Fluidized bed bottom spraying coating device

A fluidized bed and coating technology is applied in the direction of making medicines into special physical or taking form devices, which can solve problems such as troublesome operation and inability to guarantee coating effect, and achieve improved coating efficiency and coating effect. Good, the effect of shortening the coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

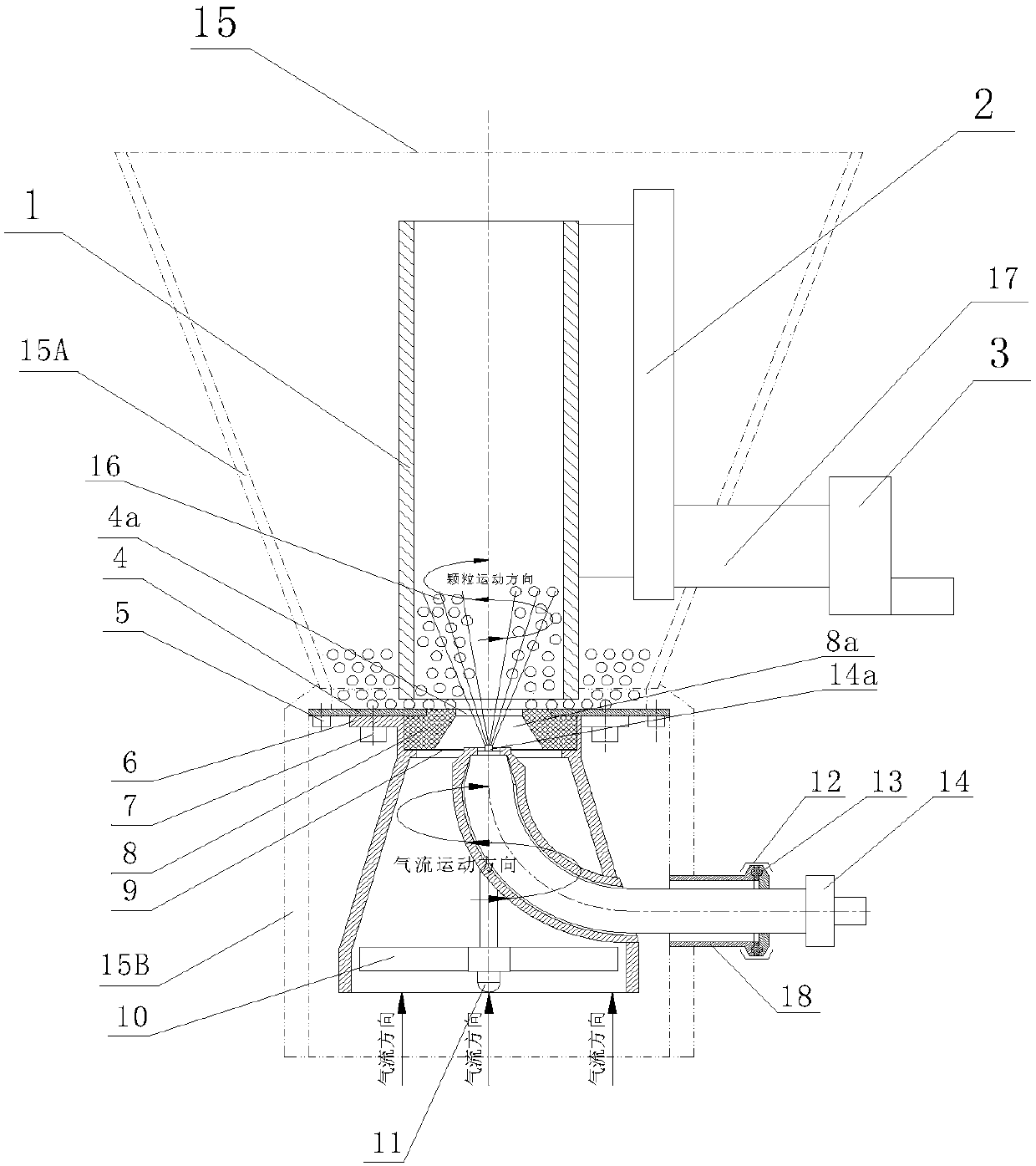

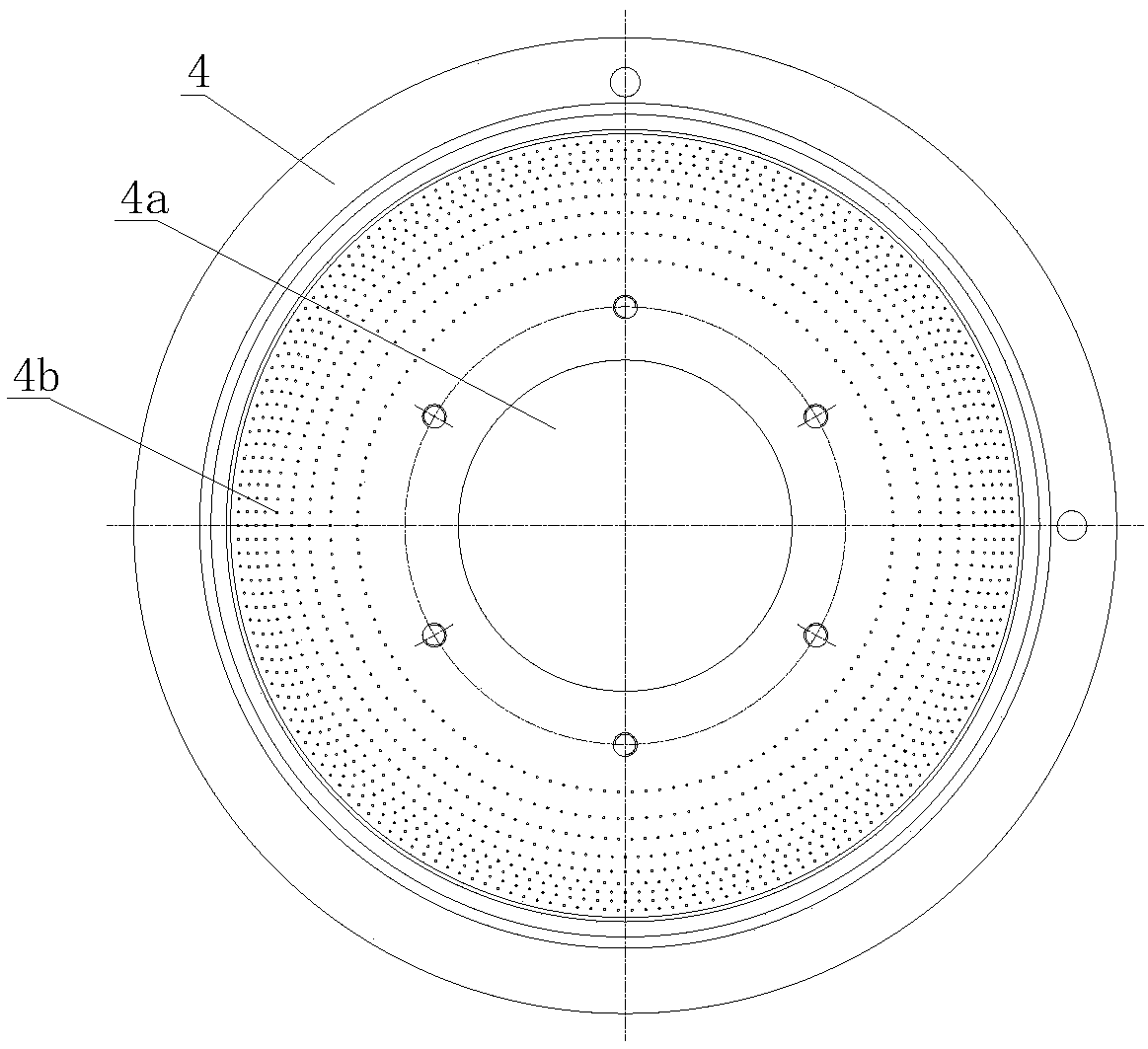

[0025] The technical solutions and beneficial effects of the present invention will be further described and illustrated below in conjunction with the above drawings.

[0026] see figure 1 , 2 , the figure shows a kind of fluidized bed bottom spray coating device that the present invention relates to, and its key technical scheme is:

[0027] The fluidized bed bottom spray coating device includes a fluidized bed body 15 with a hollow cavity, the fluidized bed body 15 includes an upper body 15A and a lower body 15B, and pharmaceutical particles 16 are placed in the hollow cavity of the upper 15A of the fluidized bed body;

[0028] A guide tube 1 is arranged coaxially and vertically in the hollow cavity of the upper part 15A of the fluidized bed body, and a guide tube lifting mechanism 2 is arranged on the axial outer side of the guide tube 1. The outer wall of the upper part 15A penetrates and is vertically connected to the rotating shaft 17 and is indirectly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com