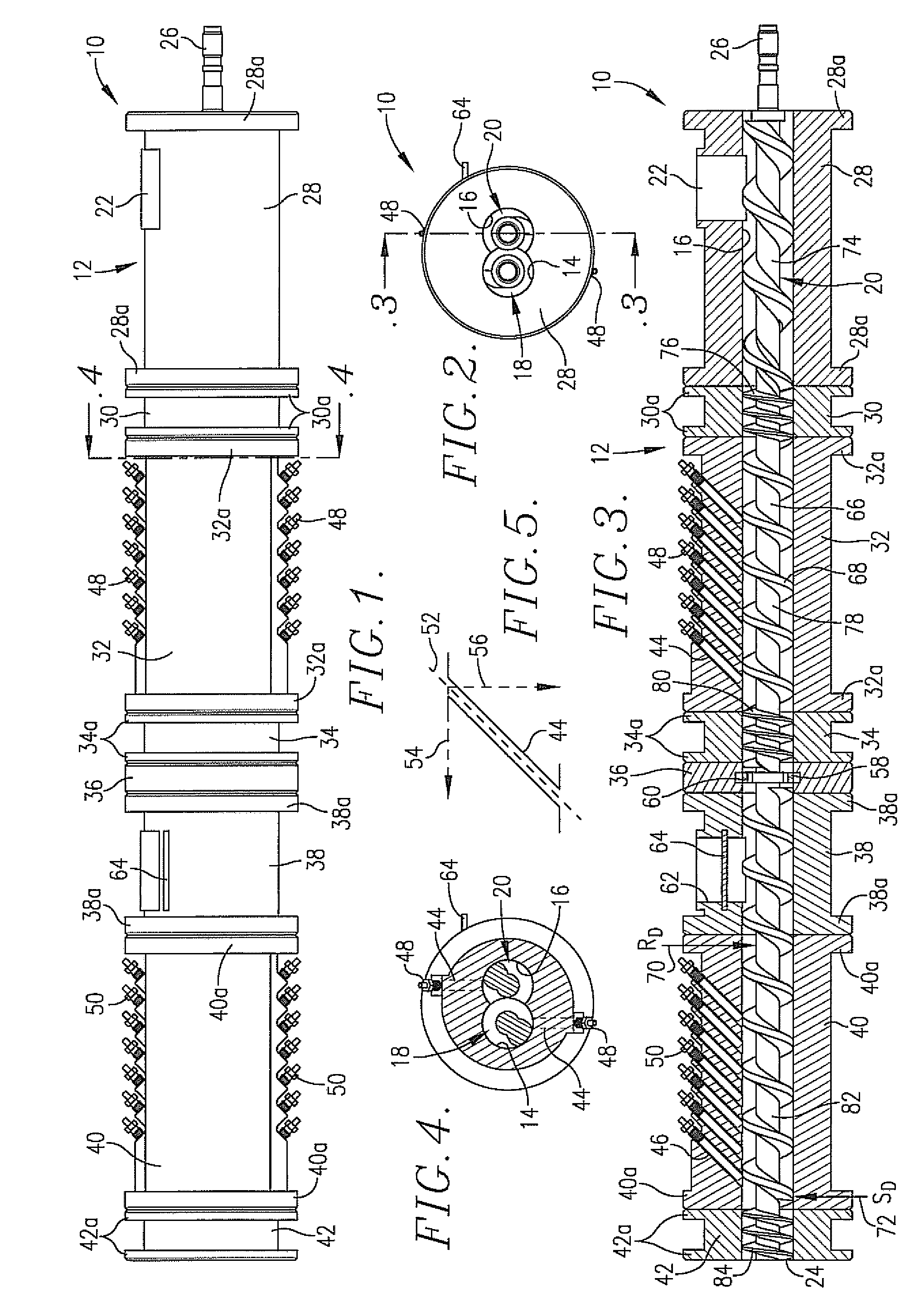

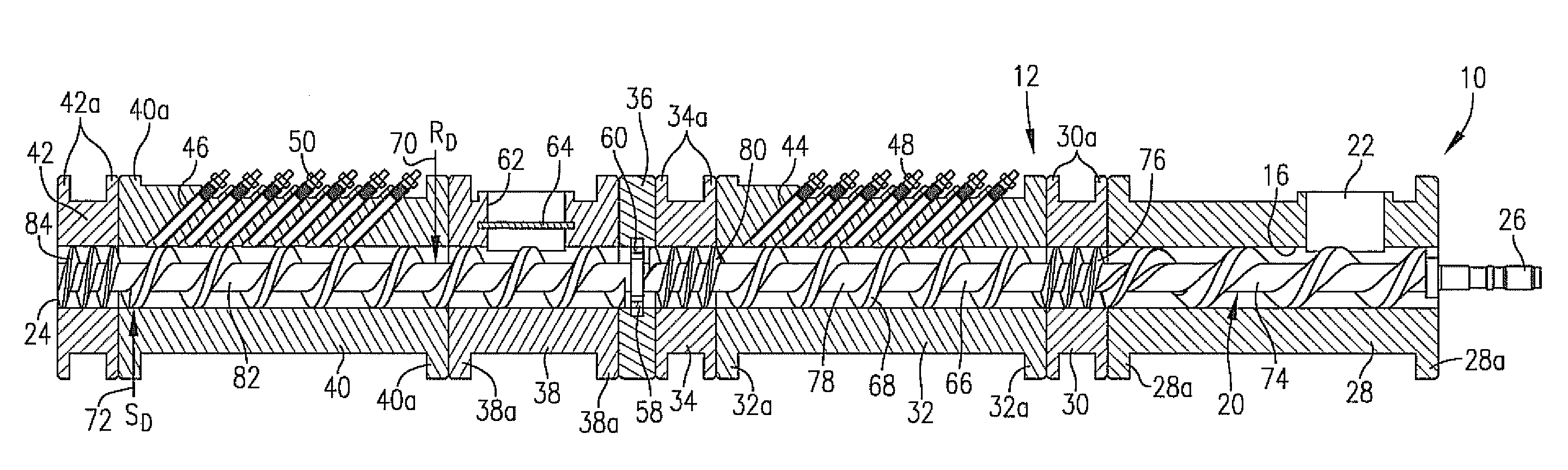

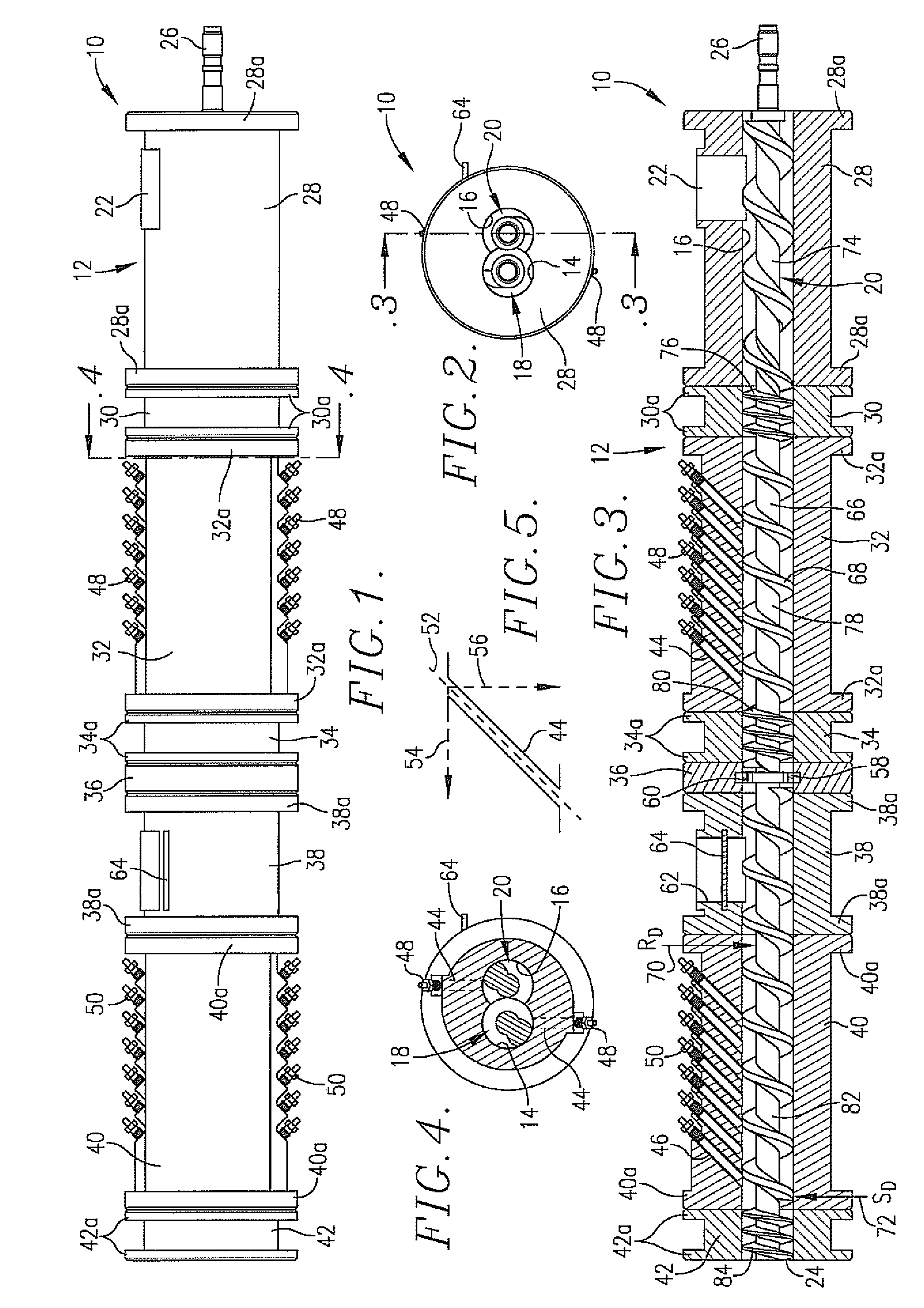

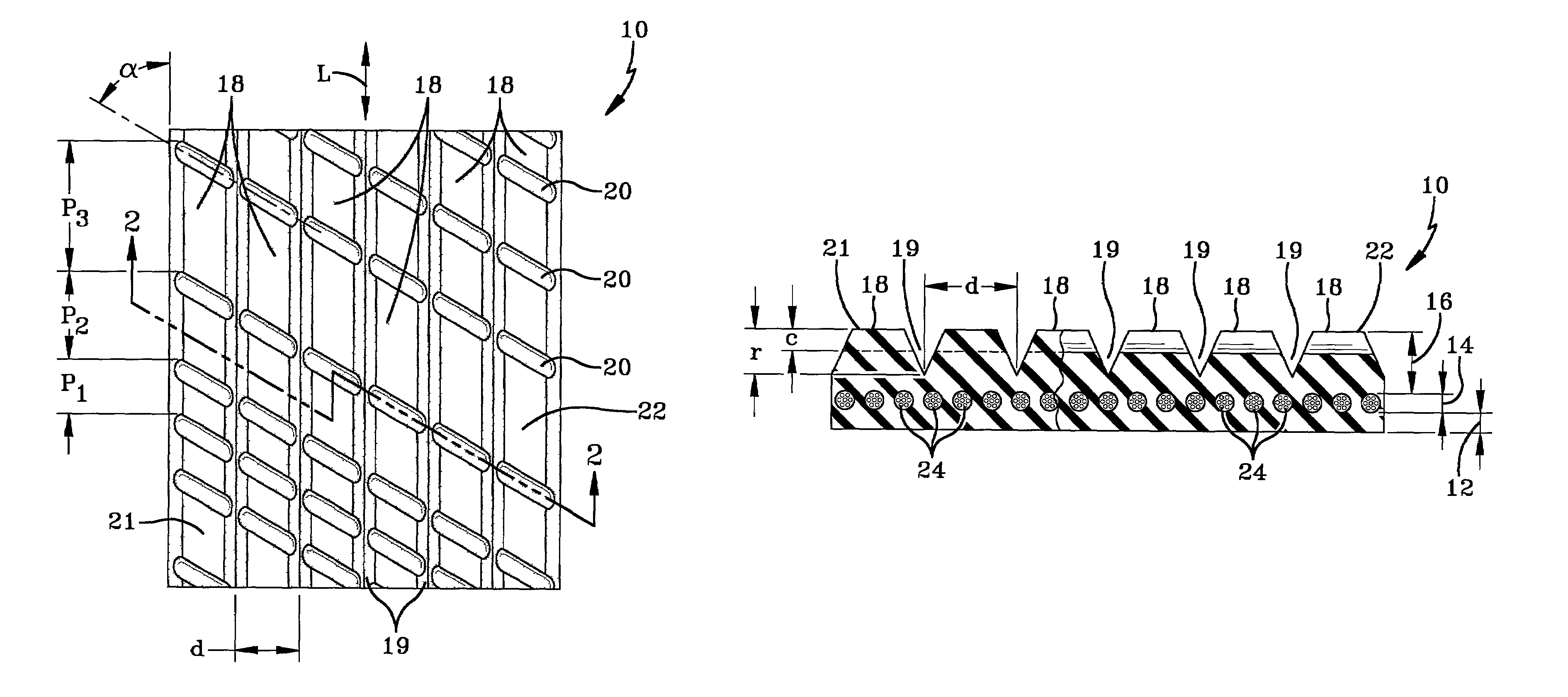

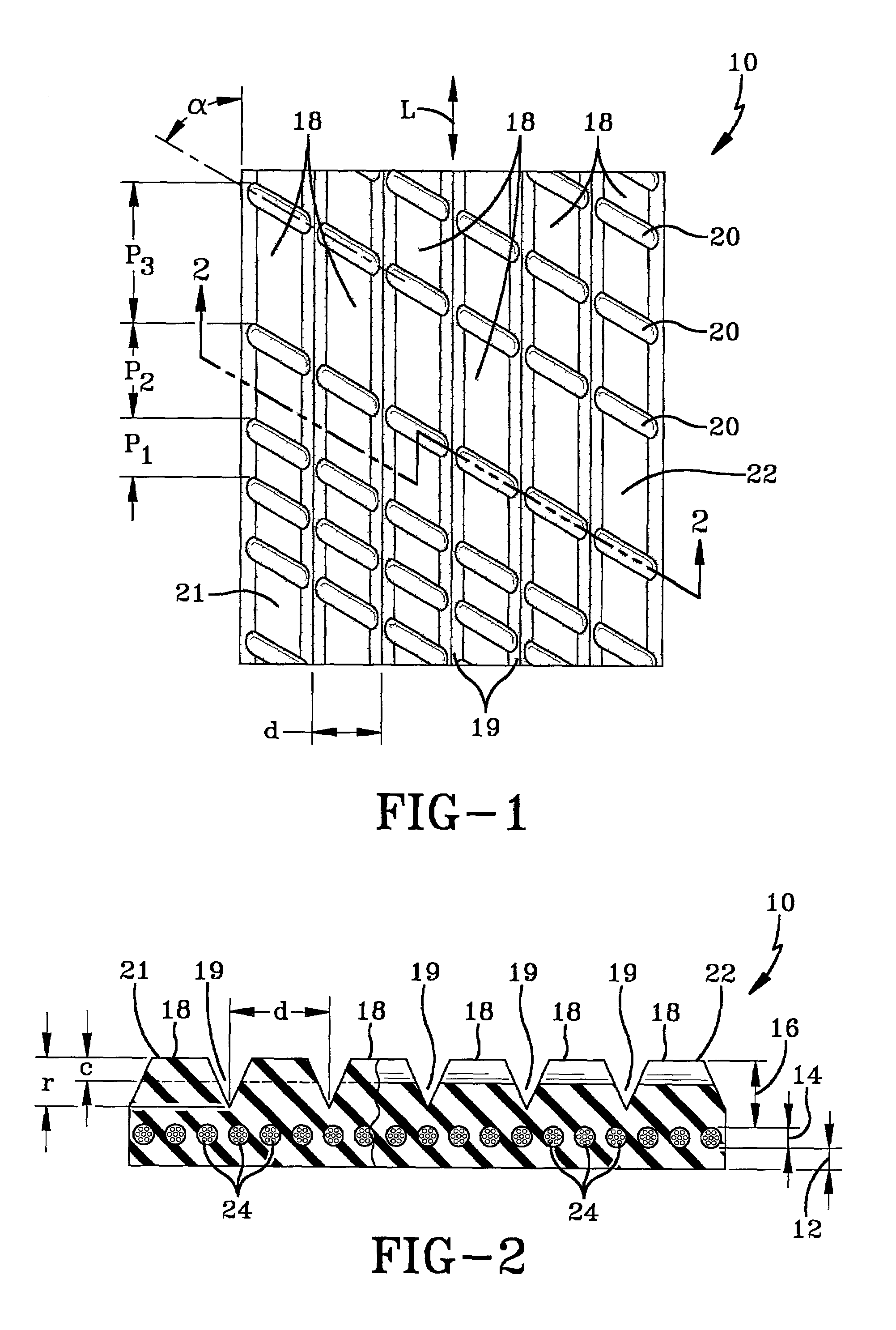

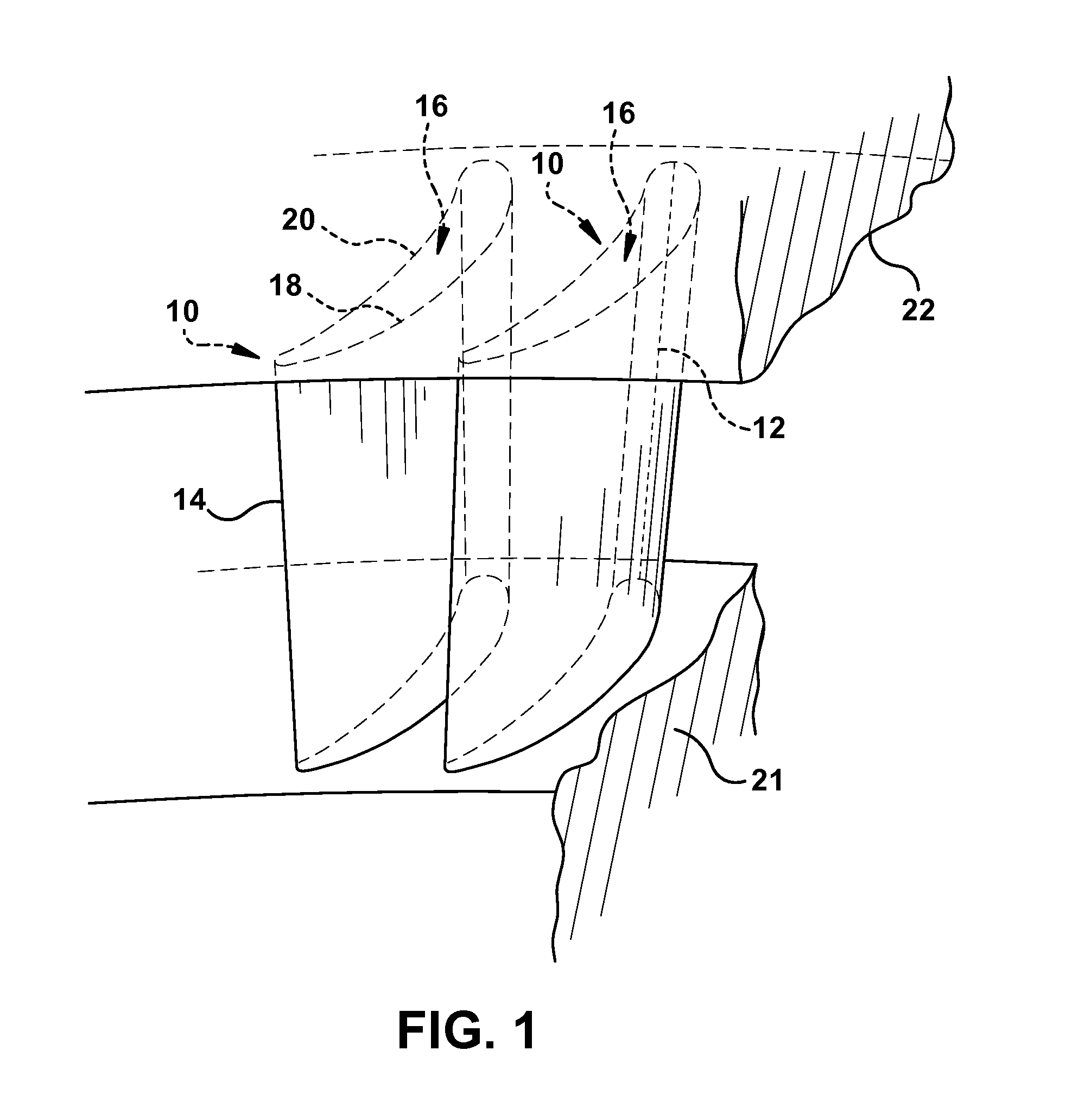

Cooking extruder with enhanced steam injection properties

ActiveUS20080223223A1Overcome problemsAvoid flowFeeding-stuffWorking-up animal fodderEngineeringPitch length

An improved extruder (10) is provided which permits successful introduction of very high quantities of injected steam into material being processed, on the order of 6-8% or more by weight steam. The extruder (10) includes an elongated extruder barrel (12) having at least one elongated, axially rotatable, helically flighted extrusion screw (16,18) therein. The barrel (12) is equipped with obliquely oriented steam injection ports (44, 46) along the length thereof, housing steam injectors (48, 50). The barrel (12) includes relatively high free volume steam injection heads (32 and 38, 40) having therein screw sections (78, 82) of relatively long pitch length, together with steam restriction heads (30, 34, and 42) on opposite sides of the injection heads (32, and 38, 40) having therein relatively short pitch length screw sections (76, 80, 84).

Owner:WENGER MFG LLC

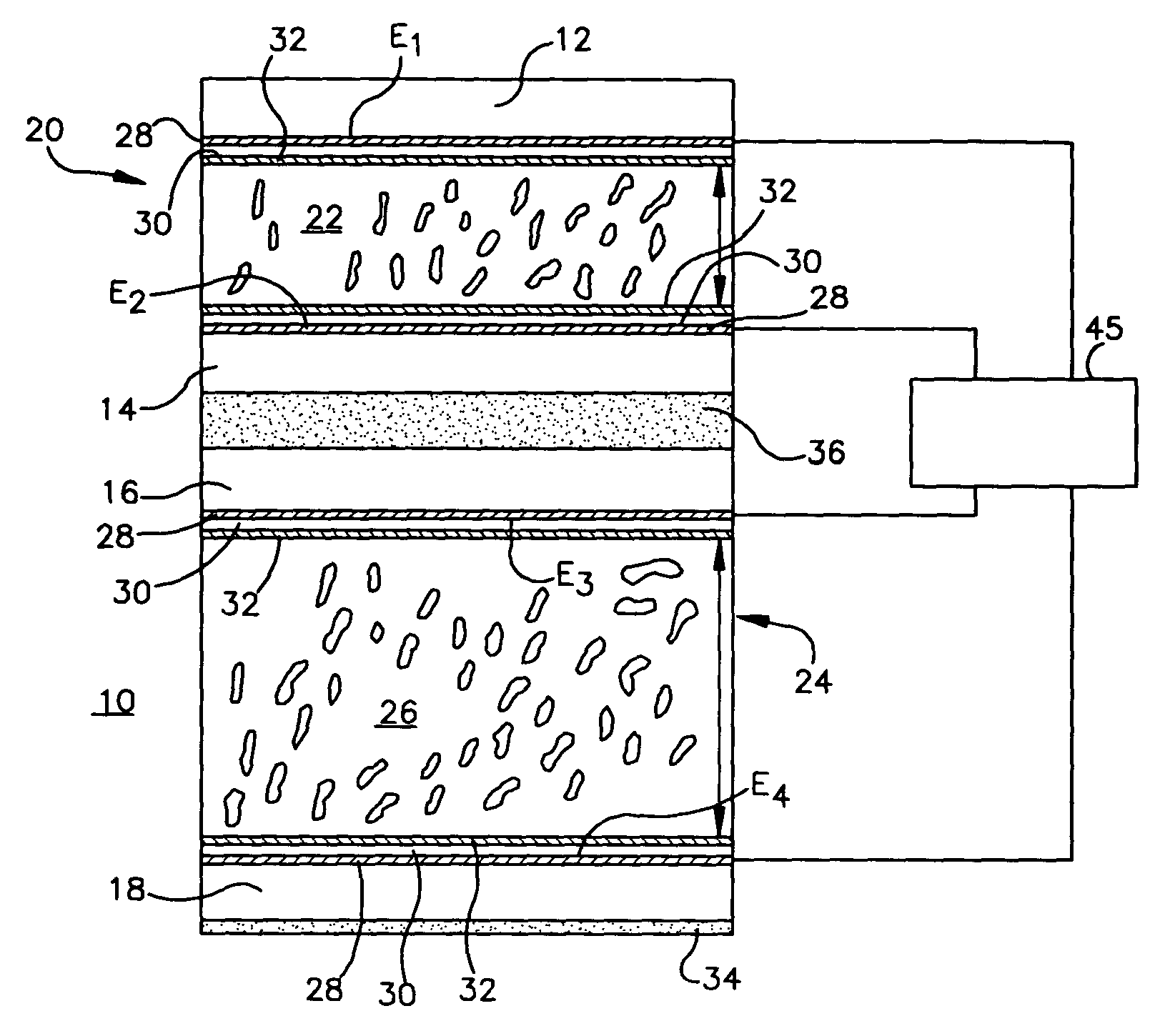

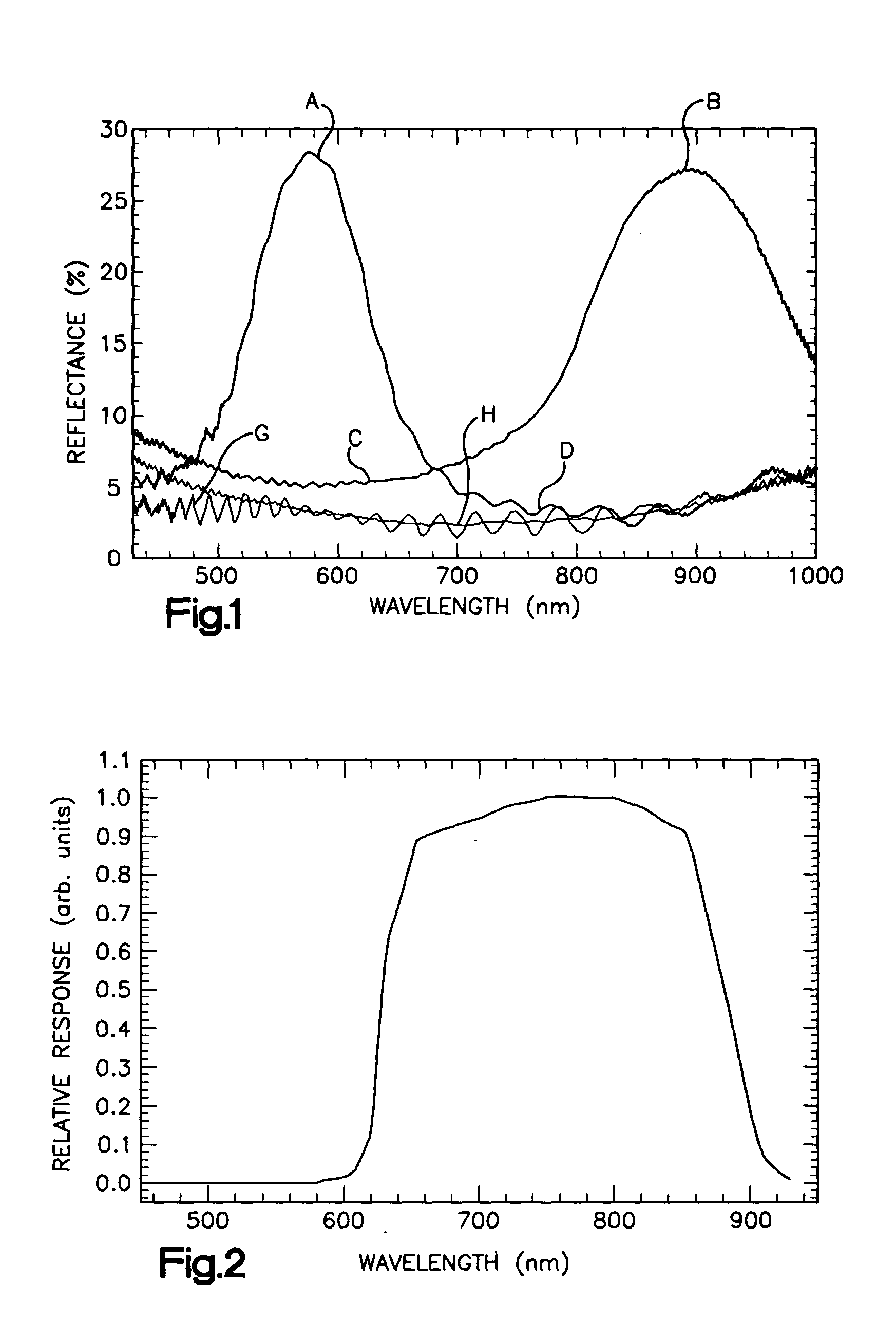

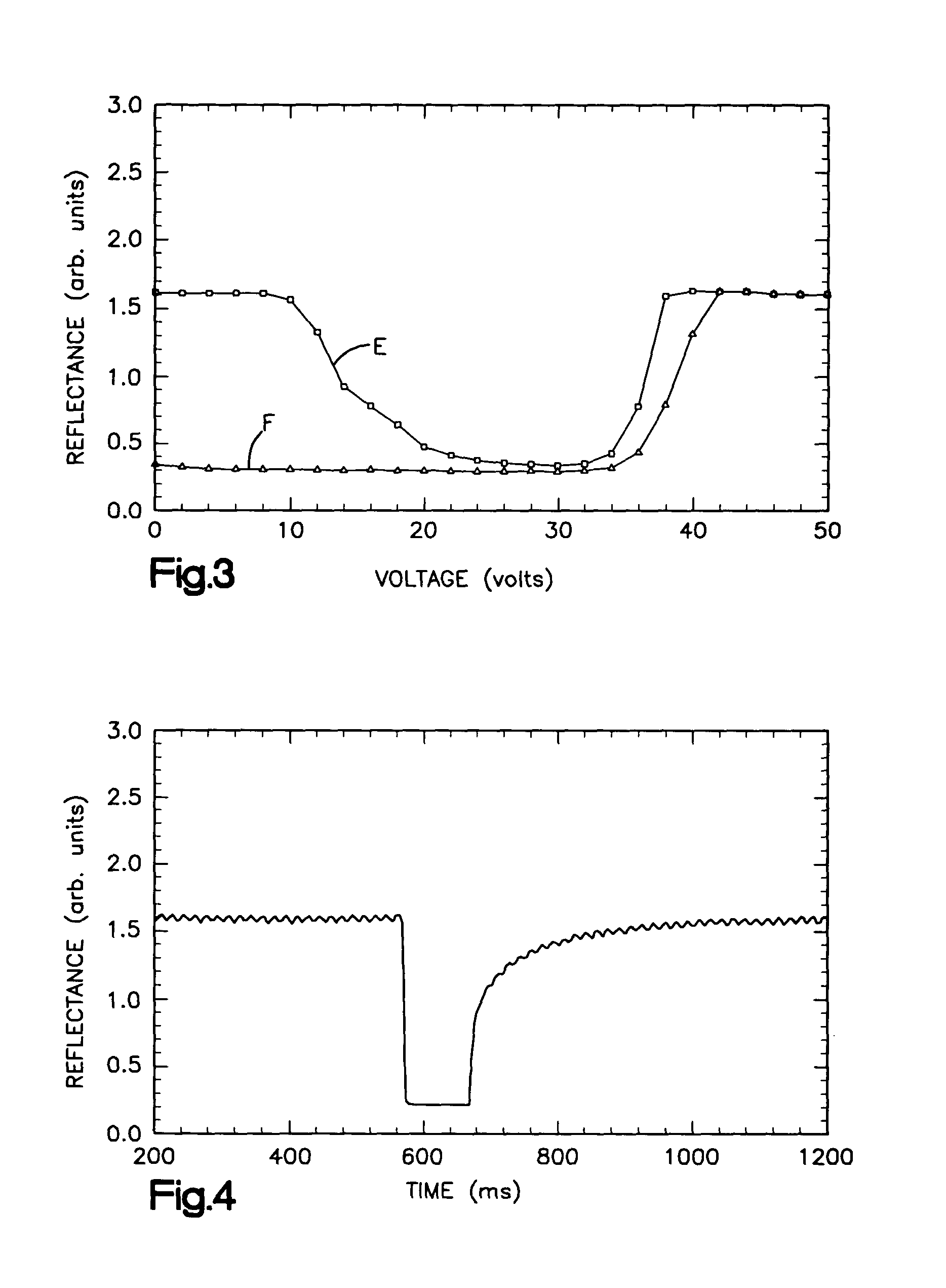

Stacked color liquid crystal display device

InactiveUS20050036077A1High bandwidthIncrease rangeLiquid crystal compositionsStatic indicating devicesDisplay devicePhotolithography

A liquid crystal display device includes cell wall structure and a chiral nematic liquid crystal material. The cell wall structure and the liquid crystal cooperate to form focal conic and twisted planar textures that are stable in the absence of a field. A device applies an electric field to the liquid crystal for transforming at least a portion of the material to at least one of the focal conic and twisted planar textures. The liquid crystal material has a pitch length effective to reflect radiation having a wavelength in both the visible and the infrared ranges of the electromagnetic spectrum at intensity that is sufficient for viewing by an observer. One liquid crystal material may be disposed in a single region or two or more liquid crystal materials may be used, each in separate regions even without the infrared reflecting layer. One aspect of the invention is directed to a photolithography method for patterning a substrate of the display. The display may also have multicolor capabilities by including separate layers of at least two or three liquid crystal materials that reflect visible light. A full color stacked display may be produced with grey scale capabilities.

Owner:KENT DISPLAY SYST

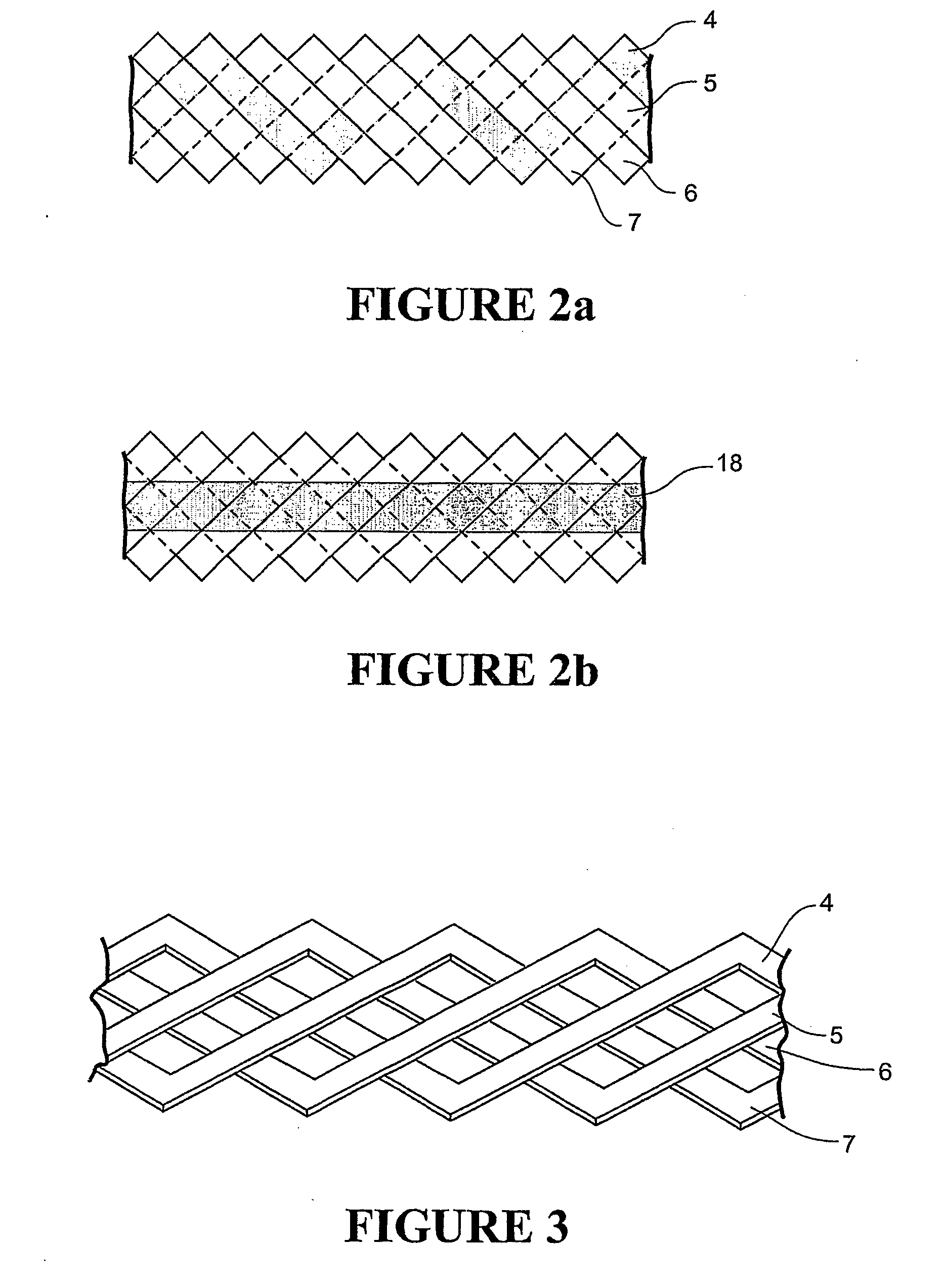

Composite Superconductor Cable Produced by Transposing Planar Subconductors

InactiveUS20080210454A1Superconductors/hyperconductorsTransformers/inductances detailsIn planeElectrical conductor

Owner:CALLAGHAN INNOVATION RES LTD

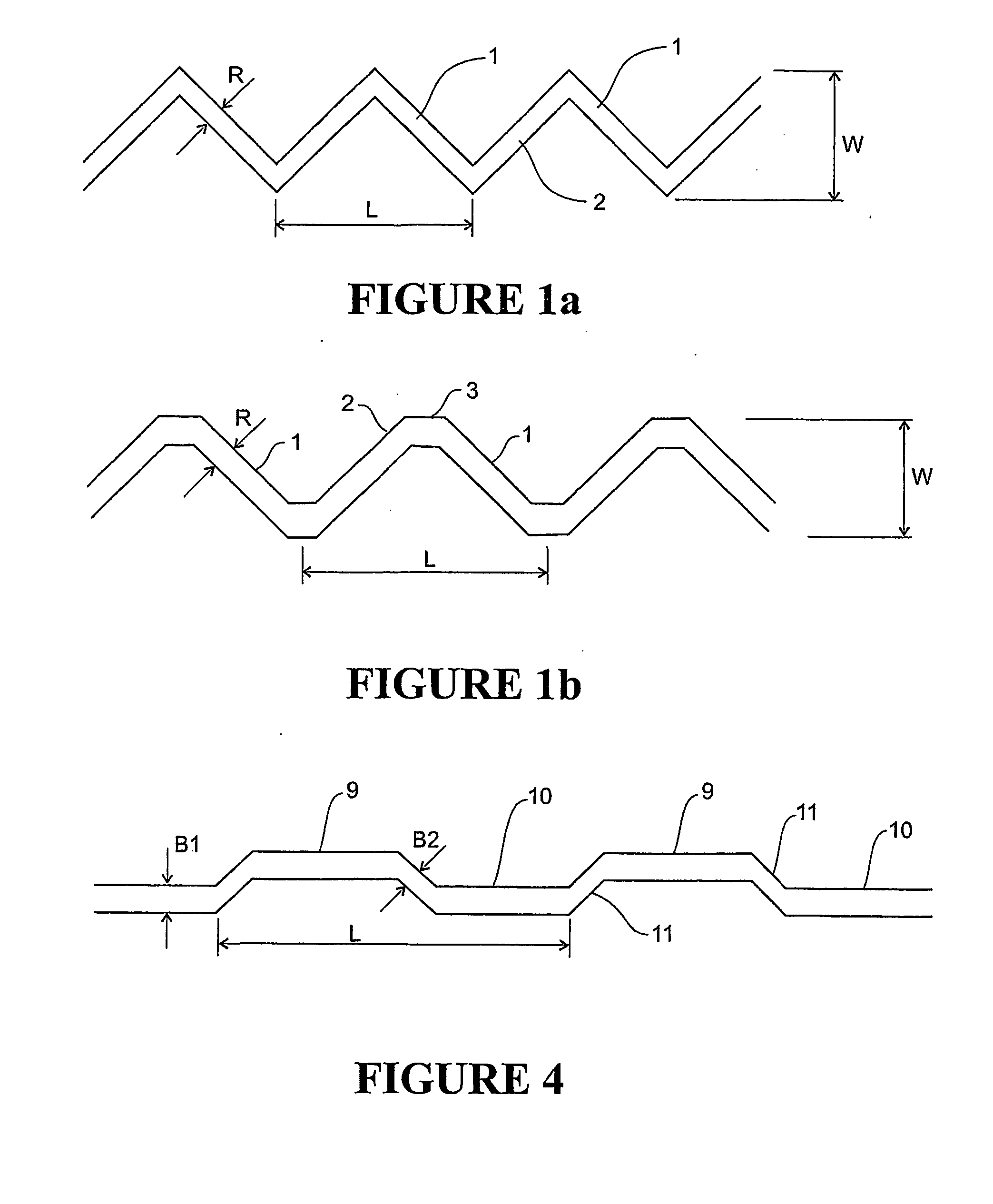

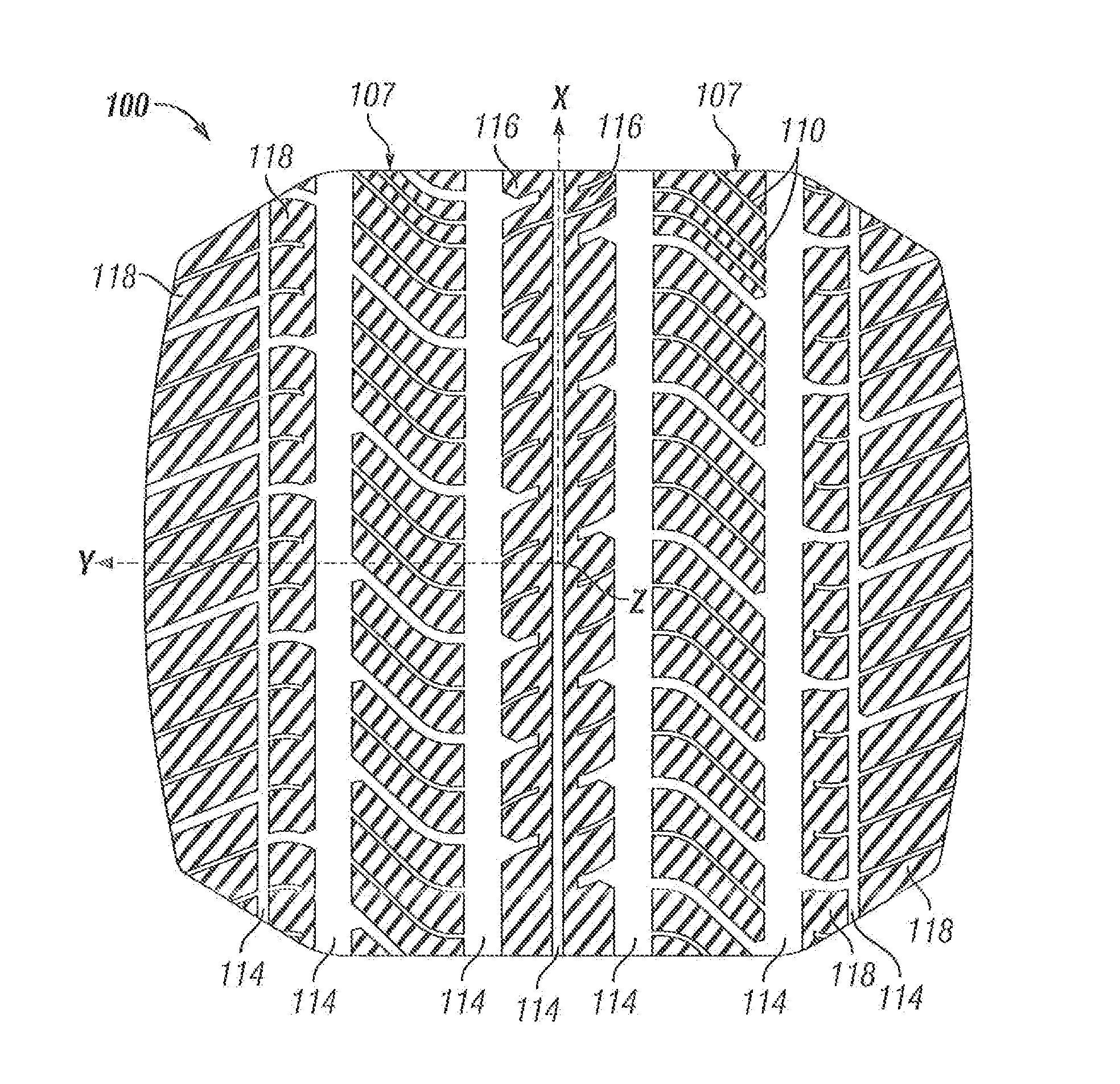

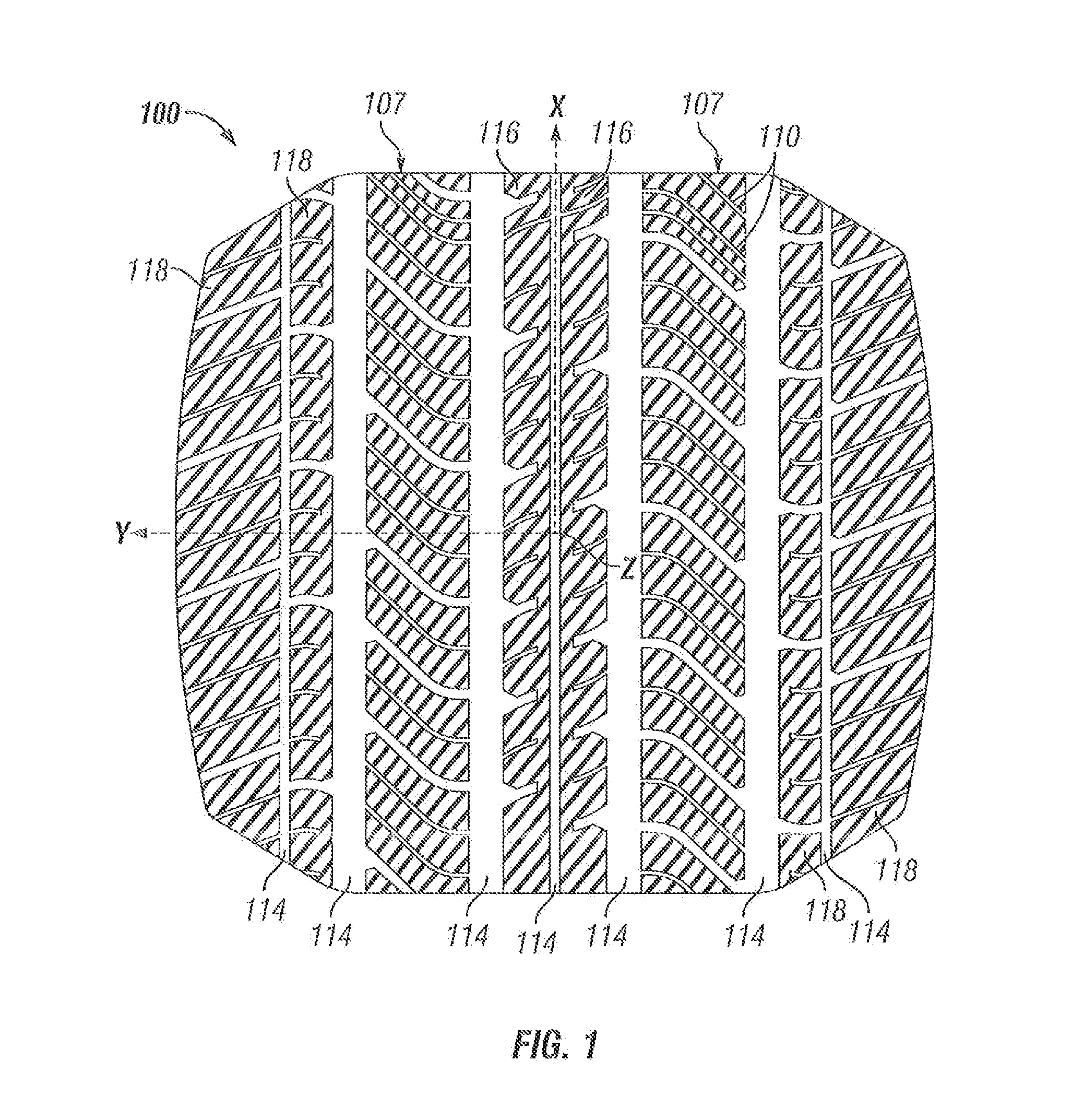

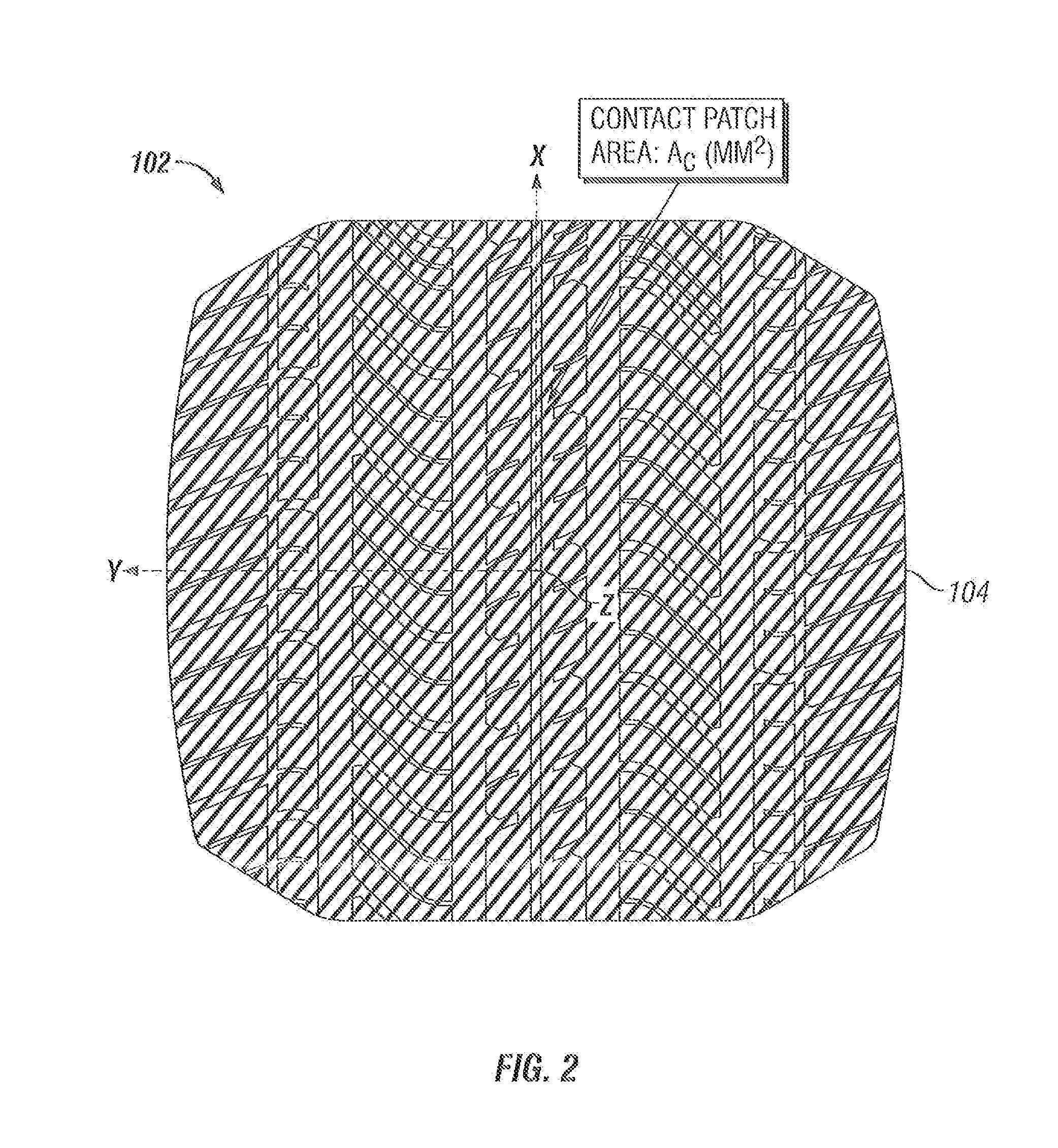

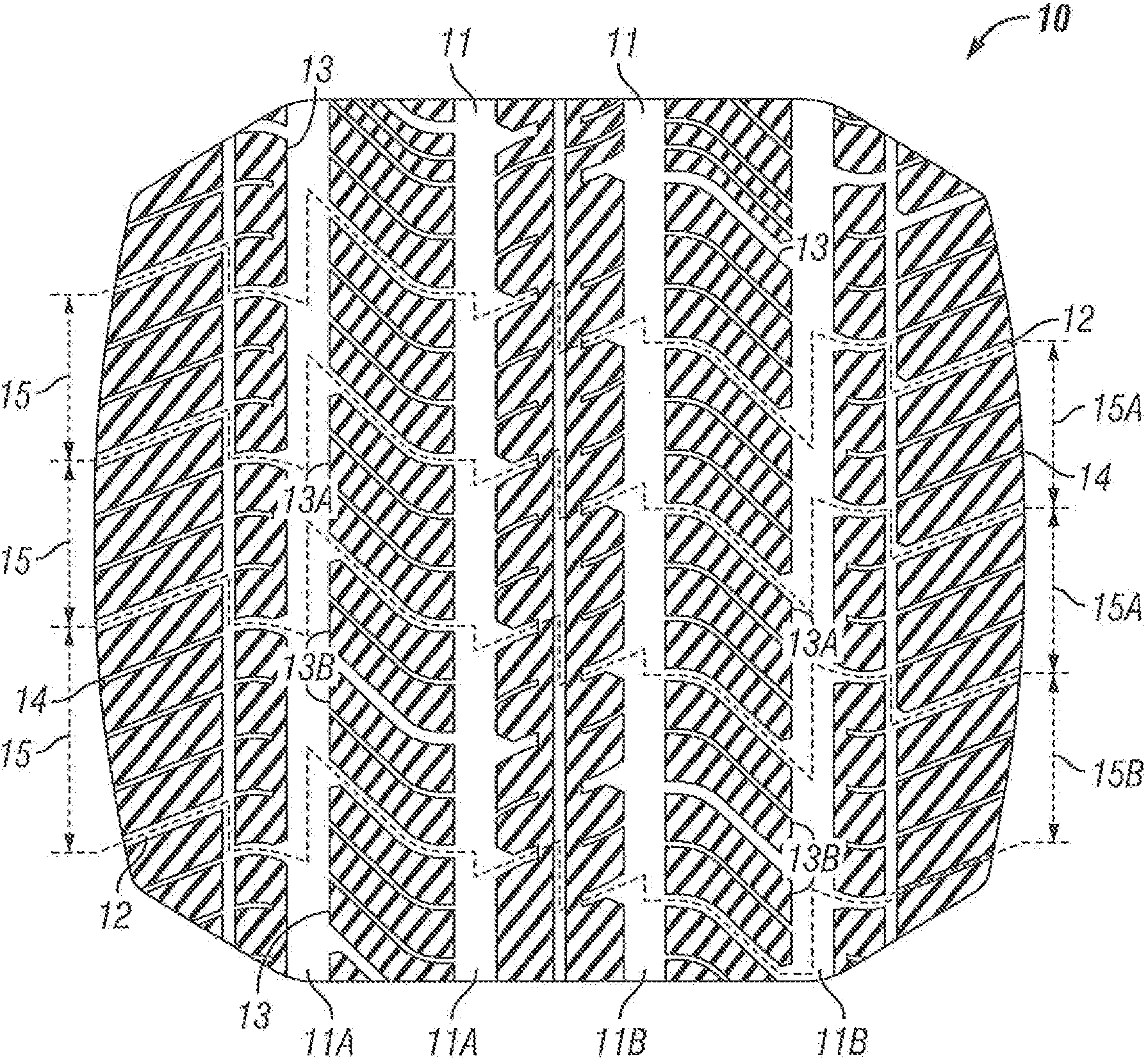

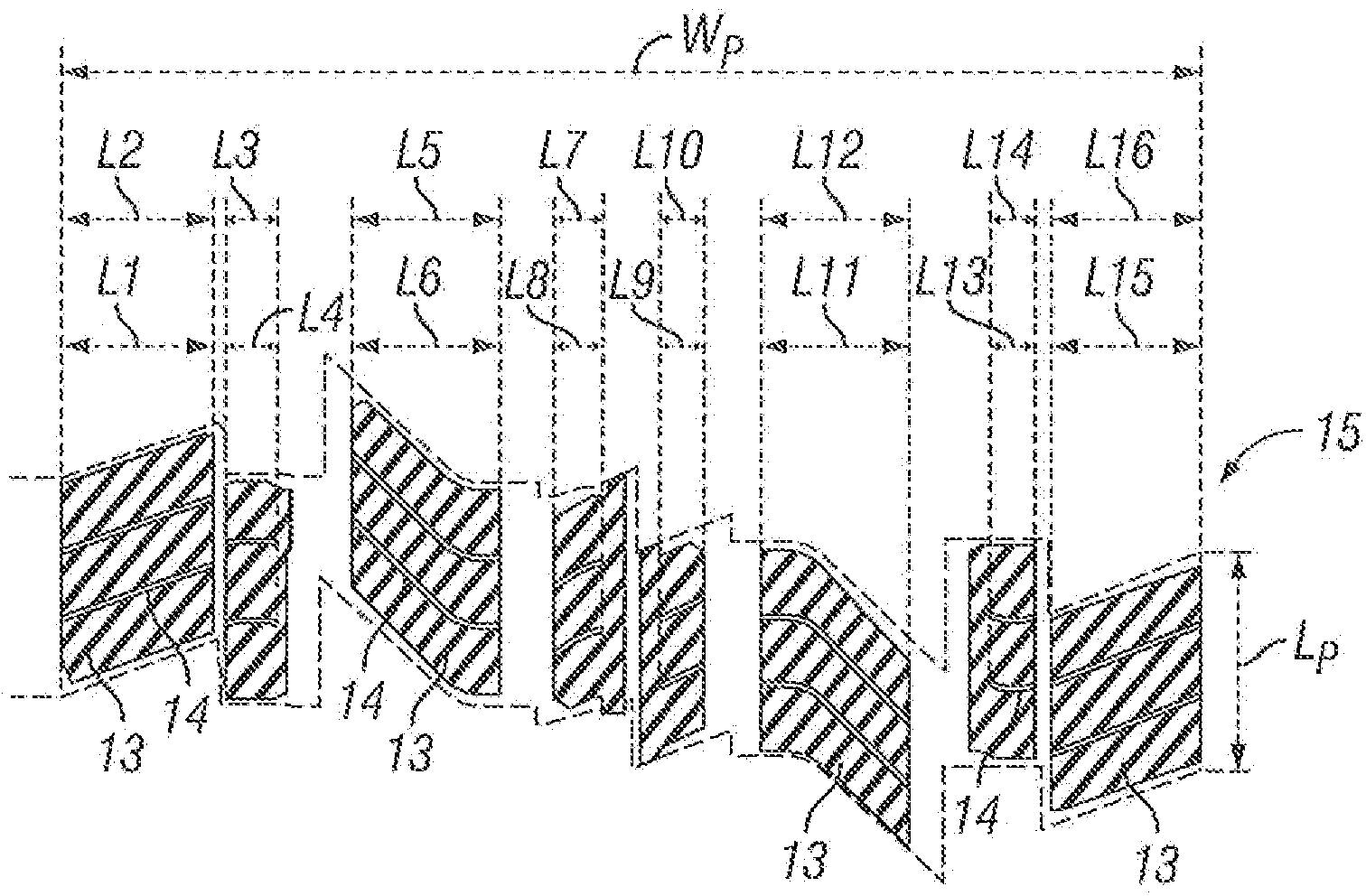

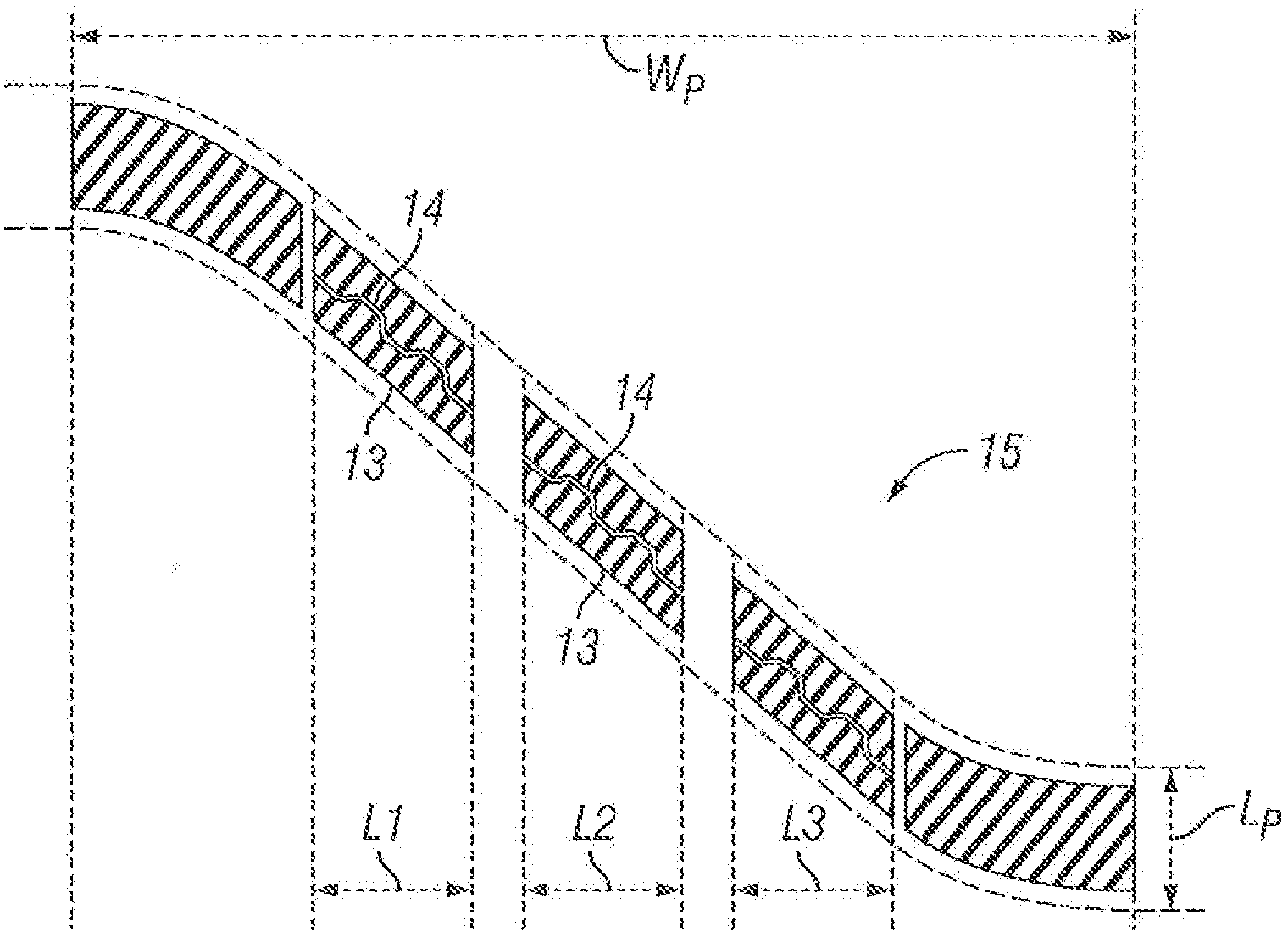

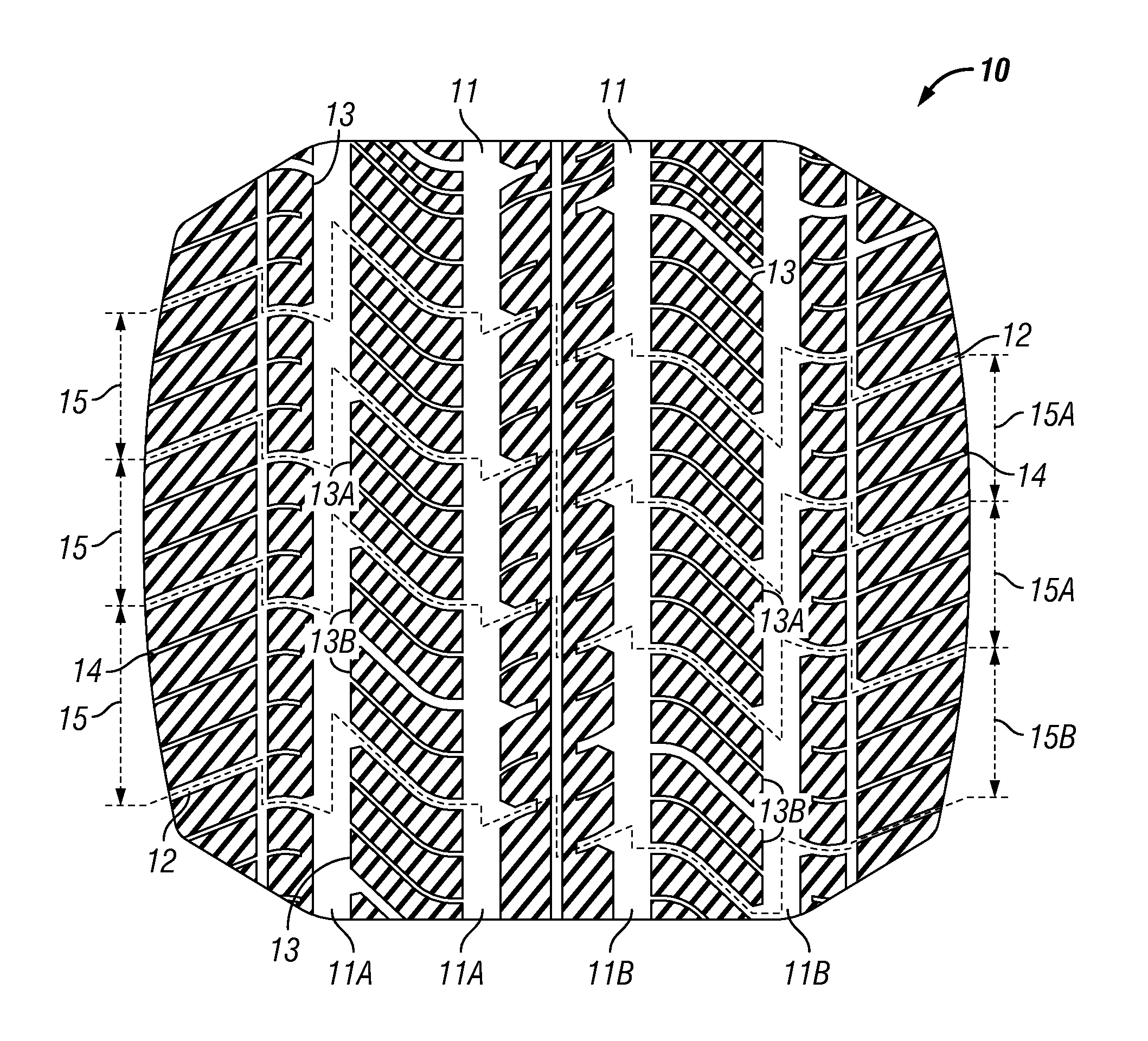

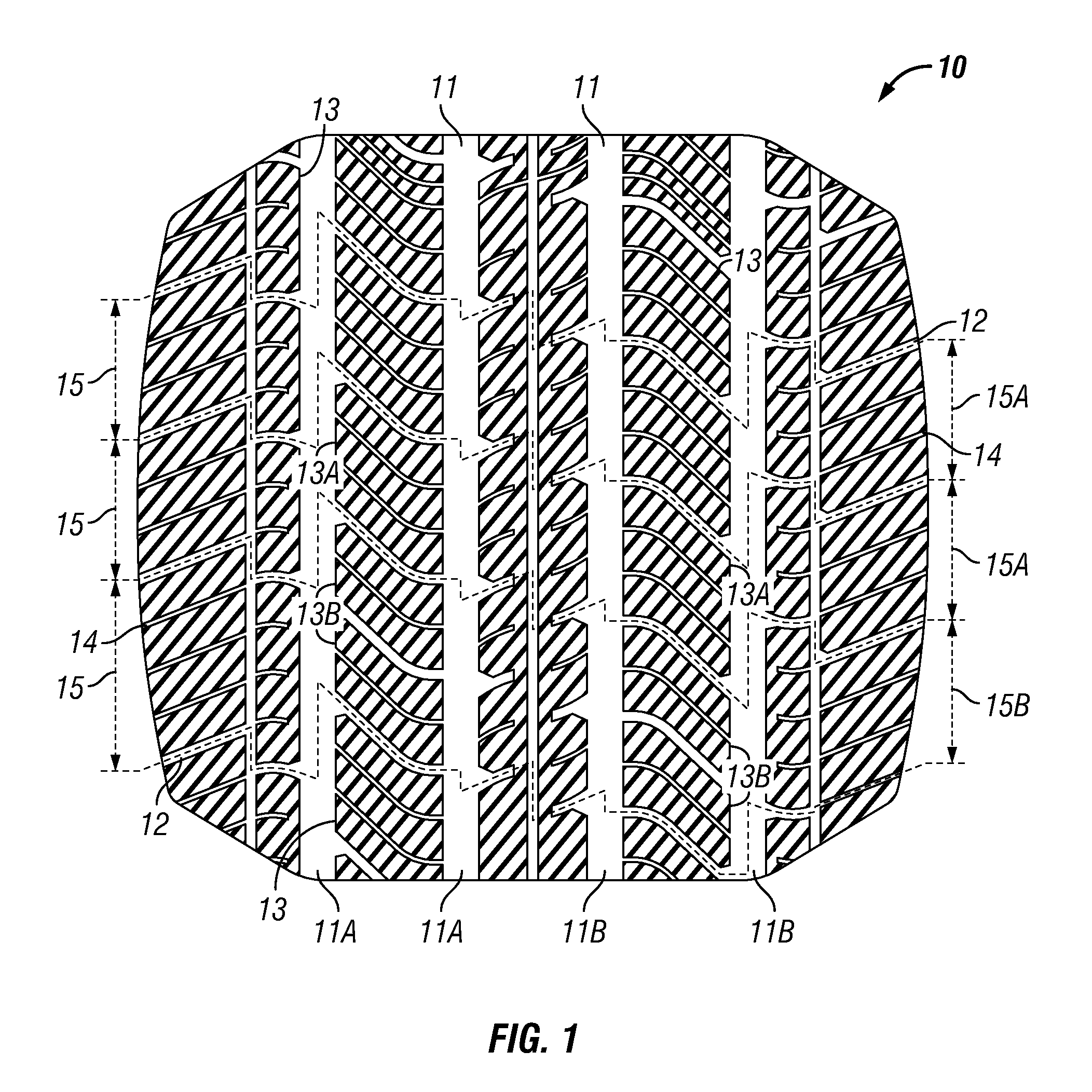

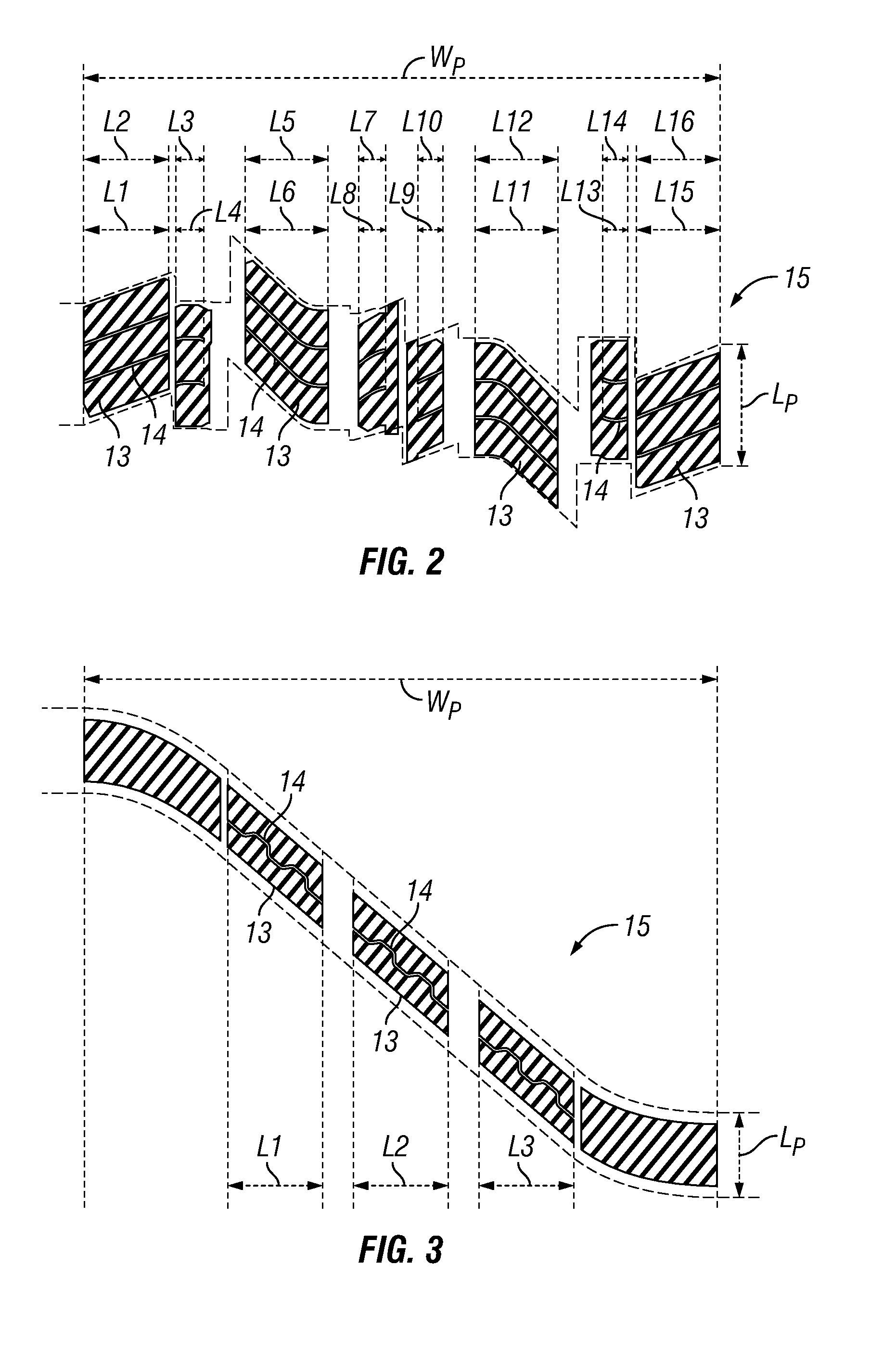

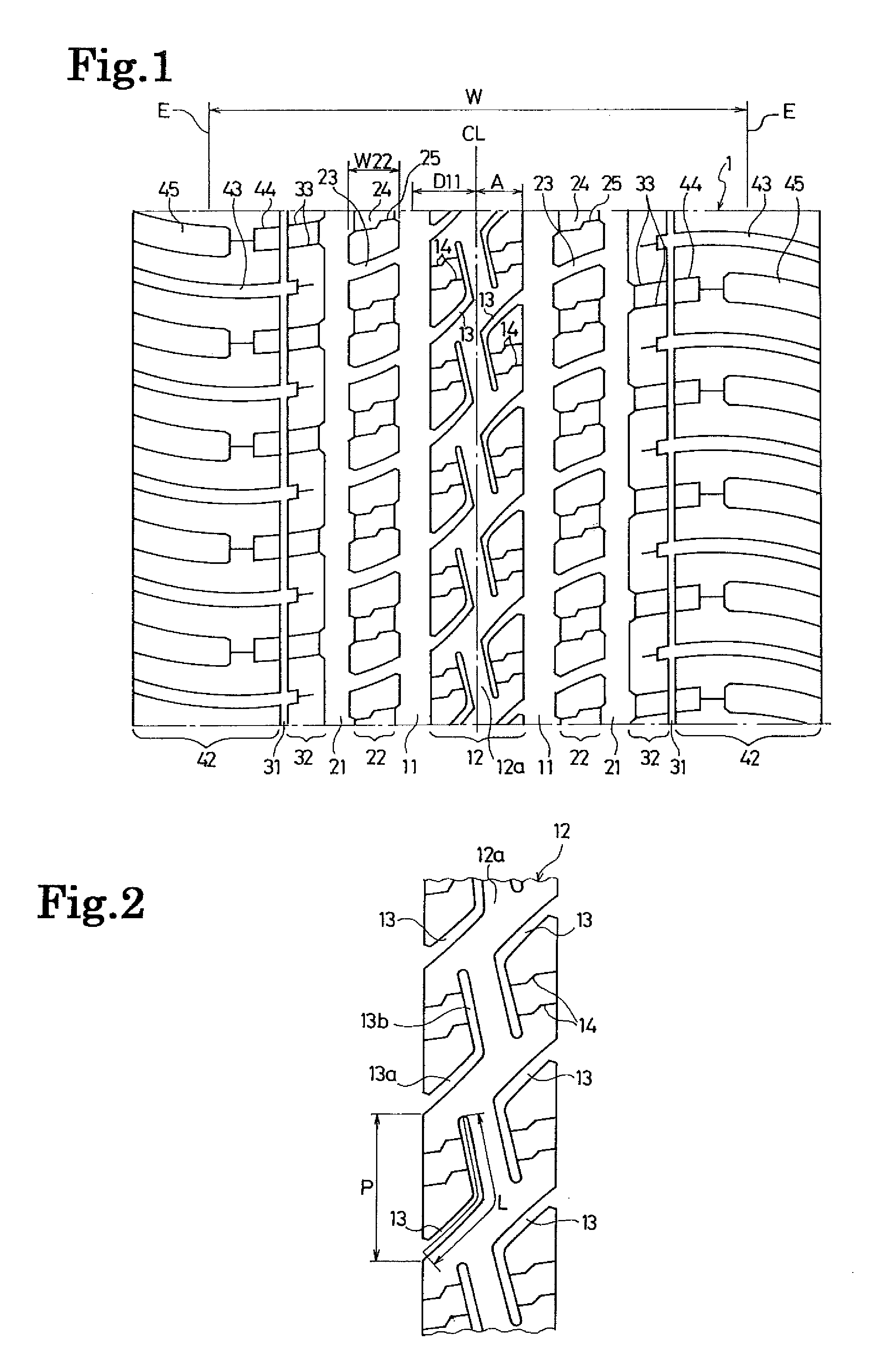

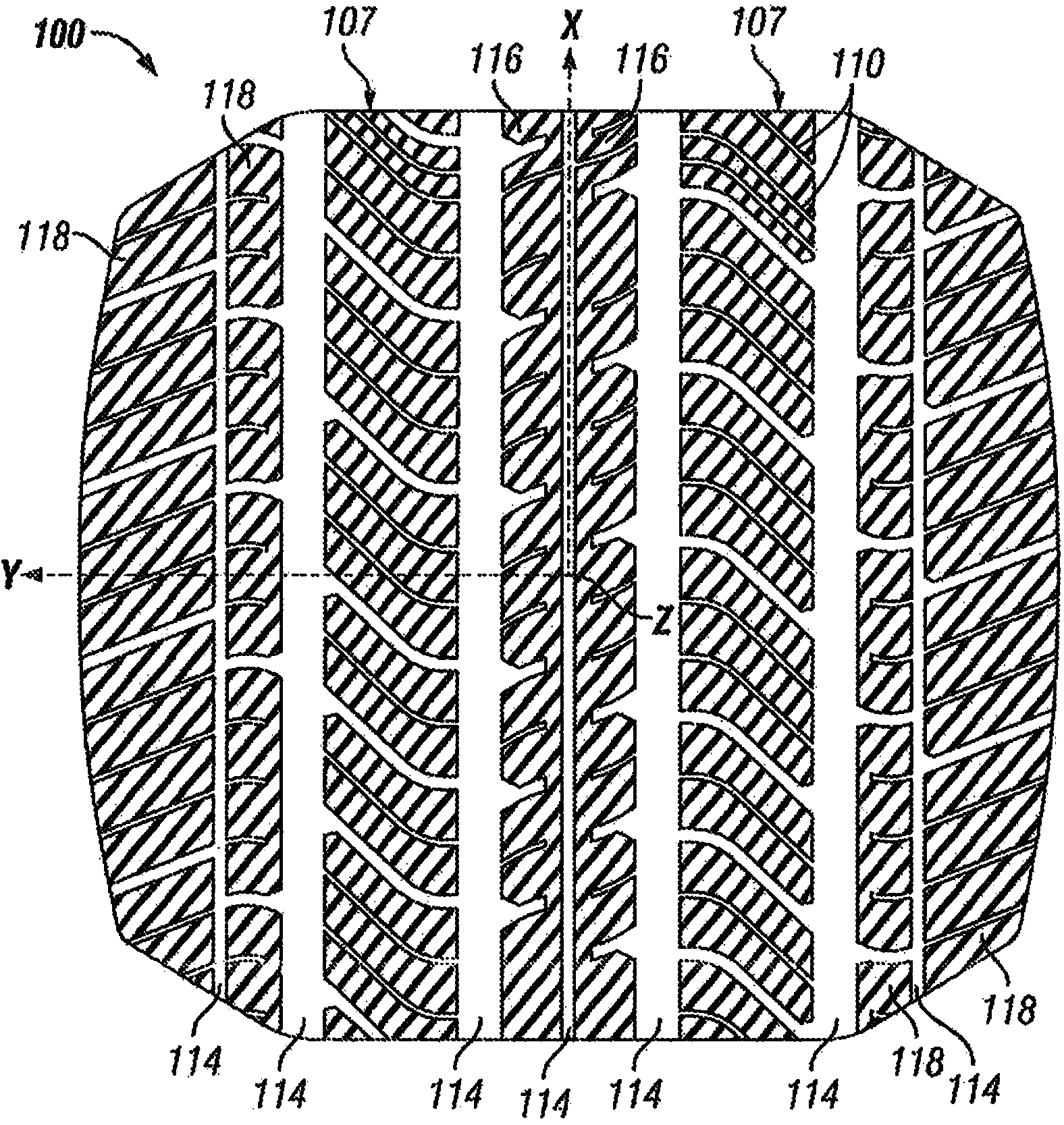

Tire with tread having improved snow and dry traction

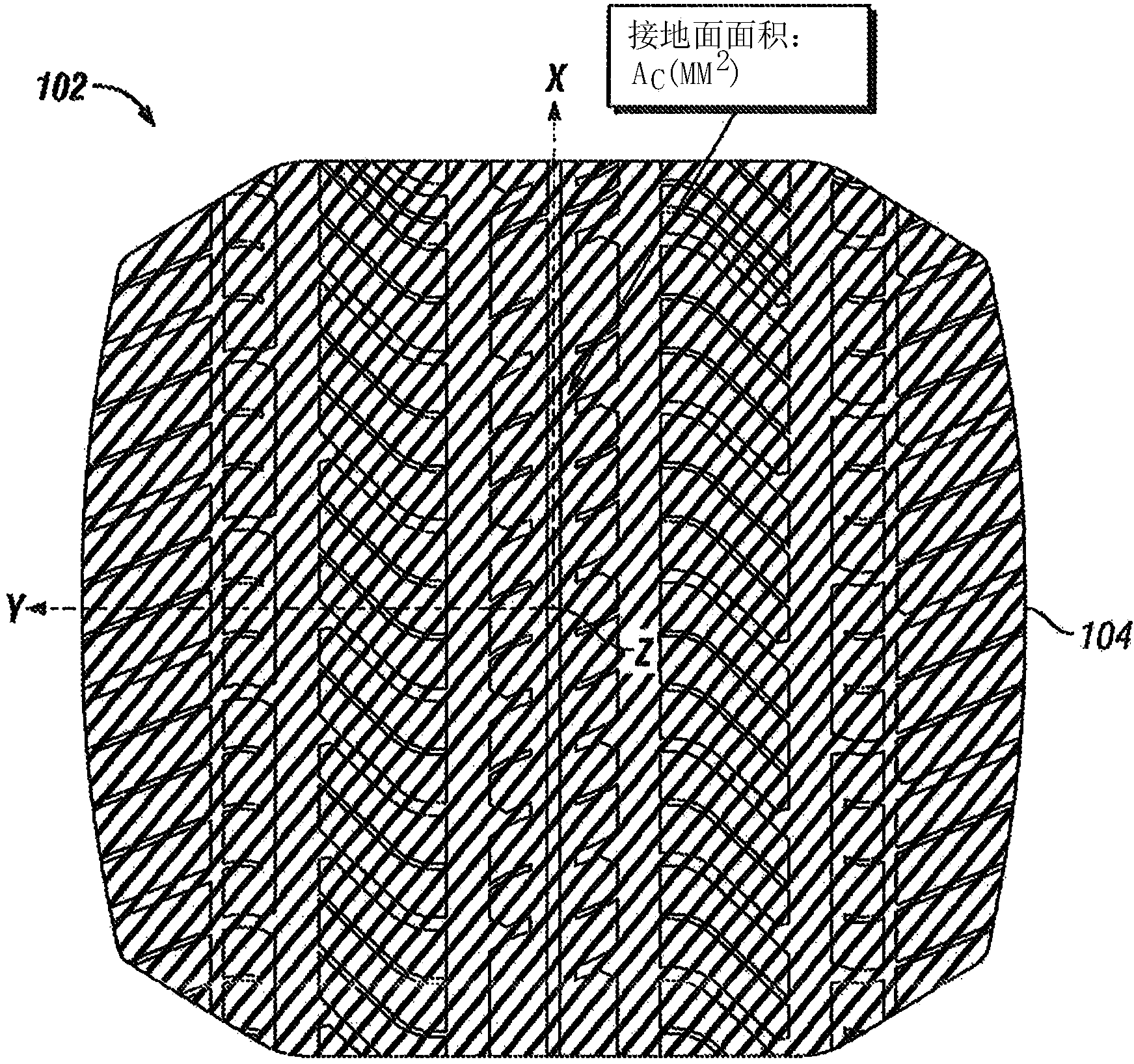

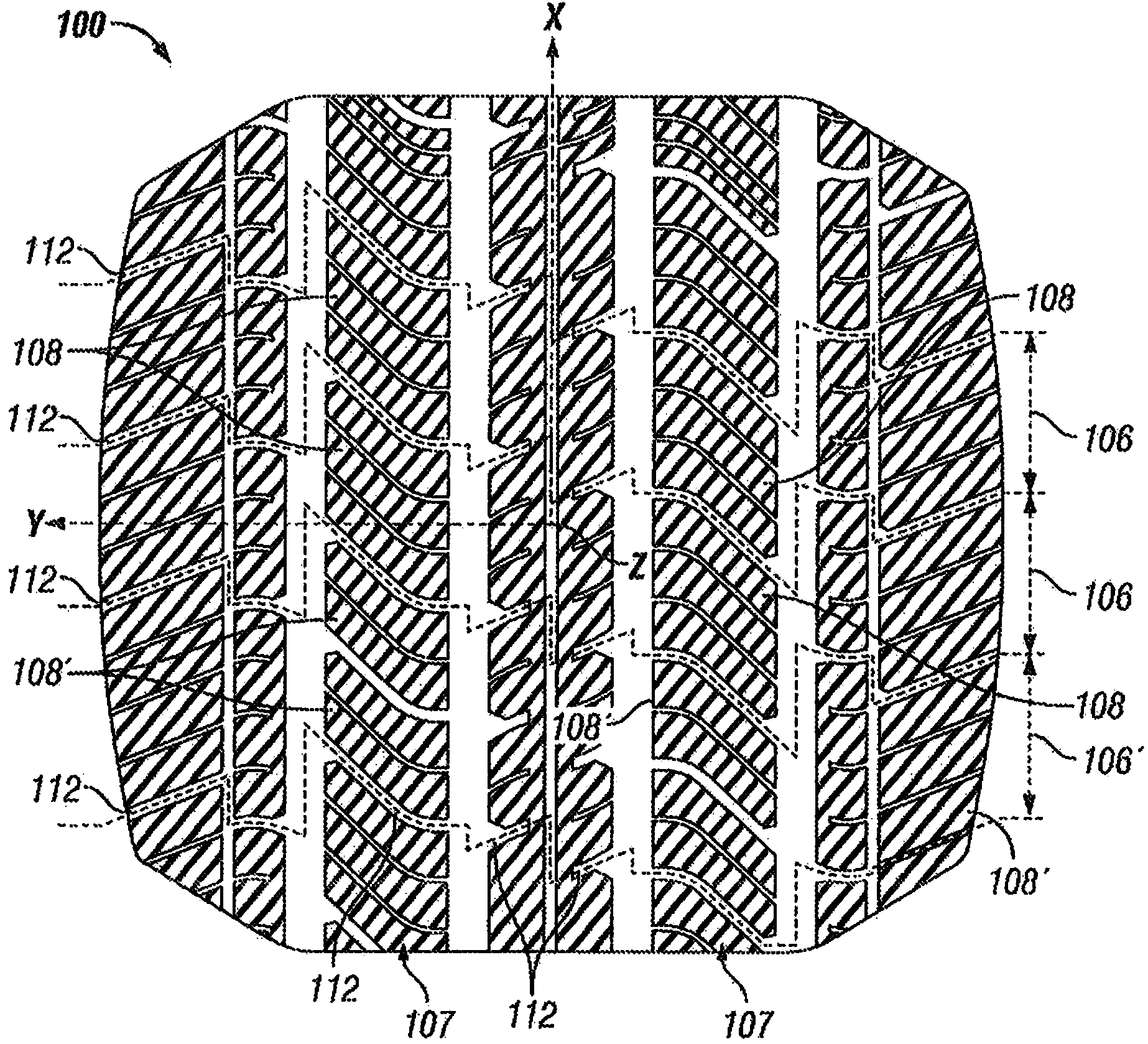

This invention relates generally to tires having treads that have a configuration and / or properties for providing suitable snow and dry traction, and, more specifically, to a tire that has a tread that has a maximum value for sipe density in the contact patch, a minimum value for lateral groove density in the contact patch, and a minimum value for the longitudinal contact surface ratio. In certain embodiments, the pitch length of pitches or repeating units of tread geometry along the circumferential direction of the tire is within a certain range and the tread depth is below a specified value. Tires with treads having a configuration that falls within these design parameters exhibit a desirably good level of snow and dry traction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

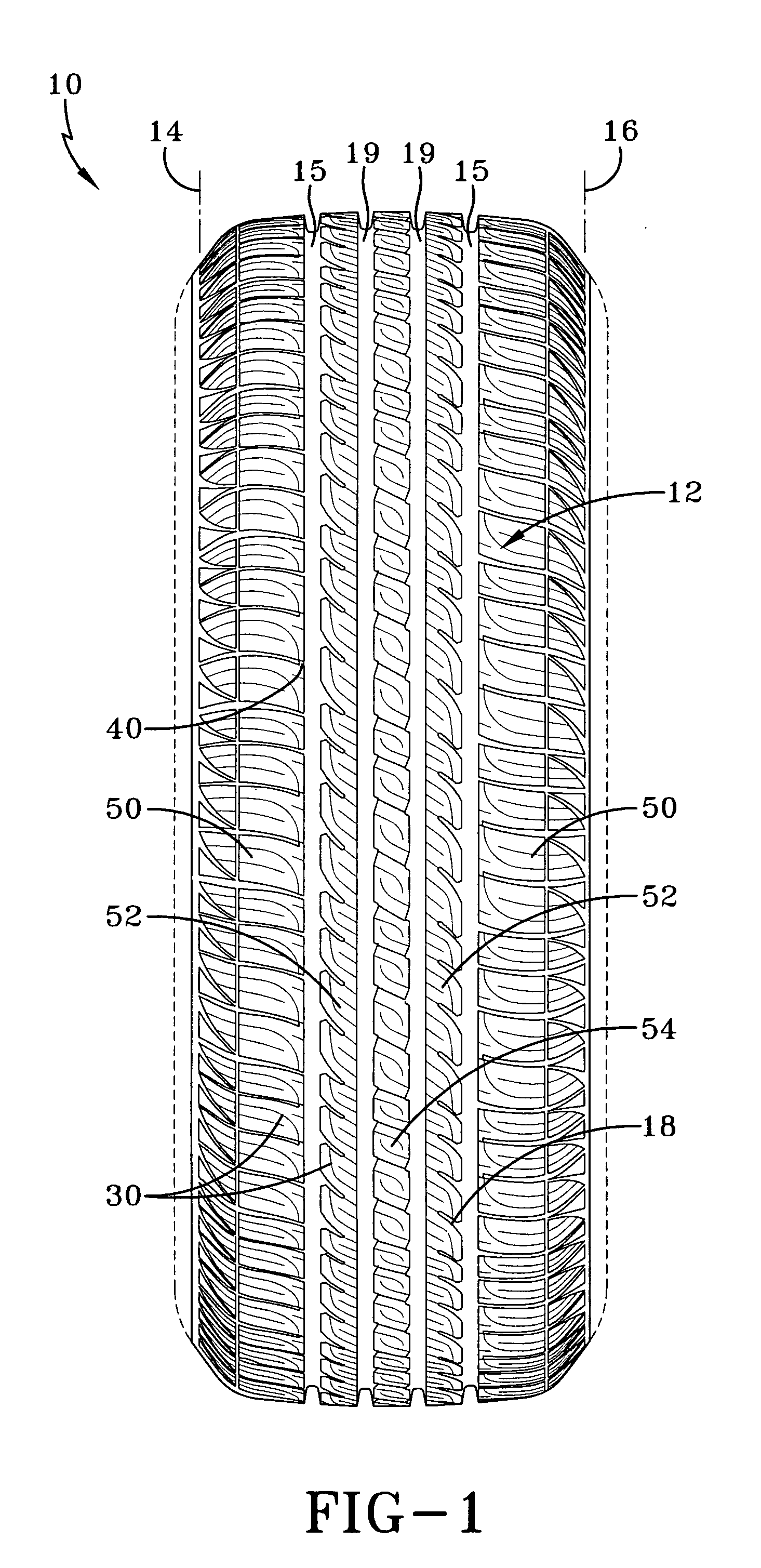

Tire tread with improved snow/dry traction

Tire treads, having one or more repeating pitches, each repeating pitch comprising individual pitches having tread blocks with sipes formed therein and each pitch having a pitch length of between 15 mm and 35 mm. Such treads may also have a weighted, average sipe density Dw of between 10 mm-1 and 37 mm-1, which is determined through the disclosed Eq. 2 below. The tread blocks are also formed from a rubber composition based upon a diene elastomer, a plasticizing system and a cross-linking system, wherein the rubber composition has a glass transition temperature of between -40 DEG C and -15 DEG C and a shear modulus G* measured at 60 DEG C of between 0.5 MPa and 1.1 MPa.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tire tread with improved snow/dry traction

Tire treads having one or more repeating pitches, each repeating pitch comprising individual pitches having tread blocks with sipes formed therein and each pitch having a pitch length of between 15 mm and 35 mm. Such treads may also have a weighted average sipe density Dw of between 10 mm−1 and 37 mm−1, which is determined through the disclosed Eq. 2 below. The tread blocks are also formed from a rubber composition based upon a diene elastomer, a plasticizing system and a cross-linking system, wherein the rubber composition has a glass transition temperature of between −40° C. and −15° C. and a shear modulus G* measured at 60° C. of between 0.5 MPa and 1.1 MPa.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Cooking extruder with enhanced steam injection properties

ActiveUS7987774B2A large amountFeeding-stuffMeat/fish preservation by heatingEngineeringPitch length

An improved extruder (10) is provided which permits successful introduction of very high quantities of injected steam into material being processed, on the order of 6-8% or more by weight steam. The extruder (10) includes an elongated extruder barrel (12) having at least one elongated, axially rotatable, helically flighted extrusion screw (16,18) therein. The barrel (12) is equipped with obliquely oriented steam injection ports (44, 46) along the length thereof, housing steam injectors (48, 50). The barrel (12) includes relatively high free volume steam injection heads (32 and 38, 40) having therein screw sections (78, 82) of relatively long pitch length, together with steam restriction heads (30, 34, and 42) on opposite sides of the injection heads (32, and 38, 40) having therein relatively short pitch length screw sections (76, 80, 84).

Owner:WENGER MFG LLC

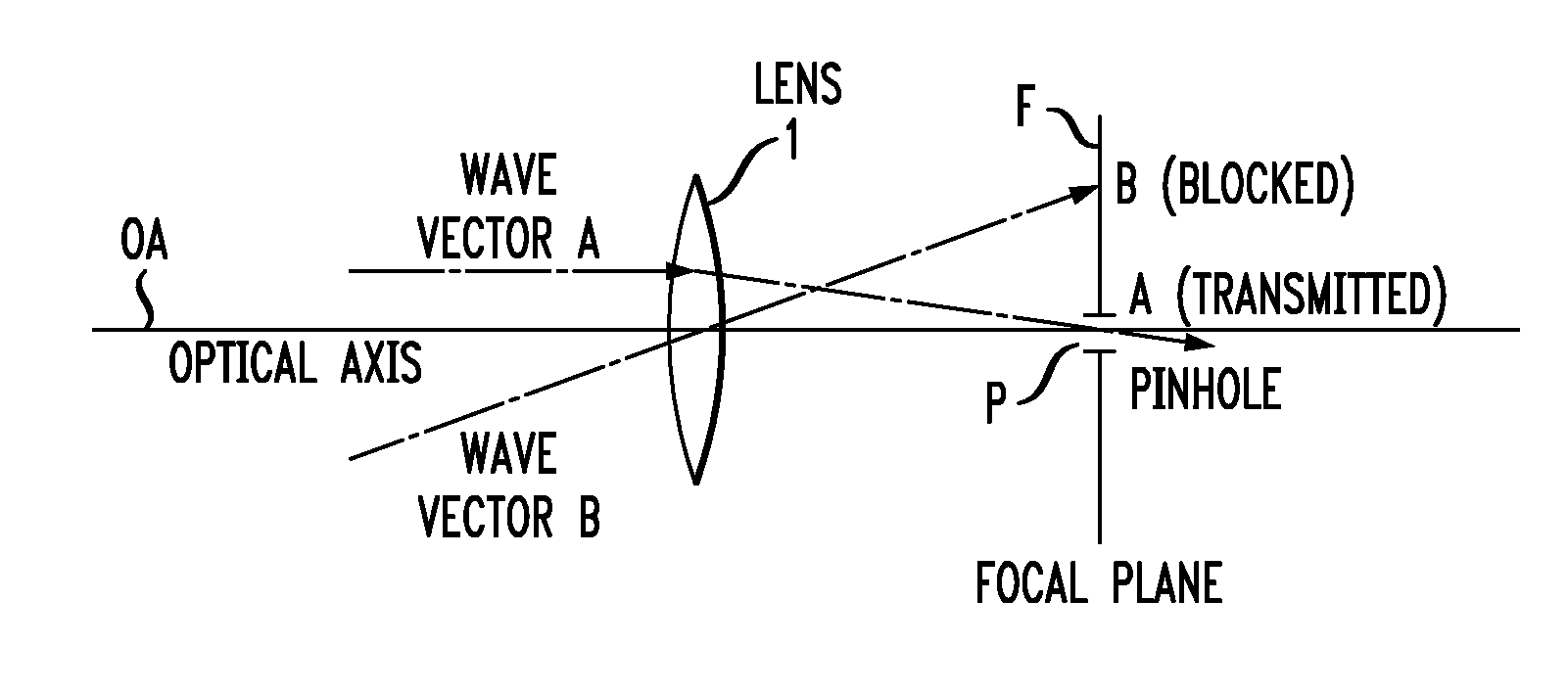

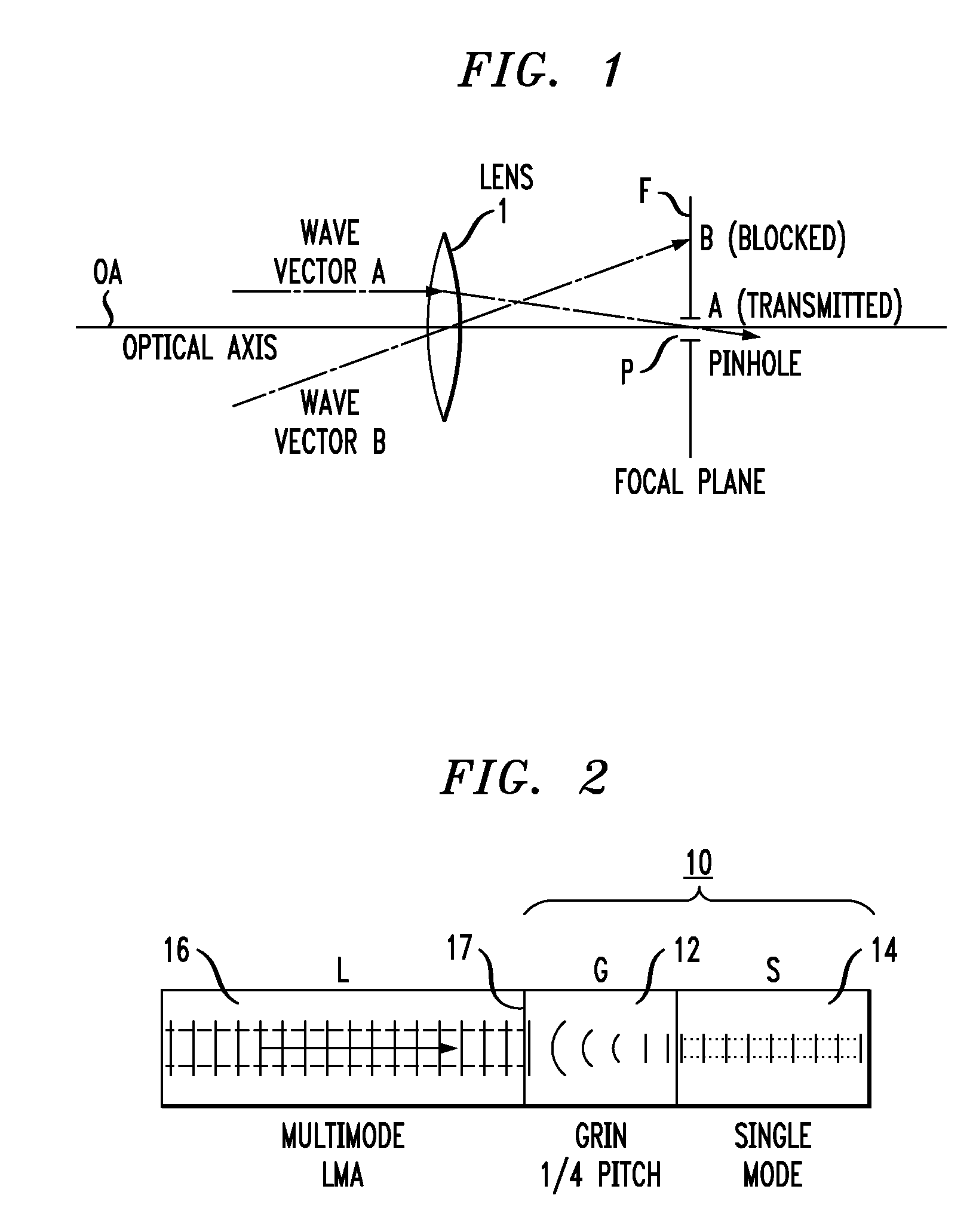

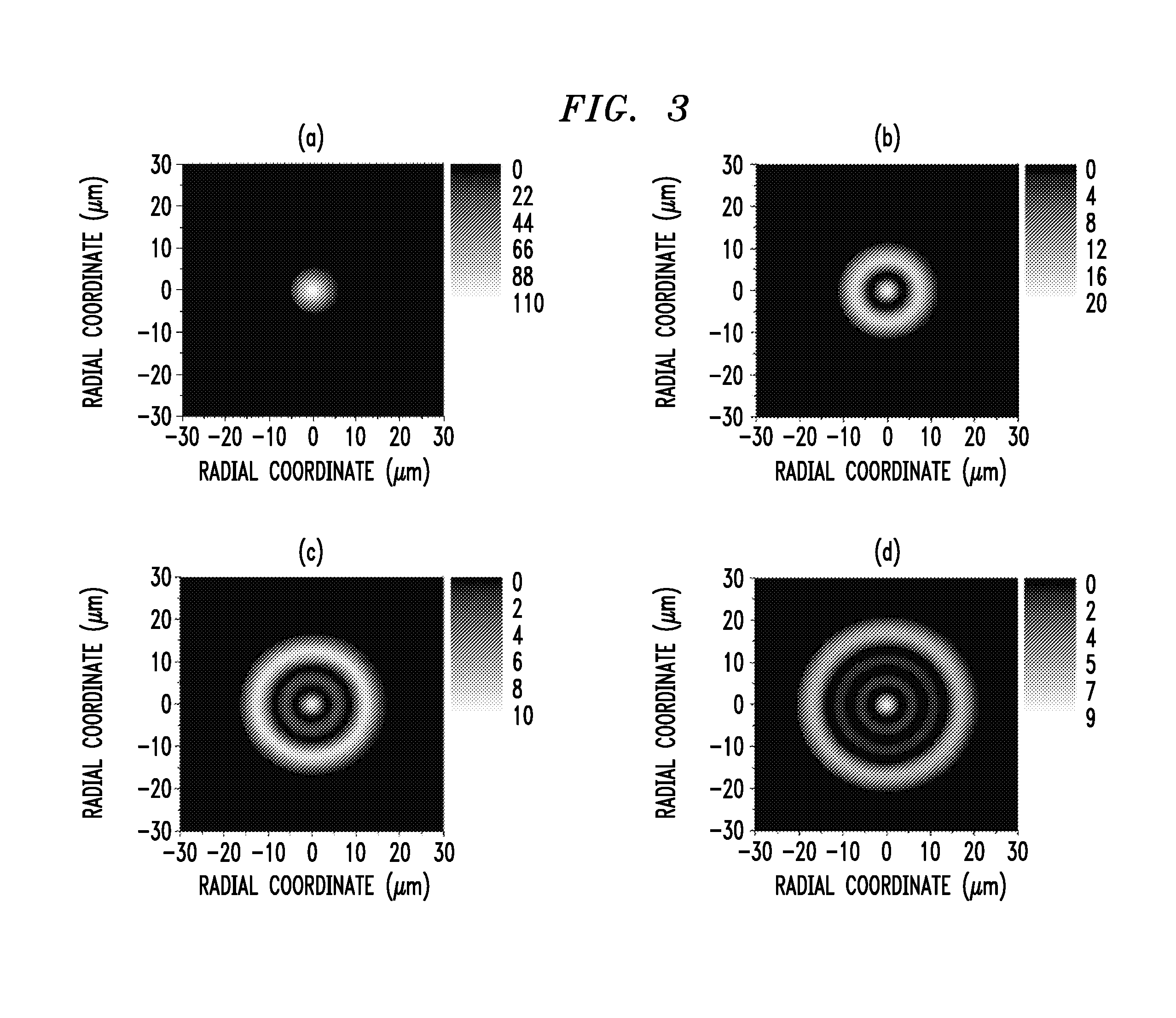

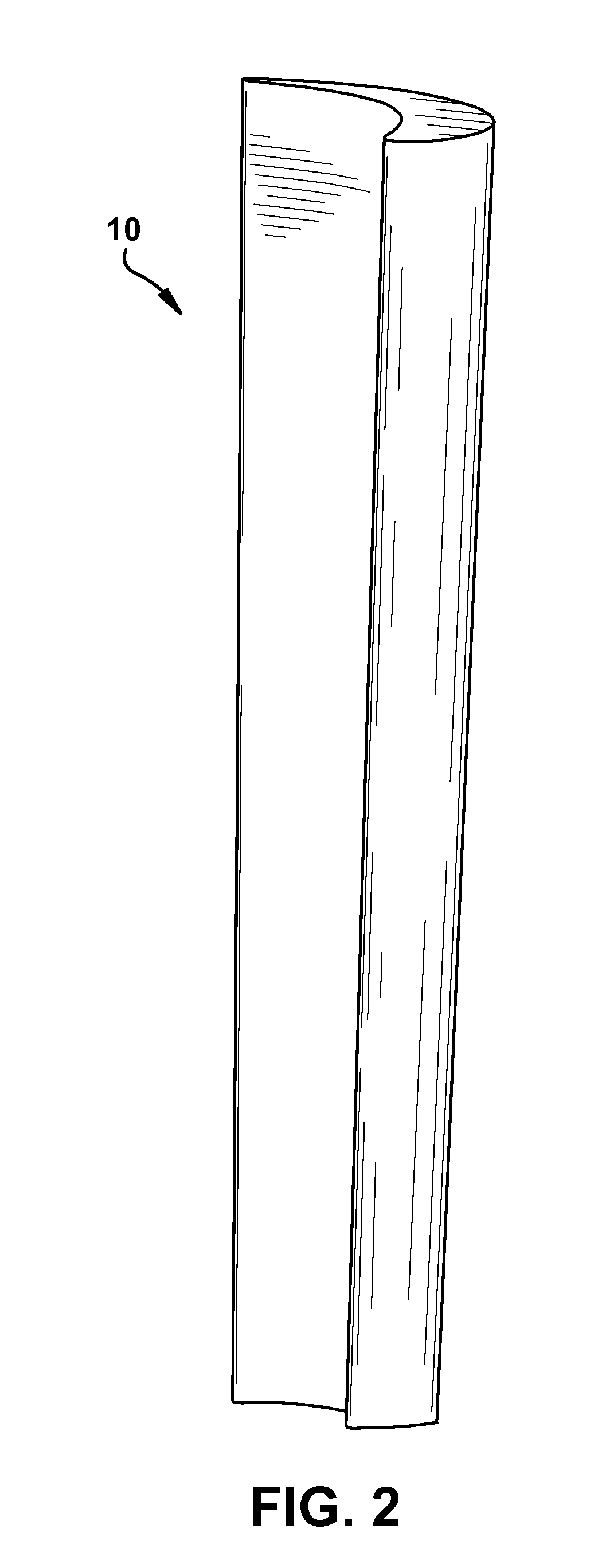

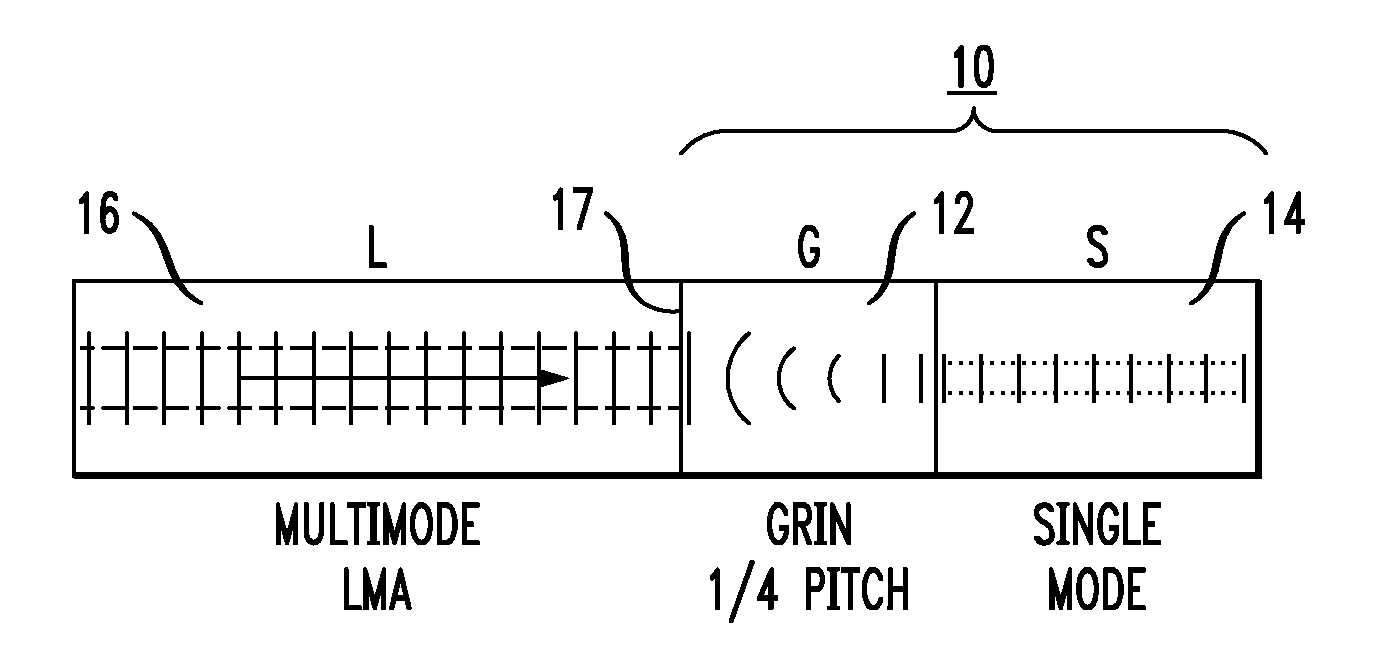

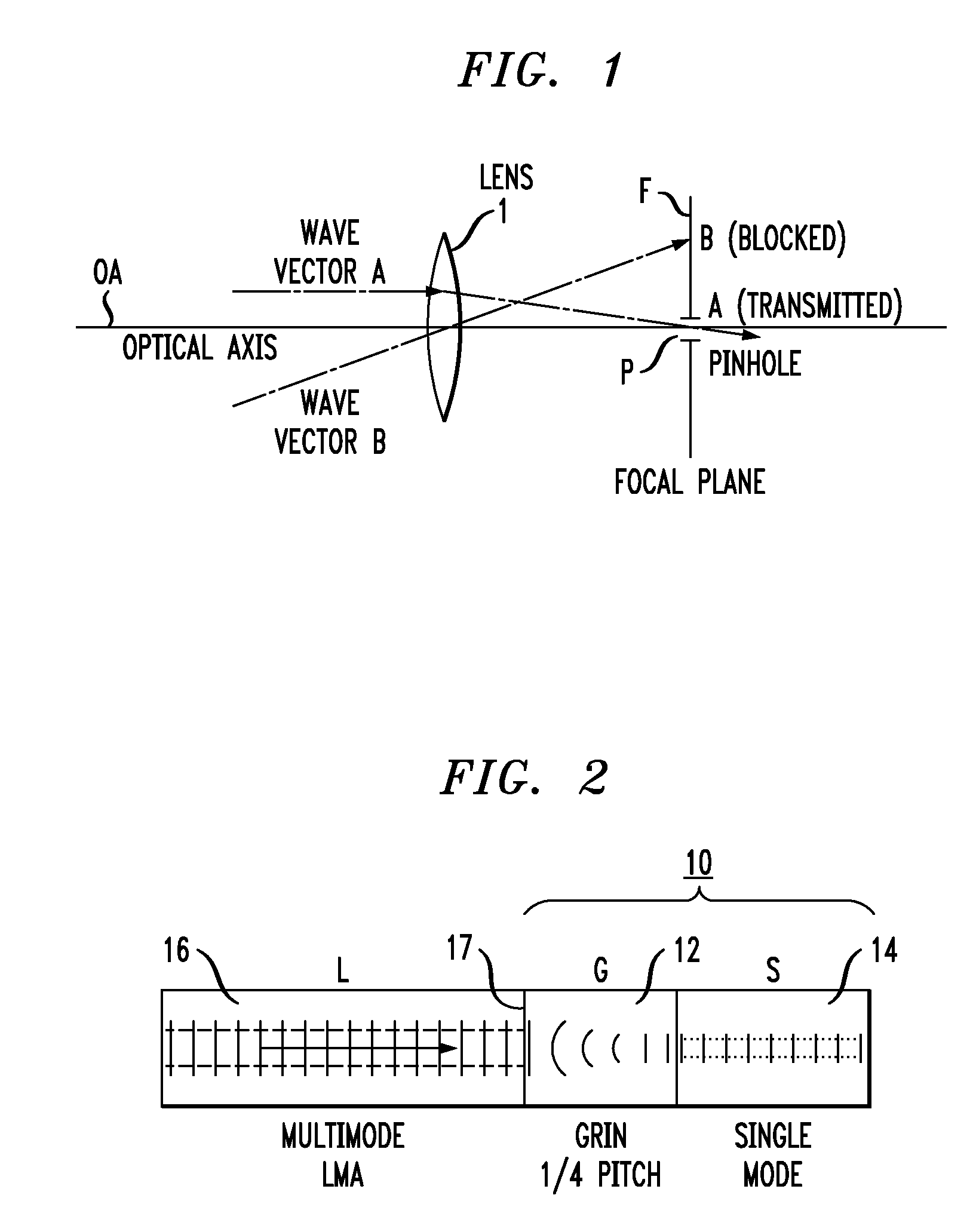

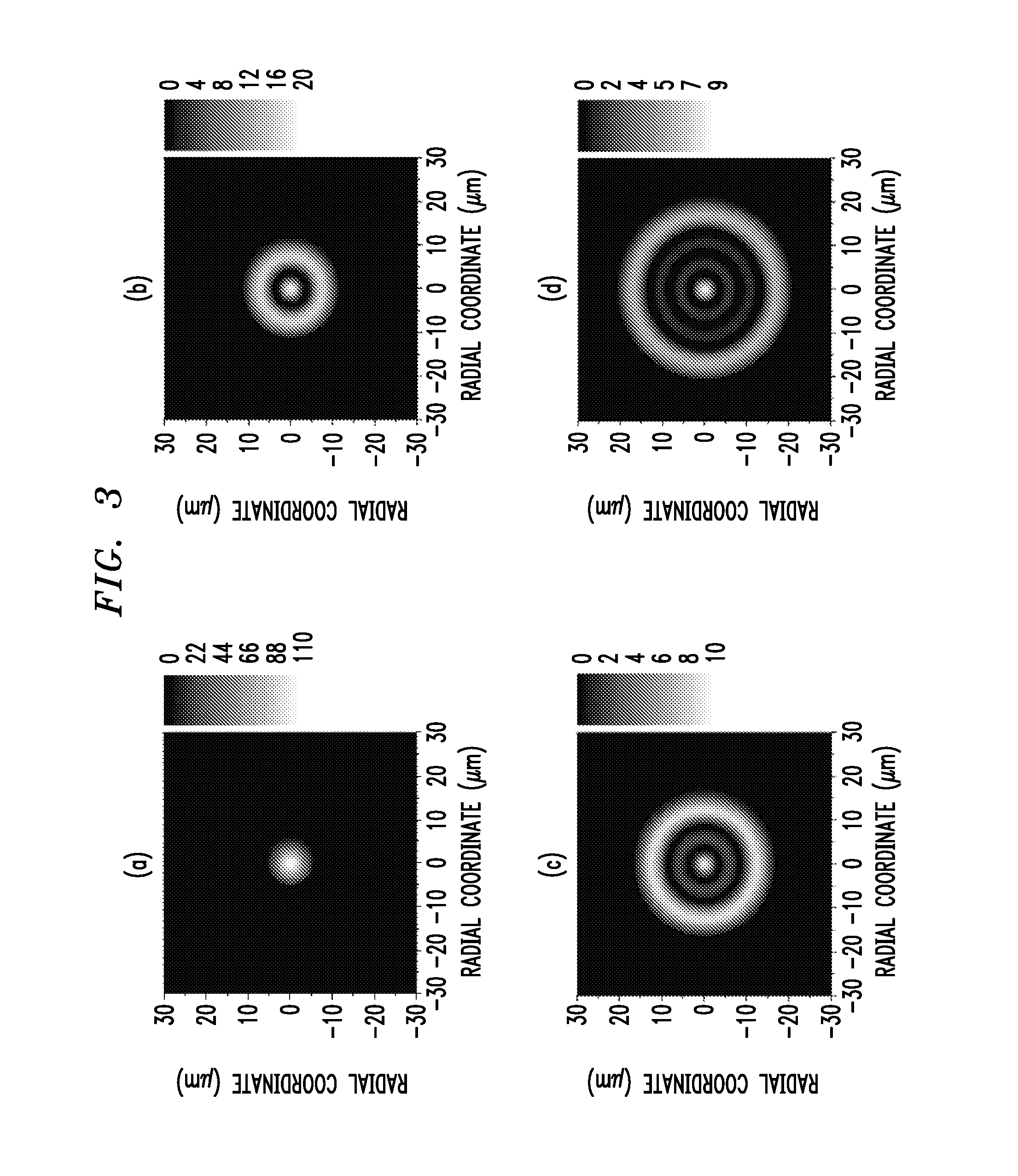

Spatial filtering of higher order modes in multimode fibers

ActiveUS20100271689A1Lower levelReduced insertion lossLaser detailsOptical fibre with graded refractive index core/claddingFiberBasic mode

A mode filter for eliminating the propagation of higher-order modes along a section of optical multimode fiber comprises a graded index (GRIN) lens, preferably of a quarter-pitch length, and a pinhole element in the form of a small core fiber. This configuration creates a Fourier spatial filter assembly that removes higher order modes propagating along an optical fiber while capturing the fundamental mode of the optical signal. A section of GRIN fiber is preferably used as the lens, with the small core fiber disposed at the output of the GRIN fiber lens to collect substantially only the on-axis fundamental mode of the optical signal. Since the higher order modes are shifted away from the origin by the GRIN fiber lens, only the fundamental mode signal is captured by the small core fiber.

Owner:OFS FITEL LLC

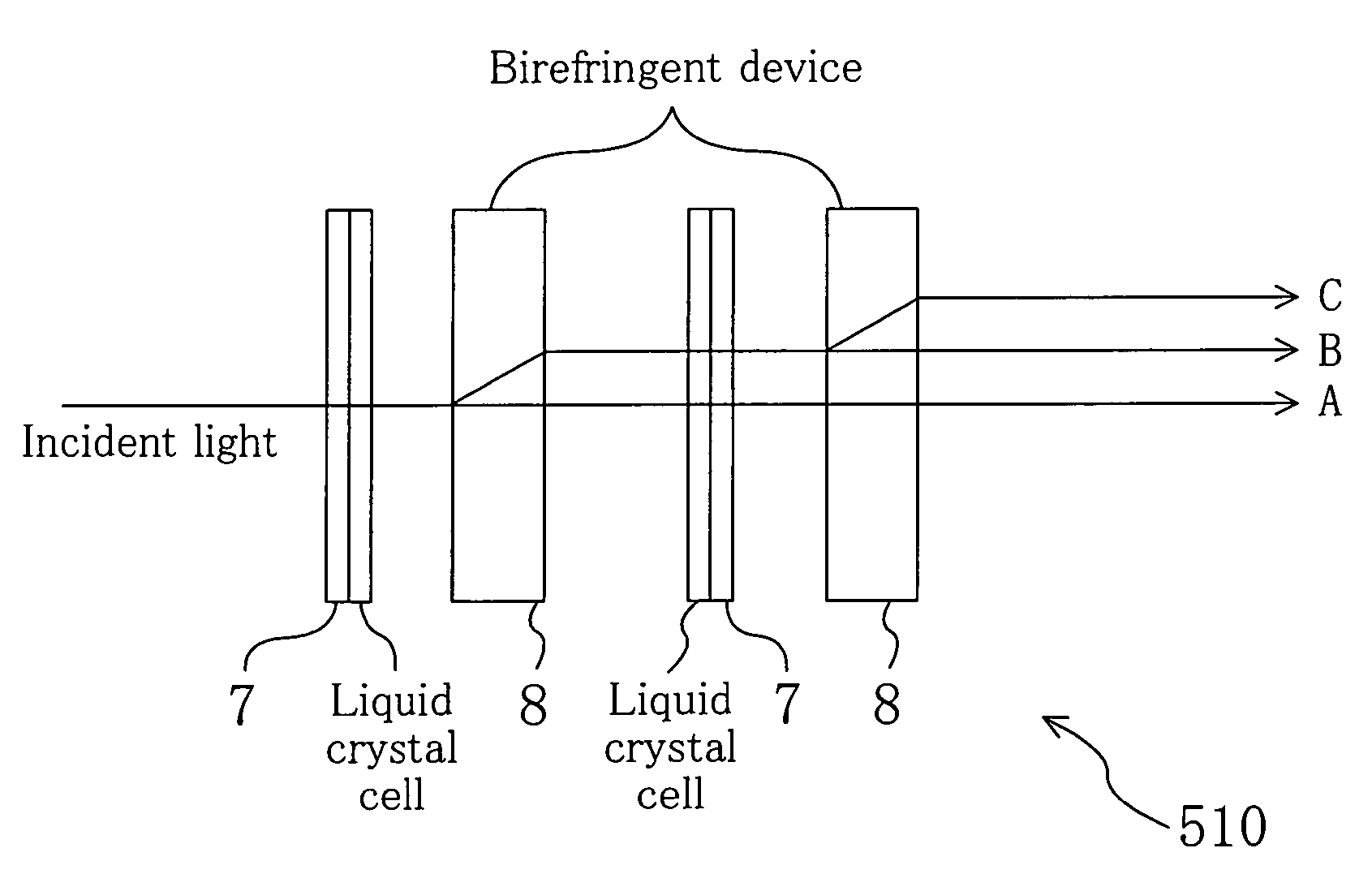

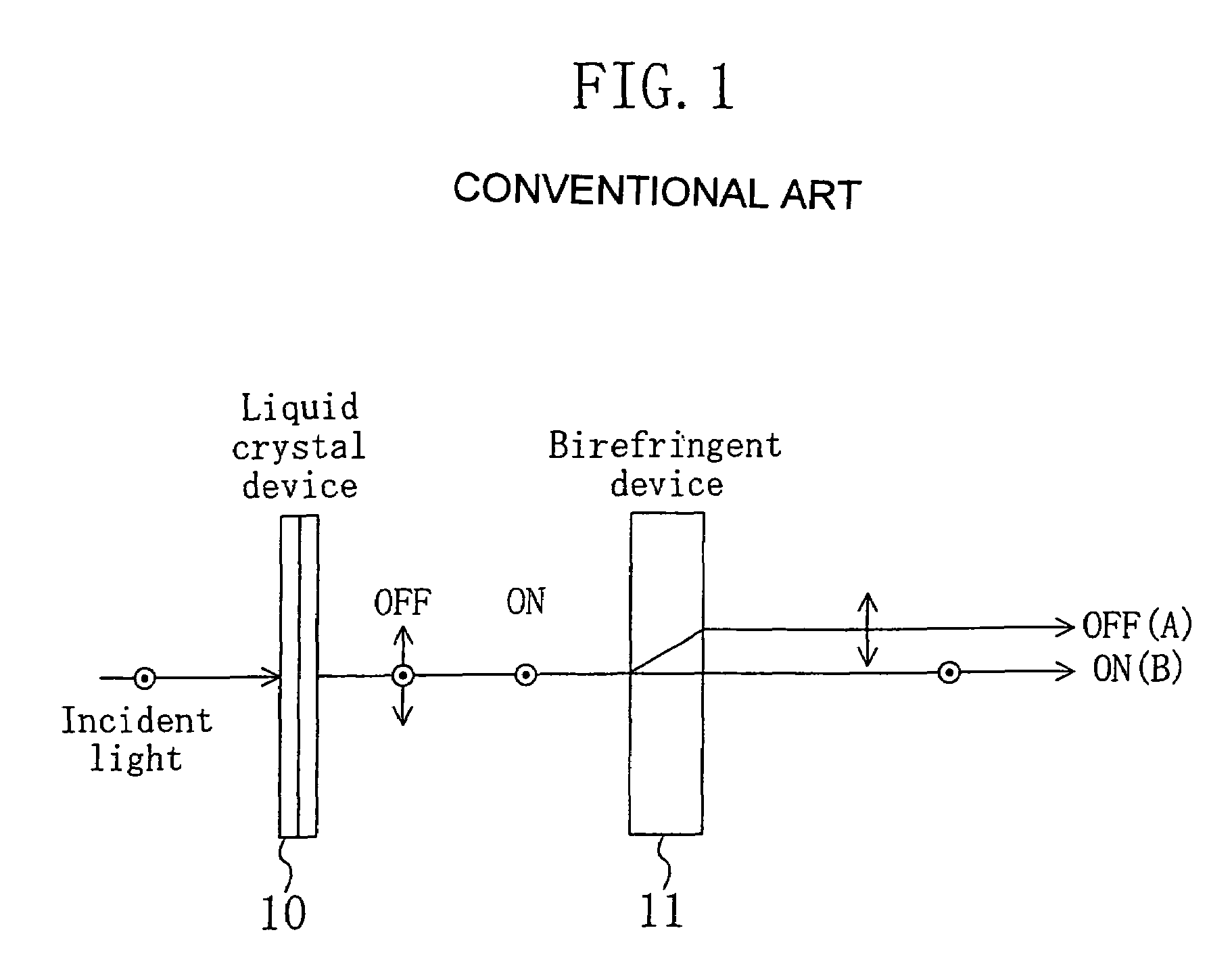

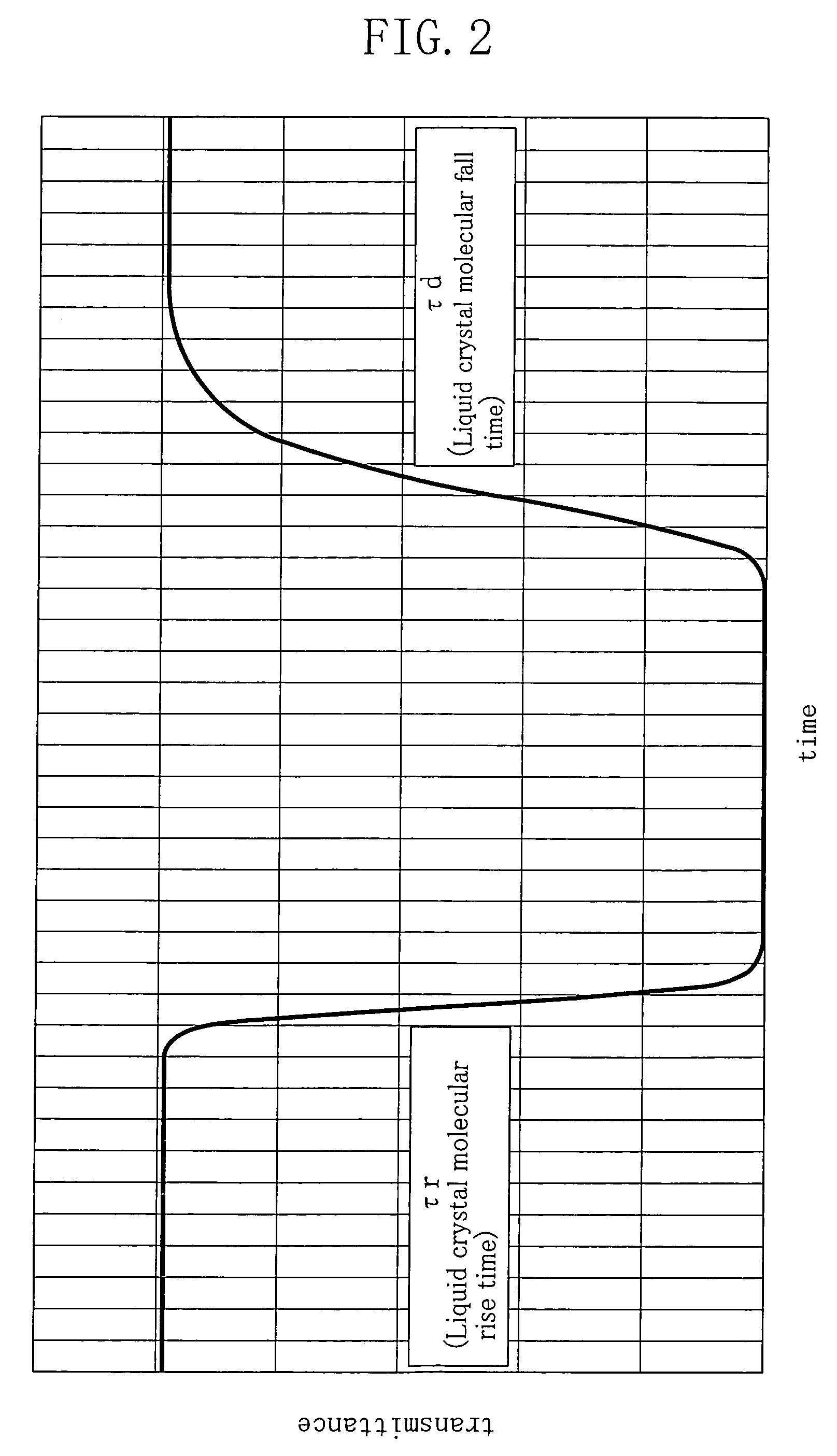

Image shifting device, image display, liquid crystal display, and projection image display

InactiveUS7277140B2Quick responseIncrease contrastTelevision system detailsPicture reproducers using projection devicesProjection imageOptical axis

The invention provides an image shifting device including at least one image shifting part for periodically shifting the position of an optical axis. The image shifting part includes a liquid crystal device 10 for switching a polarization direction of light between two orthogonal directions in accordance with High / Low level of an applied voltage, and a birefringent device 11 having different refractive indexes depending upon the polarization direction of the light. The liquid crystal device 10 and the birefringent device 11 are disposed to transmit light in this order. A liquid crystal layer included in the liquid crystal device 10 is made of a TN liquid crystal layer that satisfies a relationship formula of 0.25<d / p<1, wherein a natural pitch length is indicated by p and a cell gap is indicated by d, and is disposed to be twisted at 90° within the liquid crystal cell.

Owner:SHARP KK

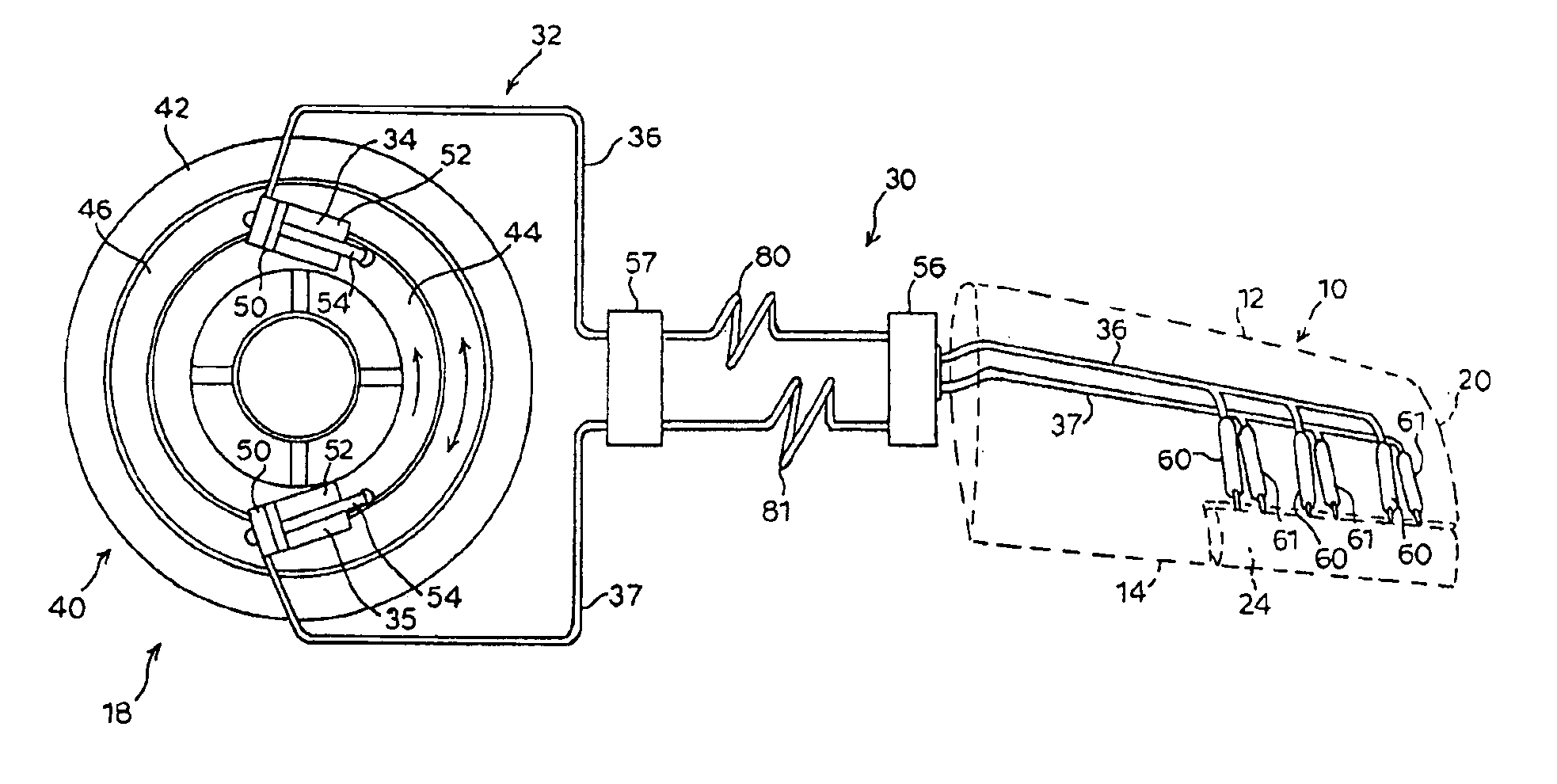

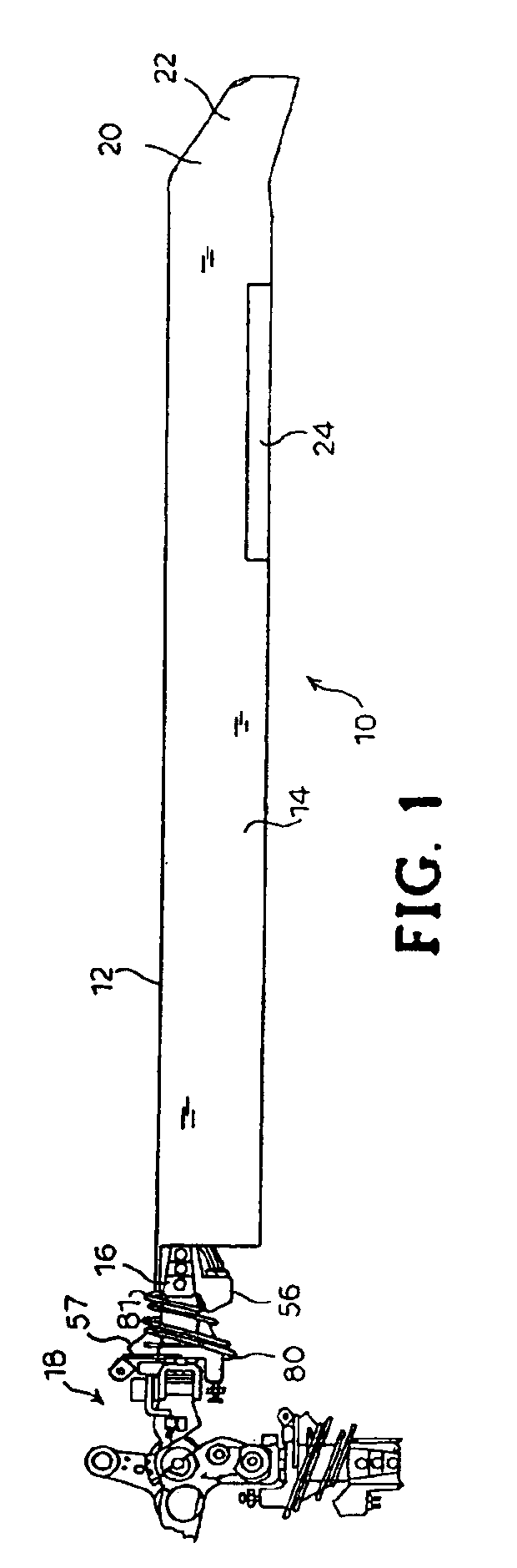

Fluid conduit for use with hydraulic actuator

InactiveUS6863239B2Hydraulically positionWing lift eficiencyAircraft power transmissionEngineeringActuator

A fluid conduit is provided for use in a hydraulic actuating system for controlling an instrumentality disposed on a rotating portion of a machine. The fluid conduit transports pressurized fluid between a fluid source disposed on a non-rotating portion of the machine and the instrumentality and comprises a rigid tubular member formed in the shape of a helix having at least about 2 revolutions and a non-constant pitch length. The ends of the tube are adapted to be sealingly connected between the fluid source and the instrumentality. The fluid conduit is used, for example, in an apparatus and system for controlling a hydraulic actuator mounted on a rotating blade.

Owner:GENERAL DYNAMICS ADVANCED INFORMATION SYSTEMS

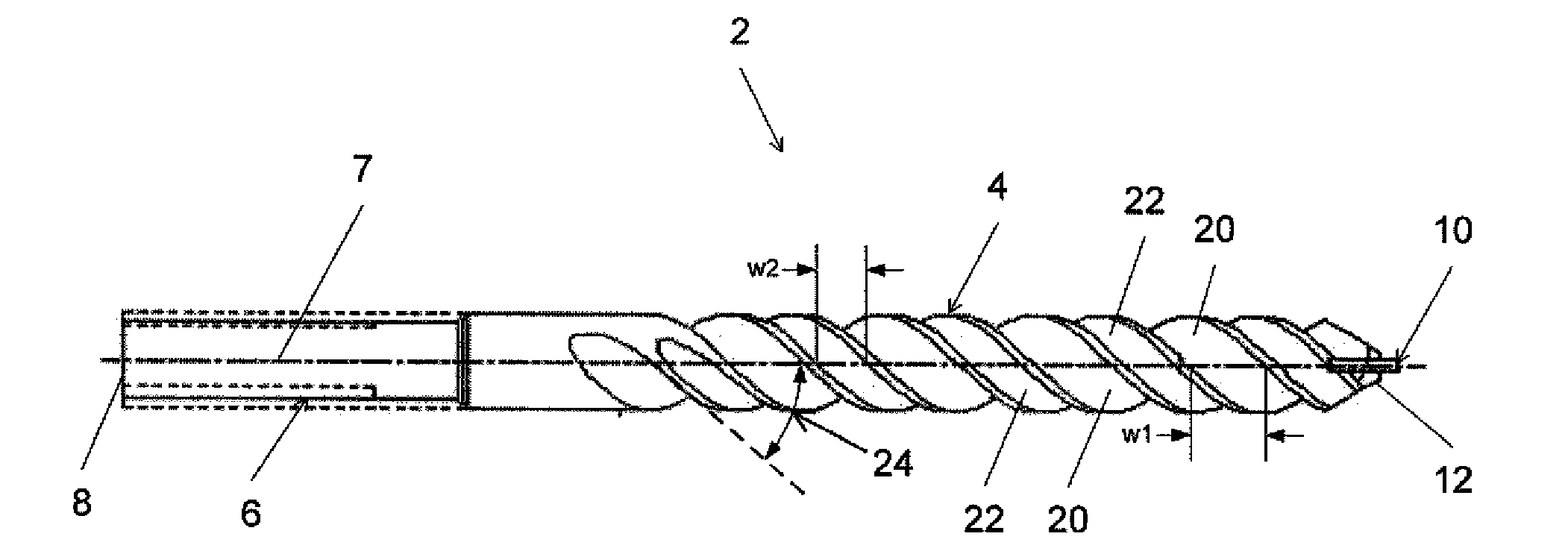

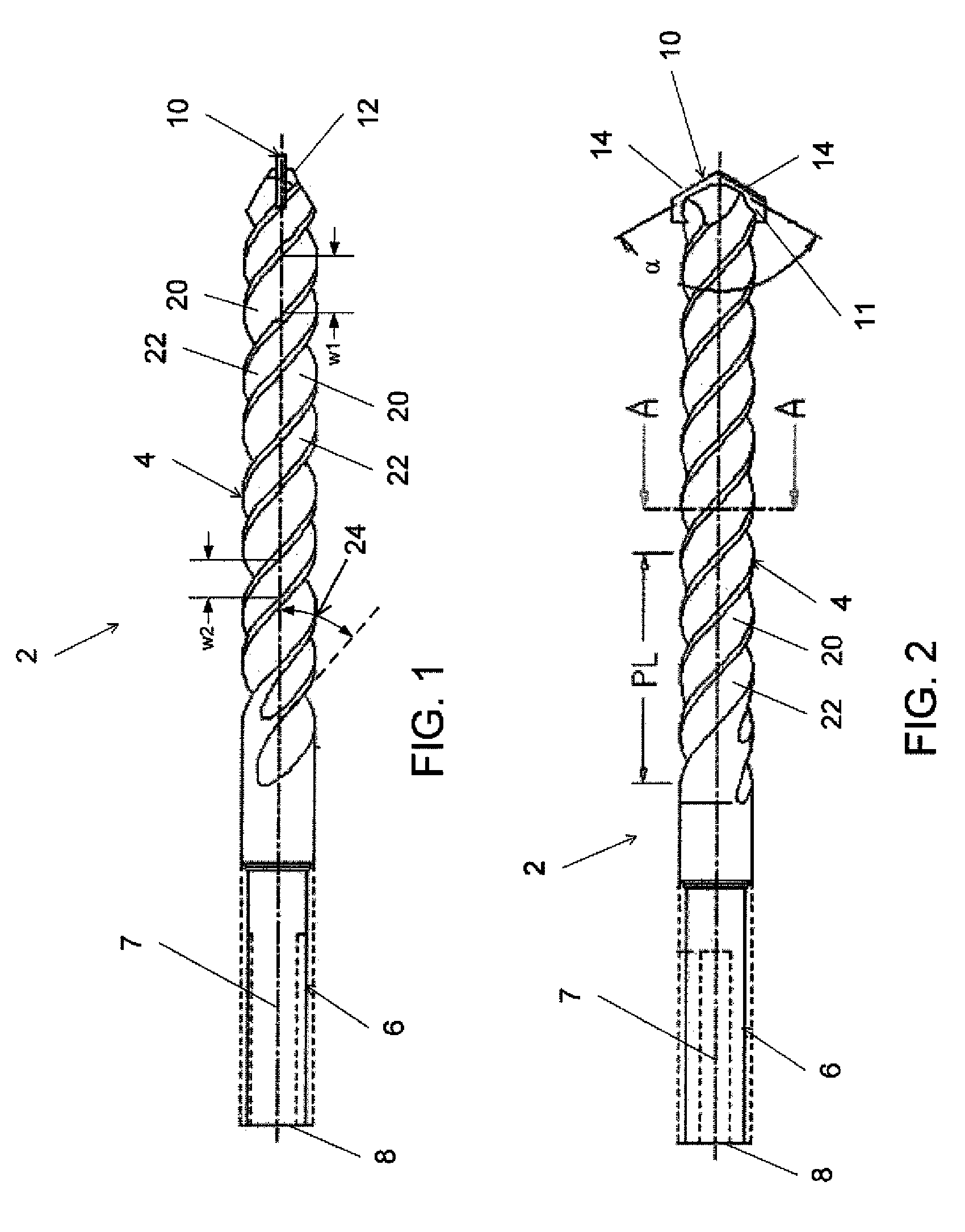

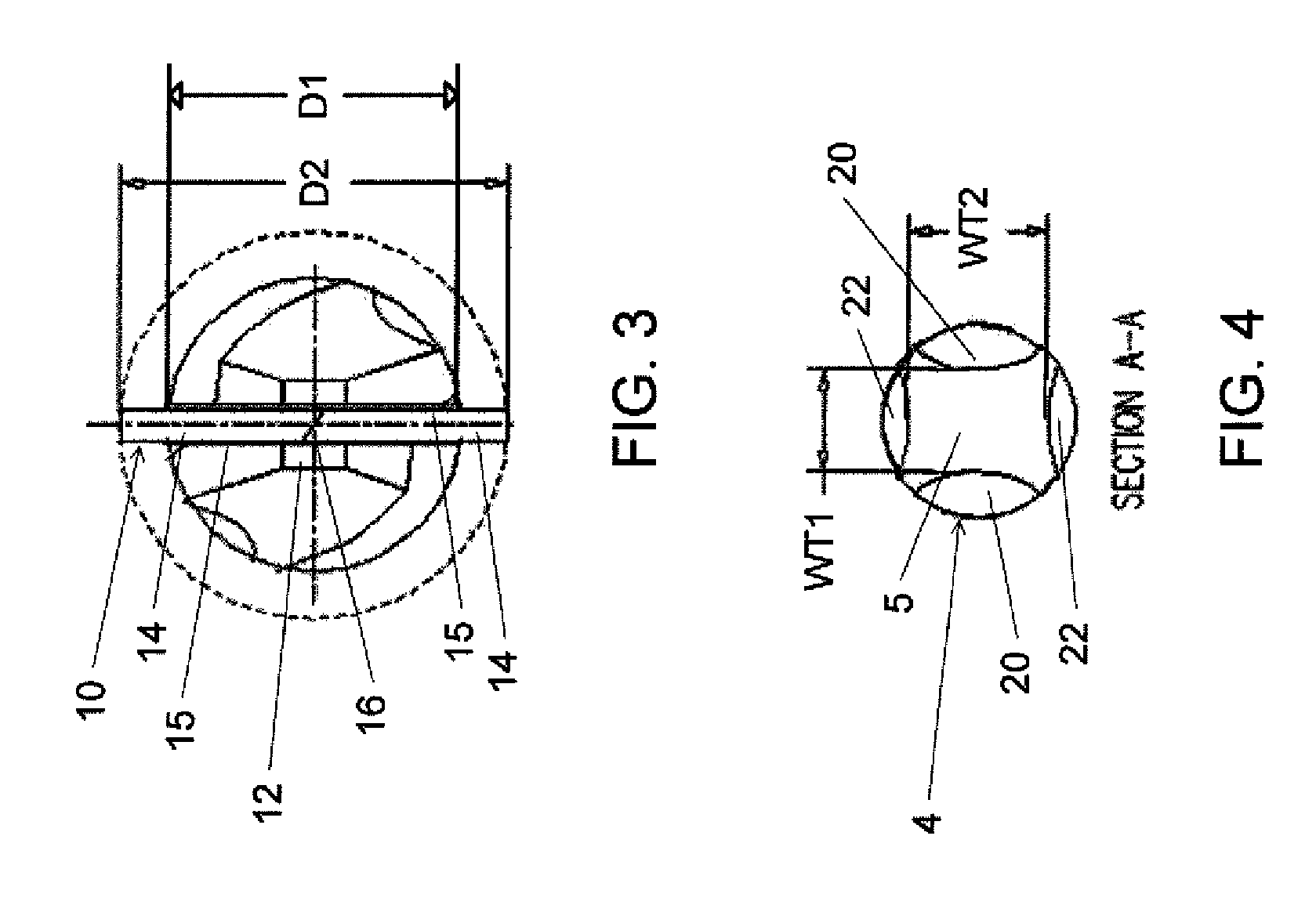

Drill Bit

A drill bit comprising a body including at least four flutes being formed on and extending along a longitudinal axis of the body and a web portion disposed between the at least four flutes. The flutes define a pitch length that is substantially the same as one another and the web portion has at least one web thickness. The ratio of the web thickness to the pitch length is within a range of about 14 to 25 percent.

Owner:EASTWAY FAIR

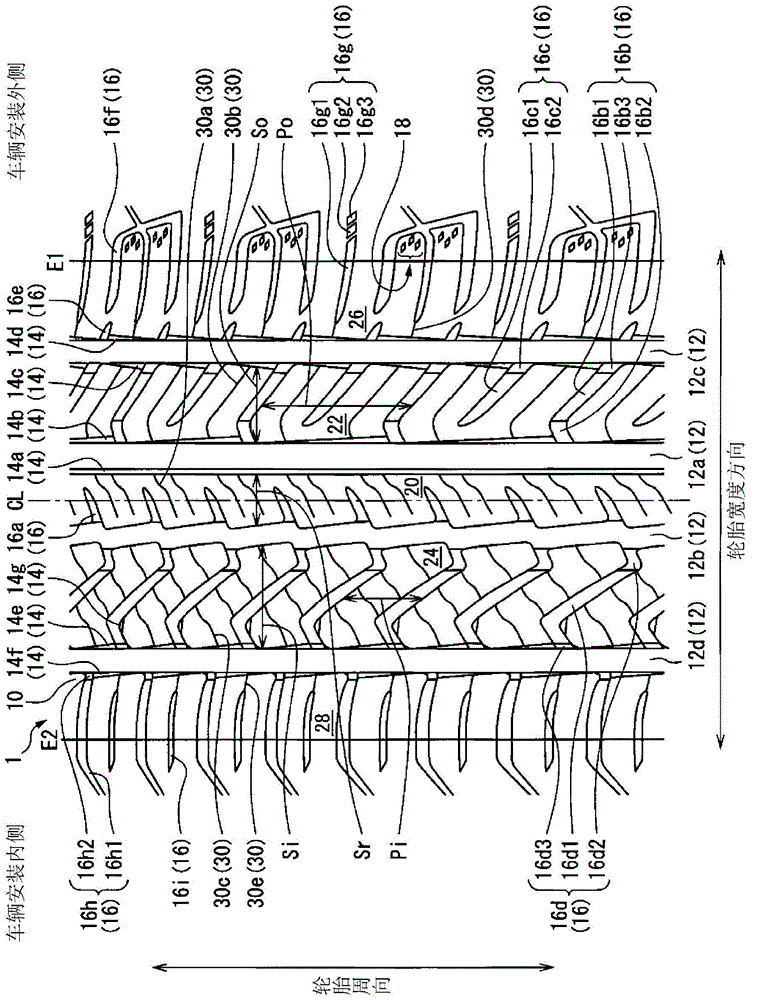

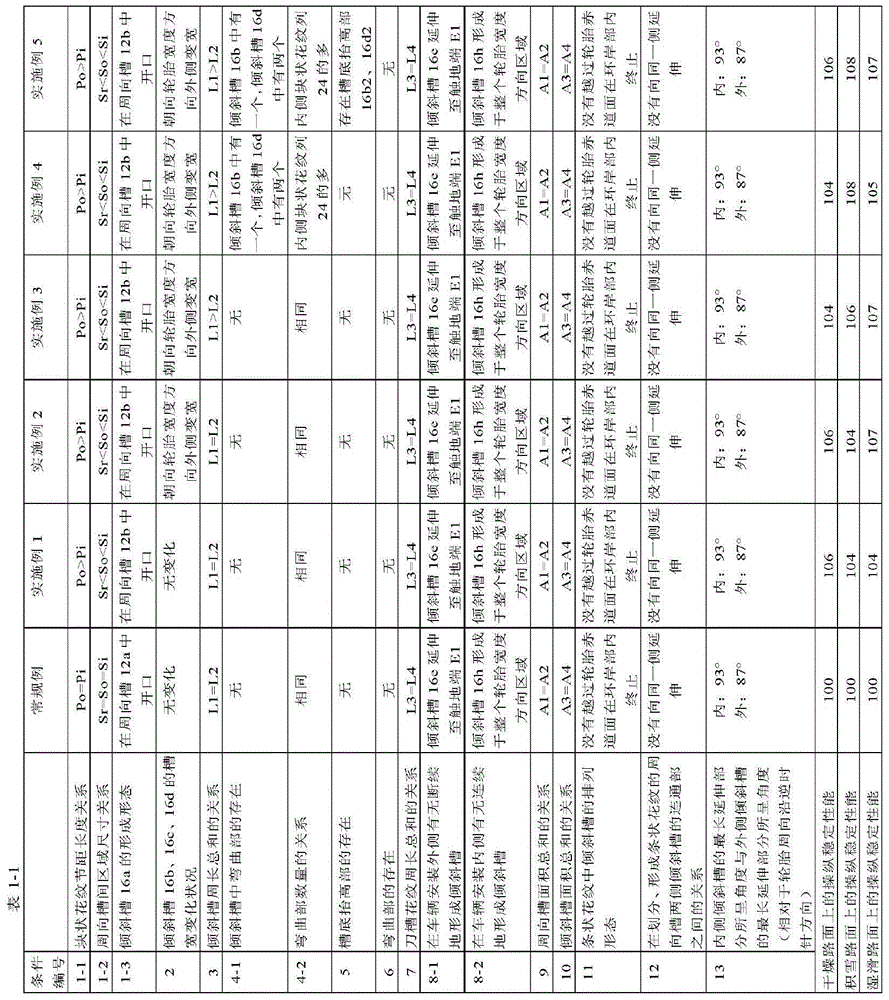

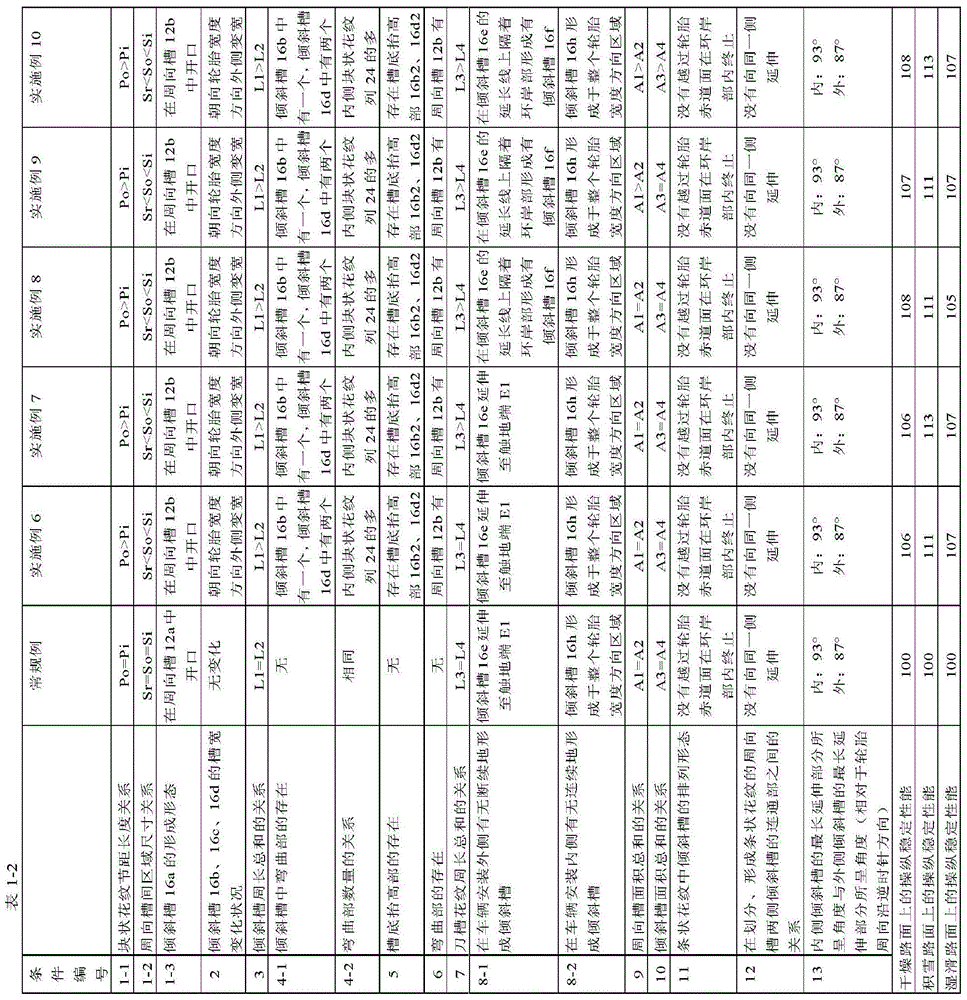

Pneumatic tire

ActiveCN104822545AImprove handling stabilityInflatable tyresTyre tread bands/patternsEngineeringRoad surface

The purpose of the present invention is to provide a pneumatic tire that exhibits excellent operating stability whether the road surface is a dry road surface, a snow covered road surface or a wet road surface. A block pitch length (Po) of an outside block column (22) is greater than a block pitch length (Pi) of an inside block column (24). The tire width direction size in a region sandwiched between two circumferential grooves becomes smaller in the order of ribs (20), the outside block column (22), and the inside block column (24). Inclined grooves (16a) partitioning and forming the ribs (20) are opened only on a circumferential groove (12b) on a vehicle mount inside region partitioning and forming the ribs (20).

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

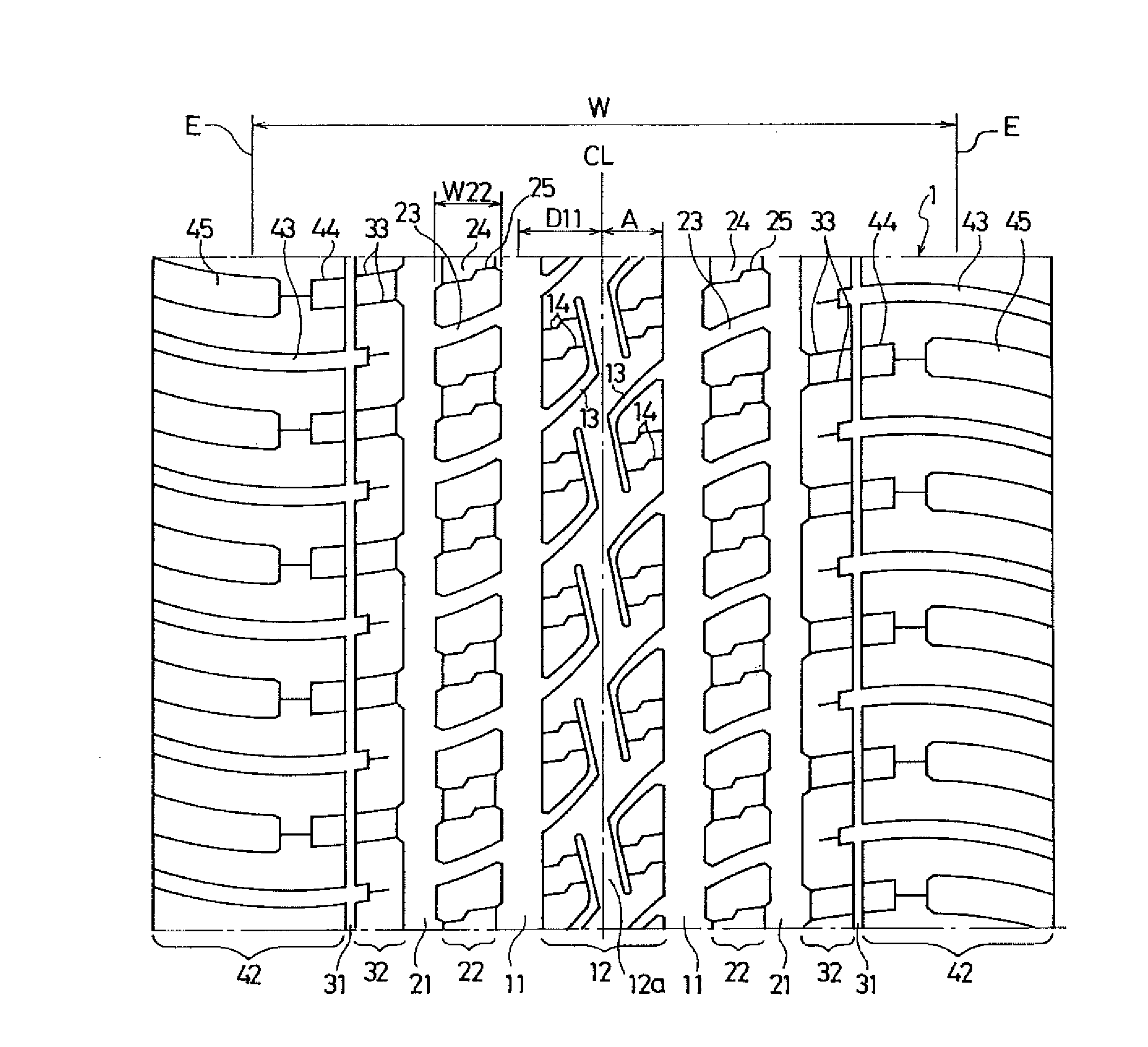

InactiveUS20110005653A1Improve rigidityImprove driving stabilityTyre tread bands/patternsNon-skid devicesGround contactCurve shape

A pneumatic tire is configured such that: paired first main grooves extending in a tire circumferential direction are provided on the two sides of a tire equator line in a tread portion, respectively; a distance between a center position of each first main groove and the tire equator line is set at 8% to 20% of a ground contact width W; a first land portion is defined between these first main grooves; multiple sub-grooves each having a curved shape are formed in each of both edge portions of the first land portion at intervals in the tire circumferential direction; one end of each sub-groove is opened to the corresponding first main groove, and the other end of the sub-groove is terminated inside the first land portion; a rib portion continuously extending in the tire circumferential direction is formed in an area of the first land portion on the tire equator line; and a relation between a length (L) of a center line of each sub-groove and a pitch length (P) of the sub-grooves in the tire circumferential direction satisfies 1.1×P≰L≰2.0×P.

Owner:THE YOKOHAMA RUBBER CO LTD

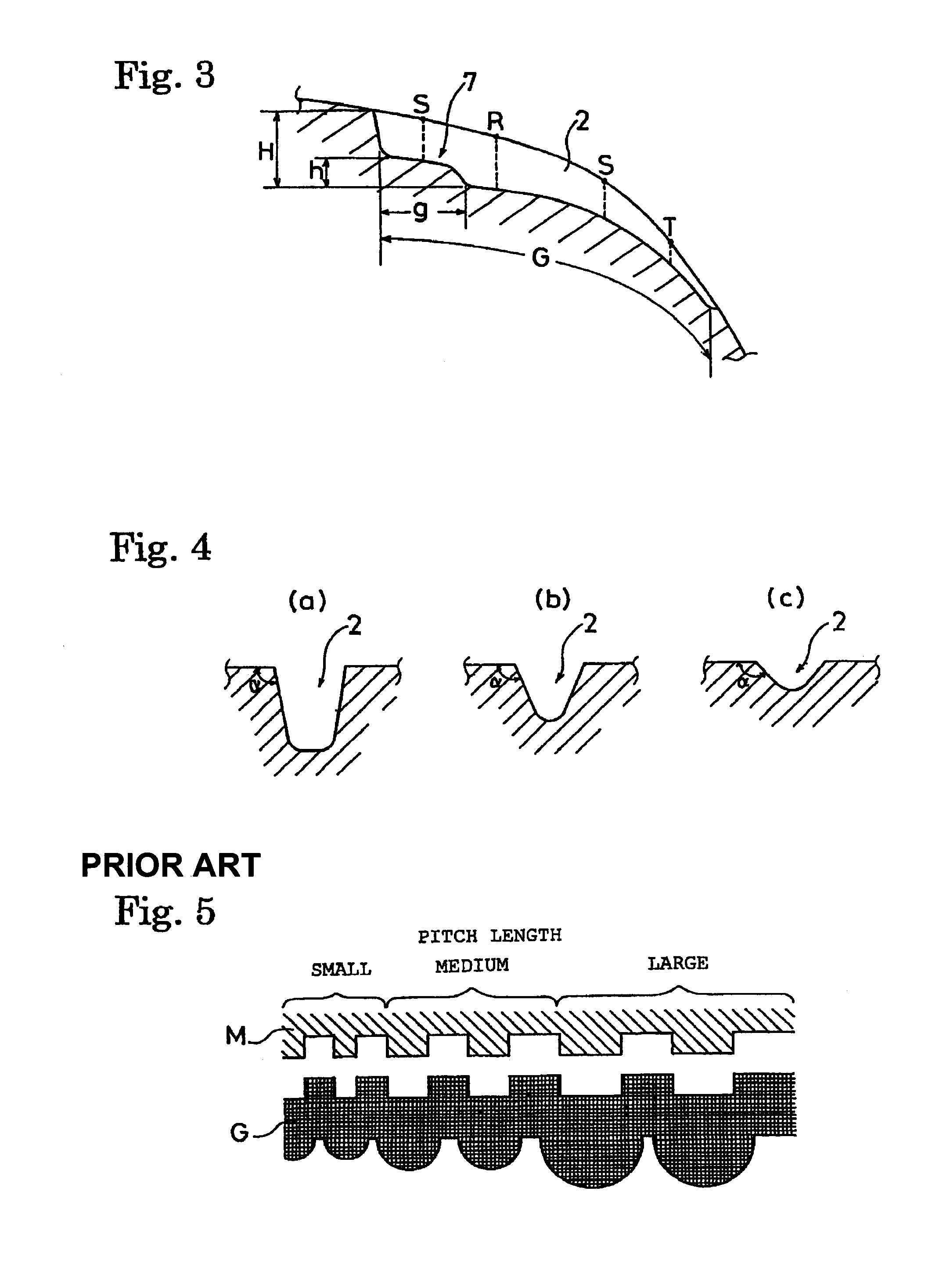

Reduced noise multi-ribbed power transmission belt

A multi-ribbed power transmission belt has transverse grooves in the compression section which are oriented at angles other than perpendicular. The combination of longitudinal grooves and transverse grooves form a plurality of cogs on the belt surface, with a row of cogs being defined between adjacent transverse grooves. Each cog has a pitch length P extending from a location on the cog to the identical location on the longitudinally adjacent cog. The pitch lengths of the rows of cogs are randomized over the entire length of the belt to reduce the noise of the belt as it travels about its associated pulleys.

Owner:CONTITECH USA INC +1

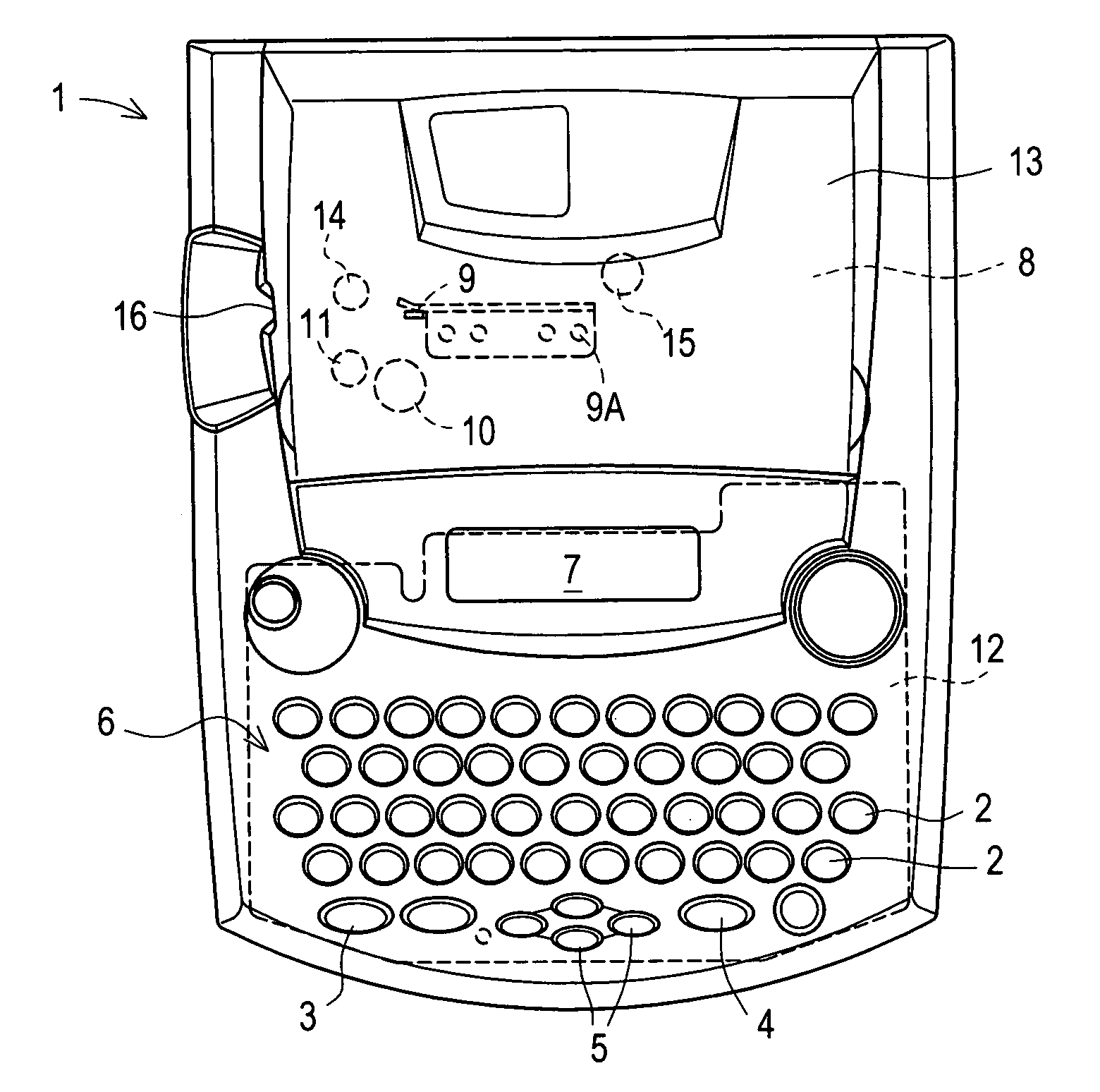

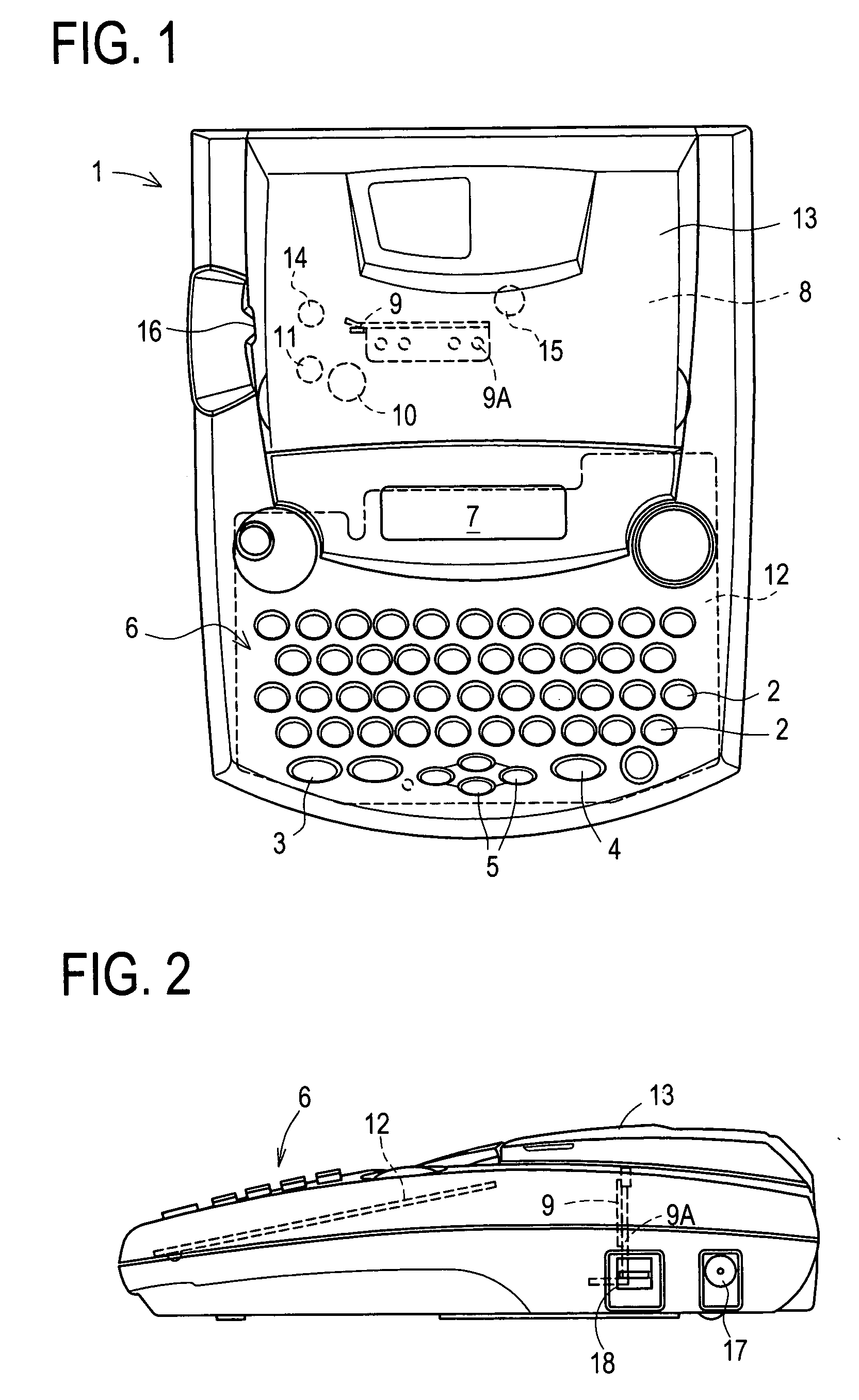

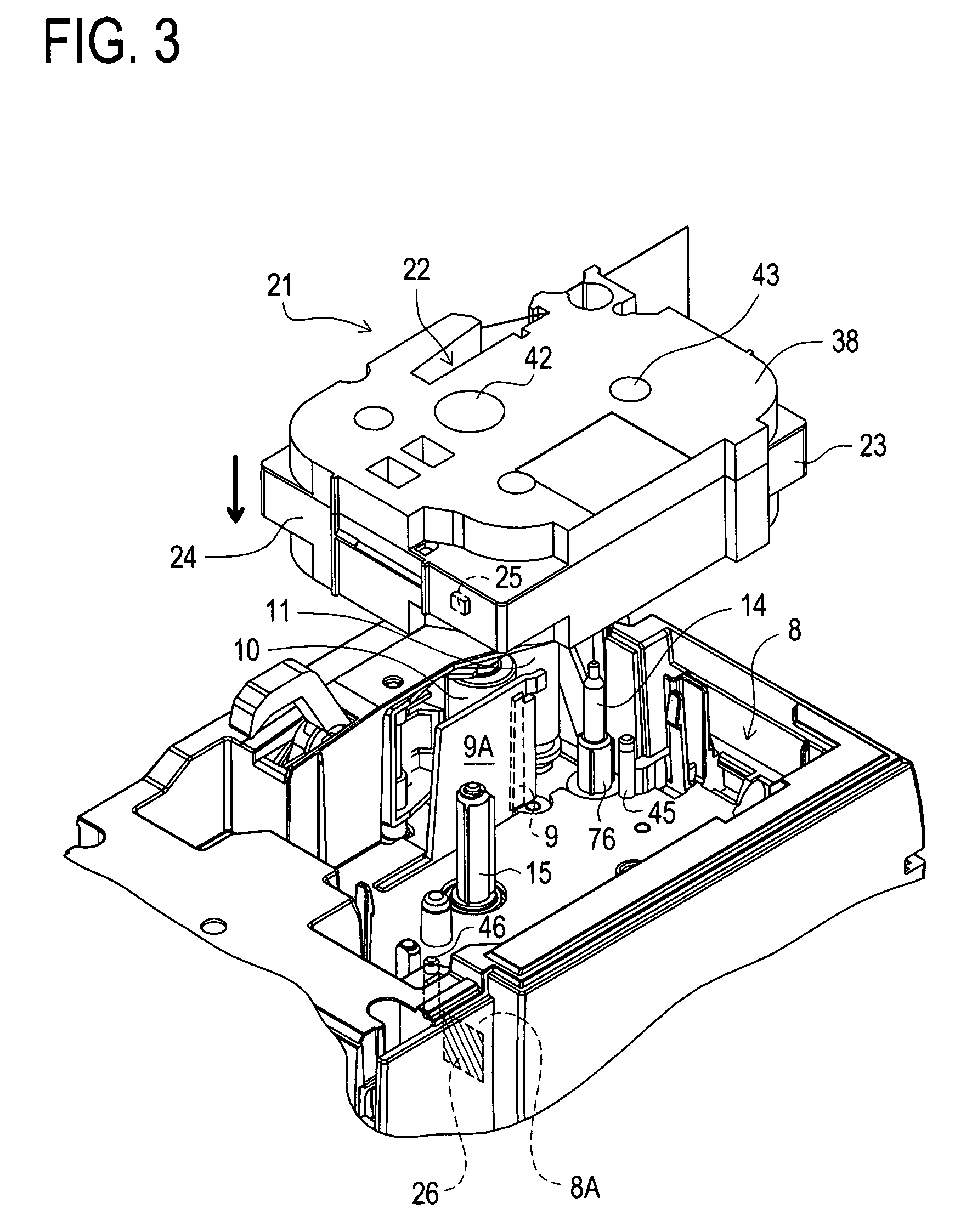

Tape Cassette and Tape Printing Apparatus

ActiveUS20080279605A1Accurate printingAvoid printingTypewritersOther printing apparatusMagnetic tapeData value

A CPU 81 displays a virtual tape 201 of a length obtained by subtracting a length (l1+l2) from an antenna 33 to a thermal head 9 from a data value of an “IC chip pitch length L” when it determines that a printing object tape 531 of type 1 is accommodated in a tape cassette 21. A “tape width” is displayed on the right side of the virtual tape 201. A tape length of the virtual tape 201 is displayed below it. A “tape type” is displayed below it. Then, the CPU 81 displays a print area 202 on the virtual tape 201 from a data value of the “print area” while a right side portion thereof serves as a non-print area. It displays the print data inputted into the print area 202 and waits for the return key 4 to be pressed.

Owner:BROTHER KOGYO KK

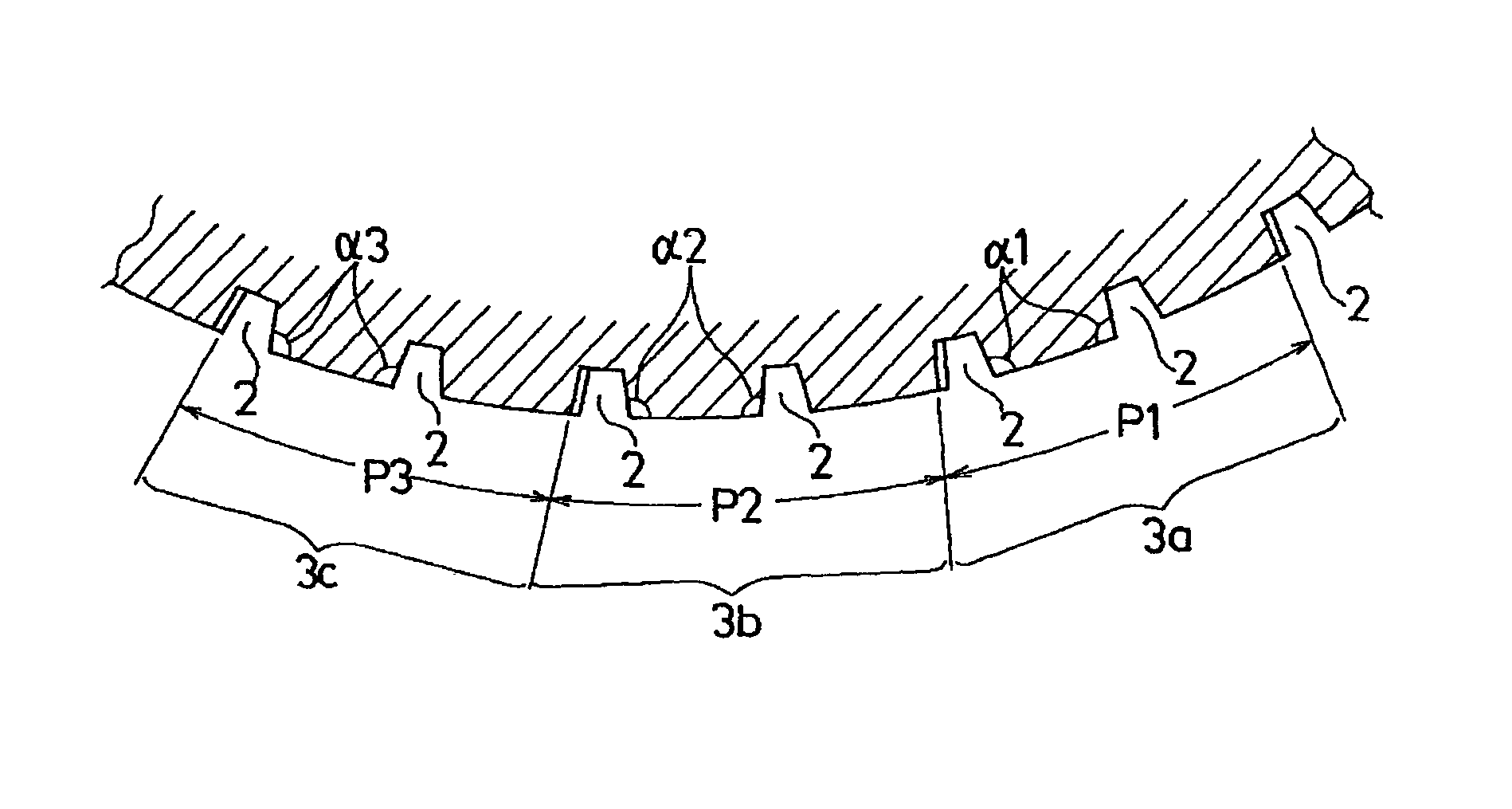

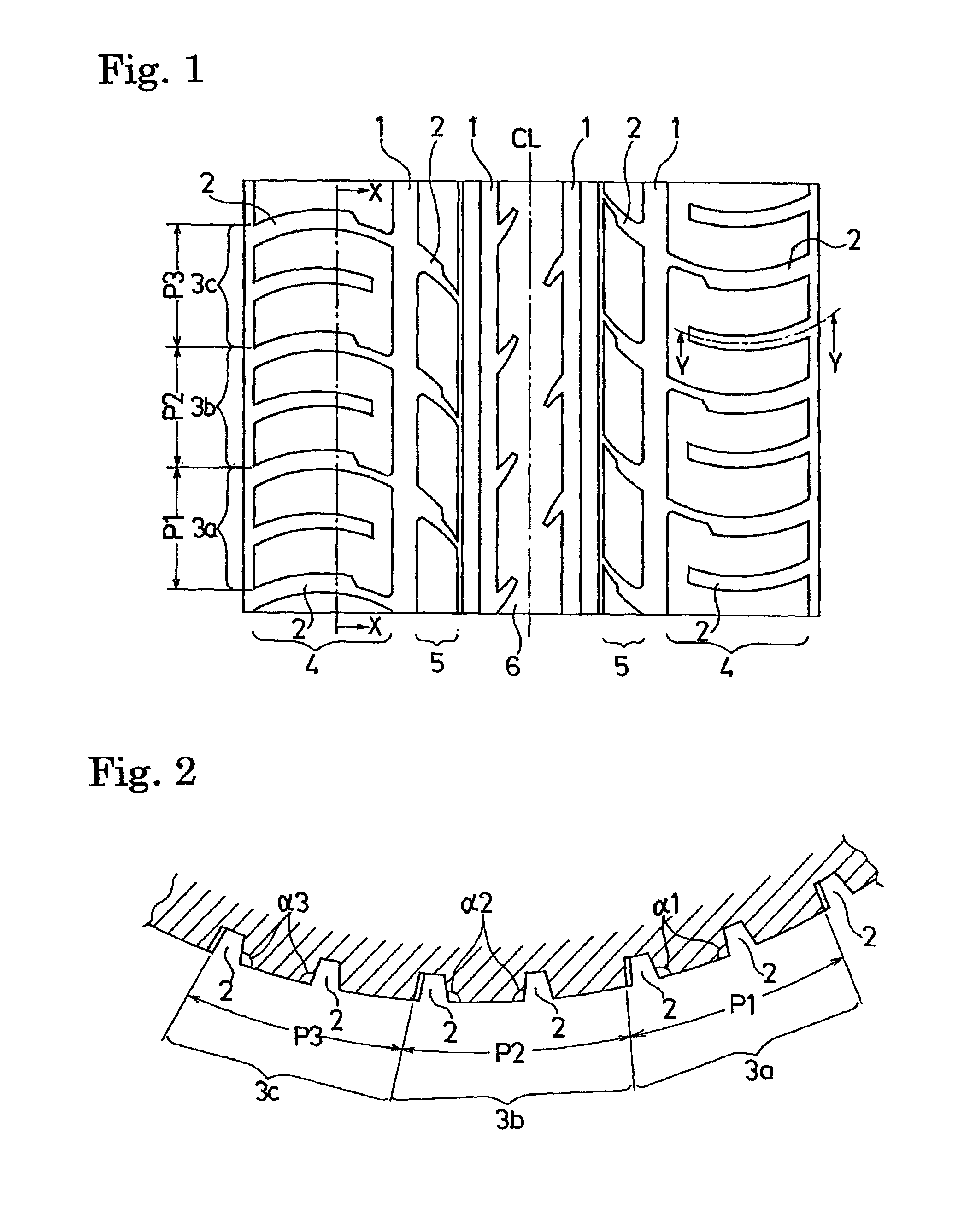

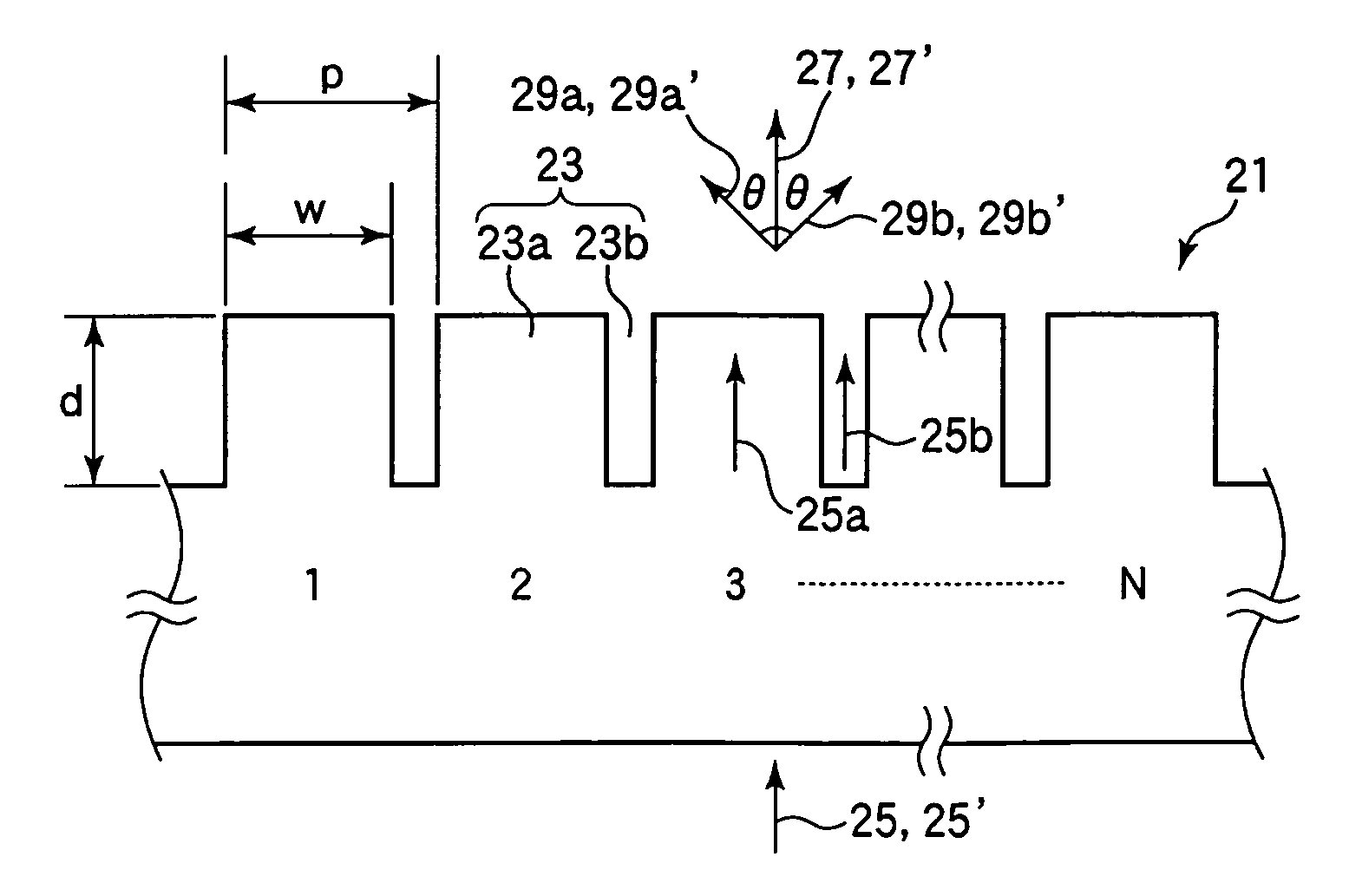

Pneumatic tire with tread having lateral grooves

InactiveUS7975738B2Improve uniformityDifference in rigidityTyre tread bands/patternsNon-skid devicesPitch variationEngineering

Provided is a pneumatic tire which employs pitch variation for suppressing pattern noise and has uniformity further improved. Pitches 3a, 3b and 3c with different pitch lengths are formed so that a pitch with a larger pitch length is set to have a smaller groove area ratio, and to have a larger groove wall angle α on the obtuse angle side that is formed by a groove wall of a lateral groove 2 and the direction tangential to the thread surface.

Owner:YOKOHAMA RUBBER CO LTD

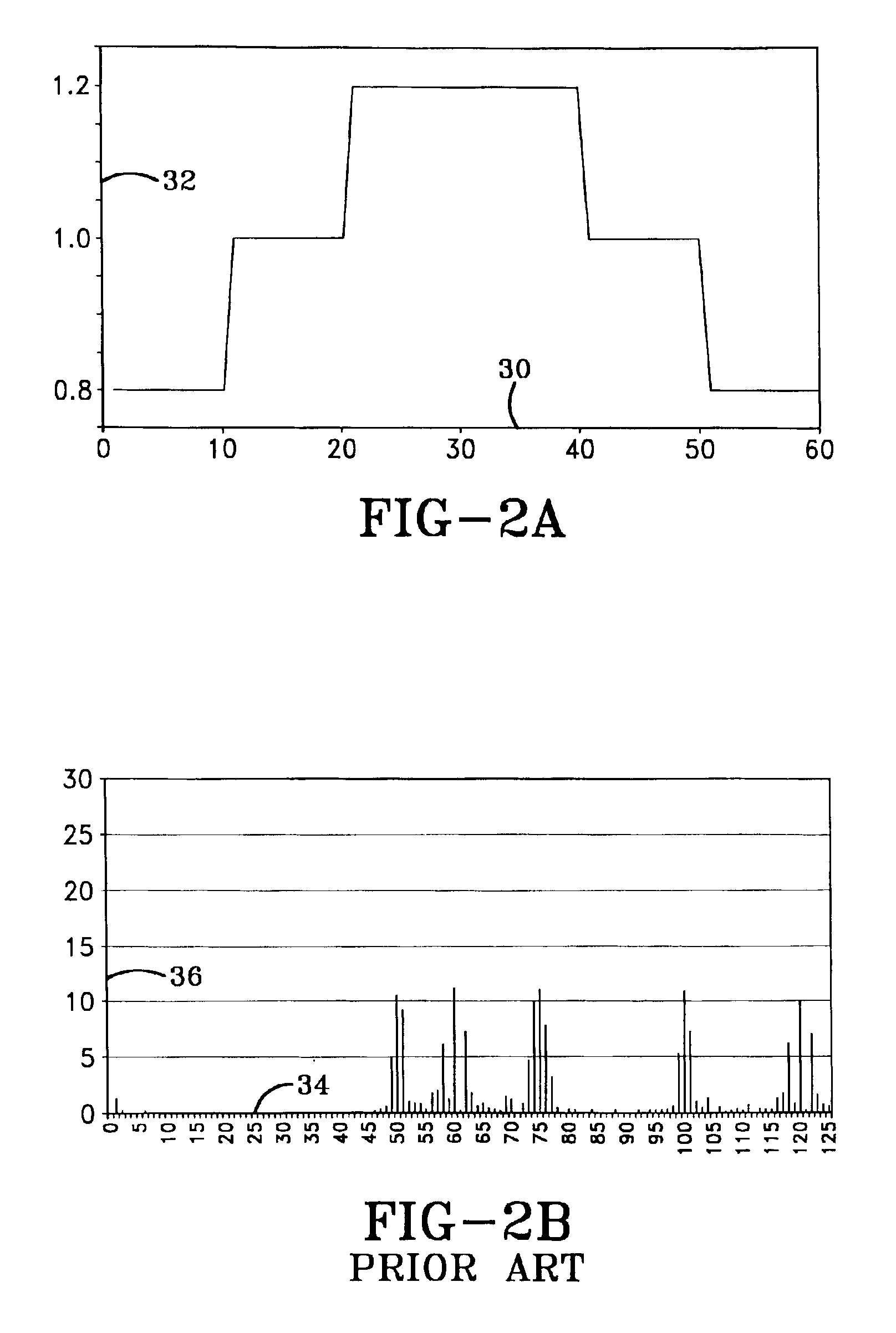

Method of analyzing tire pitch sequence based on lug stiffness variations

A method of comparing tire noise pitch sequences based on the tire noise generated by tire tread lug stiffness variations provides a secondary examination technique used to evaluate tire noise pitch sequences that have been selected by traditional evaluation techniques. The method includes the steps of defining the tire noise pitch sequence and the pitch lengths, calculating the differential between the arc length from an arbitrary fixed reference point to the end of each pitch length in the pitch sequence and the arc length of the mean pitch length of the number of pitches from that arbitrary reference point, and analyzing the differential to identify desirable and undesirable tire noise characteristics.

Owner:BRIDGESTONE FIRESTONE NORTH AMERICAN TIRE

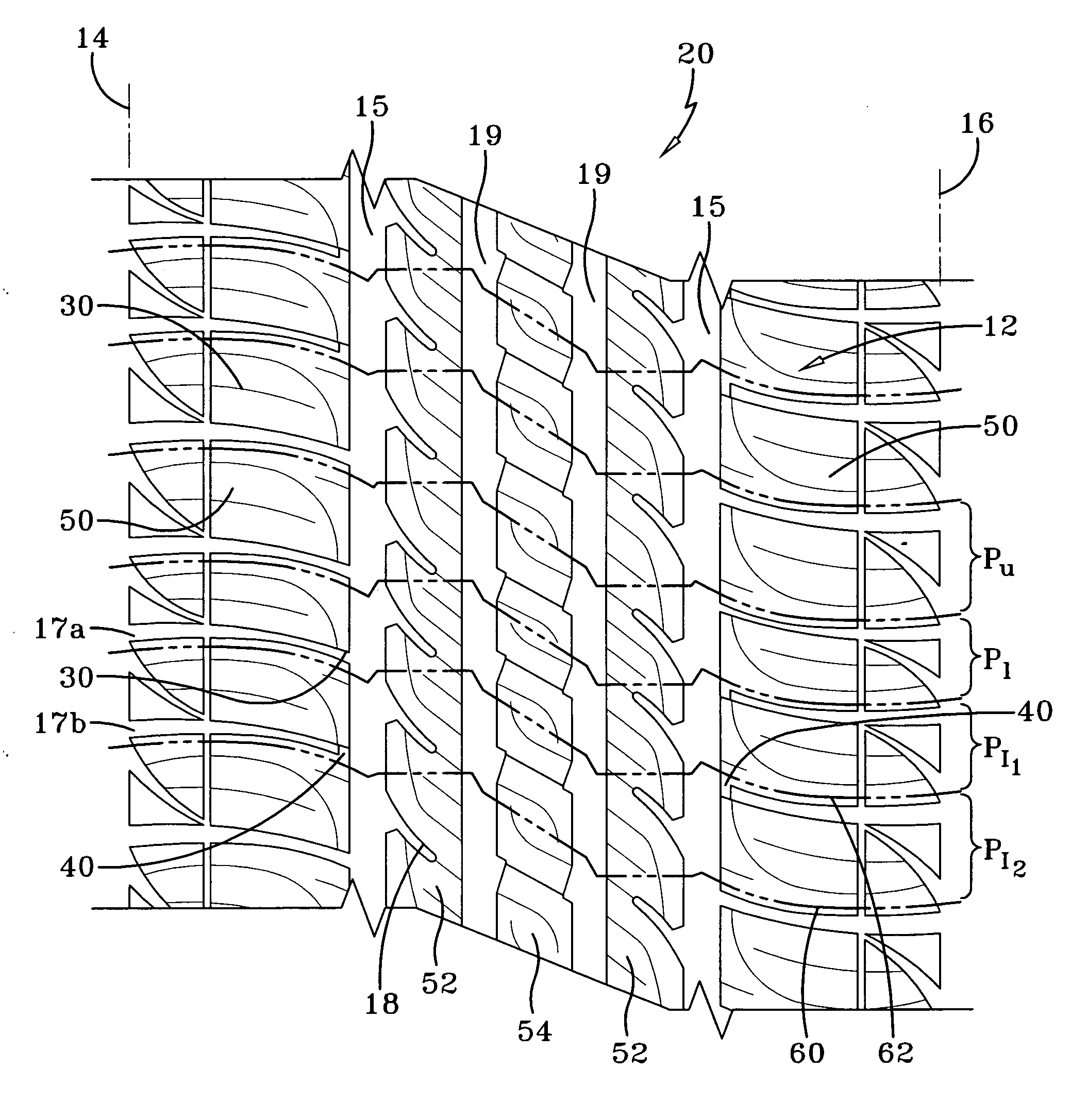

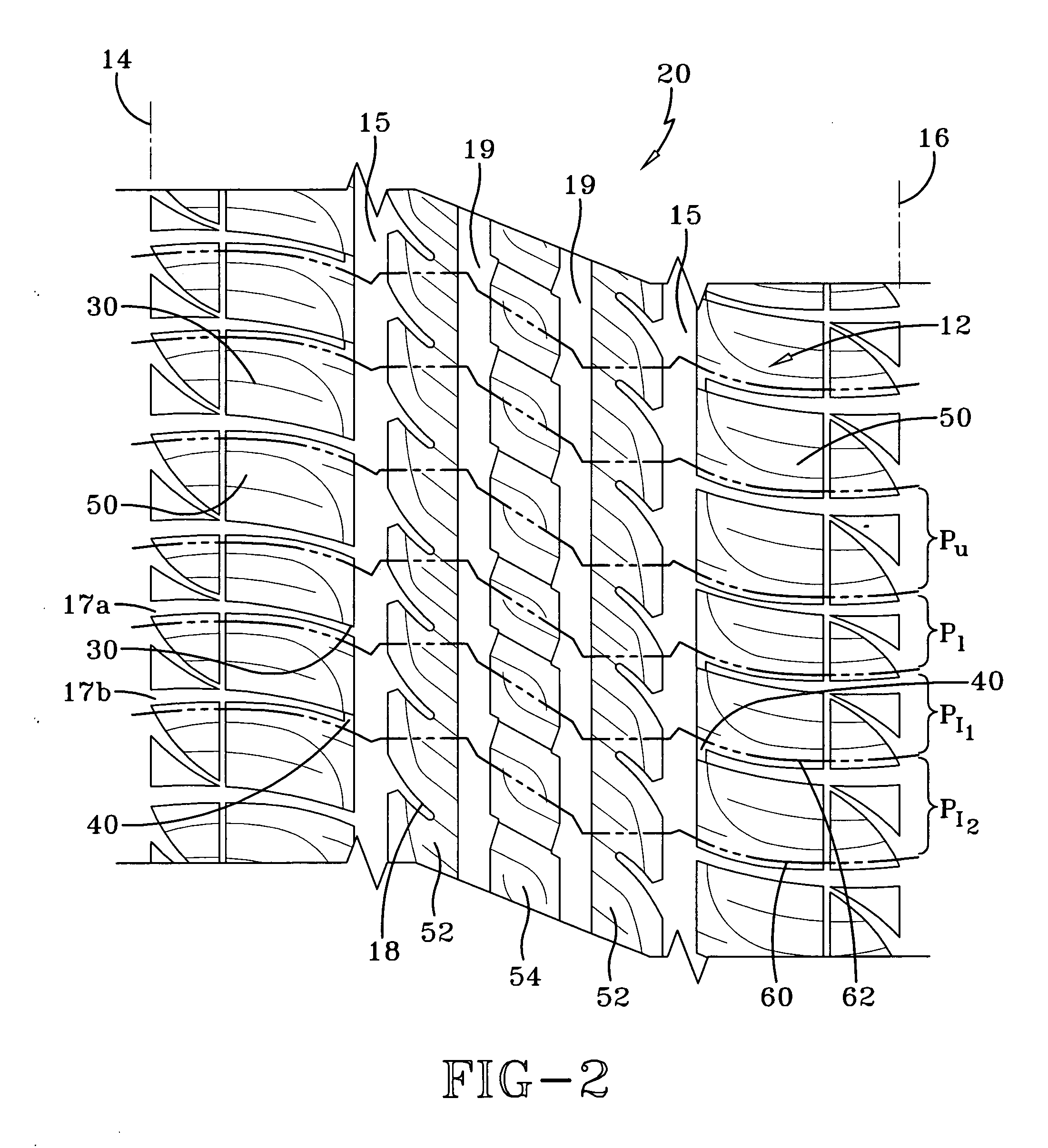

Continuous variable pitching methods

InactiveUS20070175565A1Satisfactory noise power spectrumTyre tread bands/patternsAnalogue processes for specific applicationsNoise power spectrumHarmonic

A method of pitching a tread for a tire to achieve a satisfactory noise power spectrum has the steps of: selecting an upper (u) and a lower (l) extreme of pitch ratios; permitting continuous variables of pitch ratios to exist between the upper (u) and lower (l) extreme of pitch ratios; and conducting an optimization of continuous variables between and including the two selected extremes of pitch ratios; wherein the pitch lengths of each tread element can be different in length to control noise and uniformity harmonics. The method may include other optimization steps in a combinatorial fashion such as using an integer programming formulation that determines discrete values of pitch ratios to get a pitch sequence, using genetic algorithm (GA) programming; or any other combinatorial optimization technique.

Owner:BROWN JACK EDWARD JR +1

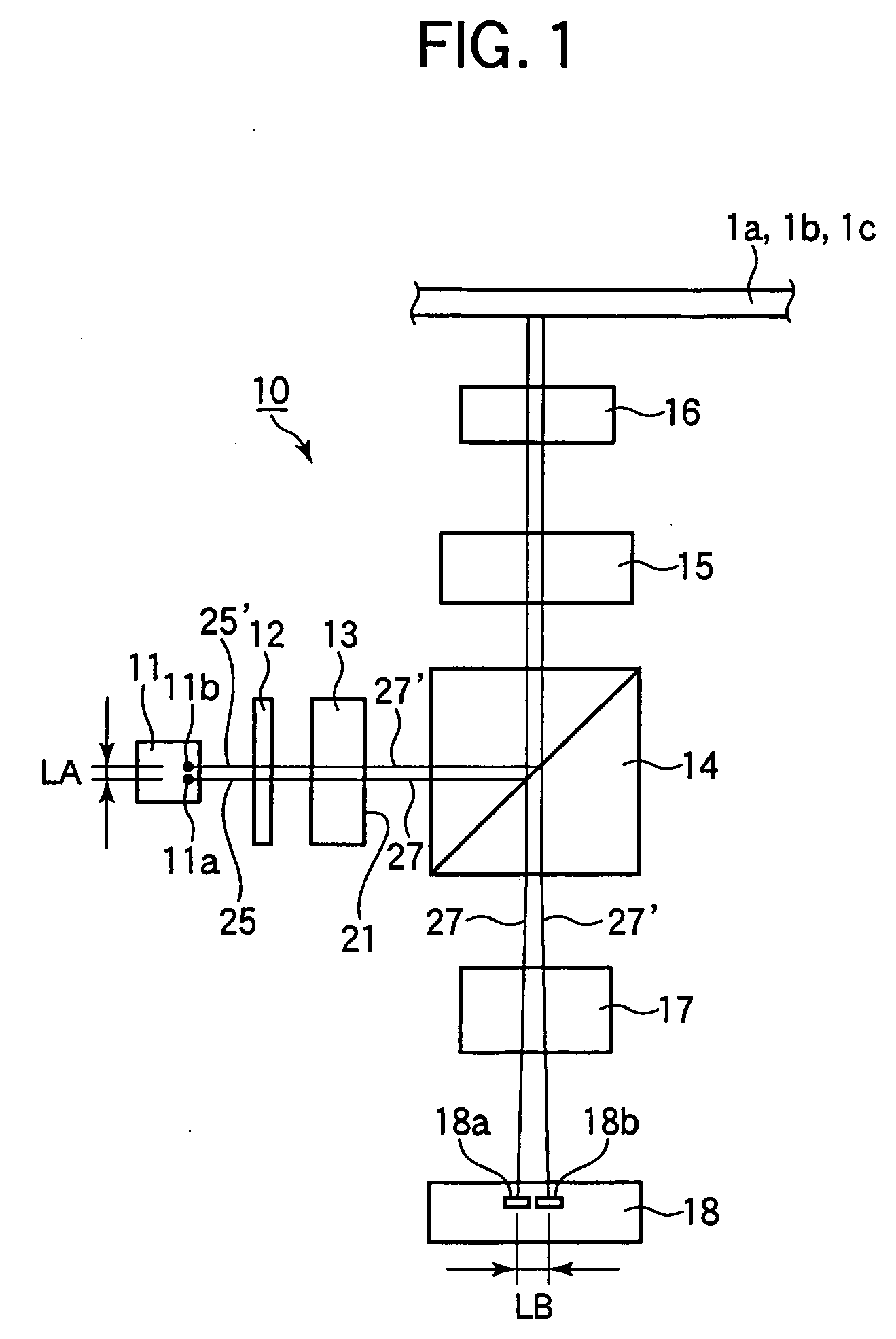

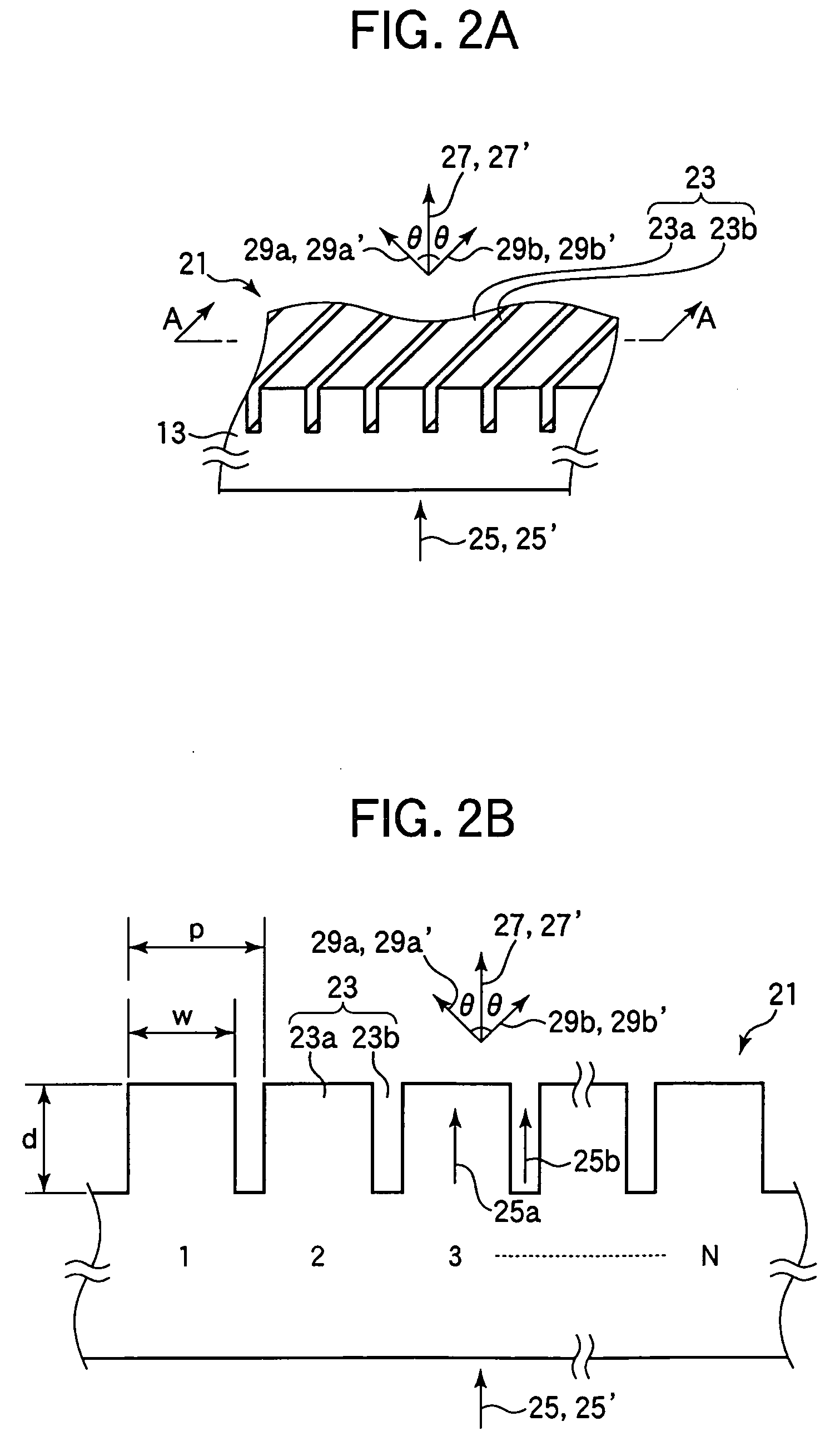

Diffraction grating, light-receiving element, and optical head and optical recording/reproducing apparatus utilizing them

InactiveUS20060193053A1Enhanced signalOther printing matterRecord information storageLight beamLaser light

The invention relates to a diffraction grating, a light-receiving element, and an optical head and an optical recording / reproducing apparatus utilizing them and provides a diffraction grating and a light-receiving element capable of detecting a signal of high quality and an optical head and an optical recording / reproducing apparatus utilizing them. A diffraction grating includes a diffracting region which is formed only on a light exit surface and which diffracts and separates first laser light or second laser light emitted by a two-wavelength semiconductor laser to generate a main beam and positive and negative first order sub beams. The depth of concavity formed on the diffracting region is 220 nm. The irregularities are formed such that the pitch length thereof is 22 μm and such that a convexity thereof has a width of 17.6 μm. The ratio of the width of the convexity to the pitch length of the irregularities is 0.8.

Owner:TDK CORPARATION

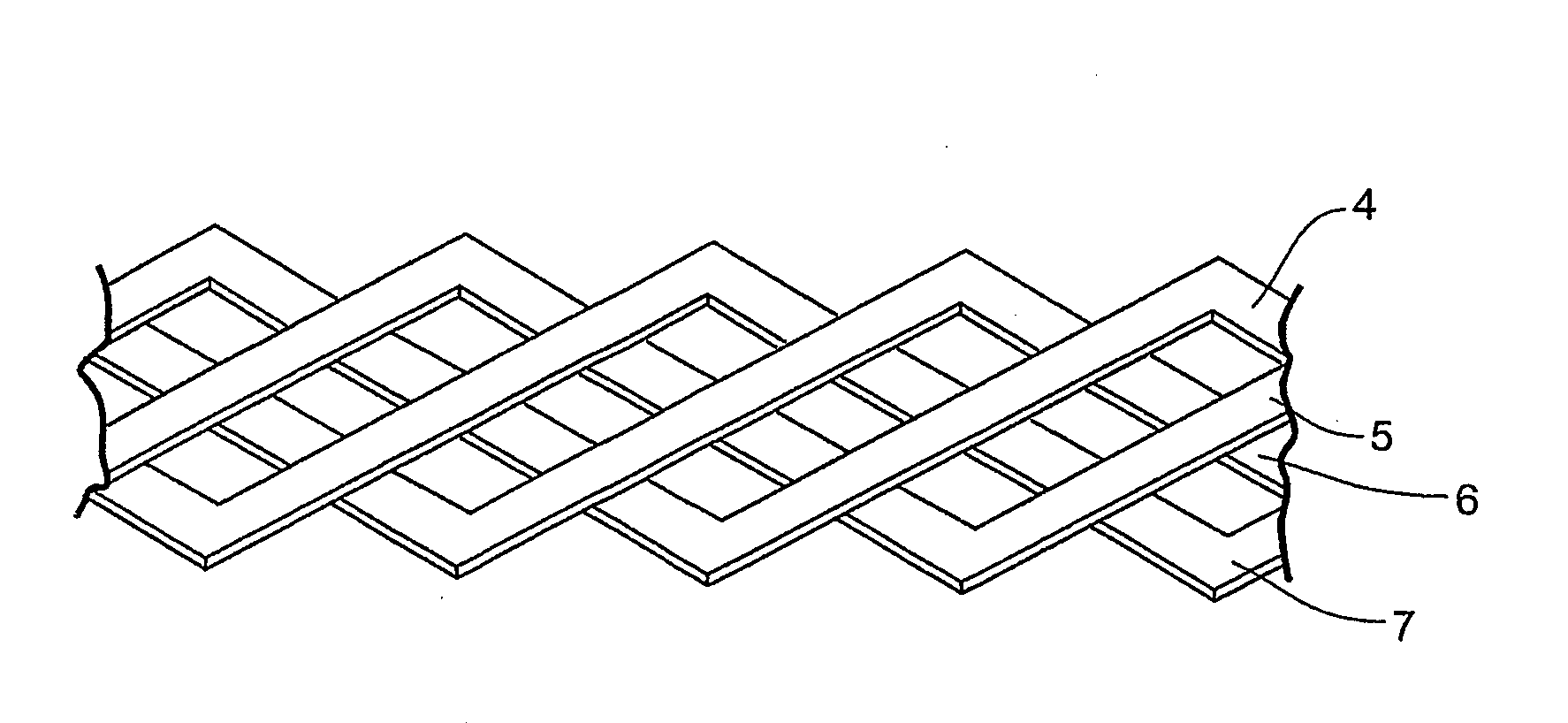

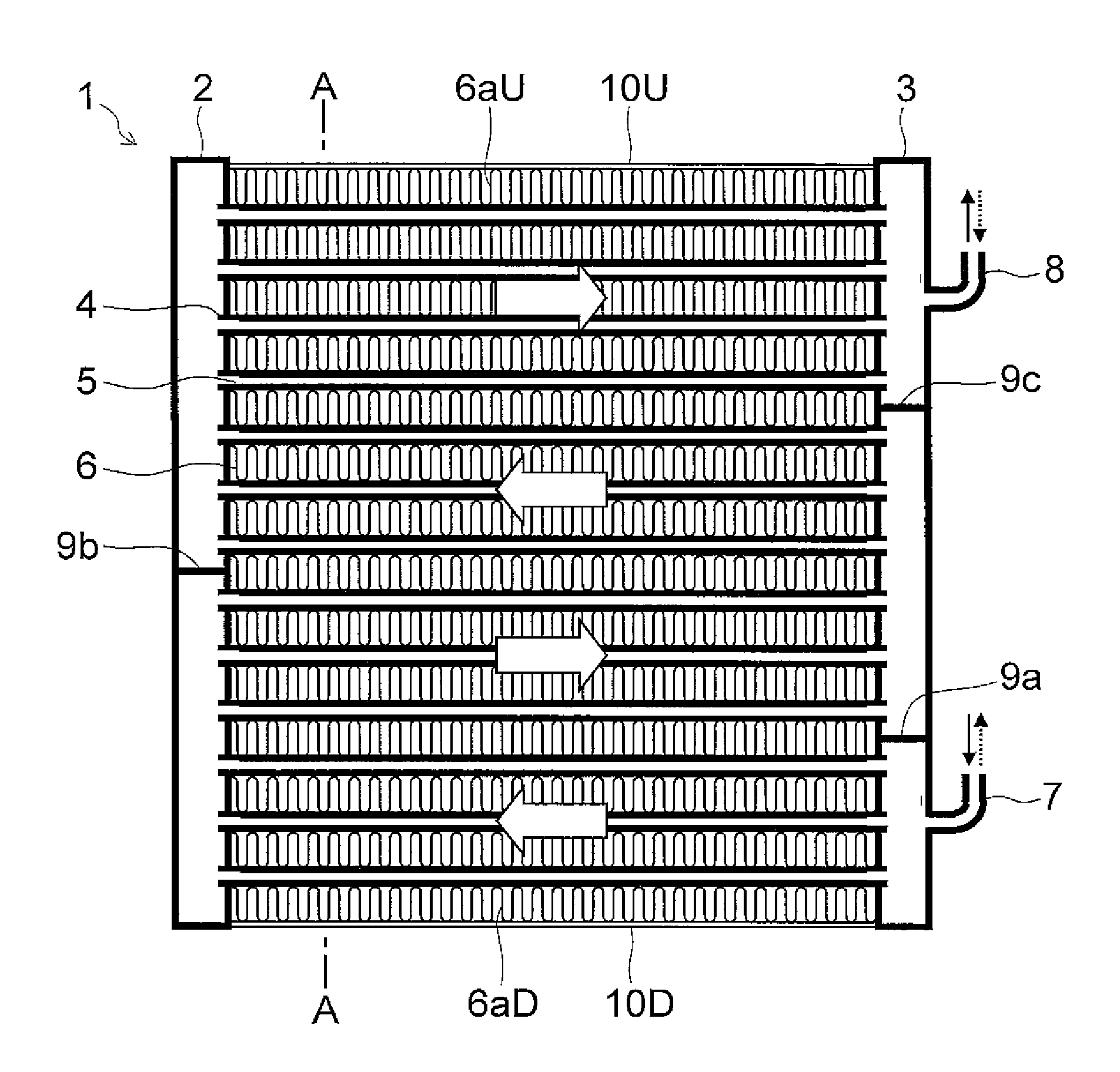

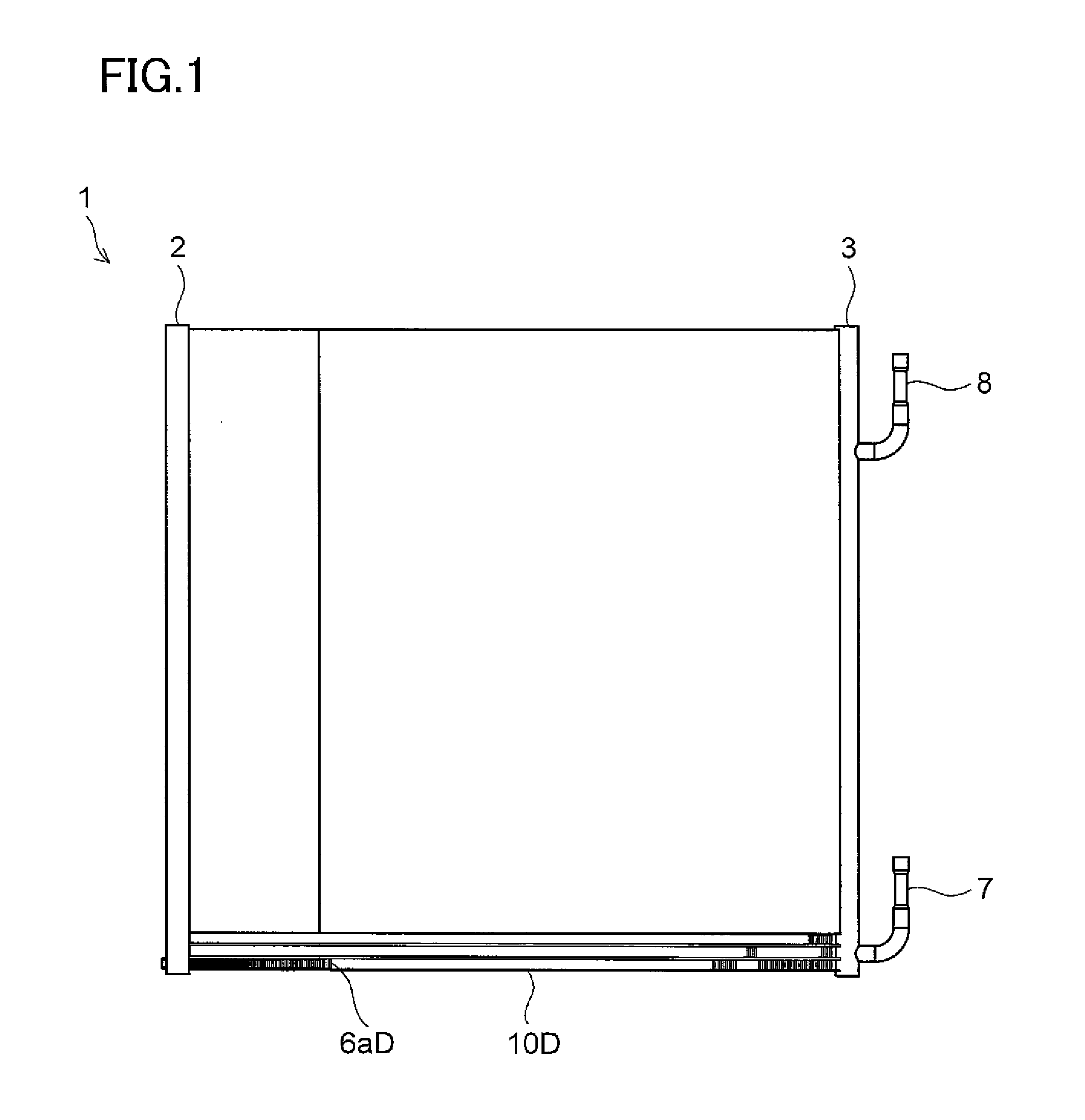

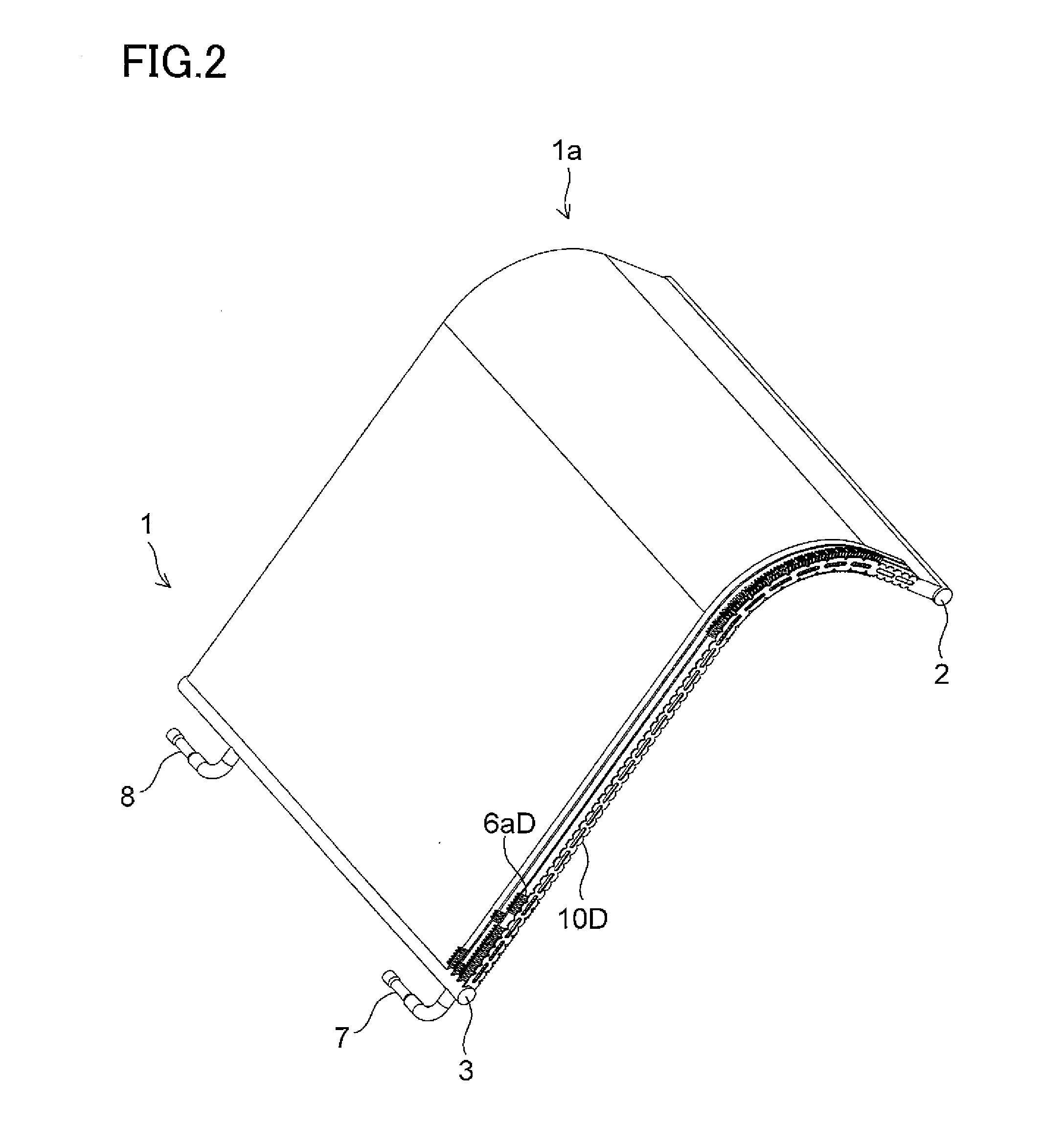

Heat exchanger and air conditioner equipped with same

InactiveUS20130240187A1Quickly drips downEvaporators/condensersStationary conduit assembliesEngineeringHeat exchanger

The heat exchanger (1) comprises: two header pipes (2),(3) arranged in parallel with an interval therebetween; a plurality of flat tubes (4) which are arranged between the header pipes and which place coolant paths (5) provided therein in communication with the interior of the header pipes; a plurality of fins (6) attached to the flat surface of each flat tube; and side sheets (10U), (10D) attached to an outside of the fins (6aU), (6aD), which are positioned farthest outward among the plurality of fins. The side sheet (10D) positioned in the bottom part of the heat exchanger (1) has a plurality of notches (11) formed at intervals from each other on the edge of the side where condensed water collects in the heat exchanger (1). The notches are each provided with a width sufficient for covering the interval pitch (P) of the fin by several pitch lengths.

Owner:SHARP KK

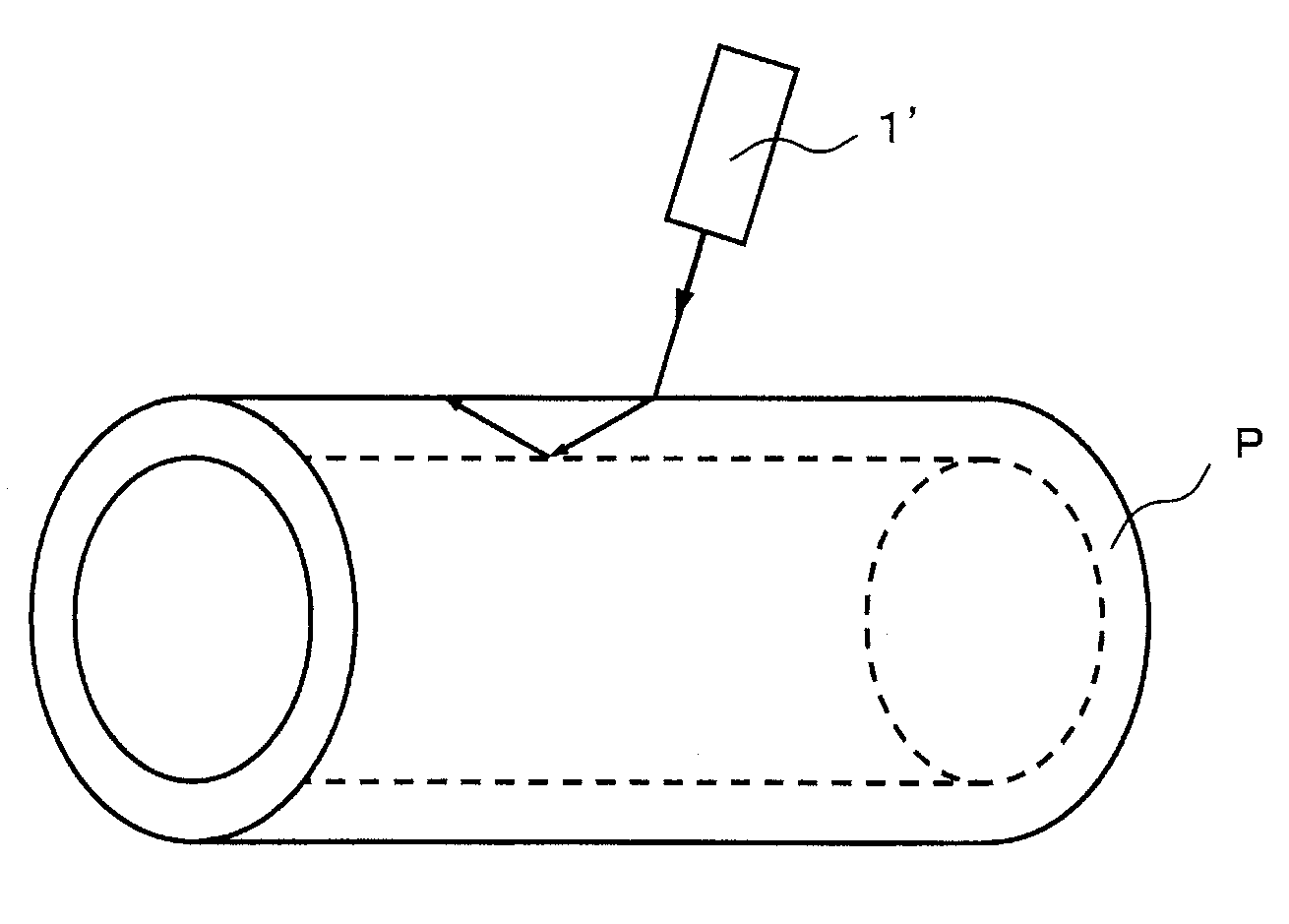

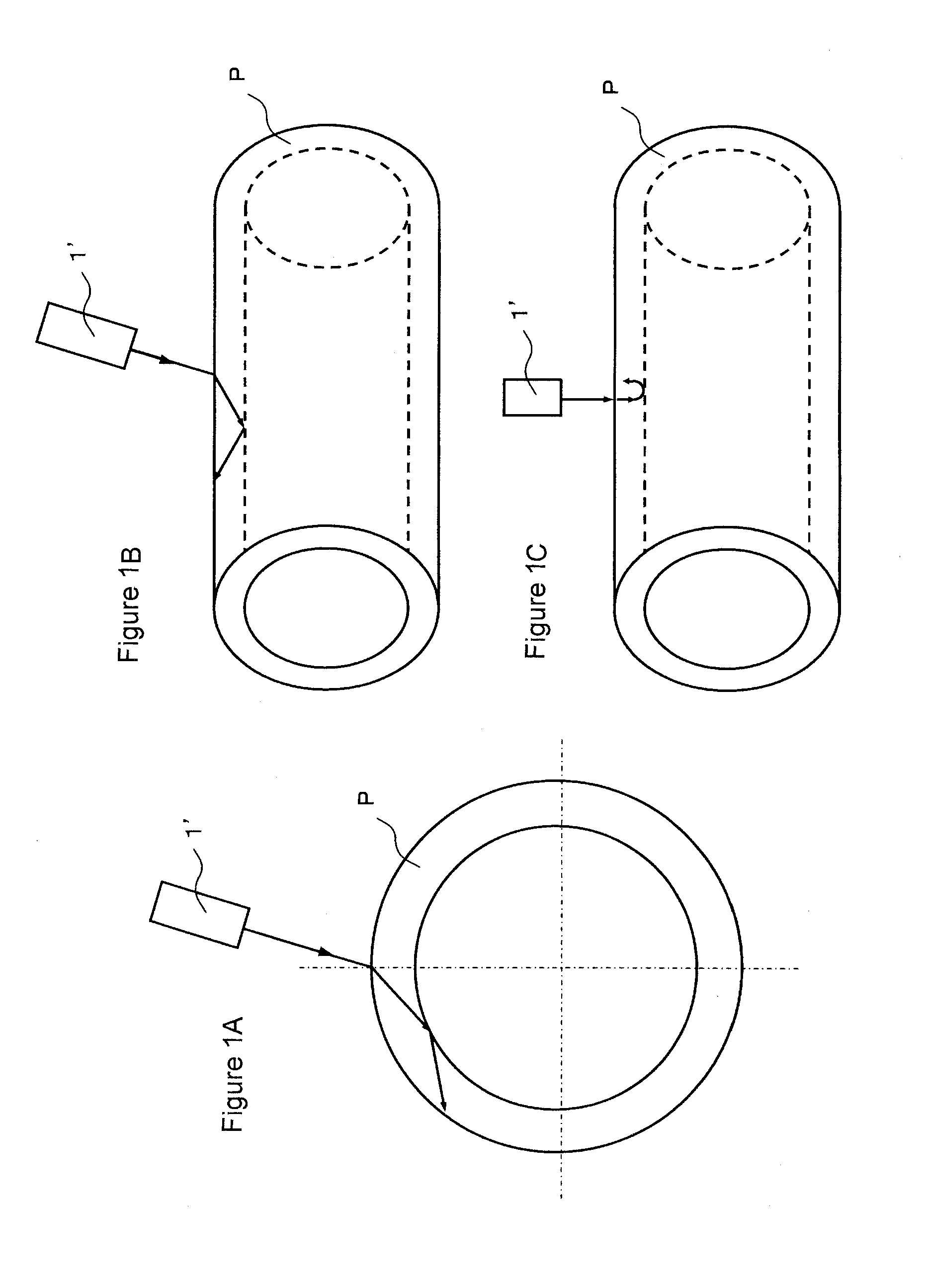

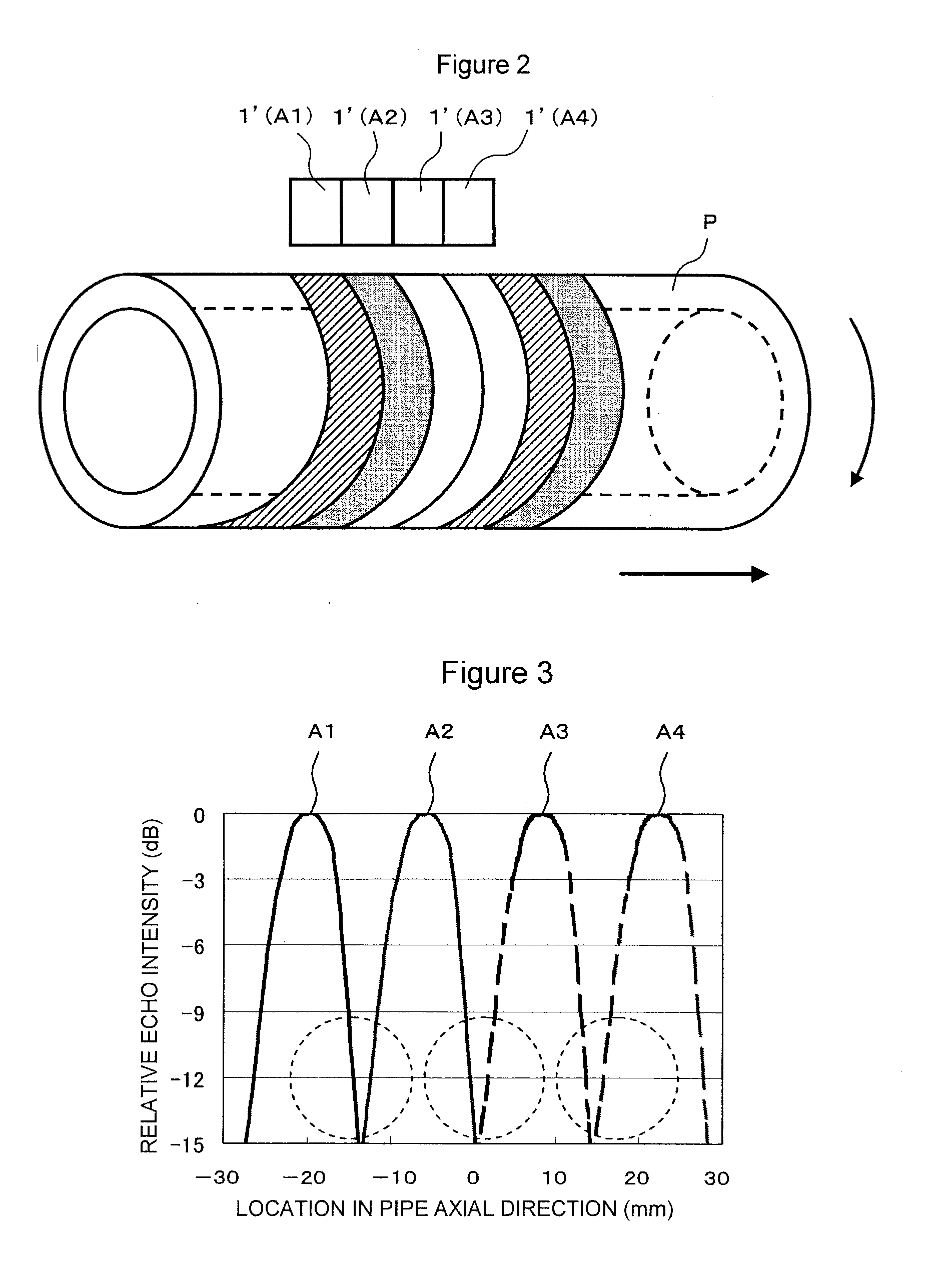

Ultrasonic testing method and apparatus

ActiveUS20110283798A1Easy to set upAccurate detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidTransducerUltrasonic testing

An ultrasonic testing apparatus 100 comprises an ultrasonic probe 1 including n (n≧2) number of transducers arranged along a predetermined direction, disposed so as to face a test object P, and a transmission / reception control device 2 for selecting m (n>m≧1) number of transducers from among the n number of transducers, transmitting ultrasonic waves from the selected m number of transducers toward the test object, receiving the ultrasonic waves therefrom, and switched m number of transducers to b selected successively. If an angle that the arrangement direction of the transducers makes with the surface of the test object which ultrasonic waves enter is θ, and the effective beam width of each selected m number of transducers with respect to a target flaw is W1, the transmission / reception control device switches m number of transducers to be selected successively by a switching pitch length P satisfying the formula: P≦W1·cosθ.

Owner:NIPPON STEEL CORP

Method for processing high-performance polyethylene braided wire for fishing gear or culture cage

InactiveCN101525810AImprove securityEnsure safetyFishing netsPisciculture and aquariaYarnSelf reinforced

The invention provides a method for processing a high-performance polyethylene braided wire for a fishing gear or a culture cage, relates to processing of a fishing screen wire, and provides the method for processing the polyethylene braided wire. The method uses a fishing self-reinforcing polyethylene monofilament, and fills a core in the center of the braided wire. The method is characterized in that the core diameter equals to (a wire diameter-2*a yarn diameter) * an empirical factor of a mandrel, and the empirical factor of the mandrel is between 0.980 and 0.990; the number of yarns for the mandrel equals to (the core diameter / the yarn diameter) <2>*an empirical factor of the yarns for the mandrel, and the empirical factor of the yarns for the mandrel is between 0.176 and 0.185; the pitch length is determined by the wire diameter multiplied by the empirical factor of the pitch length, and the empirical factor of the pitch length is between 1.240 and 1.950; the number of strands is 16; the number of the yarns for the strands equals to (pi*the wire diameter* the empirical factor of the number of the yarns for strands) / (16*the yarn diameter); and the empirical factor of the number of the yarns for the strands is between 1.360 and 1.520. The method can be used for processing the high-performance polyethylene braided wire for the fishing gear or the culture cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

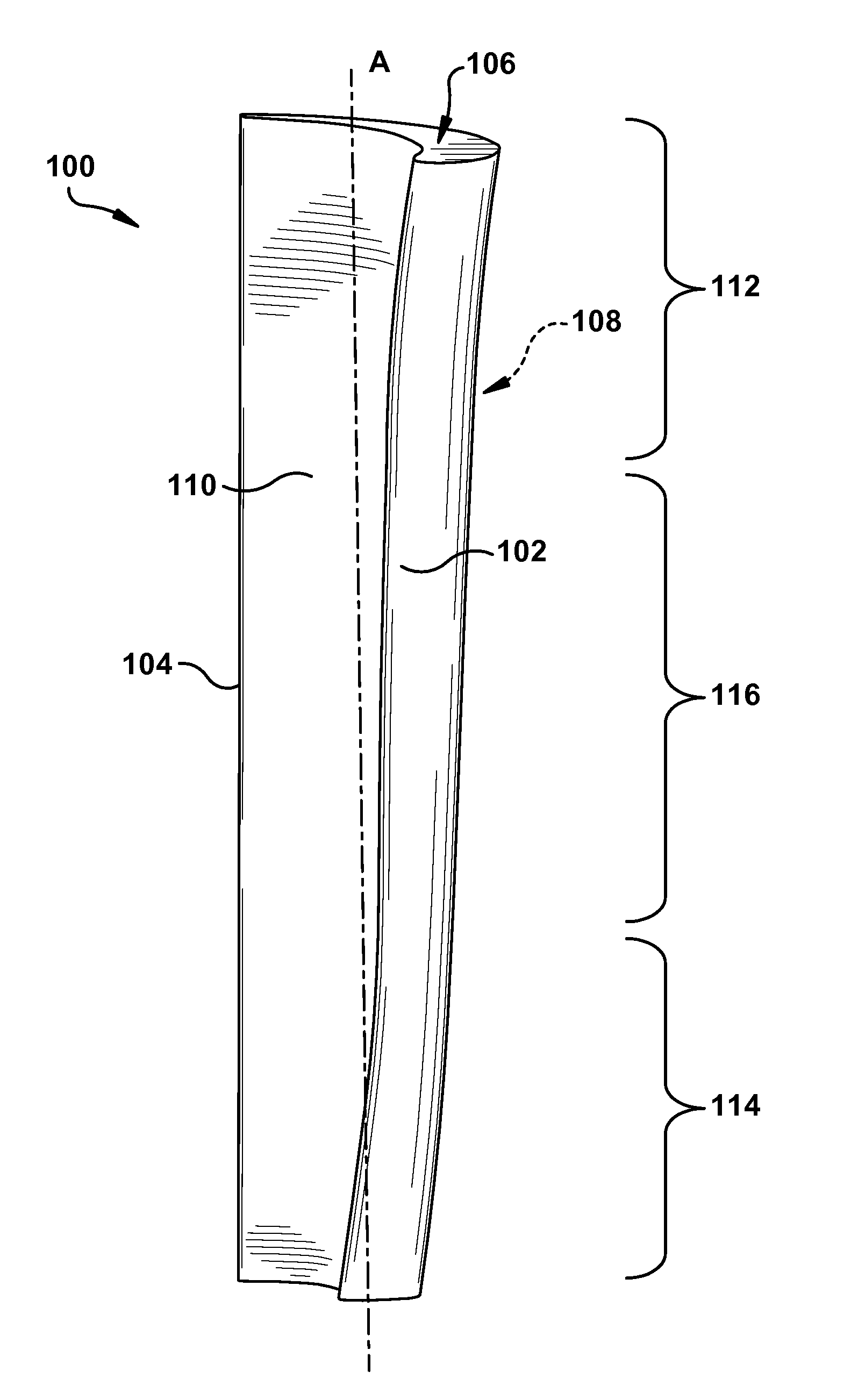

Hybrid flow blade design

Owner:GE INFRASTRUCTURE TECH INT LLC

Tire with tread having improved snow and dry traction

This invention relates generally to tires having treads that have a configuration and / or properties for providing suitable snow and dry traction, and, more specifically, to a tire that has a tread that has a maximum value for sipe density in the contact patch, a minimum value for lateral groove density in the contact patch, and a minimum value for the longitudinal contact surface ratio. In certain embodiments, the pitch length of pitches or repeating units of tread geometry along the circumferential direction of the tire is within a certain range and the tread depth is below a specified value. Tires with treads having a configuration that falls within these design parameters exhibit a desirably good level of snow and dry traction.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Spatial filtering of higher order modes in multimode fibers

ActiveUS8218928B2Low levelReduced insertion lossLaser detailsOptical fibre with graded refractive index core/claddingFiberBasic mode

A mode filter for eliminating the propagation of higher-order modes along a section of optical multimode fiber comprises a graded index (GRIN) lens, preferably of a quarter-pitch length, and a pinhole element in the form of a small core fiber. This configuration creates a Fourier spatial filter assembly that removes higher order modes propagating along an optical fiber while capturing the fundamental mode of the optical signal. A section of GRIN fiber is preferably used as the lens, with the small core fiber disposed at the output of the GRIN fiber lens to collect substantially only the on-axis fundamental mode of the optical signal. Since the higher order modes are shifted away from the origin by the GRIN fiber lens, only the fundamental mode signal is captured by the small core fiber.

Owner:OFS FITEL LLC

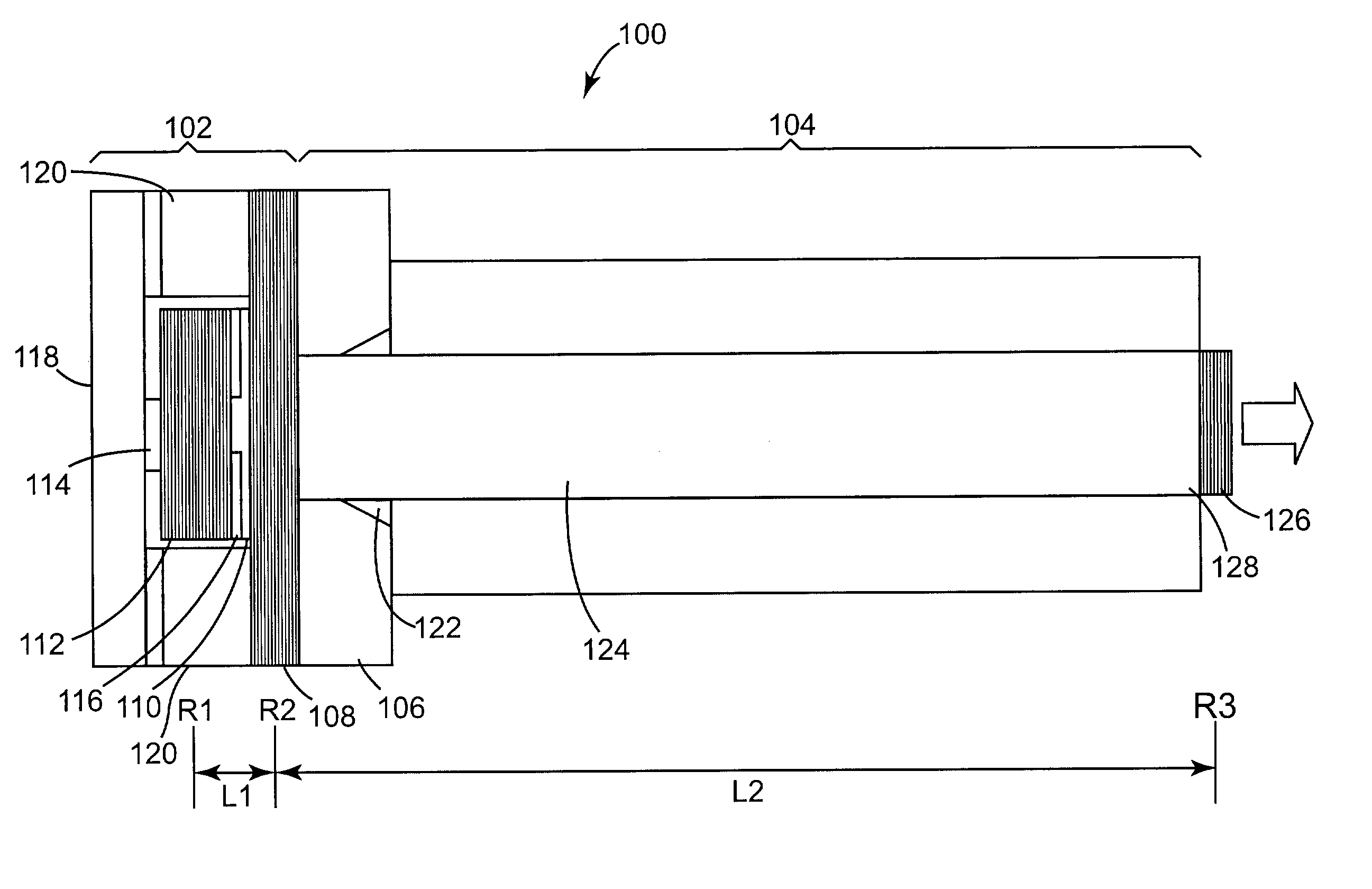

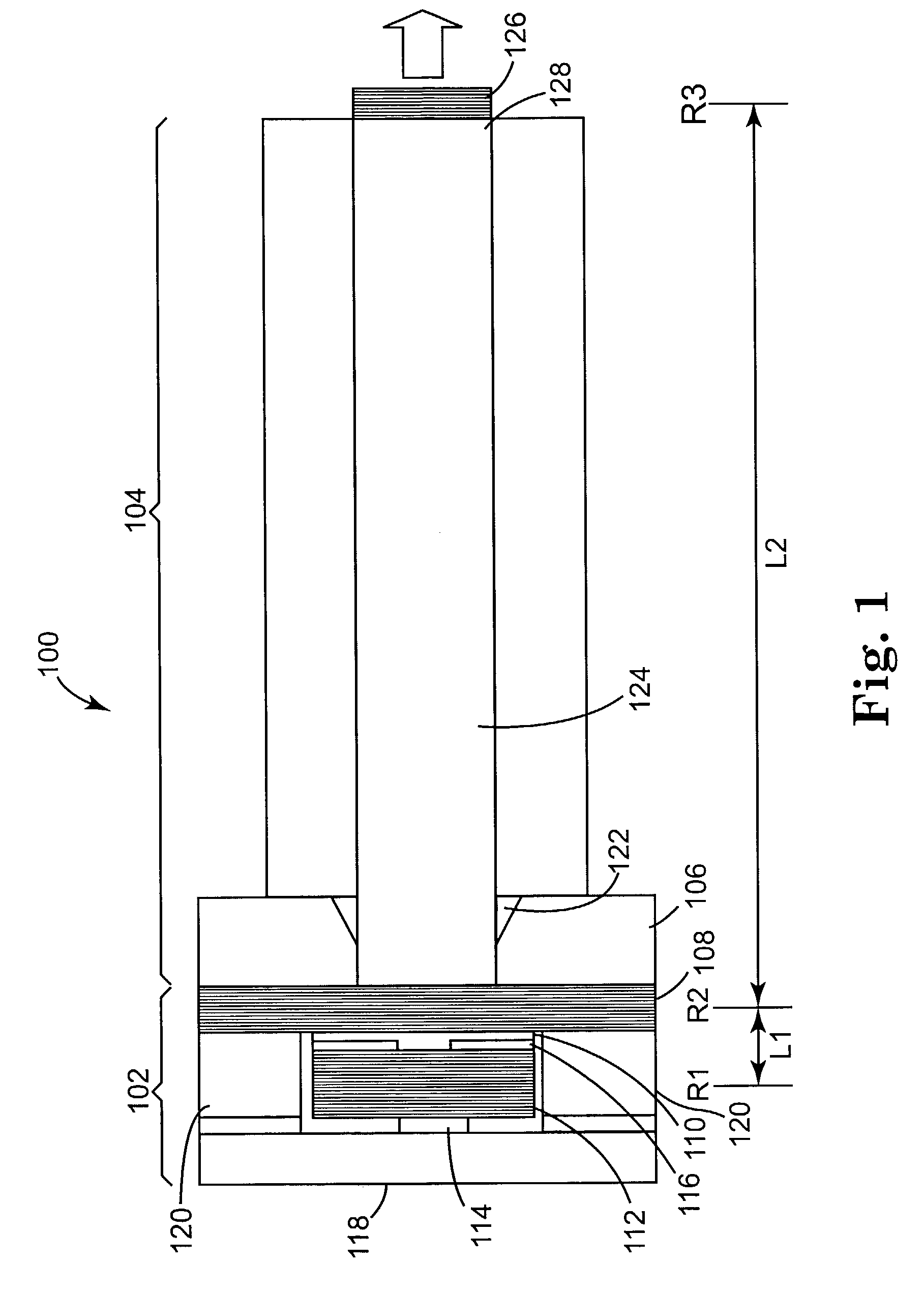

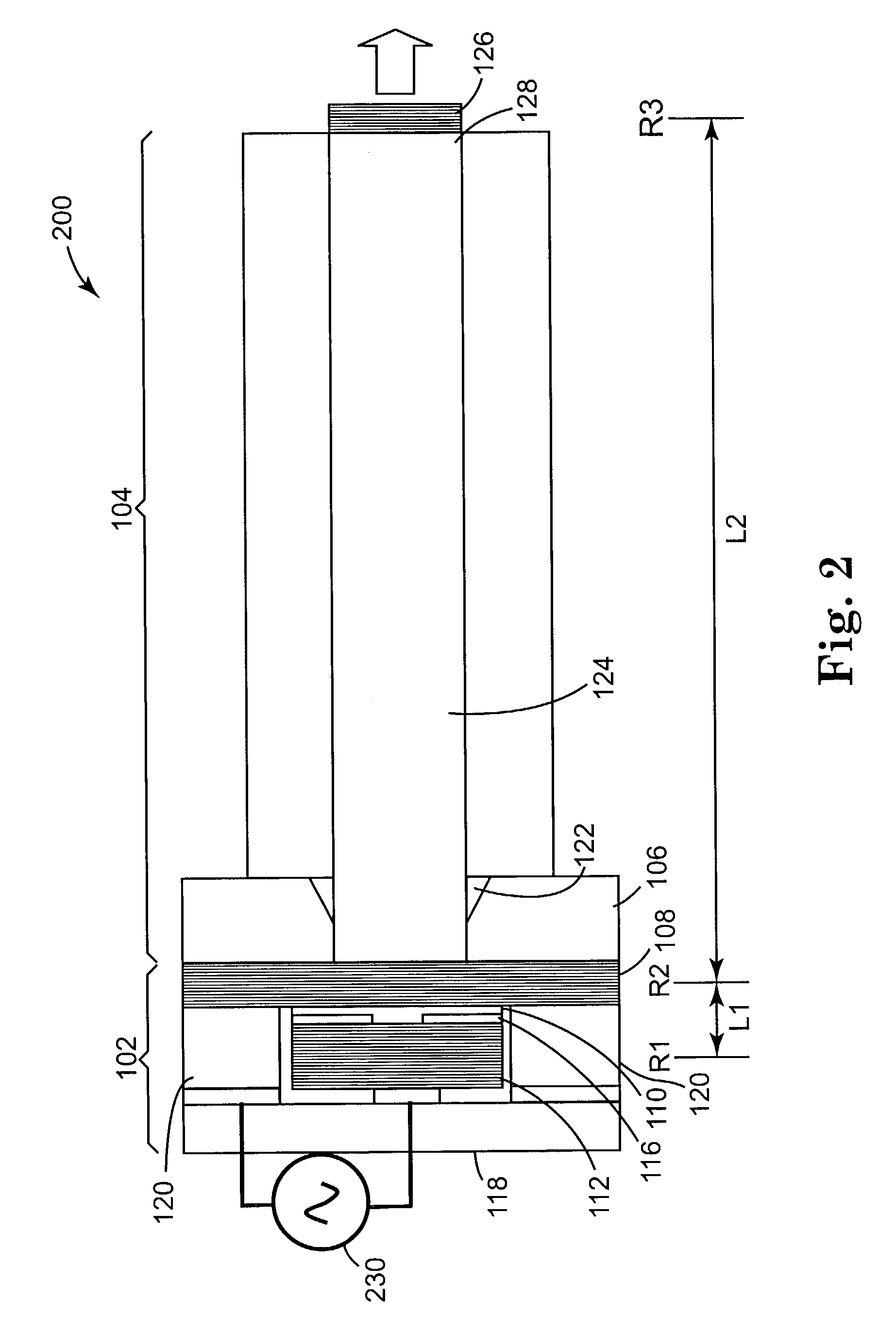

Fiber extended, semiconductor laser

InactiveUS7039075B2Low cost structureLaser using scattering effectsLaser optical resonator constructionFiber disk laserLength wave

A semiconductor laser, such as a vertical cavity, surface emitting laser (VCSEL) is coupled to an optical fiber. The other end of the optical fiber has a reflector, so as to provide a fiber-extended cavity for the VCSEL. Such a construction is useful for providing modal stability to the VCSEL or for forming a mode-locked VCSEL. The optical fiber may be a graded index fiber. In such a case, the fiber length may be selected to have an integral number of quarter pitch lengths. The fiber may be doped with an excitable species and lies within a fiber laser cavity. A semiconductor laser may pump the fiber laser, yielding an emission wavelength beyond the scope of the conventional semiconductor laser.

Owner:THORNTON ROBERT L

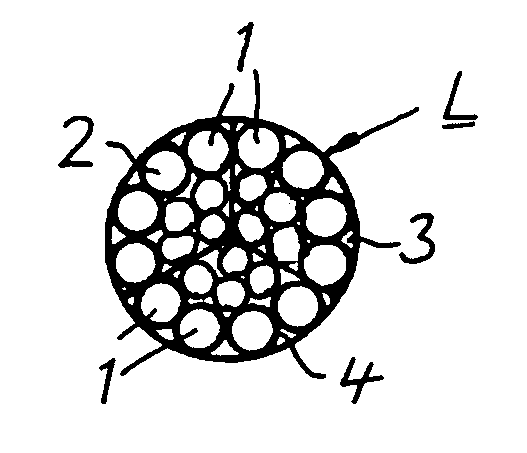

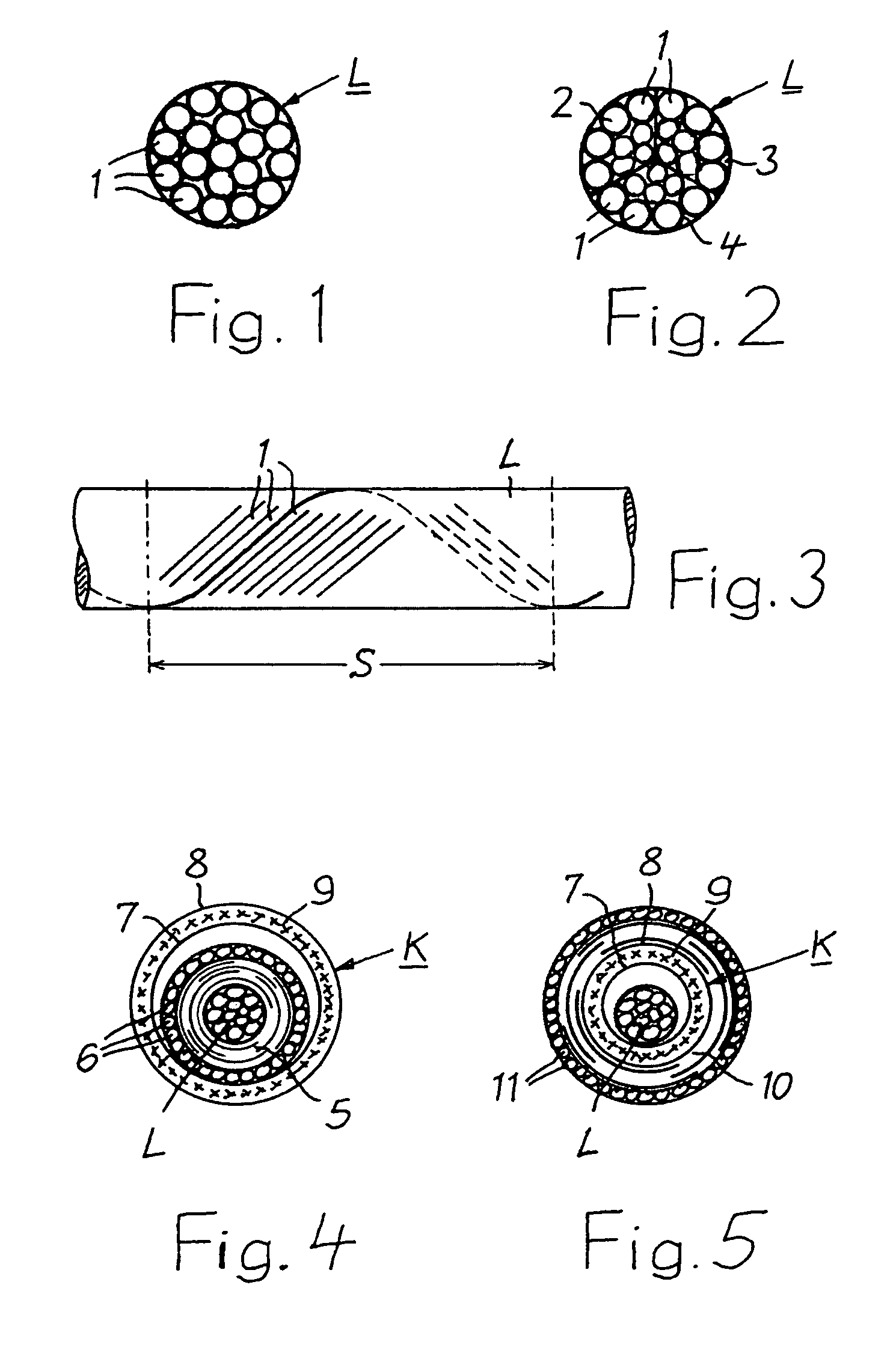

Superconductive electrical cable

InactiveUS8112135B2Easy to produceSimple structureSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorPitch length

A superconductive electrical cable is provided, which comprises a conductor consisting of superconductive wires. The conductor (L) is designed as a stranded conductor in which the wires (1) are stranded together with a predetermined pitch length (S) lying between about 5×D and about 20×D, where D is the diameter of the stranded conductor.

Owner:NEXANS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com