Pneumatic tire

A technology for pneumatic tires and tire width directions, which is applied to pneumatic tires, tire parts, tire treads/tread patterns, etc., can solve problems such as ambiguity, and achieve excellent handling and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

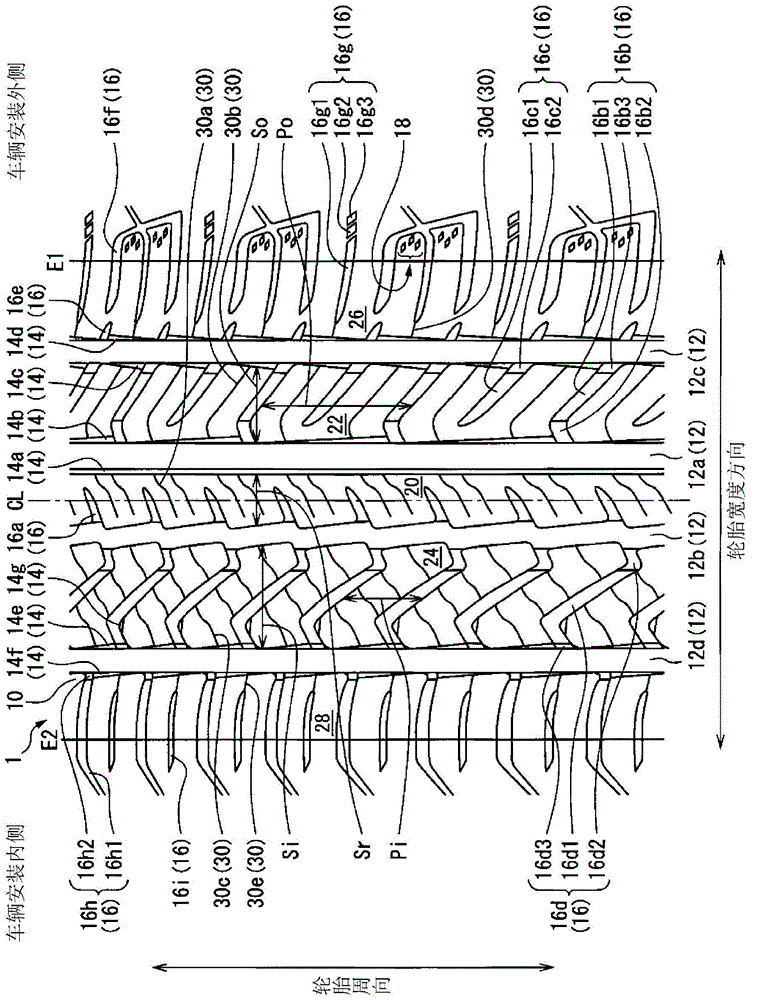

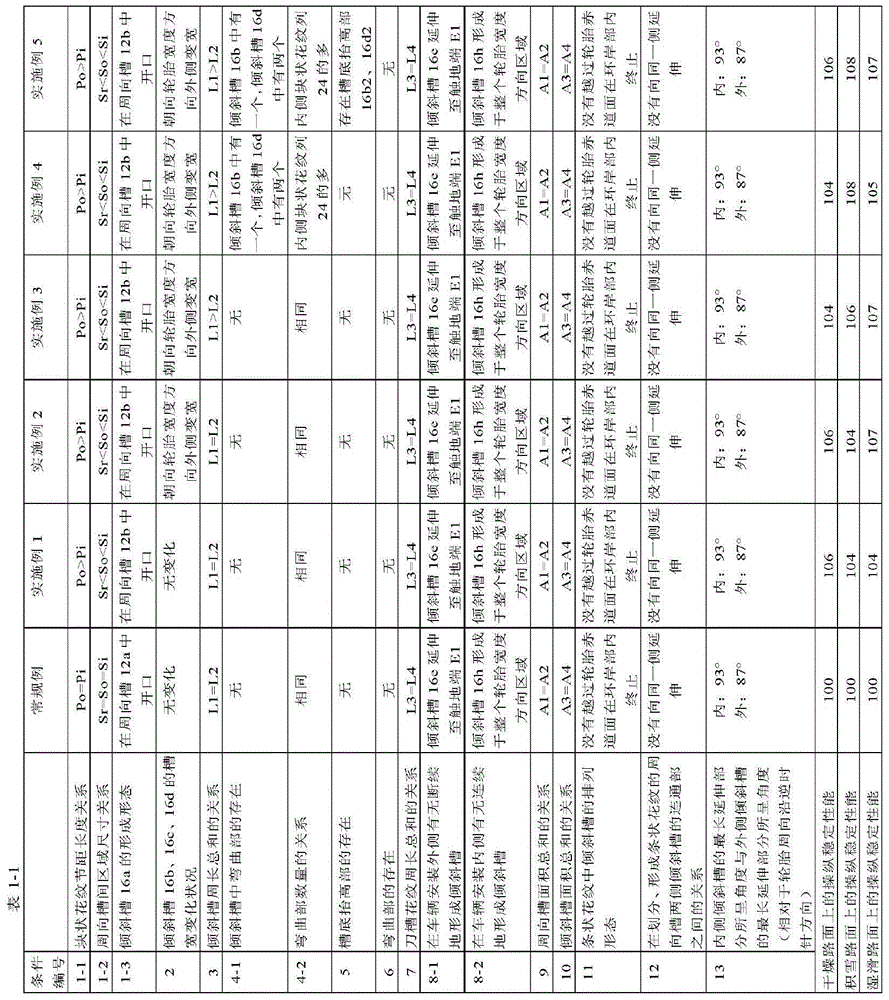

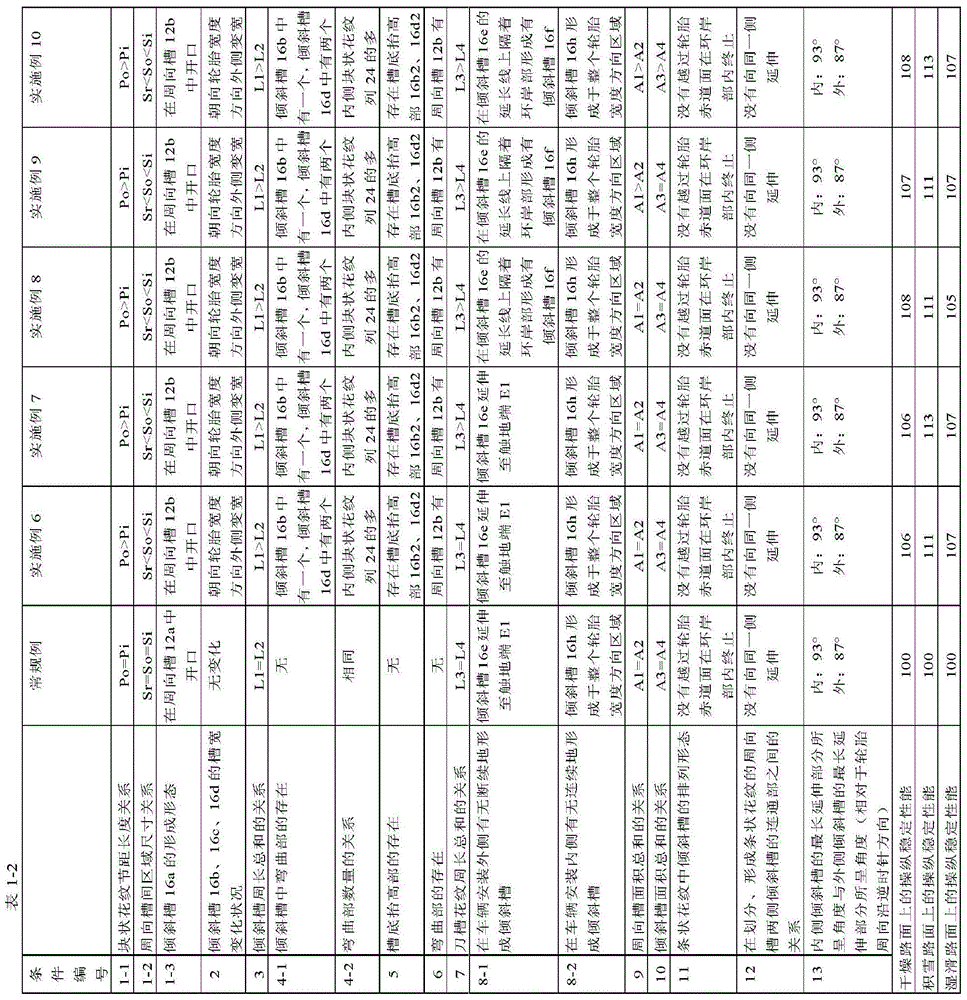

[0136] Set the tire size to 215 / 45R17 87W for figure 1 The components 12 to 30 shown are in accordance with the following conditions shown in Table 1-1 to Table 1-3:

[0137] (1-1) The relationship between the block pattern pitch length Po of the outer block pattern row 22 and the block pattern pitch length Pi of the inner block pattern row 24 (block pattern pitch length relationship),

[0138] (1-2) The relationship between the circumferential groove area sizes Sr, So, and Si of the strip pattern 20, the outer block pattern row 22, and the inner block pattern row 24 (the relationship between the circumferential groove area size),

[0139] (1-3) Formation of the inclined groove 16a for dividing and forming the striped pattern 20 (formation of the inclined groove 16a),

[0140] (2) The change of the groove width when the inclined grooves 16b, 16c that divide and form the outer block pattern row 22 and the inclined grooves 16d that divide and form the inner block pattern row 24 extend o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com