Film coating bearing frame

A carrier and tray technology, applied in the direction of sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of inconsistent film characteristics, time-consuming, and inability to maintain completely consistent environmental parameters, etc., to reduce The number of times of heating and vacuuming, and the effect of shortening the coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

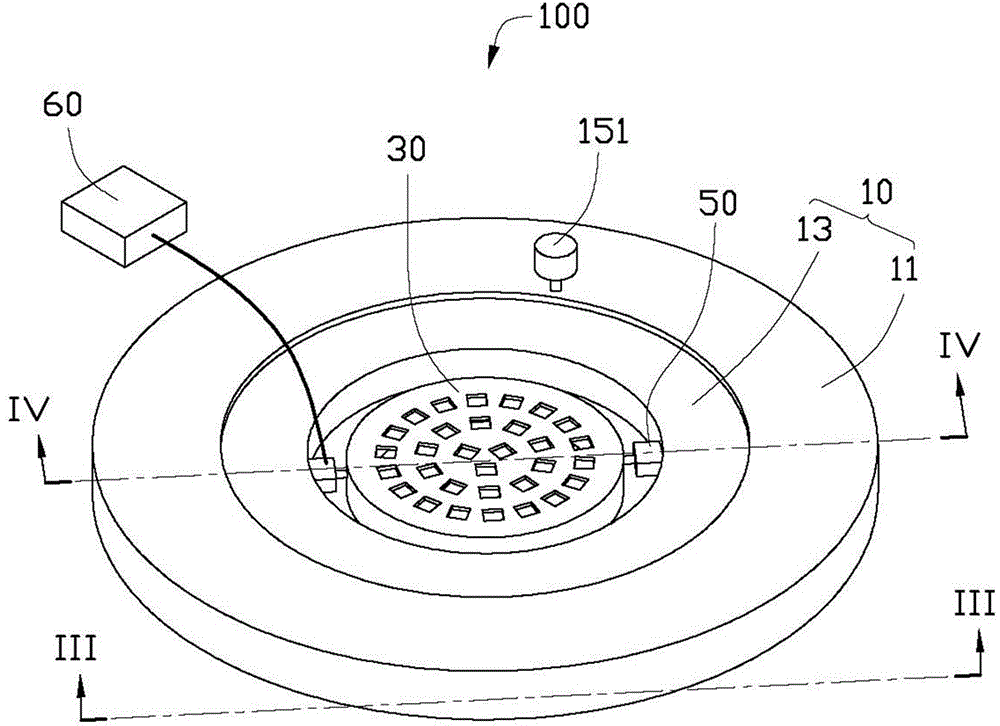

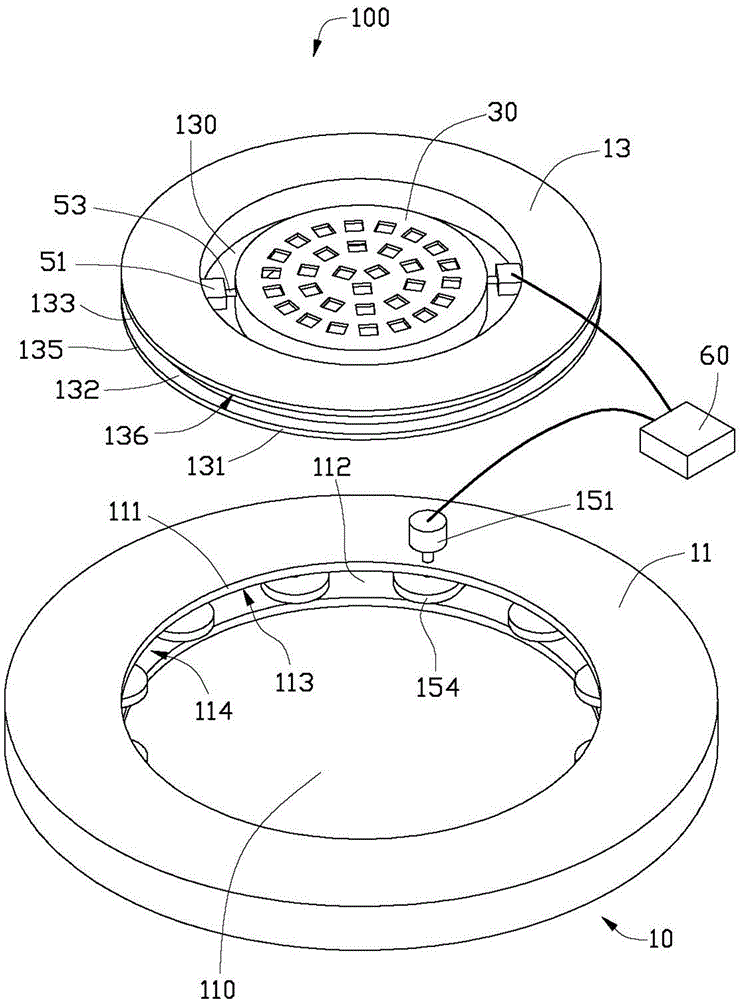

[0013] see figure 1 , is a coating carrier 100 provided in an embodiment of the present invention, which is used to carry a plurality of parts to be coated. The coating carrier 100 includes a base 10 , a carrier plate 30 , a turning assembly 50 and a controller 60 .

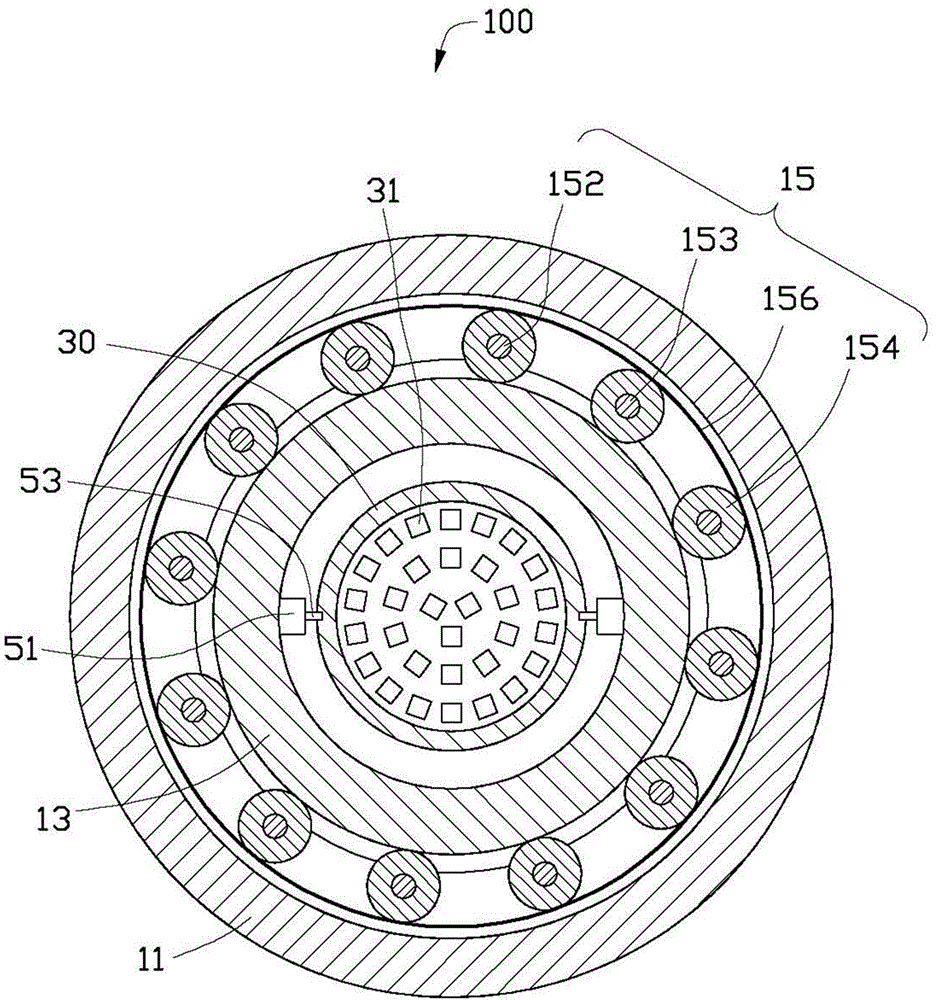

[0014] Such as figure 2 and image 3 As shown, the base 10 includes a disc-shaped outer frame 11 , a disc-shaped inner frame 13 and a rotating assembly 15 .

[0015] The outer frame 11 is fixed in a coating chamber (not shown). The outer frame 11 defines a first through hole 110 around its own center of circle to form a circular inner wall 111 . An accommodating groove 112 is defined on the inner wall 111 along its own circumferential direction. The accommodating groove 112 includes an annular upper surface 113 and an annular lower surface 114 opposite to the upper surface 113 .

[0016] The radius of the inner frame 13 is equal to the inner diameter of the first through hole 110, so that the inner frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com