Patents

Literature

37results about How to "Does not affect production operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shore power supply for ship

InactiveCN102255517AReduce the numberReduce noiseFlexible AC transmissionConversion with intermediate conversion to dcLow voltageAlternating current

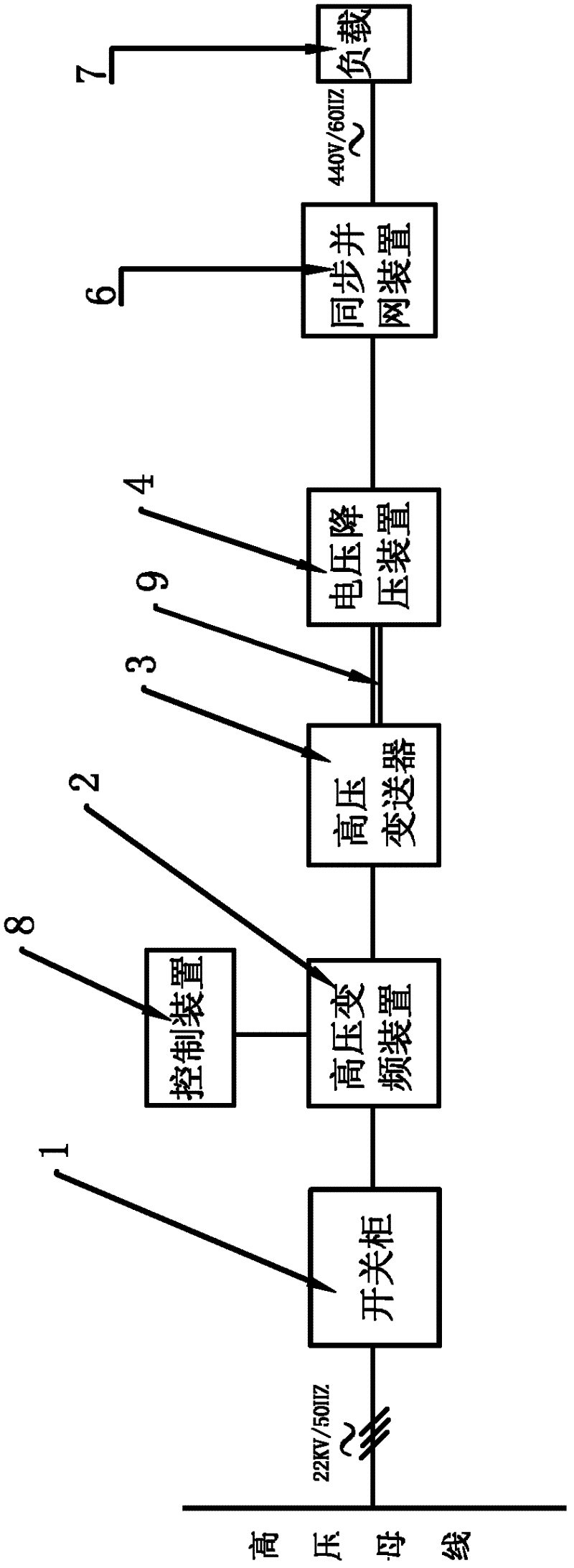

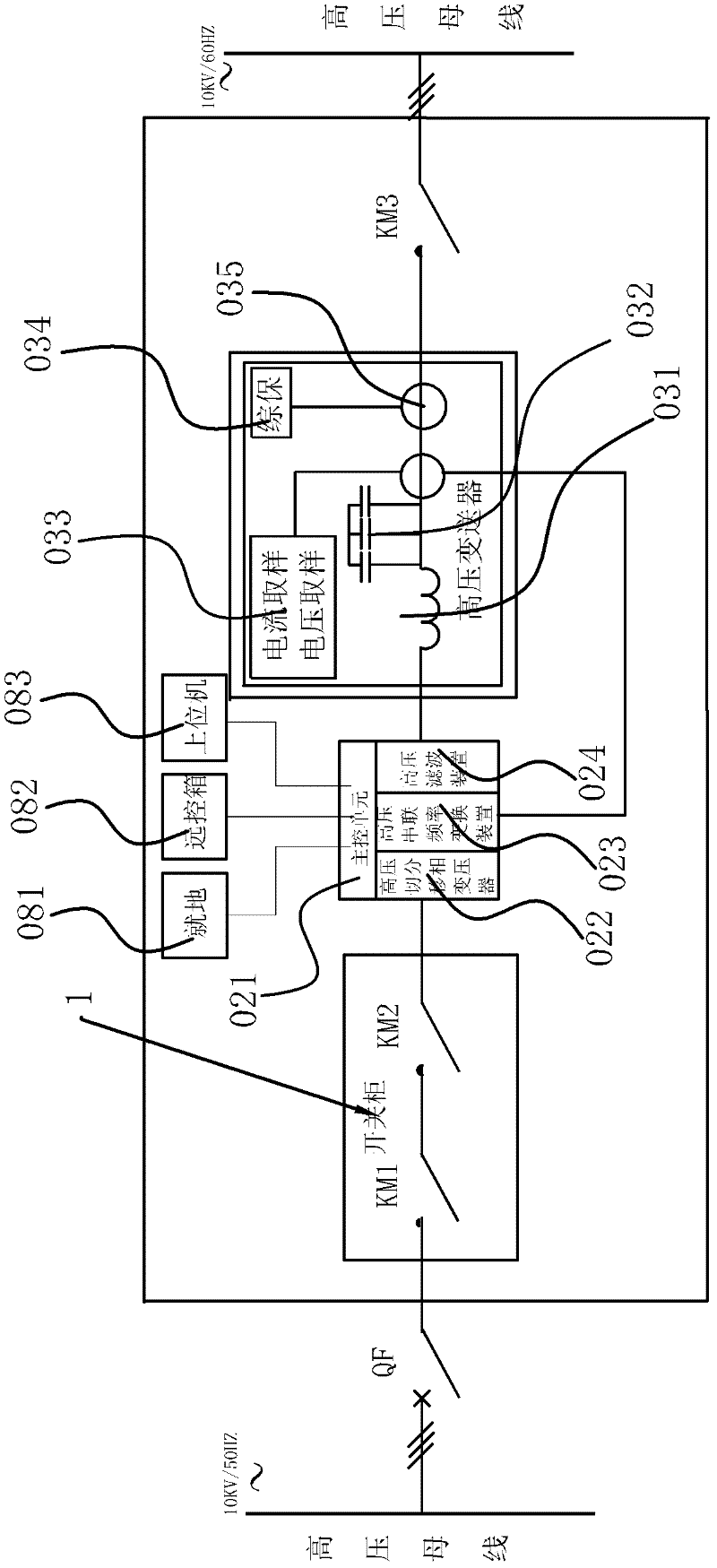

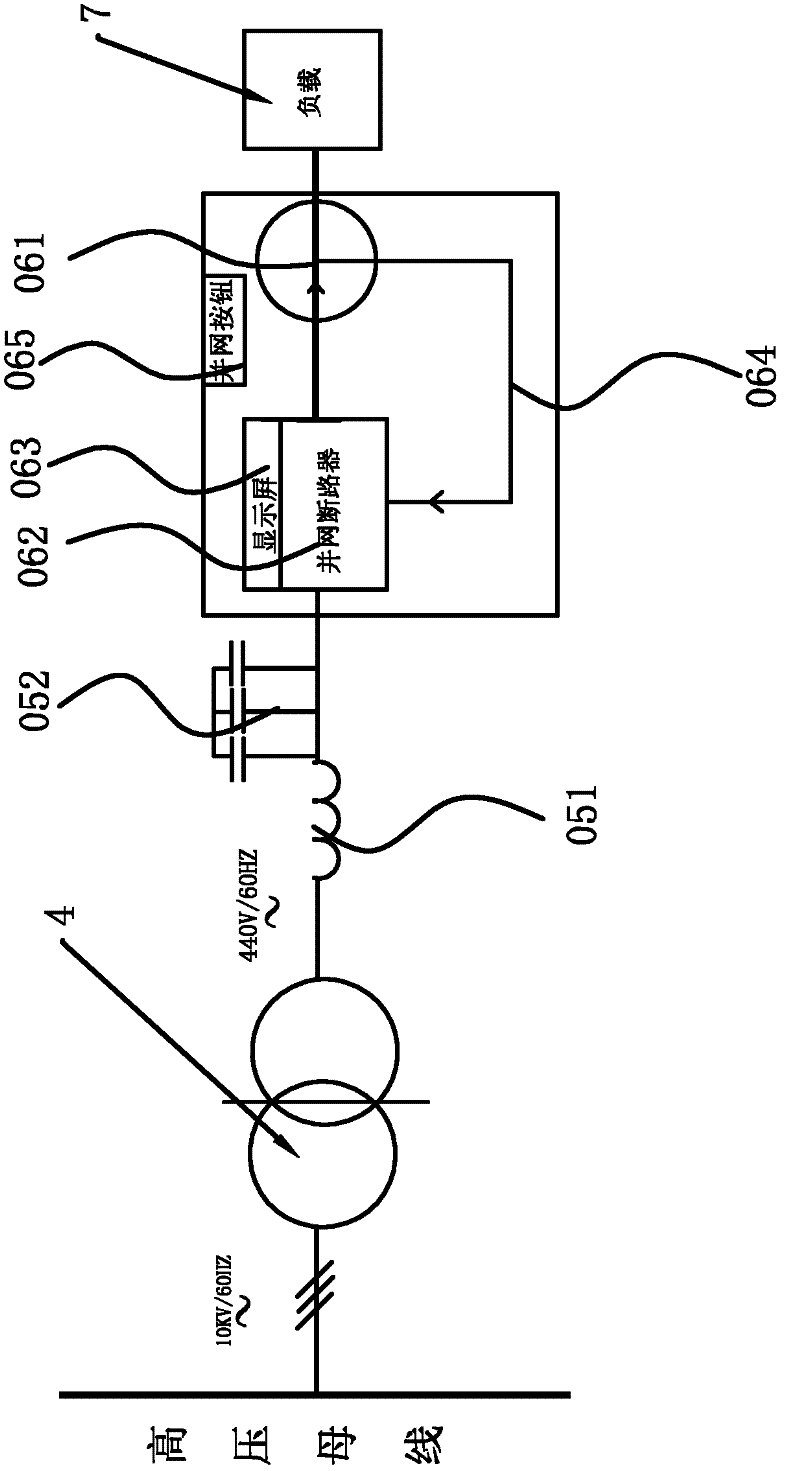

The invention provides a shore power supply for a ship, which belongs to the technical field of ship power supplies and is used for solving the problems that power cannot be supplied remotely or supplied to large-sized ships, uninterrupted parallel running of chips cannot be realized and the like. The shore power supply for the ship comprises a switch cabinet, a shoreside high-voltage frequency conversion device, an onboard voltage reducing device and a synchronous grid-connected device, wherein the shoreside high-voltage frequency conversion device is connected with the switch cabinet; the high-voltage side of the high-voltage frequency conversion device is connected with the high-voltage side of the voltage reducing device through a high-voltage cable; the low-voltage side of the voltage reducing device is connected with the synchronous grid-connected device; three-phase high-voltage alternating current can be subjected to cutting, phase shifting, rectifying and inverting by using the high-voltage frequency conversion device to obtain needed frequency; and three-phase alternating current which is subjected to frequency conversion and voltage reduction can be seamlessly combined into a power grid of the ship, and the power supply of the ship can be switched off by using the synchronous grid-connected device. By adopting the shore power supply, remote power supply or power supply for large-sized ships can be realized, automatic grid-connected operation can be realized, the ship runs unremittingly, and normal production operation is not influenced.

Owner:ZHEJIANG NEW FOLINN ELECTRIC

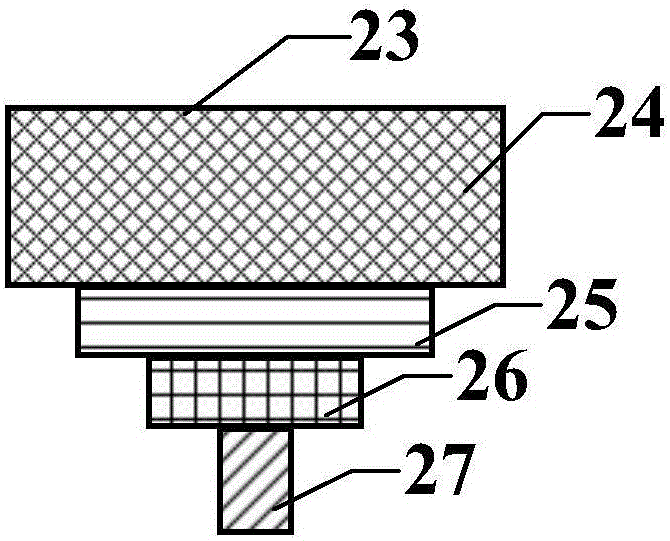

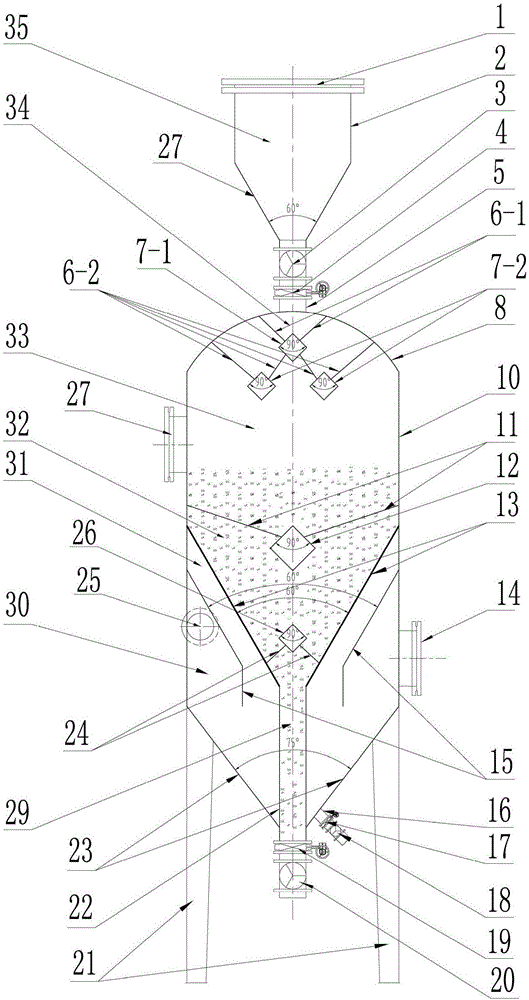

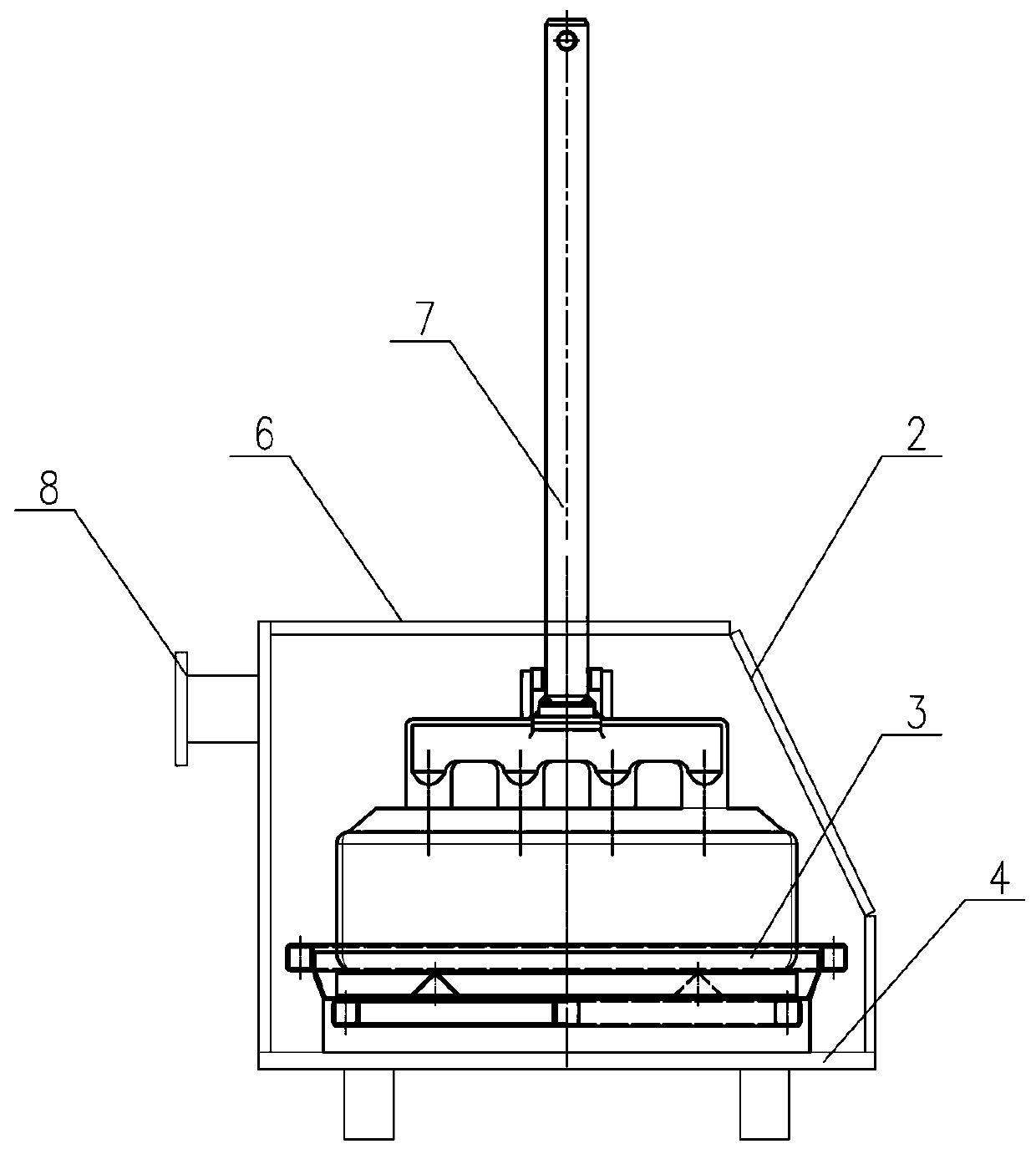

Fluidized bed bottom spraying coating device

PendingCN107638295ARun as usualRealize online gun clearingPharmaceutical product form changeFluidized bedSpray nozzle

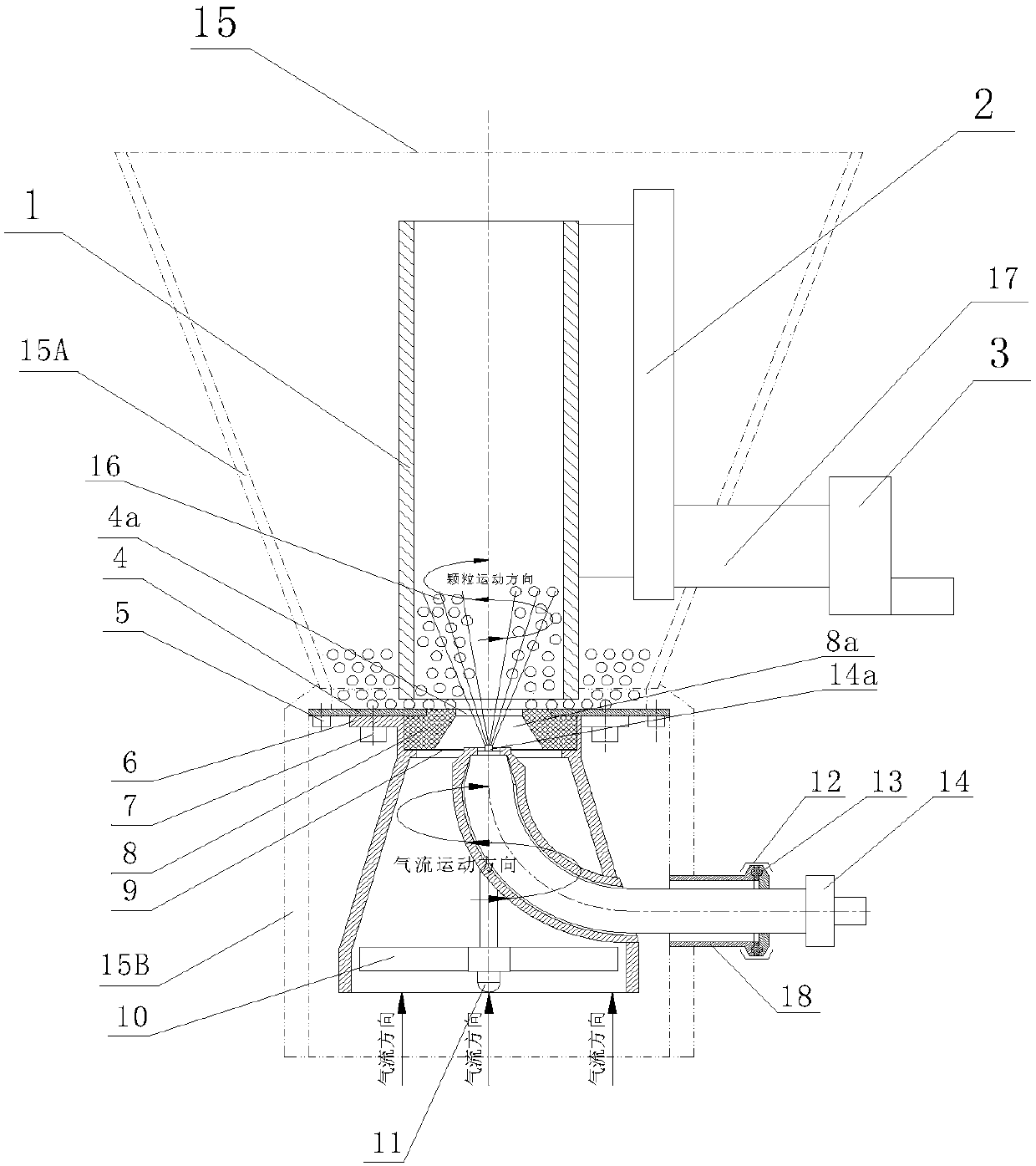

A fluidized bed bottom spraying coating device comprises a fluidized bed body with a hollow cavity, and the fluidized bed body comprises an upper body part and a lower body part; the upper body part is provided with pharmaceutical granules and coaxially and vertically provided with a flow guide cylinder; a flow guide cylinder lifting mechanism is arranged on the axial outer side of the flow guidecylinder, and the flow guide cylinder lifting mechanism is indirectly connected with a hand wheel through a rotating shaft; an air flow distribution plate is arranged below the bottom of the flow guide cylinder, an air flow hole communicated with the inner cavity of the flow guide cylinder is formed in the middle of the air flow distribution plate; the air flow distribution plate is connected withthe lower body part; a spray gun mounting base is arranged in the cavity of the lower body part, the top of the spray gun mounting base is connected with the air flow distribution plate; the lower body part is provided with a spray gun base, and a coating spray gun is arranged on the spray gun base; a pressing block is arranged on the air flow distribution plate; a conical center hole is formed in the pressing block, and an intercepting net is arranged on the bottom surface of the pressing block; a nozzle of the spray gun directly faces the conical center hole of the pressing block and protrudes out of the top surface of the intercepting net. By means of the coating device, online gun cleaning is achieved, and operation is convenient; the granules move spirally, the coating effect is good, the coating time is short, and the coating efficiency is high.

Owner:SHANGHAI HAN OU PHARMA EQUIP CO LTD

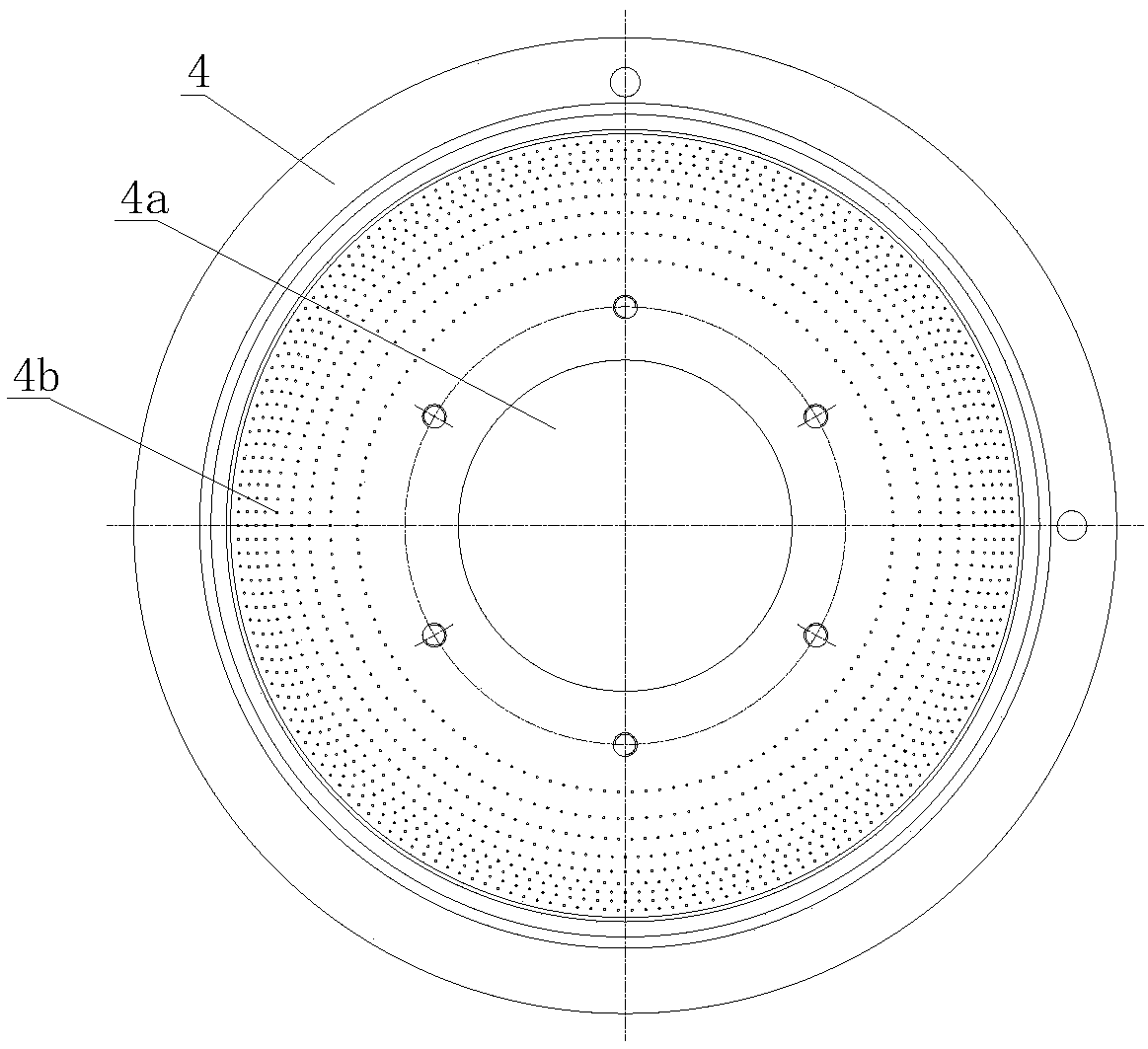

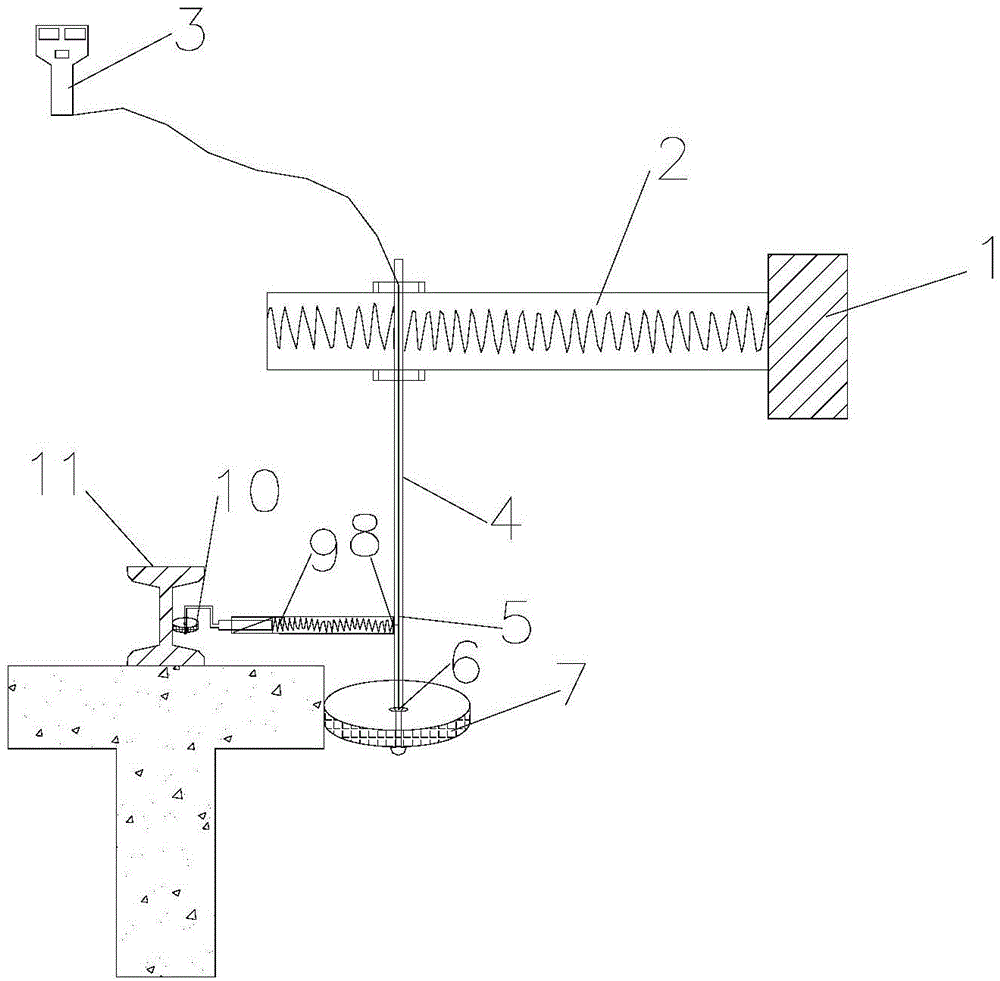

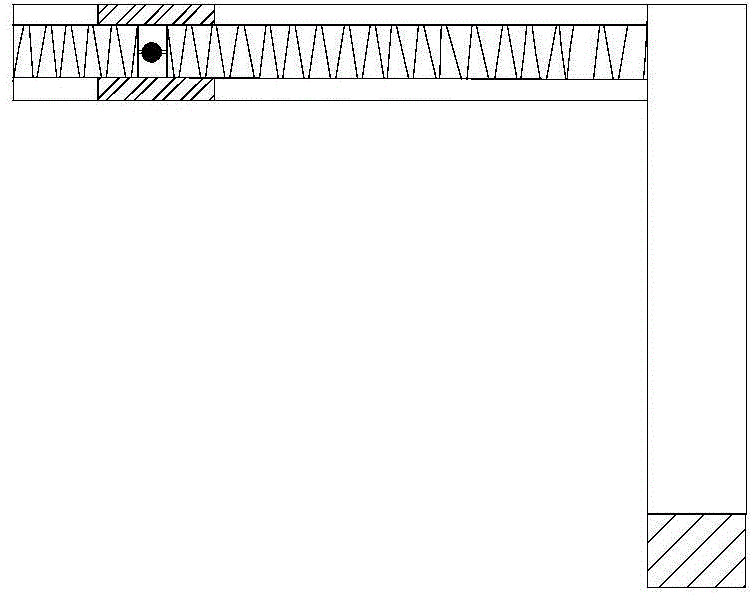

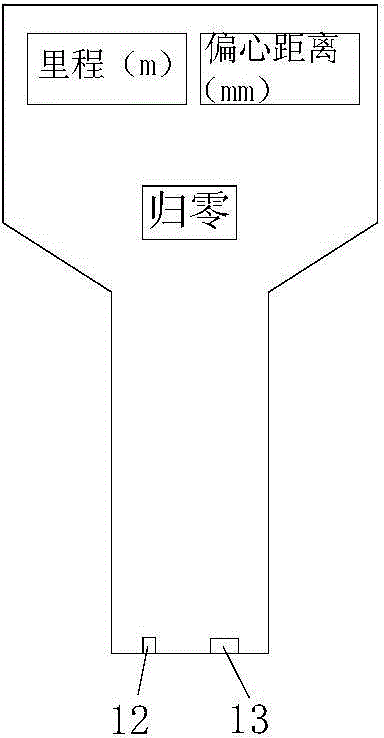

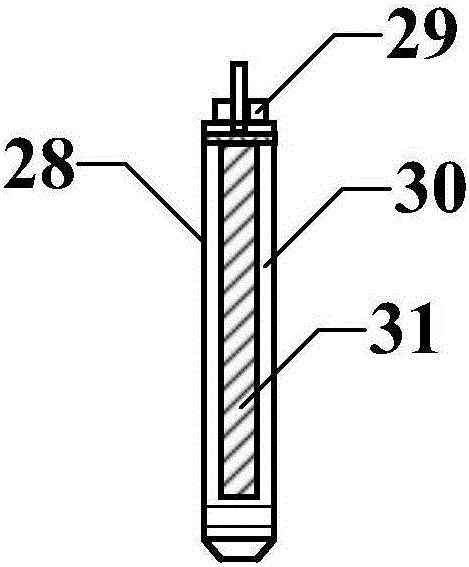

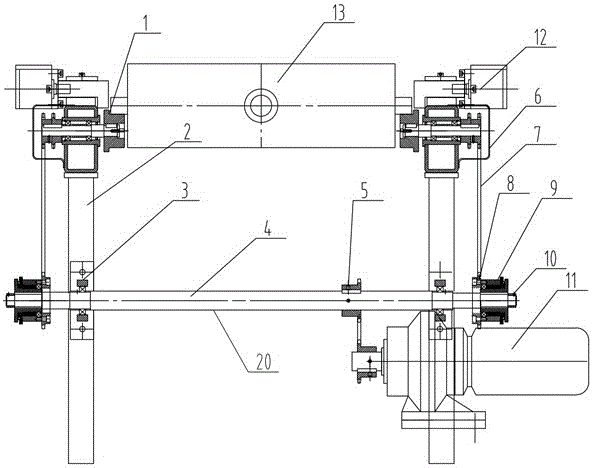

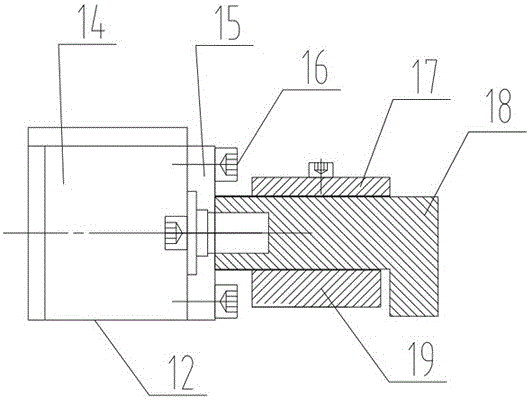

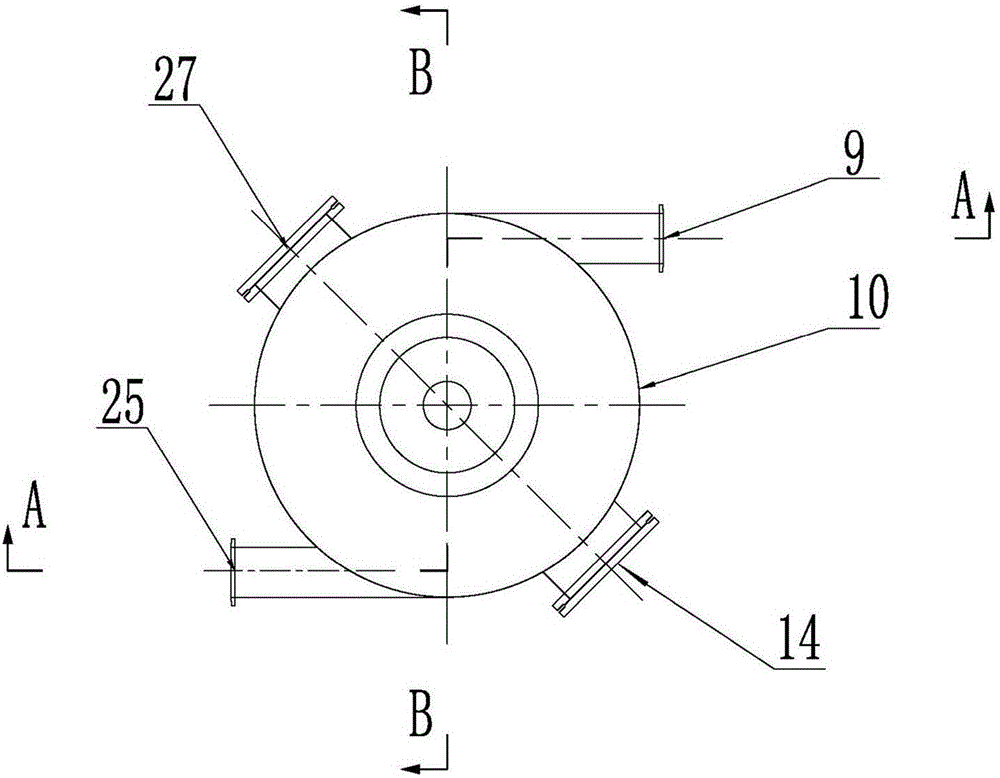

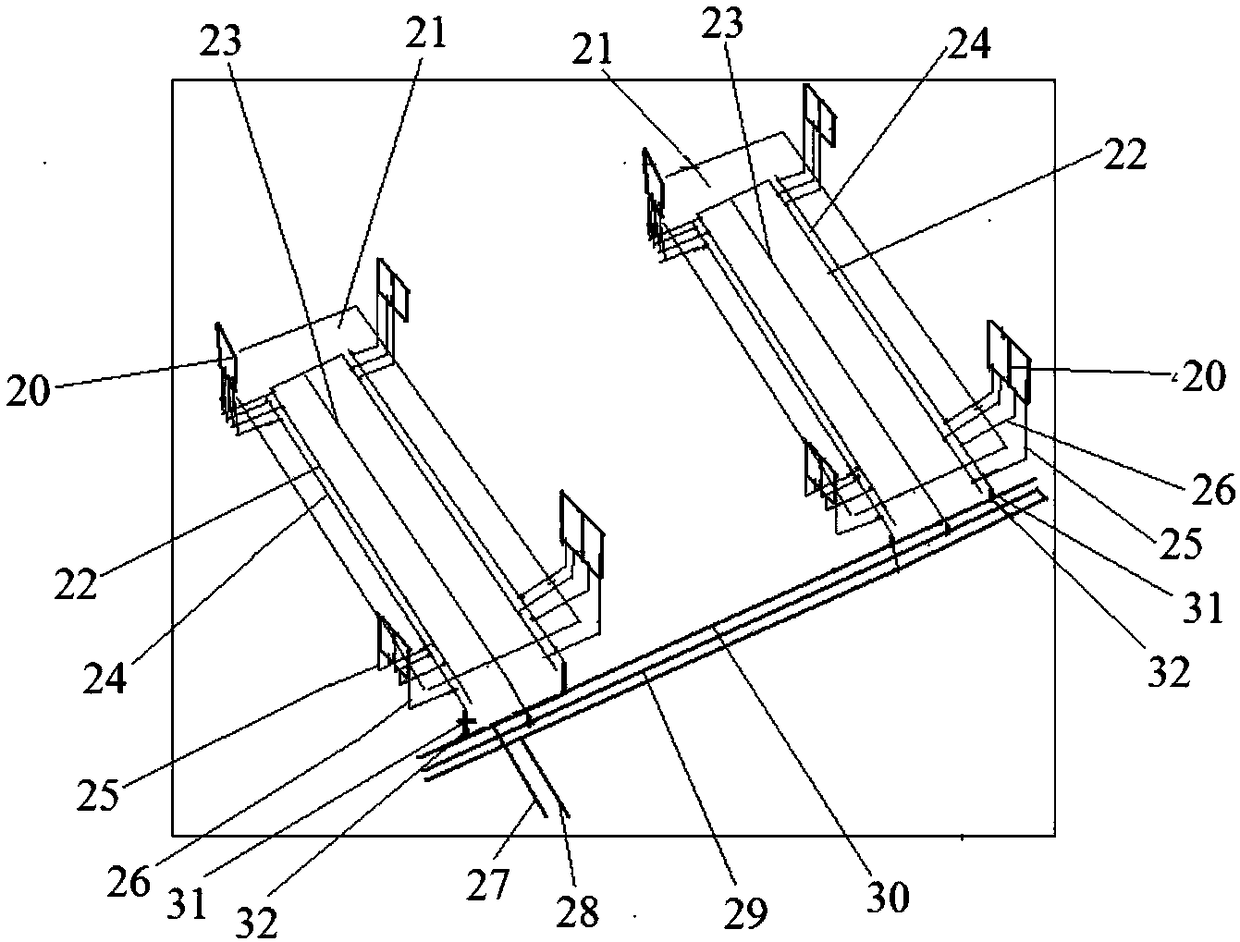

Crane beam track eccentricity measurement device and method

ActiveCN104535039AAccurate measurementDoes not affect production operationsMeasurement devicesSupporting systemMeasurement device

The invention relates to a crane beam track eccentricity measurement device and method, and belongs to the field of structure detection and appraisal for industrial buildings. The device is mainly composed of an electromagnet base and support system, a pressure sensor, a journey recording device, a portable reading instrument, a big wheel and a small wheel. The whole device is fixed to an overhead travelling crane through the electromagnet base and support system, the big wheel is located on the side edge of a crane beam flange, the small wheel is located on the side edge of a track beam web, and the pressure sensor and the journey recording device are installed on a support system and connected with the portable reading instrument through data lines. The crane beam track eccentricity measurement device is convenient to disassemble, easy to operate, and capable of fast detecting crane beam track eccentricity on the premise of not affecting production and ensuring accuracy and visualizability of detecting data and suitable for regular self-inspection of various industrial factory buildings or special detection units.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

CCUS system for extracting oil based on gas lifting method and application thereof

ActiveCN105114045AReduce manufacturing costEasy to recycleOther gas emission reduction technologiesCleaning apparatusGrounding gridChemistry

The invention discloses a CCUS system for extracting oil based on a gas lifting method and application thereof. The CCUS system comprises an extraction pipeline, a carbon dioxide pipeline, a natural gas pipeline, a gas generator set and an electric heating paraffin removal device, wherein the extraction pipeline is used for separating a gas source into carbon dioxide and natural gas; one part of the natural gas is used for extracting oil of a gas lifting well set by using the gas lifting method; the other part of the natural gas is used for supplying power to the electric heating paraffin removal device through the gas generator set. According to the design of the CCUS system, the power supply cost and the technique difficulty of ground grids are reduced; the grid load is reduced; the extracted natural gas can be utilized on site; both the carbon dioxide generated by extracting oil and the carbon dioxide discharged by the gas generator set are used for extracting the oil of the gas lifting well set by using the gas lifting method, so that the recycling rate of the carbon dioxide is greatly increased and the emission of the carbon dioxide is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

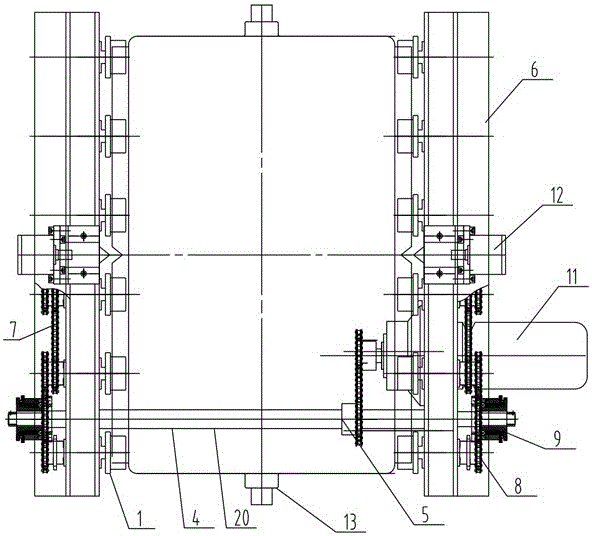

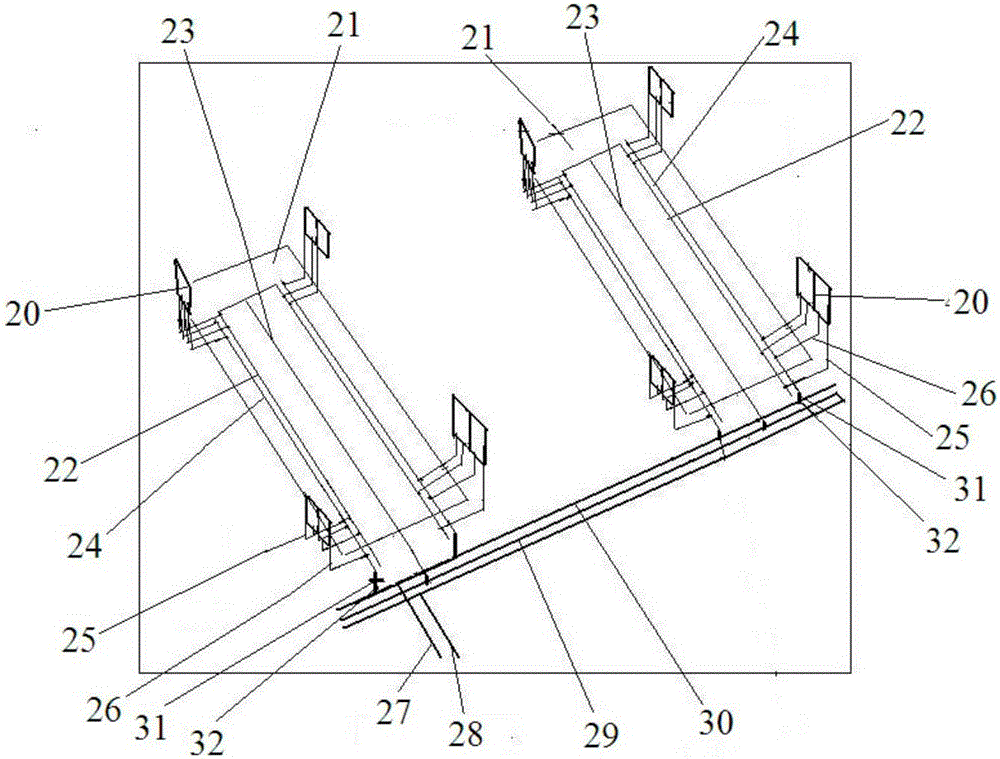

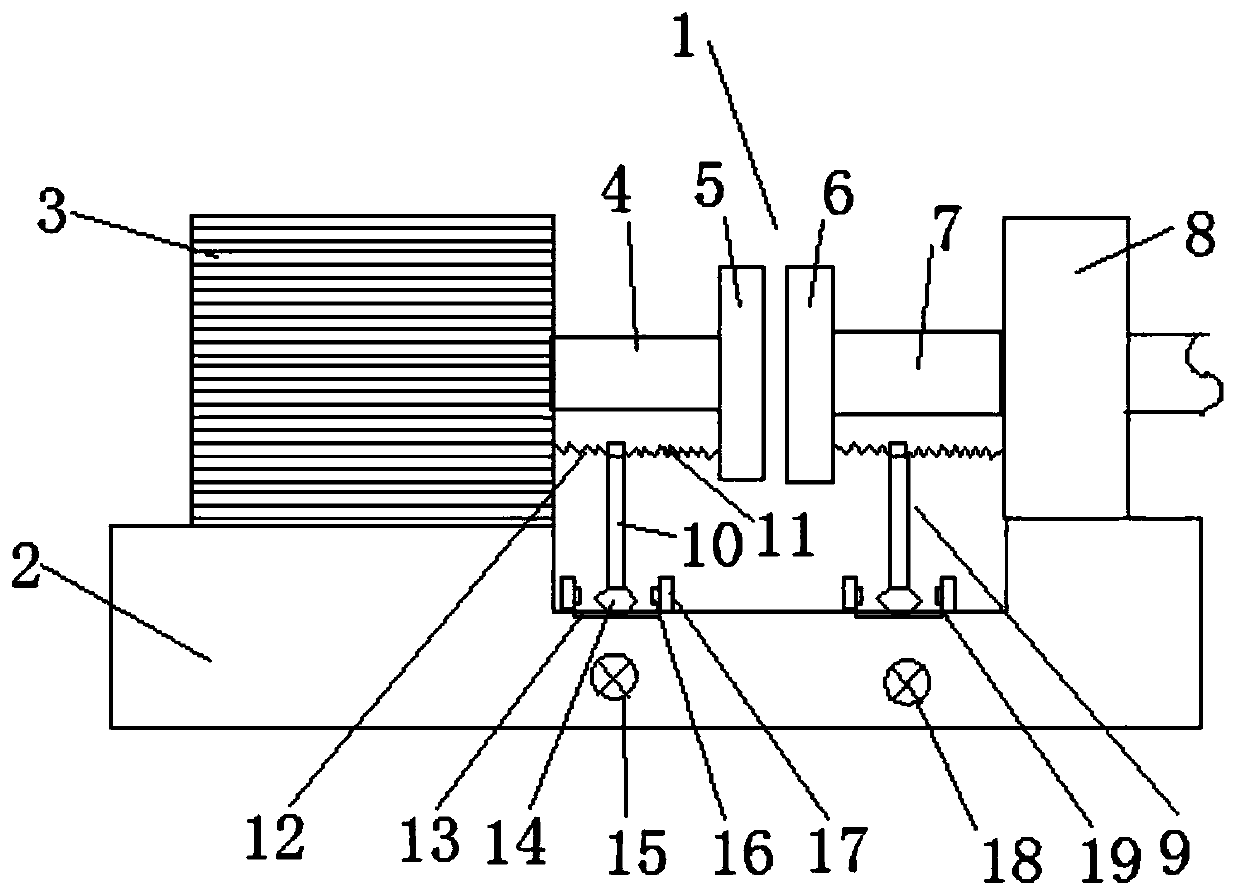

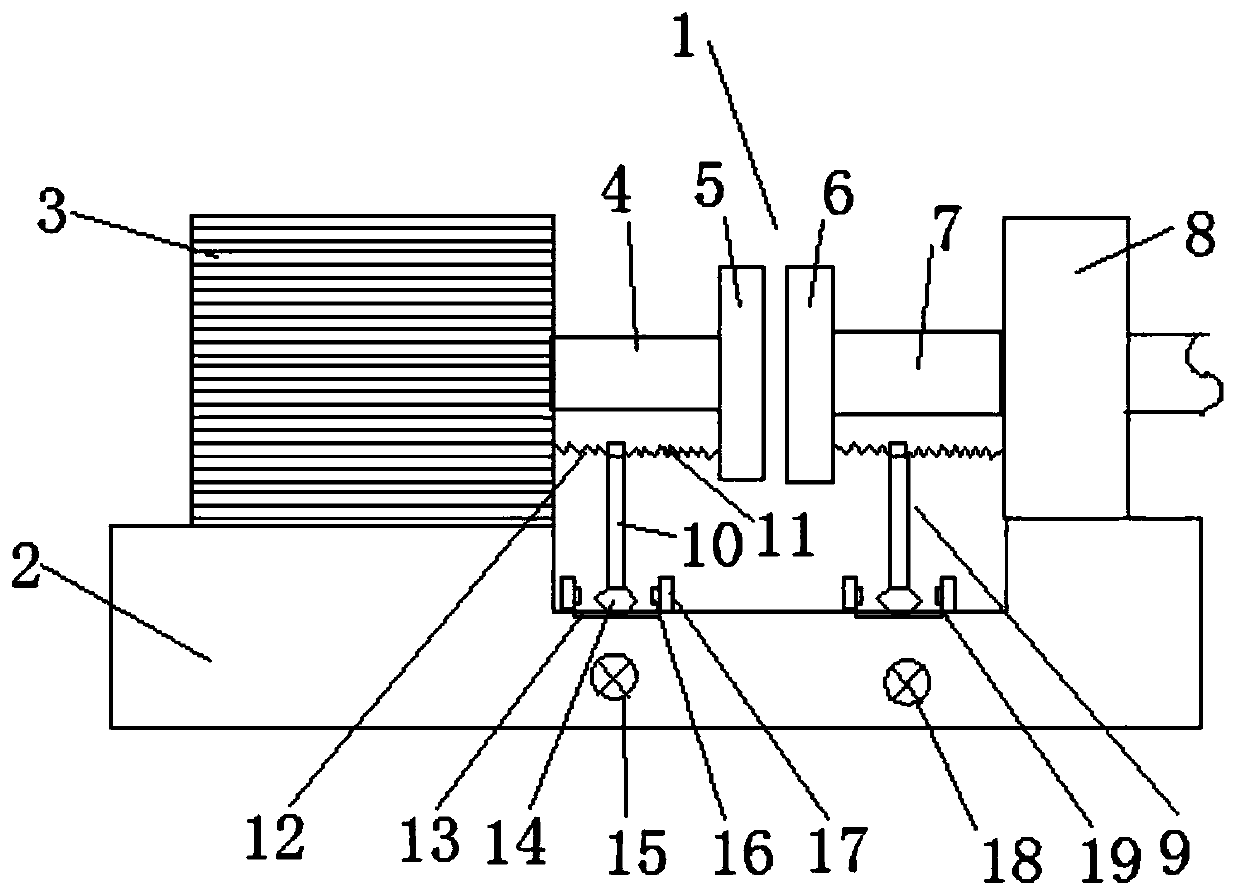

Iron mold power rollgang device

InactiveCN105752673AAccurate positioning accuracyExtended service lifeConveyorsConveyor partsProduction lineDrive shaft

The invention relates to an iron mold power rollgang device, and belongs to the field of sand-lined iron mold casting equipment.The iron mold power rollgang device comprises a rollgang frame, a motor, a plurality of roll mechanisms, a positioning and clamping mechanism and a transmission mechanism.The roll mechanisms are installed on the rollgang frame.The motor is fixed to the rollgang frame.The transmission mechanism comprises a bearing pedestal, a driving shaft, a chain wheel, a chain, a clutch chain wheel and a clutch, the clutch chain wheel is fixed to the clutch, and the driving shaft is fixed to the rollgang frame through the bearing pedestal and is connected with the motor through the chain wheel and the chain.The positioning and clamping mechanism is fixed to the rollgang frame.The iron mold power rollgang device is simple and reasonable in structure, high in production efficiency and small in occupied space, the problems that iron molds on a sand-lined iron mold production line are difficult to convey, and iron molds and rolls are seriously abraded are solved, and accurate positioning is achieved.

Owner:浙江省机电设计研究院有限公司

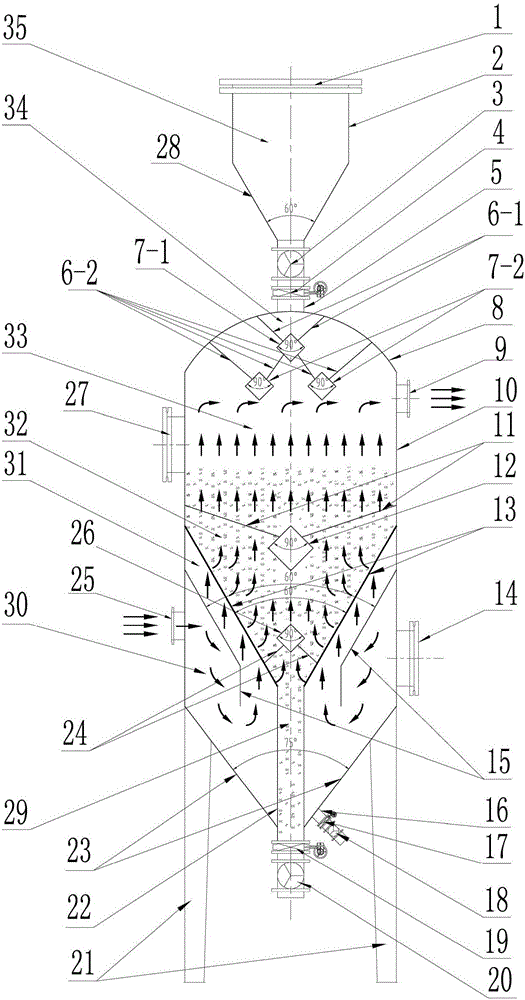

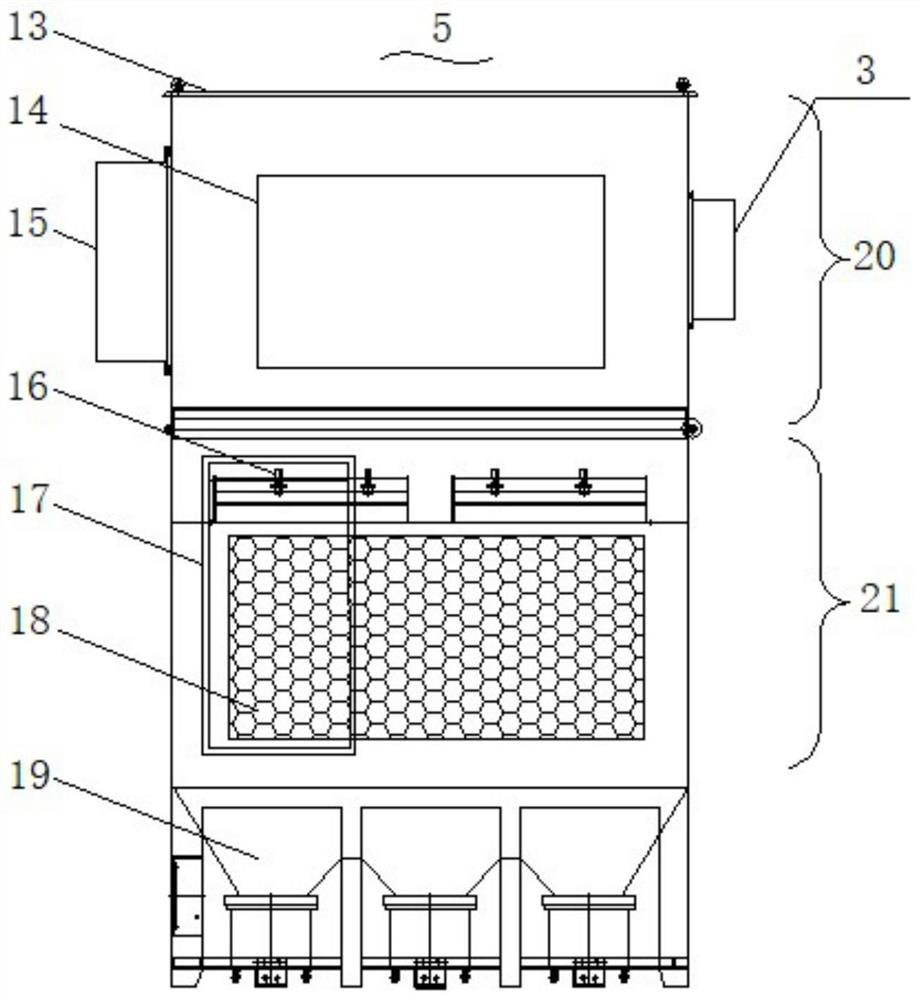

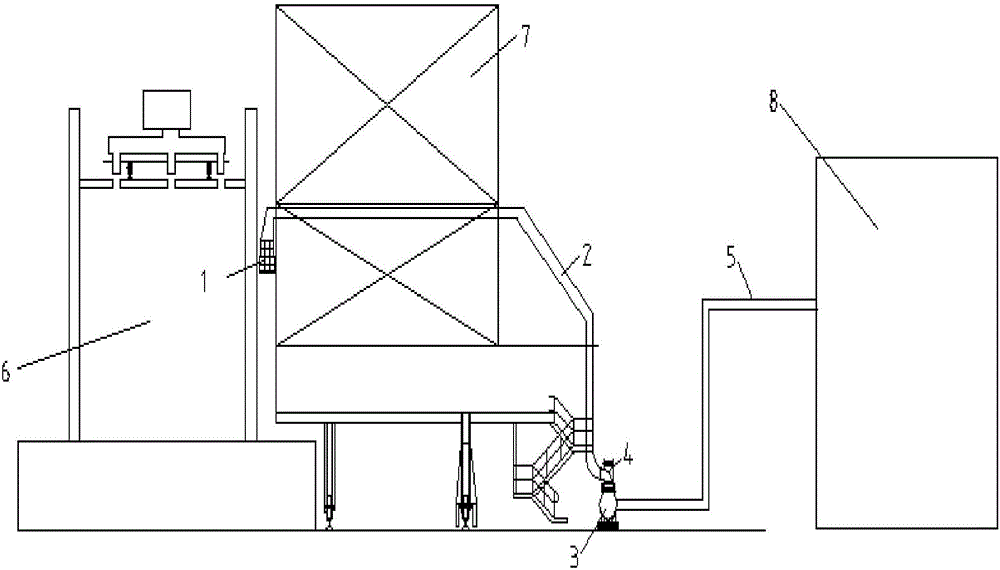

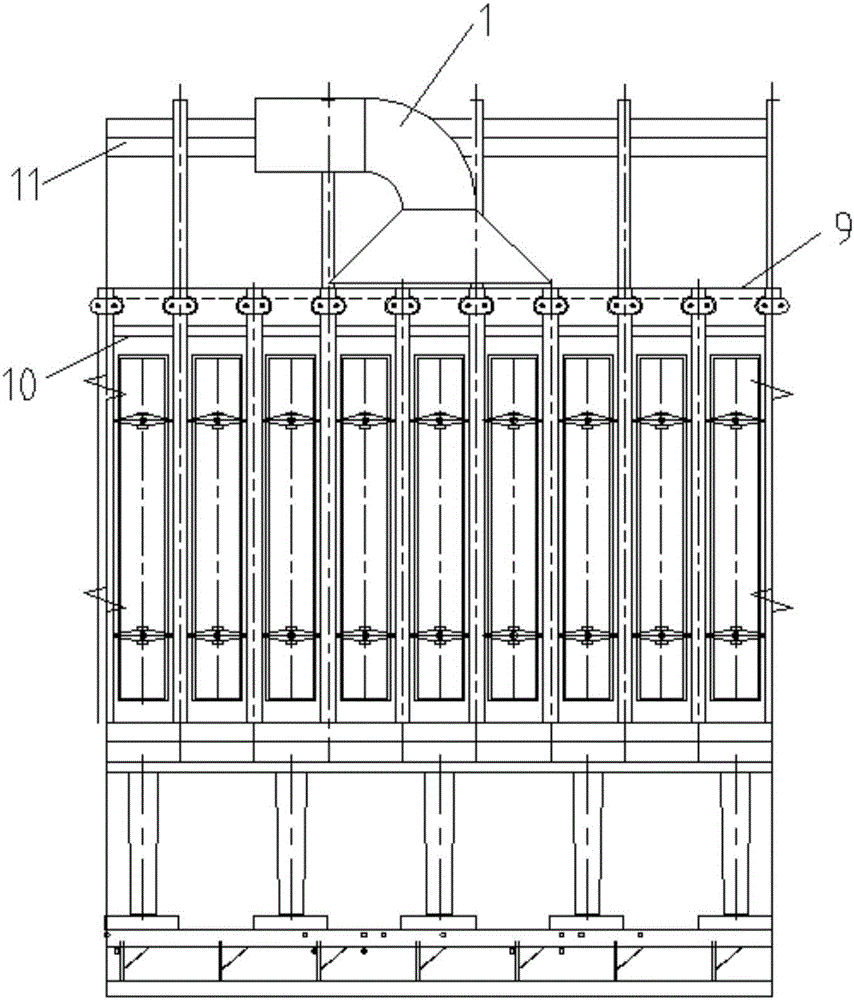

Activated carbon flowing bed adsorption combination device for adsorbing dust and organic waste gas

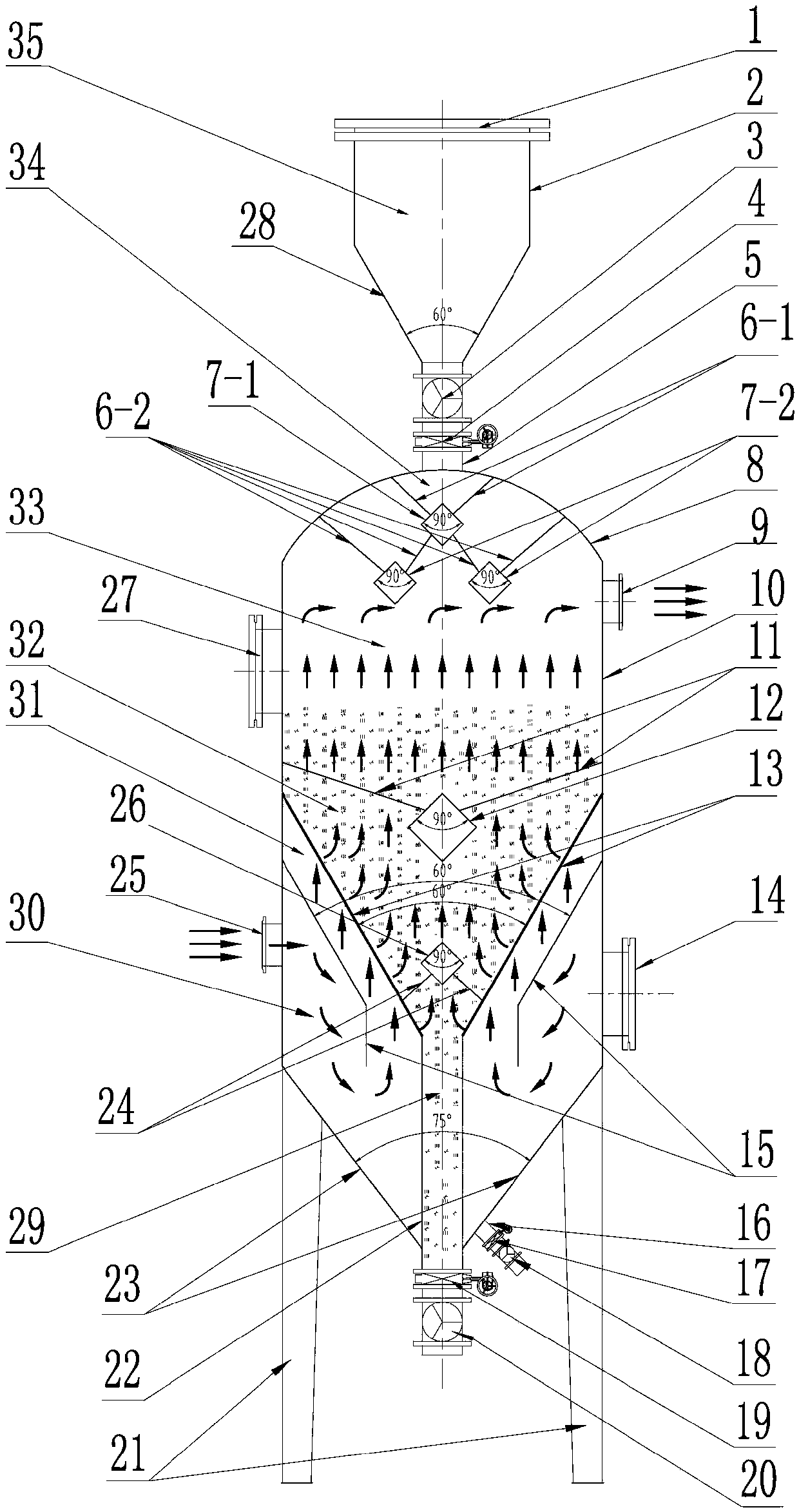

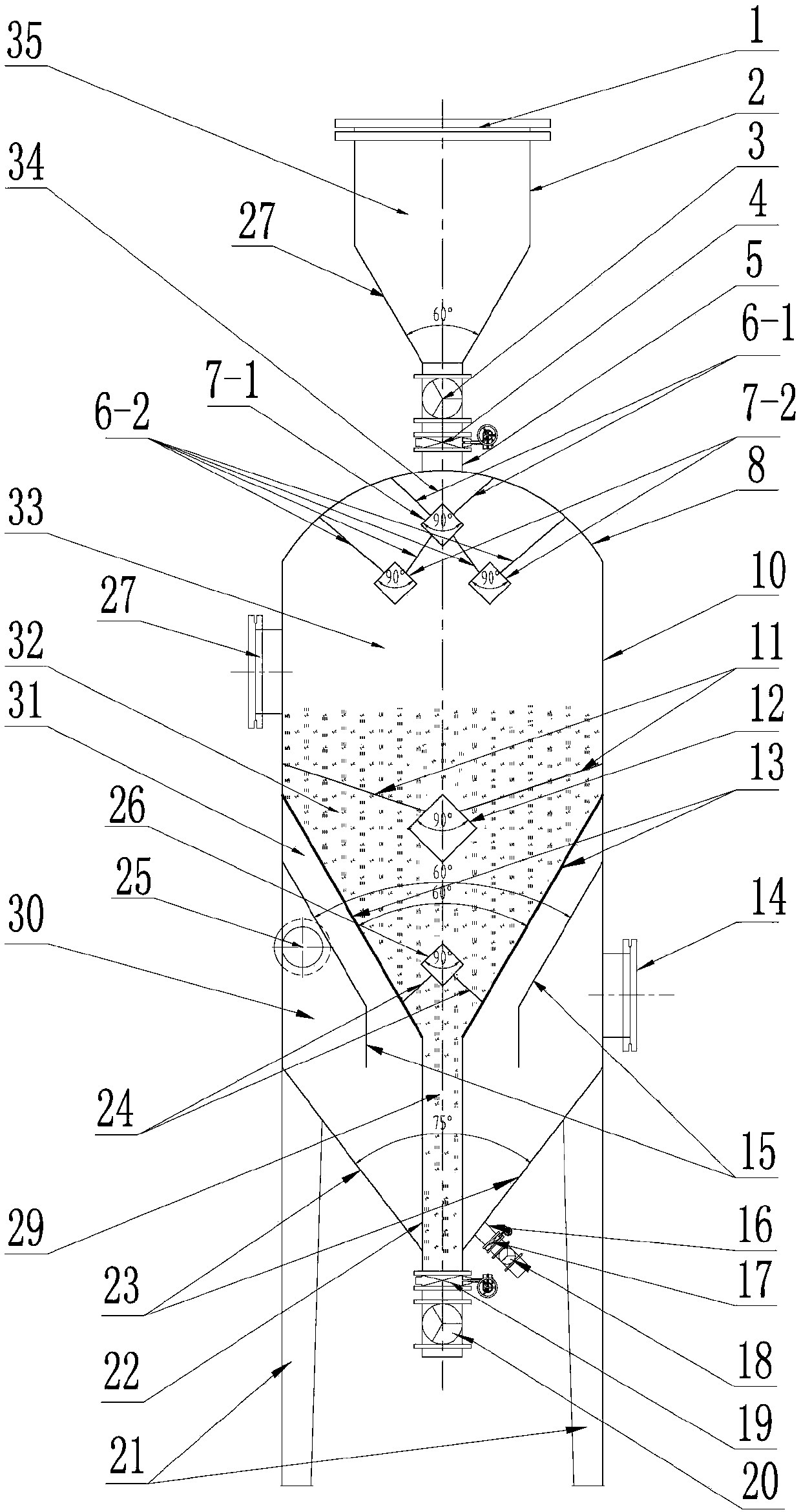

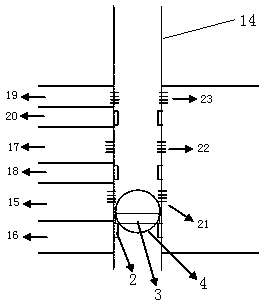

ActiveCN106166431AReduce labor operation intensityEasy to operateCombination devicesGas treatmentModular compositionGas solid

The invention relates to a device for treating dust and organic waste gas, in particular to a treatment combination device which adsorbs dust and organic waste gas through an activated carbon flowing bed. The device sequentially comprises seven function areas which are a fresh activated carbon storage area, a fresh activated carbon feeding equal-allocation area, a purified gas buffer area, an activated carbon distribution area, a rotational flow uniform air-distributing area, a waste gas gas-solid hydrocyclone separation area and an area for discharging activated carbon subjected to adsorption saturation. The latter six areas are located in a working barrel, and the working barrel is composed of a sealing head, a barrel body and a conical hopper from top to bottom. The working barrel is installed on a supporting leg. The activated carbon flowing bed adsorption combination device is of a series modularized composite structure. Gas-solid hydrocyclone separation, activated carbon granule adsorption, fresh activated carbon feeding and operation of discharging recycling of activated carbon subjected to adsorption saturation can be performed simultaneously, operators' labor operation intensity is reduced, operation steps are simplified, and the organic waste gas can be adsorbed continuously.

Owner:江苏江大环境工程有限责任公司

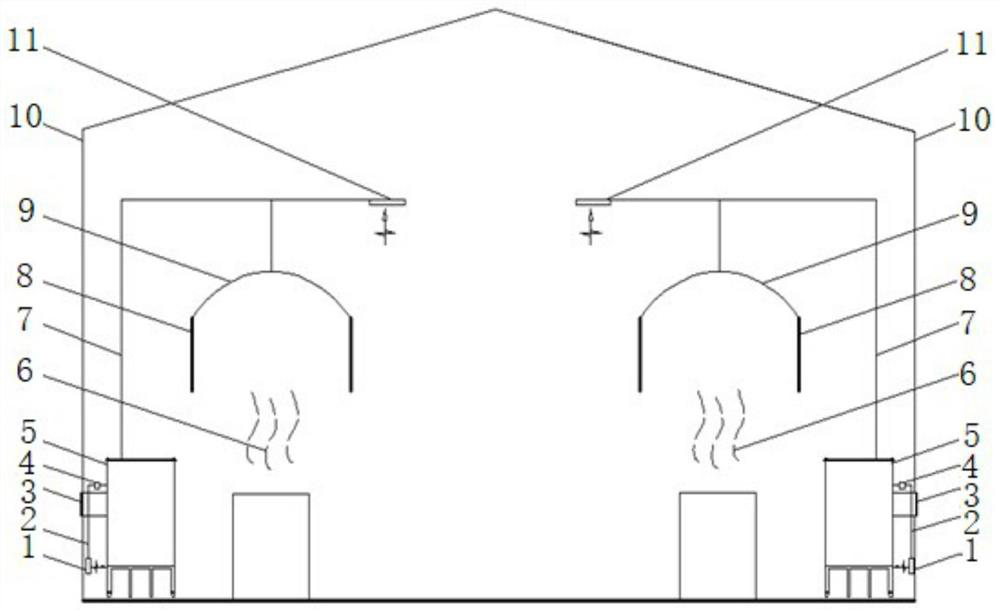

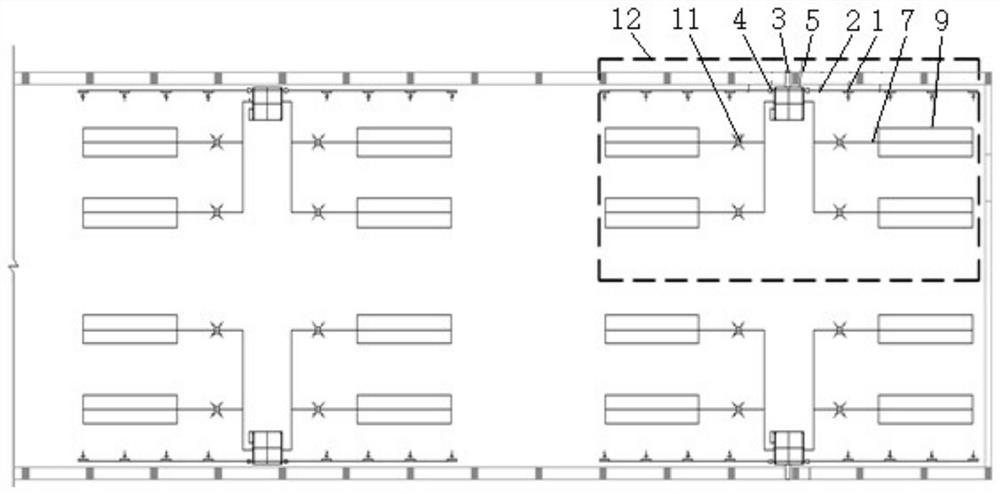

Partitioned joint control purification system for plant dust treatment

PendingCN111750480AAchieve independent governanceReduce passive energy consumptionGas treatmentMechanical apparatusControl systemHigh energy

The invention discloses a partitioned joint control purification system for plant dust treatment. The system comprises a plurality of air treatment units corresponding to all dust generation areas ina factory. Each air treatment unit comprises a dust removal unit, an air supply pipeline and an air return pipeline, wherein the air supply pipeline and the air return pipeline are respectively connected with the dust removal unit, an air supply port of the air supply pipeline communicates with the interior of the factory, and at least one air return port communicating to the corresponding dust generation area is formed in the air return pipeline. The dust generation areas are provided with dust concentration sensors serving as signal triggering units of the air treatment units of the dust generation areas and are in feedback connection with a control system of the air treatment units. By monitoring the dust distribution condition in each dust generation area in real time, controllers coordinate starting, stopping and frequency-variable operation of each dust removal unit. By adopting the air treatment units to carry out partitioned control on the whole factory production area, modulararrangement can be realized, and meanwhile, the problem of high energy consumption of part of areas in the large-space production factory during work is solved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

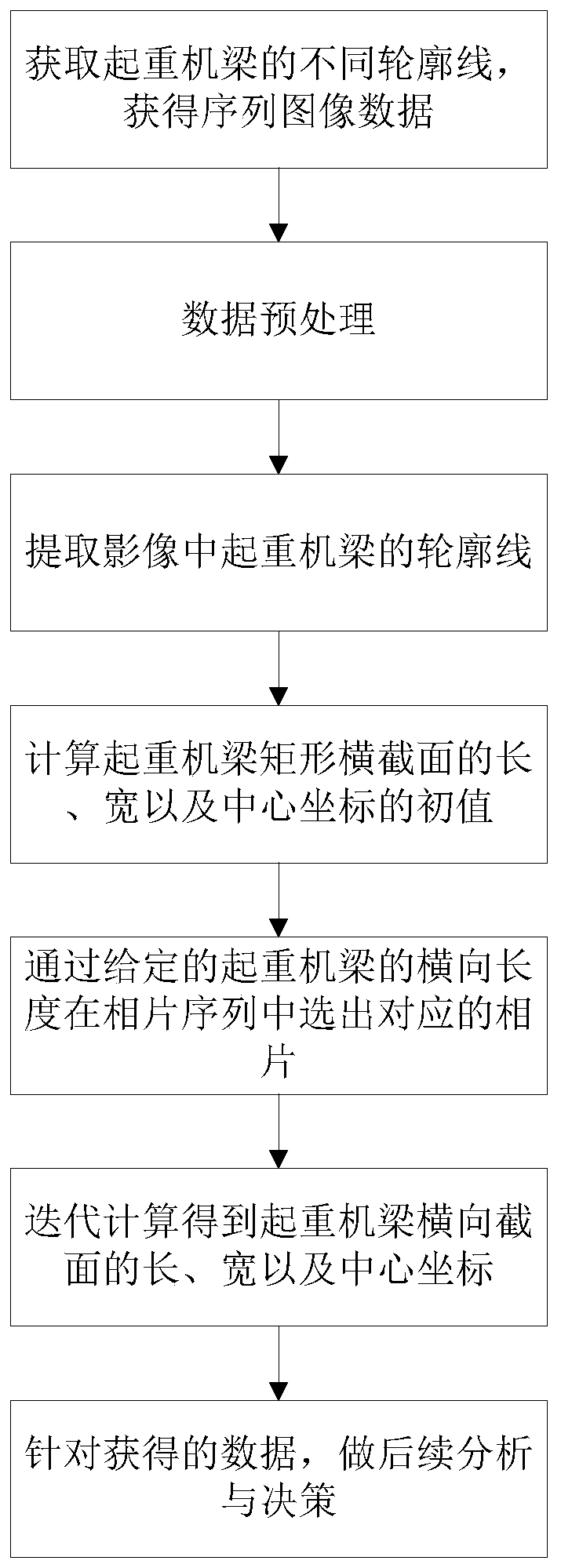

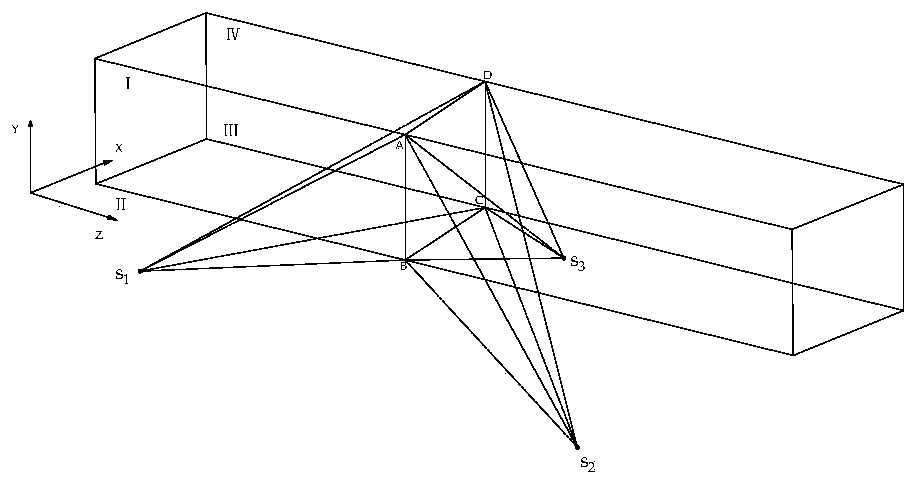

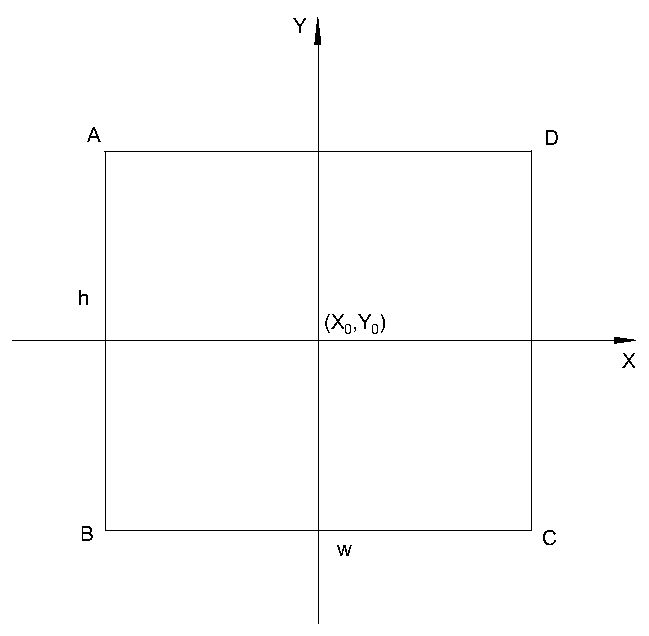

Large portal crane beam deformation measuring method based on image and geometric contour

InactiveCN109764822ADoes not affect production operationsHigh measurement accuracyUsing optical meansMeasurement precisionData pre-processing

The invention discloses a large portal crane beam deformation measuring method based on an image and a geometric contour. The method comprises the following steps of firstly, acquiring different contour lines of a crane beam to obtain sequence image data; carrying out data preprocessing, and extracting the contour lines of the crane beam in the image; computing initial values of the length, the width and the center coordinates of a rectangular cross section of the crane beam; selecting a corresponding photo from a photo sequence through the transverse length of the given crane beam; carrying out iterative computation to obtain the length, the width and the center coordinates of a transverse section of the crane beam; and finally, carrying out subsequent analysis and decision-making on theobtained data. The method is low in requirement for personnel for field measurement, and does not need to have a relatively high skill requirement for field measurement like a traditional measuring method, and a relatively high measurement precision is kept for a long time; and the method is obtained by strict mathematical calculation, so that the whole process is stricter.

Owner:WUHAN UNIV OF TECH

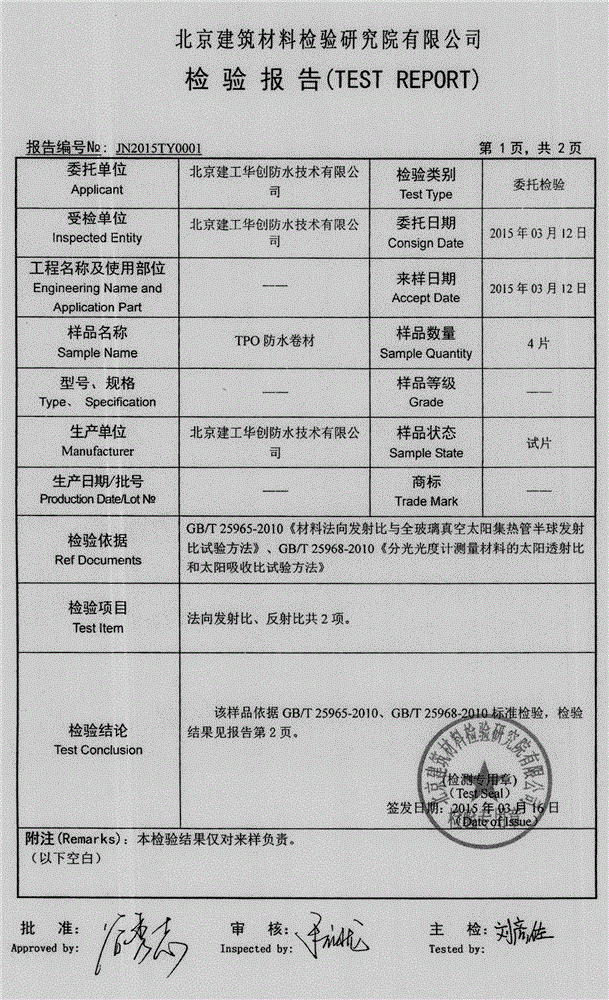

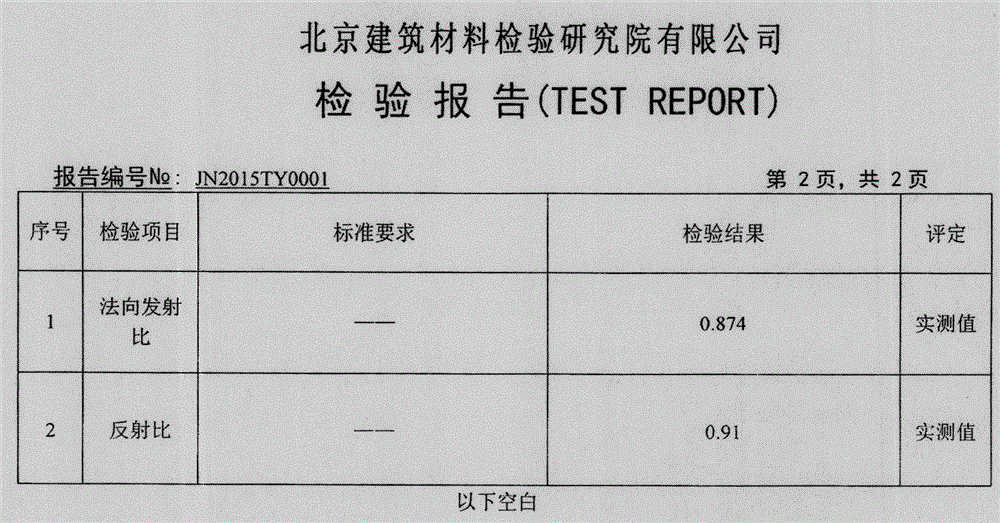

Waterproof coiled material with heat insulation and reflection functions

InactiveCN105176055AExcellent physical properties and bonding propertiesHigh peel and shear strengthCobalt(III) oxidePolypropylene

The invention discloses a waterproof coiled material with heat insulation and reflection functions, which is prepared from the following components in percentage by mass: 10-25% of polypropylene, 20-35% of polyethylene, 20-50% of TPU thermoplastic polyurethane), 0.5-15% of metal oxide, 3-25% of reflection and emission modifying material, 0.1-5% of antioxidant and 0.1-5% of light stabilizer. The metal oxide adopts the special-structure Ca(OH)2; and the reflection and emission modifying material adopts one or more of ferric oxide, manganese peroxide, cobaltic oxide, copper oxide and other reflective spinel materials. The waterproof coiled material with heat insulation and reflection functions is composed of a thermoplastic polyolefin material, a filler with reflection and emission functions and a high-performance self-adhesive coating, and has excellent functions of water resistance, weather resistance, heat insulation and reflection.

Owner:BEIJING JGHC TEC

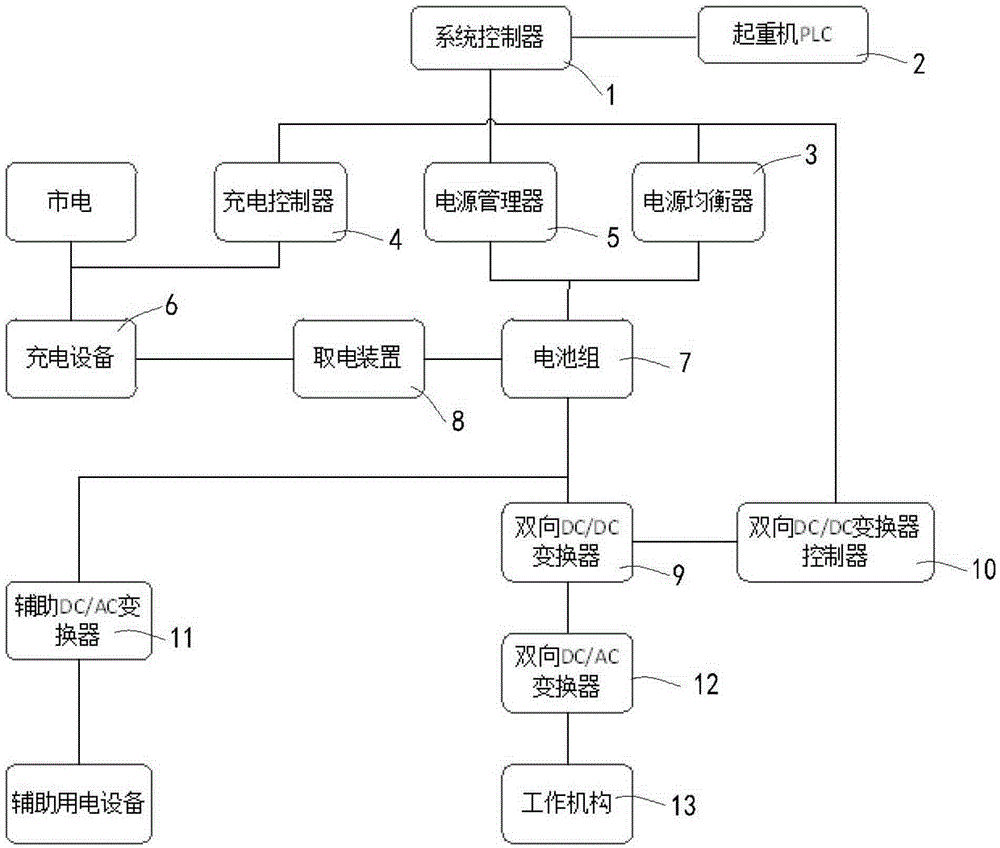

Pure electric system for gantry crane

InactiveCN104410127AFlexibility limitationsZero pollutionBatteries circuit arrangementsElectric powerElectricityEngineering

The invention discloses a pure electric system for a gantry crane. The system comprises a system controller, an electricity getting device, a battery set, a bidirectional DC / DC converter, an auxiliary DC / AC converter, a charge controller, a bidirectional DC / DC converter controller, a power supply manager connected with the battery set, a power supply balancer and charge equipment connected with a commercial power supply, wherein the charge controller, the bidirectional DC / DC converter controller, the power supply manager and the power supply balancer are connected with the control end of the system controller; the charge end of the battery set can be automatically connected with the charge equipment through the electricity getting device. According to the system disclosed by the invention, the battery set is adopted for supplying power, so that zero pollution and zero emission are realized and the gantry crane is high in flexibility of use.

Owner:安同会

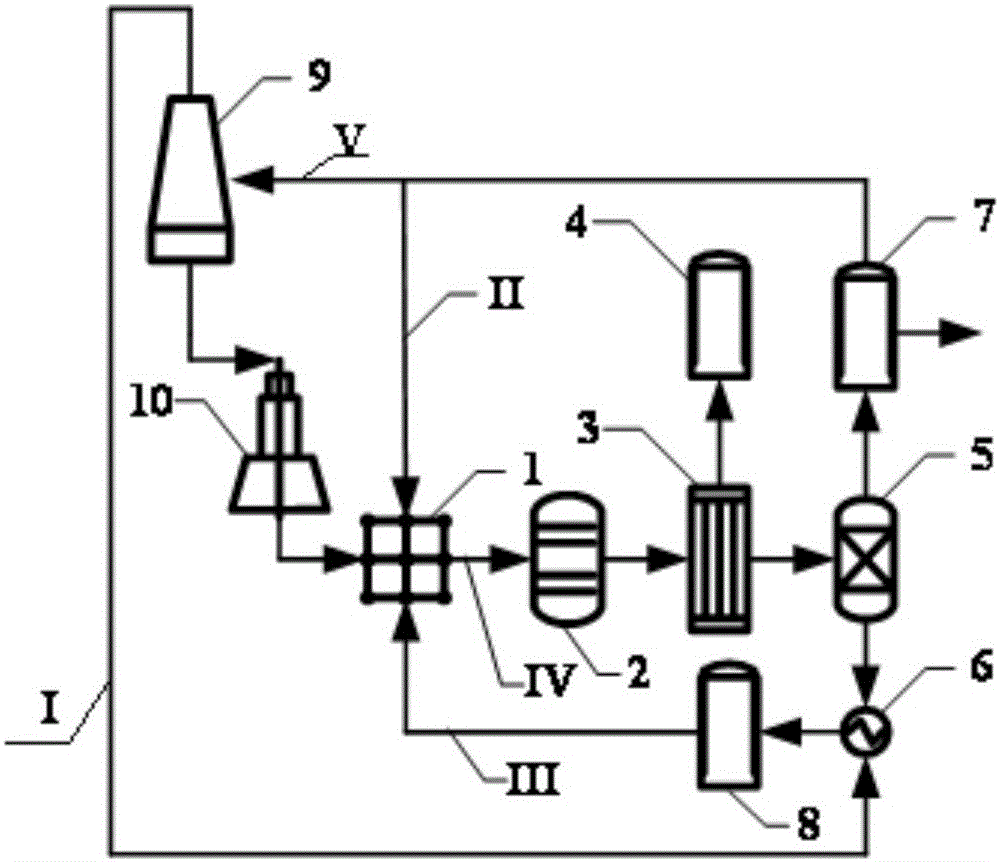

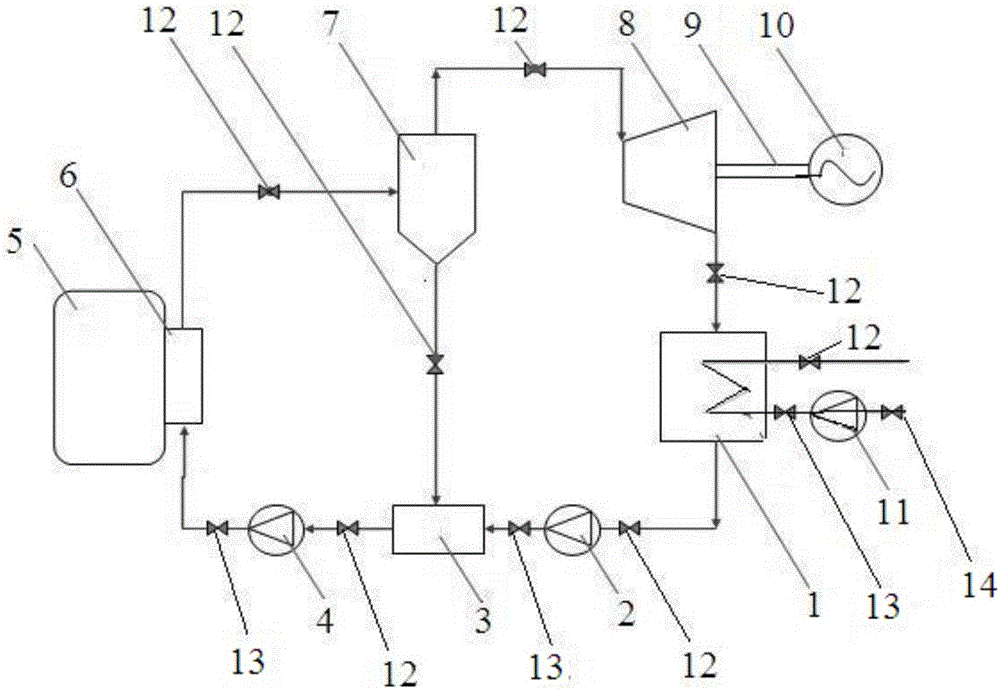

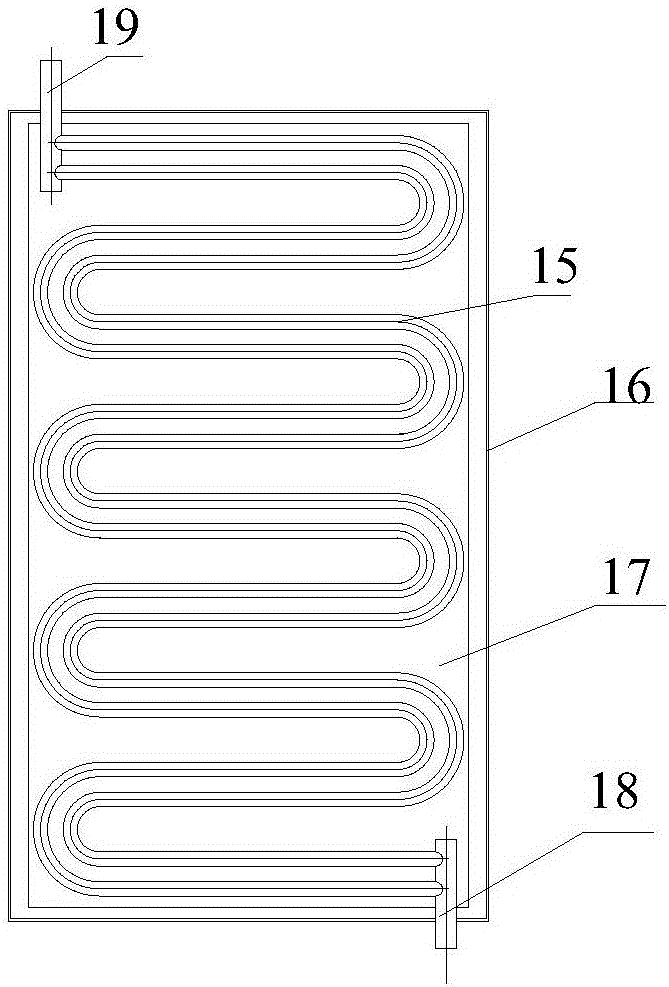

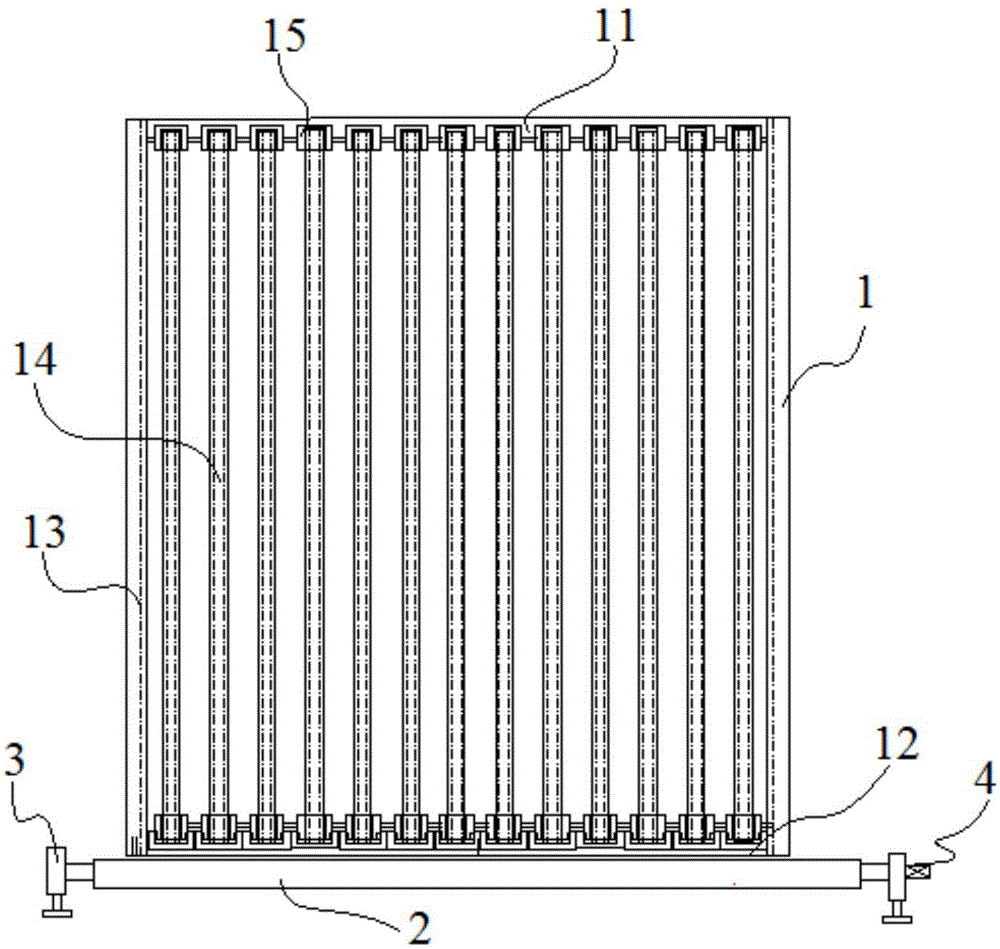

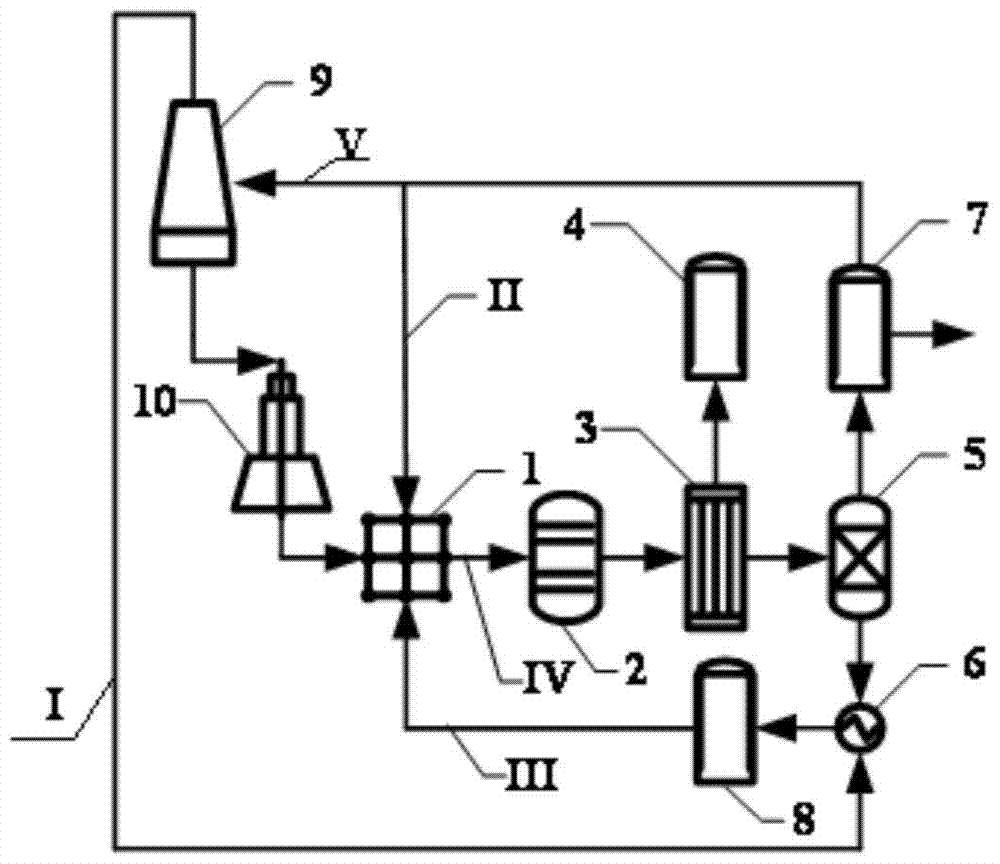

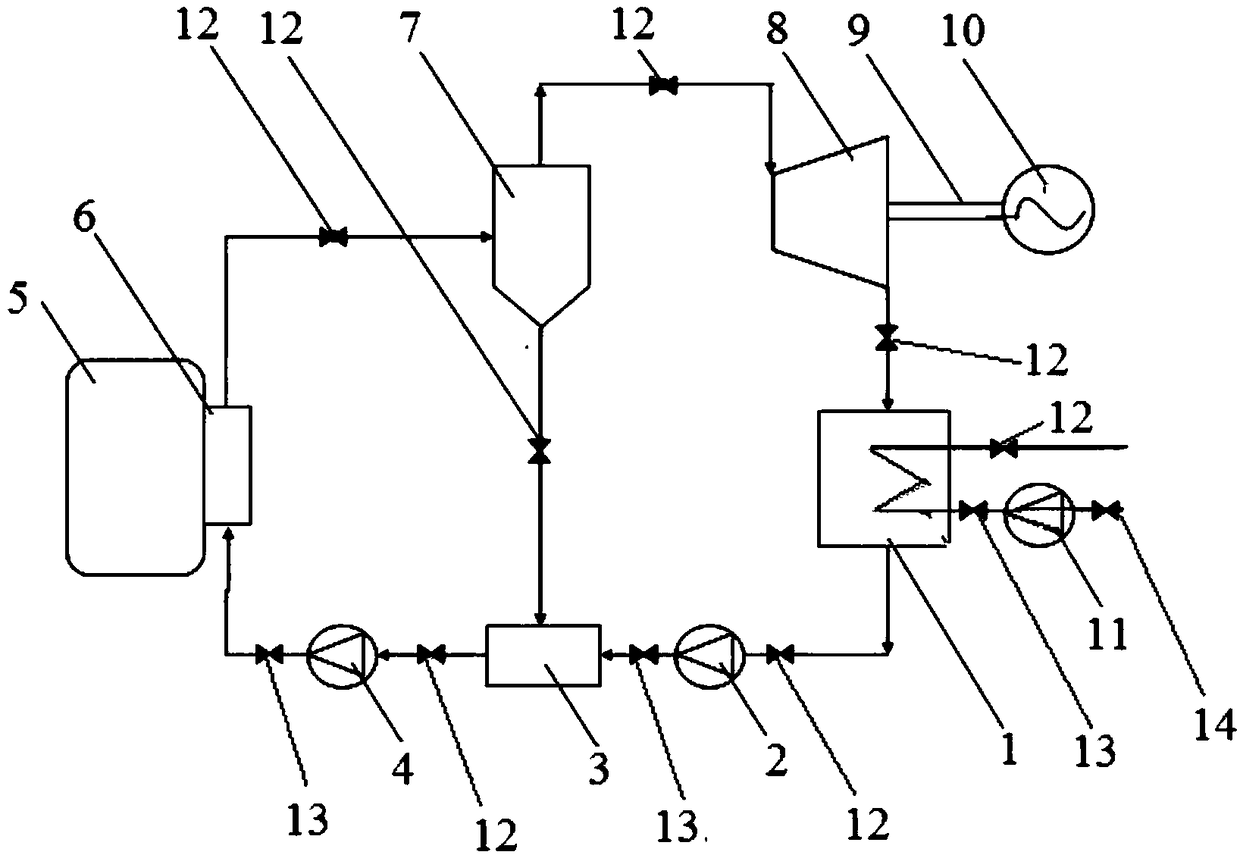

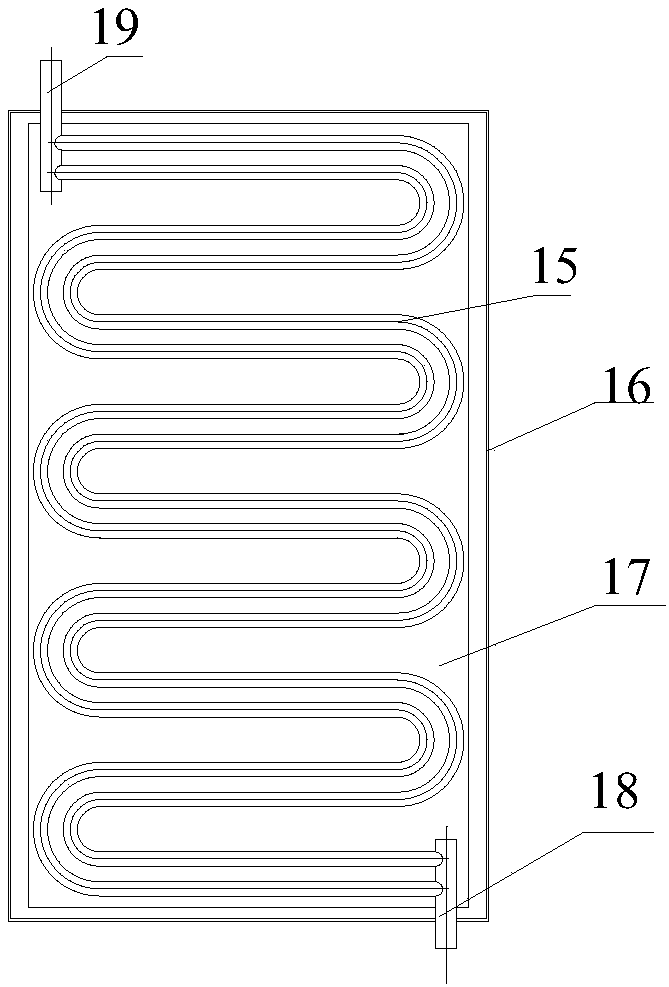

Aluminum electrolysis cell side wall waste heat power generation device based on organic flash evaporation circulation

ActiveCN106591887AImprove energy conversion efficiencyLow costSteam engine plantsElectrolysisBoiling point

The invention discloses an aluminum electrolysis cell side wall waste heat power generation device based on organic flash evaporation circulation, and relates to the technical field of thermoelectric equipment waste heat recovery and utilization. The aluminum electrolysis cell side wall waste heat power generation device comprises a condenser (1), a first working medium pump (2), a mixer (3), a second working medium pump (4), an aluminum electrolysis cell (5), a wall surface heat exchanger (6), an evaporator (7), a low boiling point working medium steam turbine (8), a power generation set (10) and a cooling water pump (11). The aluminum electrolysis cell side wall waste heat power generation device can effectively recycle waste heat of the side wall of the aluminum electrolysis cell, and is applicable to technological transformation on the conventional different levels of aluminum electrolysis cells without making large change to the original aluminum electrolysis production system, the original production operation is fundamentally not affected during system operation, and the transformation risk is little.

Owner:武汉光谷环保科技股份有限公司 +1

Materials and sundries clearing device and method thereof

The invention discloses a materials and sundries clearing device and a method thereof, which belongs to the technical field of mineral screening. The device includes a screen which consists of a grating, a sleeve, a base and frames. The screen is located in the hopper and the upper part of the screen is located under a scraper blade of an upper belt head wheel. A transmission shaft is arranged in the bottom of the screen and connected to a transmission connecting rod. An inclined chute is arranged under the base of the screen and is located outside the hopper. The method includes the steps that the transmission connecting rod is driven through a motor, the transmission connecting rod drives a transmission shaft to adjust the angle between the plane where the screen is located and the horizontal direction to be over 70 DEG C and less than 90 DEG C. The materials drop on the belt through the screen and the sundries are left on the screen. Affected by their own action of gravity, the materials and sundries move downward the plane where the screen is located and pass the inclined chute. Then the device separates the materials and sundries and can effectively eliminate the sundries in the material, satisfying the requirements of pelletizing process operation. The device can be used to eliminate the sundries in the materials like concentrate fines.

Owner:MAANSHAN IRON & STEEL CO LTD

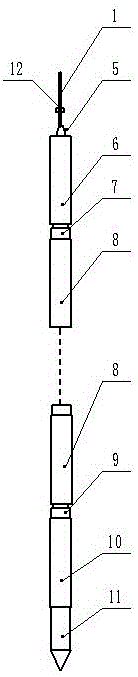

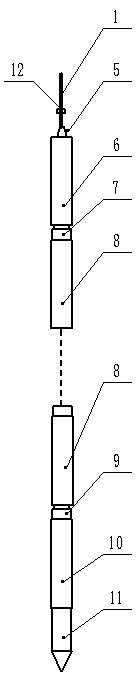

Vertical-well fixed-point multistage fracturing method and application

ActiveCN106761642ARealize vertical effective useIncrease productionFluid removalWell cementingEngineering

The invention provides a vertical-well fixed-point multistage fracturing method. The method includes the following steps: according to a plurality of fracturing segments divided from the reservoir stratum, when a casing is setting into a casing seat, performing well cementing and completion; putting a gauge cutter to the artificial well bottom; setting an elastic ring releasing tool and a perforation combined operation tool string to the position of the casing seat at the lowest end through a cable; energizing the cable to enable gunpowder in the elastic ring releasing tool to burn, and pushing an elastic ring out of the releasing tool to be seated on the casing seat; lifting the tool string through the cable to the perforation position for perforation, and pulling out the tool string; throwing in a soluble ball which is seated on an elastic ring to plug the lower layer, and performing fracturing through a polished casing to complete fracturing of this layer; repeating the above operation, and completing operation of multiple intervals from bottom to top in sequence till well completion. Polished casing injected fracturing is adopted, construction displacement is large, and technical requirements for volume fracturing are met; the bottom layer is plugged by the aid of the soluble ball, the soluble ball is dissolved after fracturing without drilling, the problem of drilling plug of the conventional bridge-plug separate-layer fracturing process is solved, construction is safe, and cost is low.

Owner:PETROCHINA CO LTD

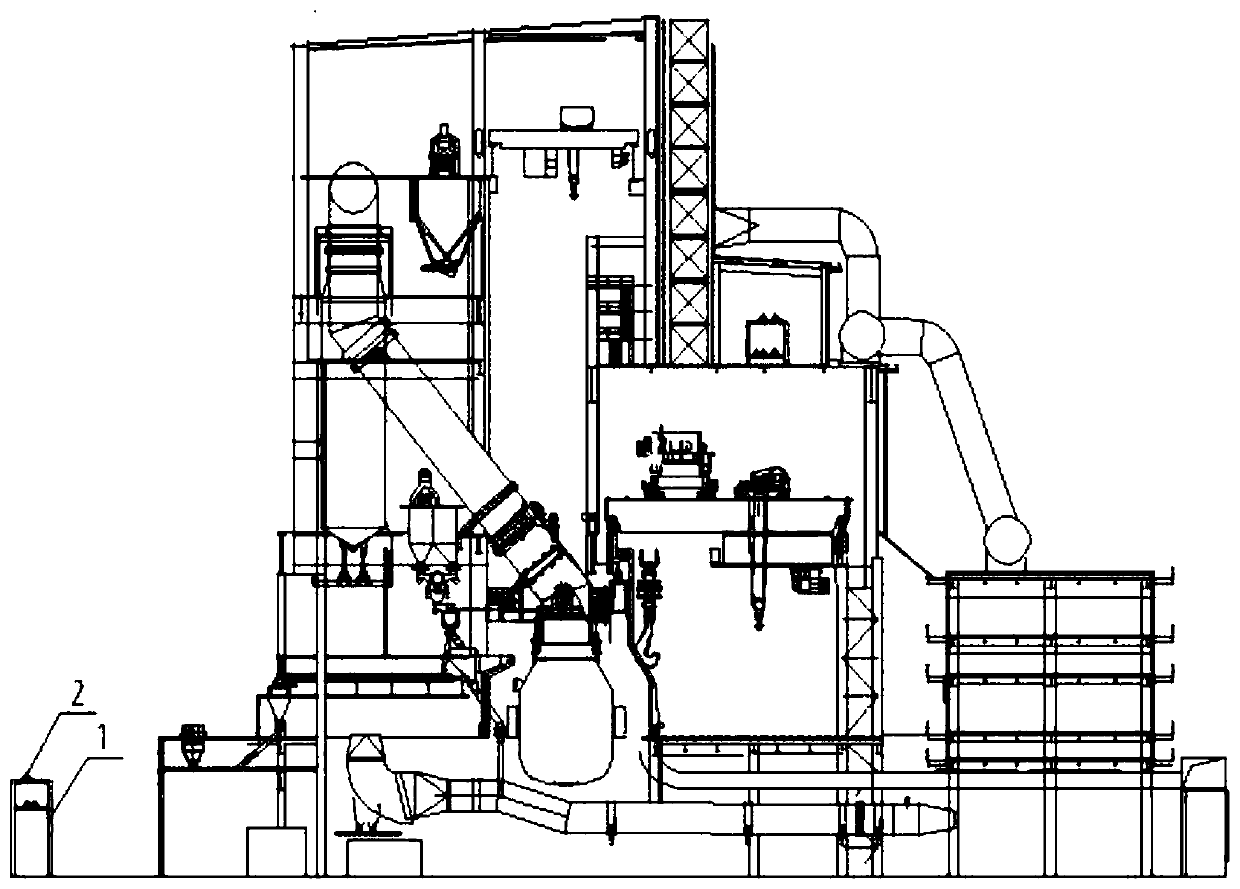

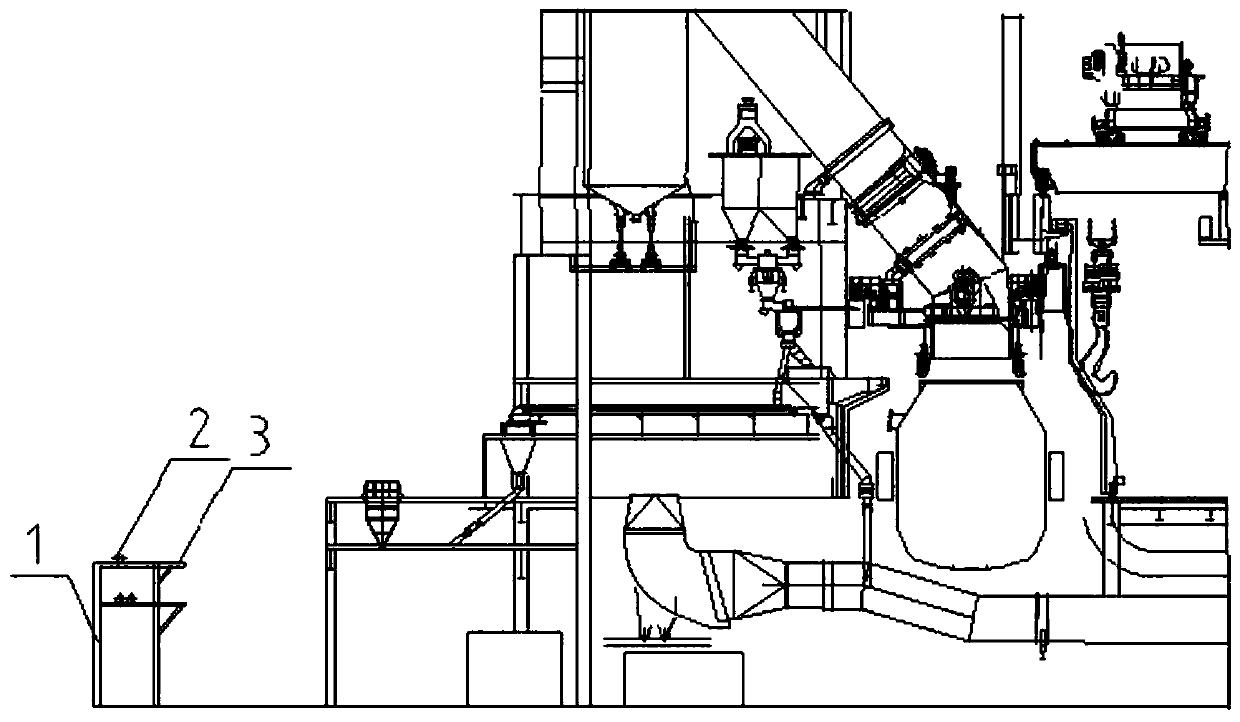

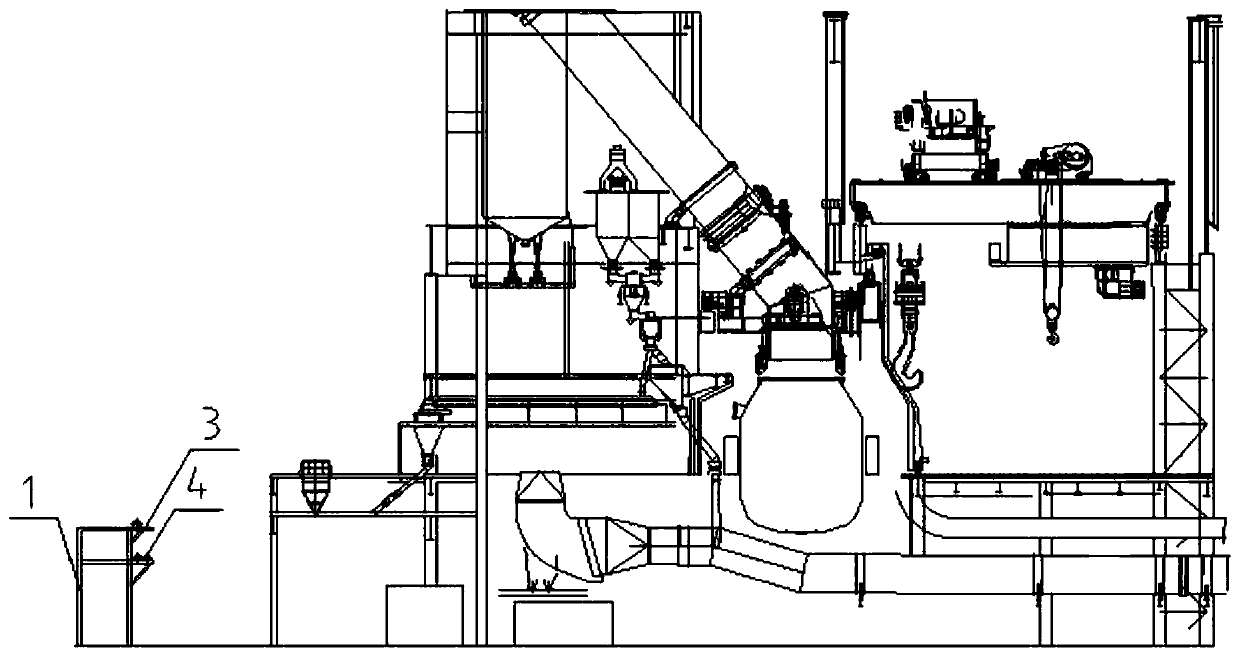

Invertible mobile coke oven machine-side dust-removing device

InactiveCN106675588AAchieve dust removalDoes not affect production operationsCoal charges mechanical treatmentOven incrustations prevention/removalFlue gasCoke oven

The invention discloses an invertible mobile coke oven machine-side dust-removing device. The device comprises a dust hood arranged on the side door of a coke oven, wherein the dust hood is connected with a dust collecting pipeline; the dust collecting pipeline is connected with a dust collecting main pipe through an invertible sealed belt cart; and the dust collecting main pipe is connected with a dust removing ground station through the dust collecting main pipe. The invertible mobile coke oven machine-side dust-removing device is simple and reliable, is convenient to implement, and has the beneficial effects that the coke oven production operation is not influenced, dust removal for spillover flue gas can be realized, and cost increase caused by online transformation and large-sized steel structure assembly can be avoided.

Owner:京蓝能科技术有限公司

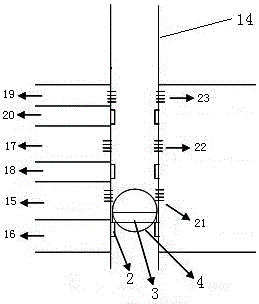

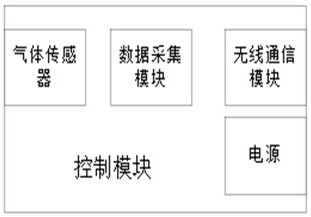

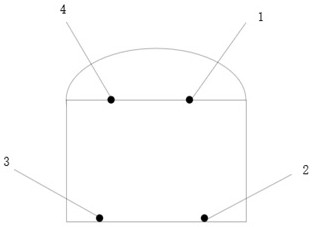

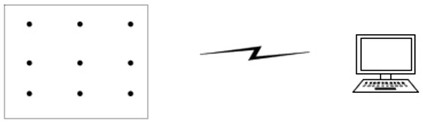

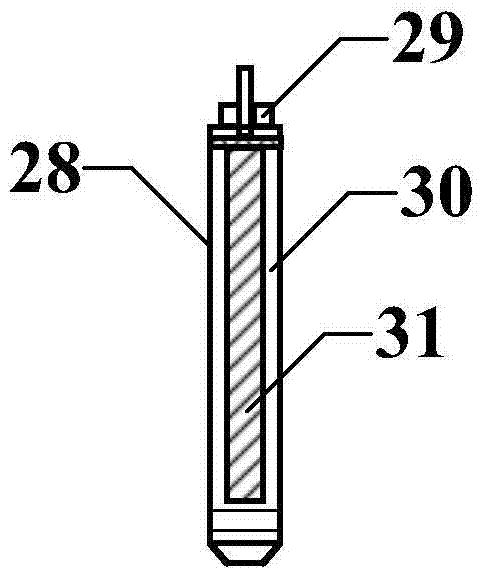

A three-dimensional measurement system and method of greenhouse gas concentration

ActiveCN114047305BExtended service lifeHumidity has little effectTransmission systemsGas analyser construction detailsGreenhouseAtmospheric sciences

The invention discloses a three-dimensional measurement system and method for gas concentration in a greenhouse. The measurement system includes a control terminal, a mobile gas concentration measurement device, a track, and a height moving device. The control terminal includes a space measurement position planning unit for acquiring measurement Demand, plan the sequence of the target position and target height for gas concentration measurement, and form the measurement point control information. The track is used to carry the mobile gas measurement device, and the height mobile device is used to adjust the mobile gas concentration measurement device according to the measurement point control information. Height to target height; the mobile gas concentration measuring device is used to move to a specific target position, and perform gas concentration measurement and data collection at the specific target position and target height, and send the gas concentration data to the control terminal through the wireless communication module . The system and method of the invention can automatically and conveniently realize the three-dimensional measurement of the gas concentration in the greenhouse.

Owner:AGRI INFORMATION INST OF CAS

A ccus system based on gas lift method and its application

ActiveCN105114045BRealize nearby materialsBenefit protectionOther gas emission reduction technologiesCleaning apparatusPower gridGas lift

A CCUS system and application based on gas lift oil recovery, including production pipelines, carbon dioxide pipelines, natural gas pipelines, gas-fired generator sets and electric heating paraffin removal devices, the gas source is separated into carbon dioxide and natural gas through the production pipelines , in which part of the natural gas is used for gas lift oil recovery for the gas lift well group, and the other part of the natural gas is used to supply power to the electric heating wax removal device through the gas generator set. This design not only reduces the power supply cost and technical difficulty of the ground power grid, but also reduces the The load of the power grid, but also enables the production of natural gas to be used near production; the carbon dioxide produced by oil production and the carbon dioxide discharged by the gas-fired generator set are uniformly used for the gas-lift oil recovery of the gas-lift well group, which greatly improves the regeneration of carbon dioxide efficiency and reduce carbon dioxide emissions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

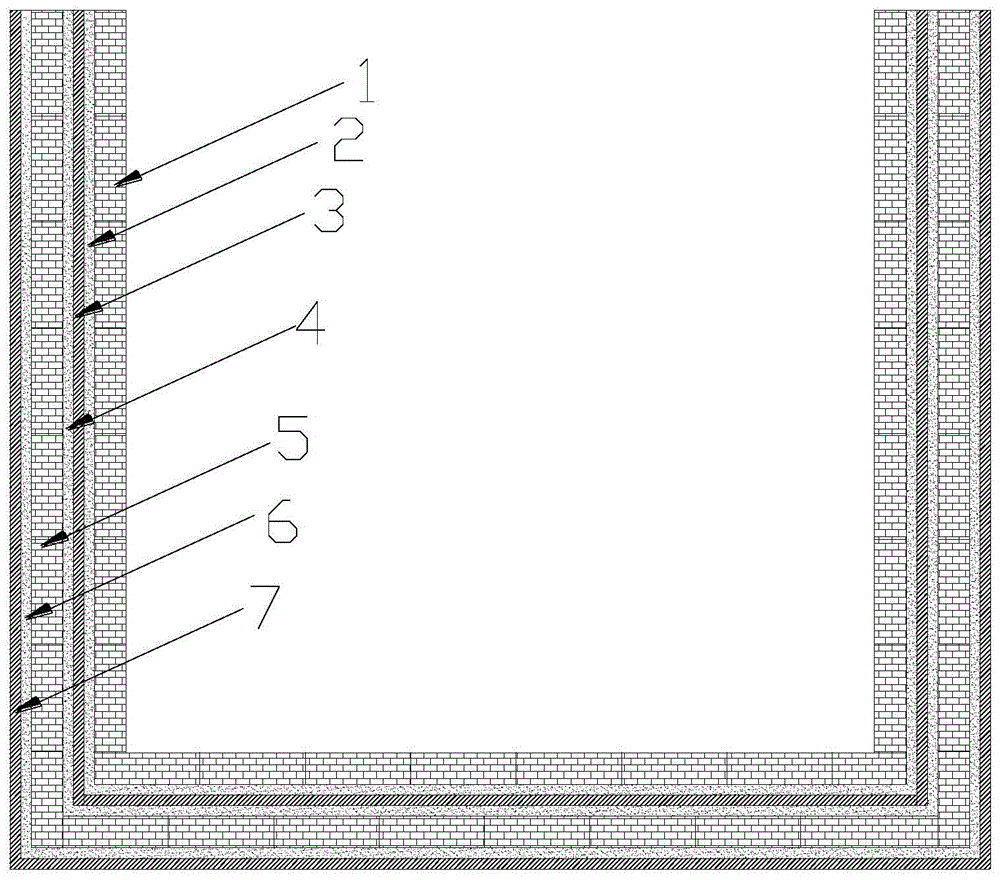

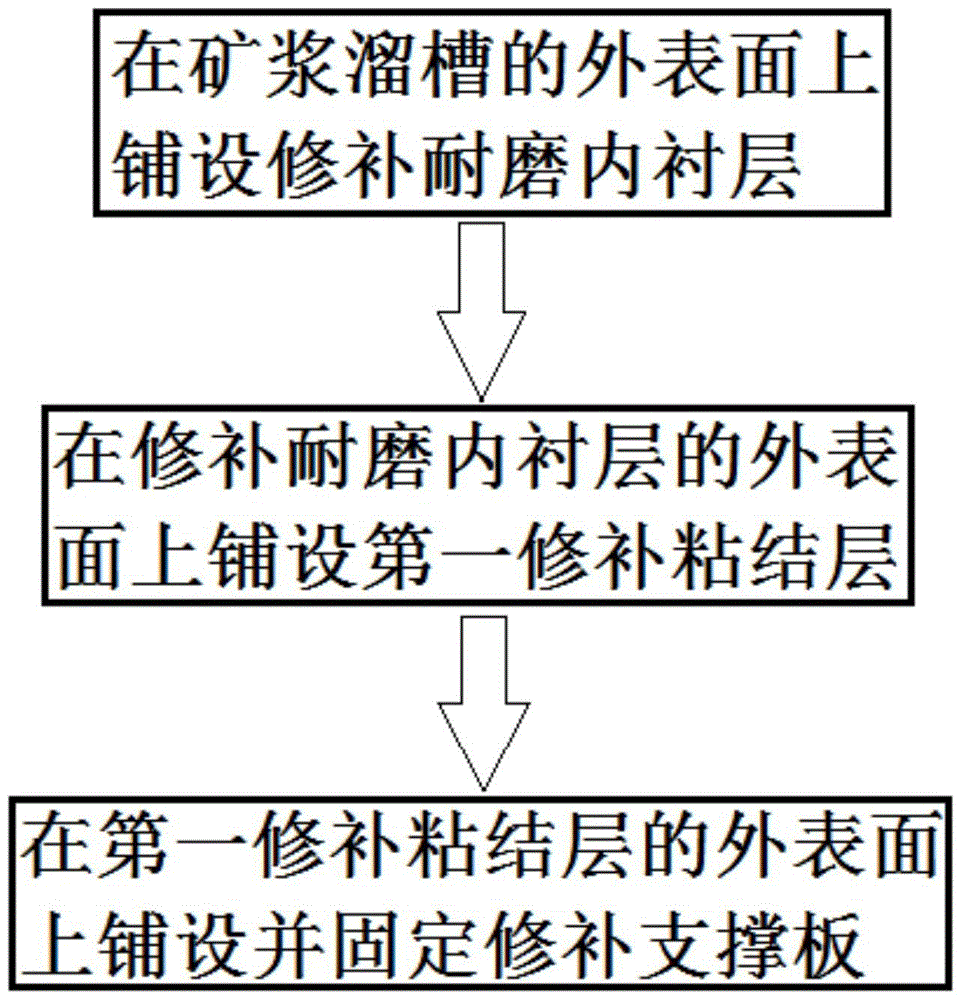

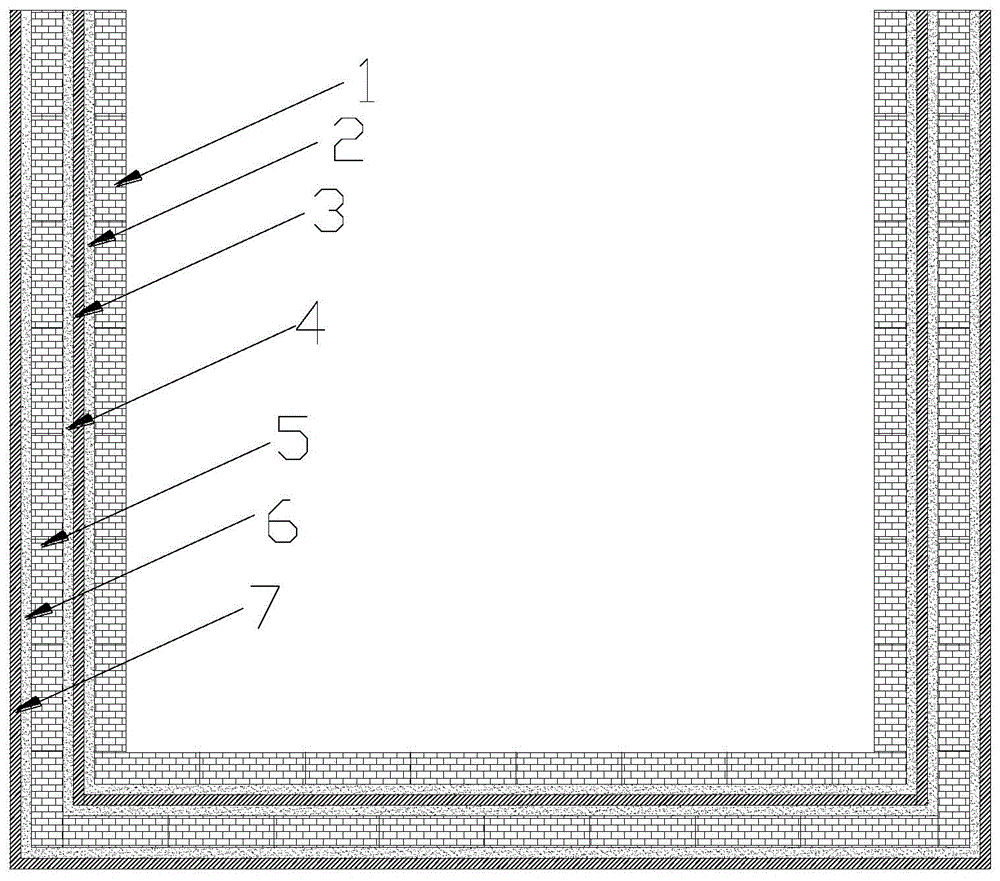

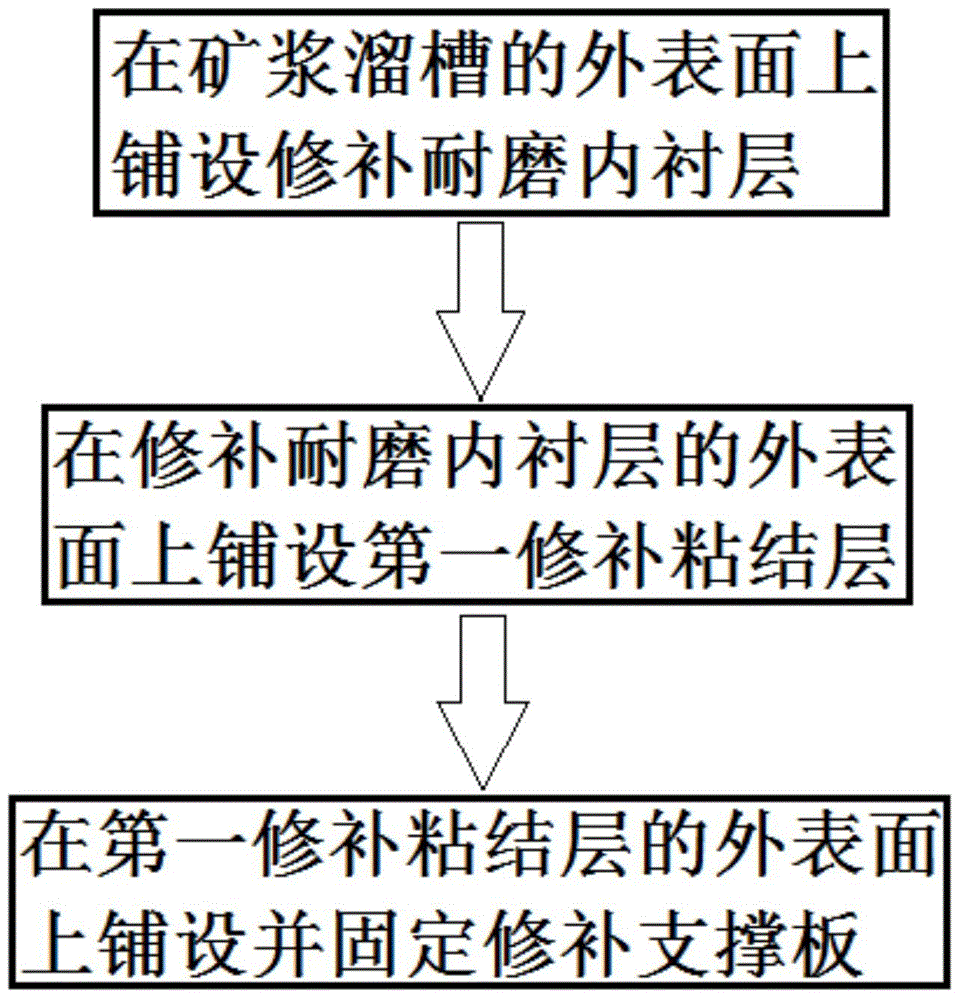

A kind of repair method of slurry chute

ActiveCN104589487BReduced removal stepsShorten the timeSurface layering apparatusWear resistantSlurry

The invention discloses a repair method for an ore slurry chute, wherein the method comprises the following steps that 1, repair wear-resistant inner lining layers (5) are paved on the outer surfaces of the two side parts and the bottom of the ore slurry chute; 2, first repair bonding layers (6) are paved on the outer surfaces of the two side parts and the bottom of the repair wear-resistant inner lining layers (5); 3, repair support plates (7) are paved and fixed on the outer surfaces of the two side parts and the bottom of the first repair bonding layers (6). Through the technical scheme, under the condition of not dismounting the original ore slurry chute, the repair work is carried out outside the ore slurry bottom, the dismounting step is omitted, time is reduced, particularly, the method can be used for the ore slurry chute conveying ore slurry, the production and the operation are not influenced, and the production efficiency is improved.

Owner:PANGANG GRP MINING

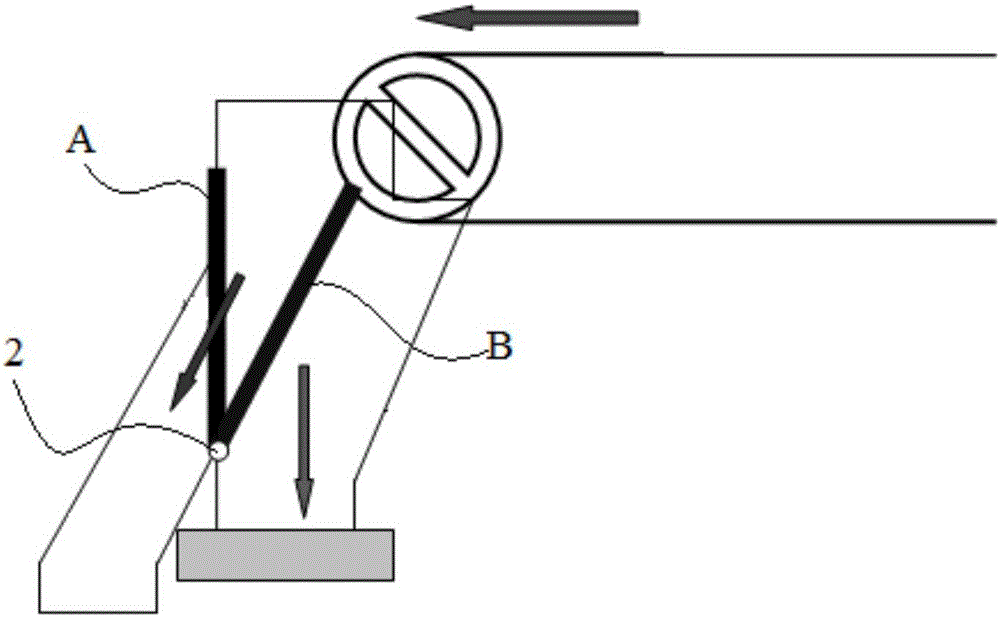

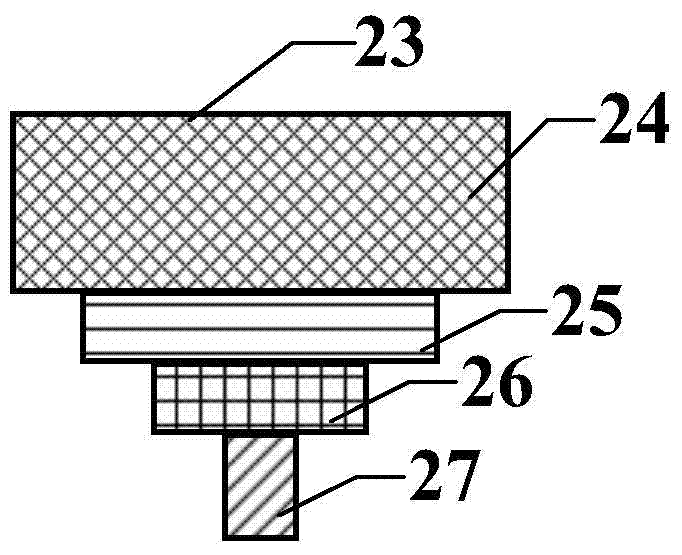

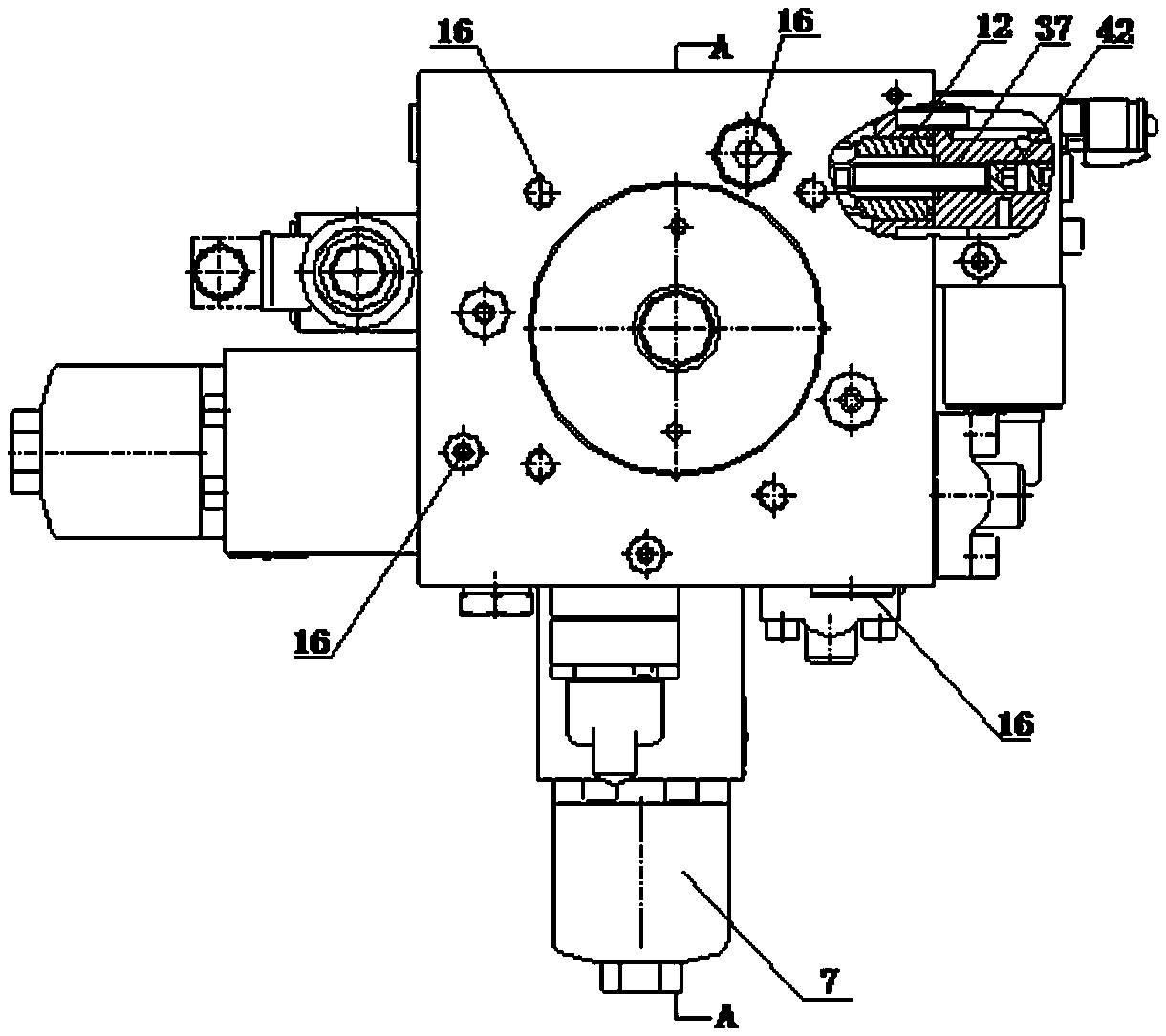

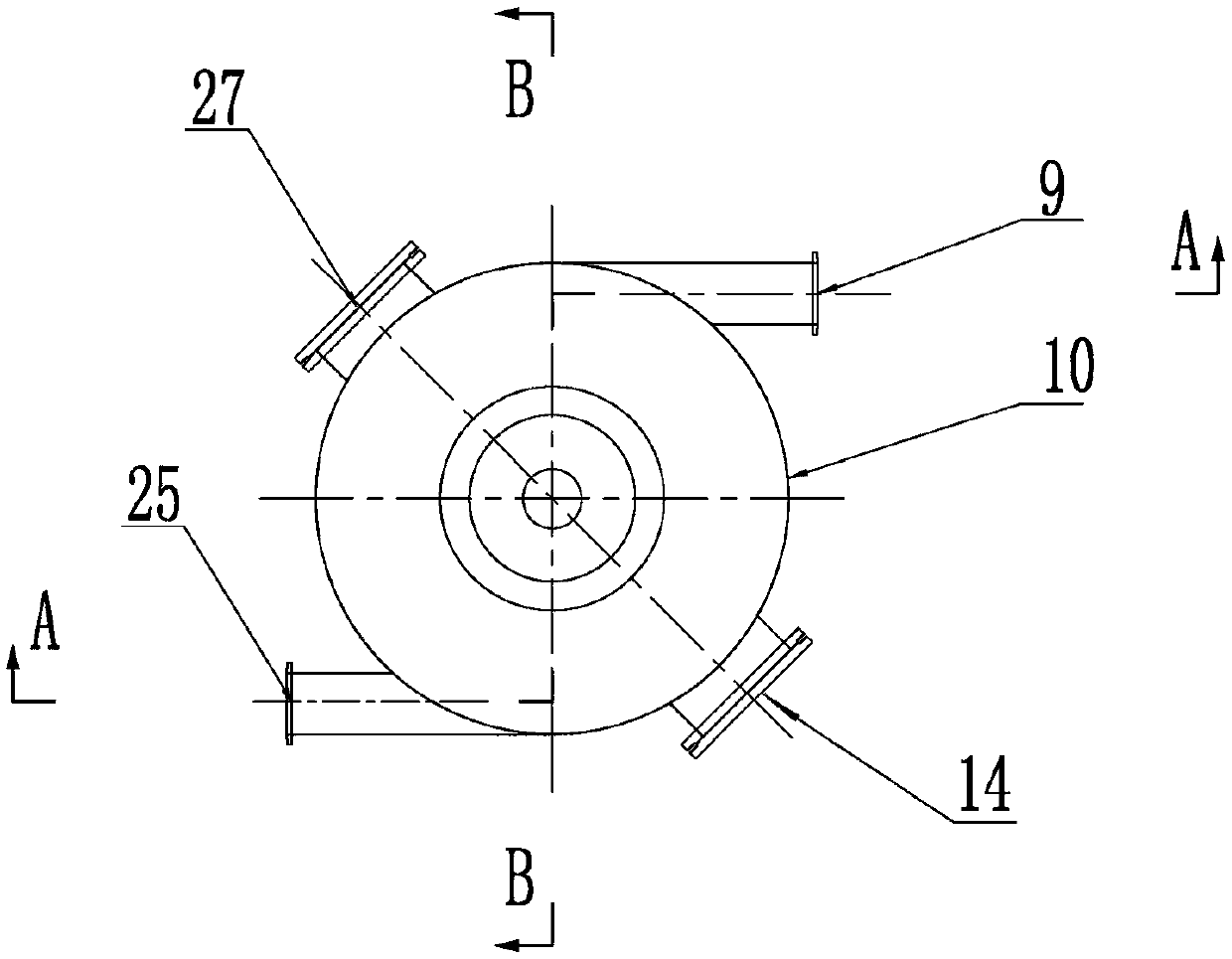

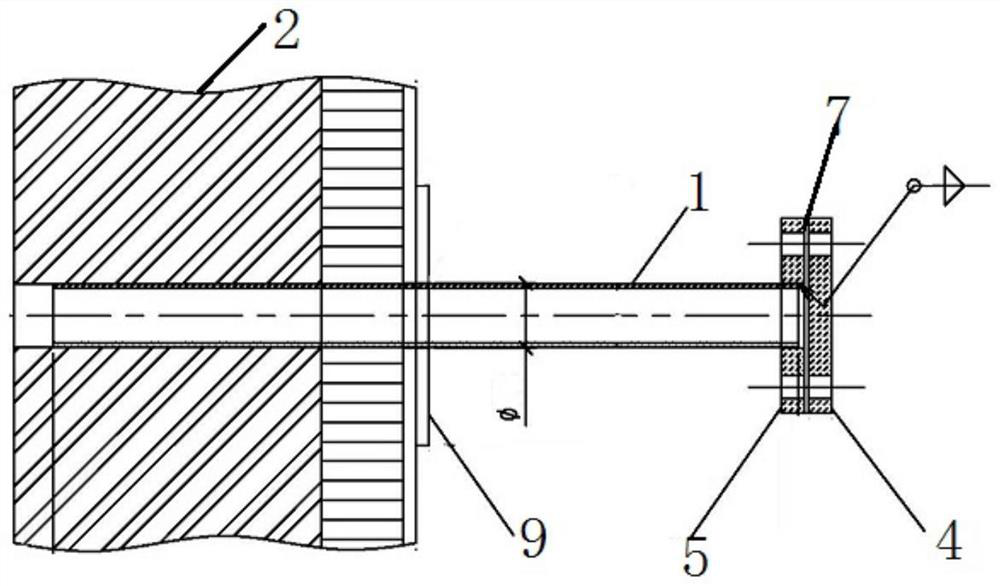

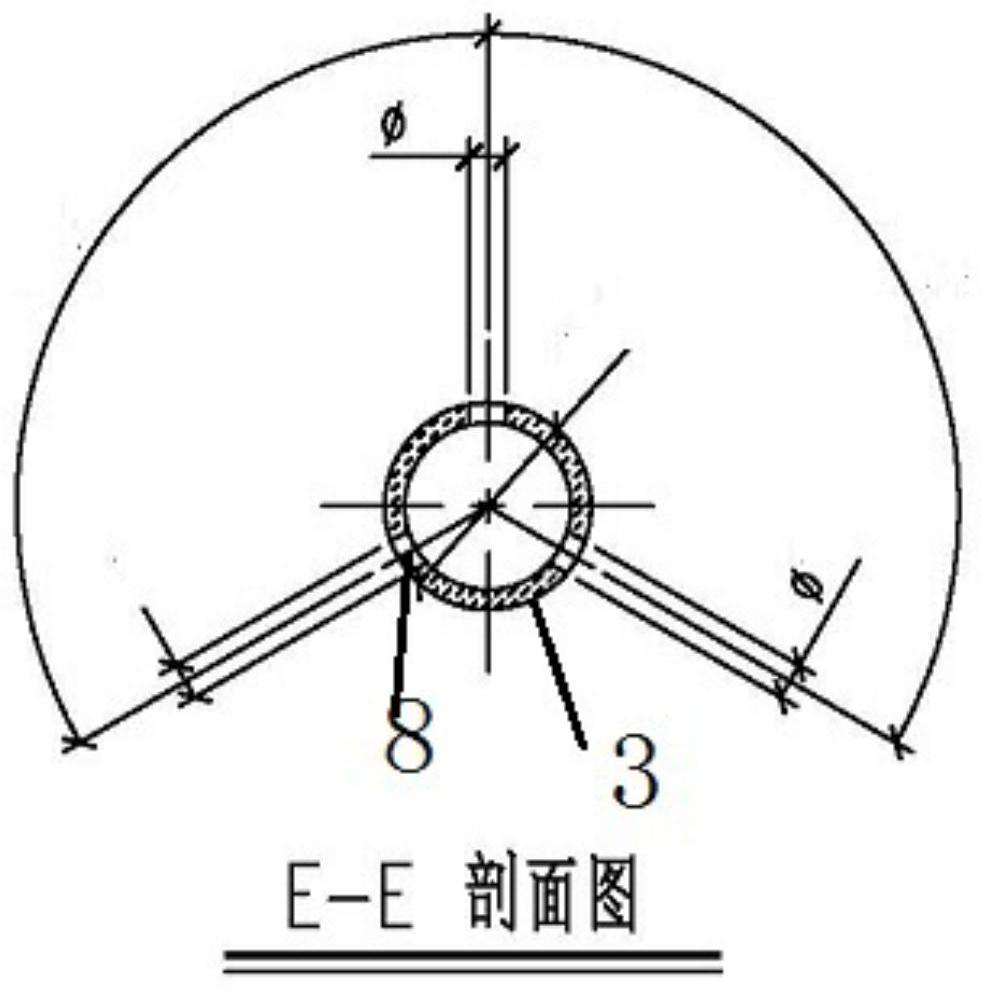

Suspension cone type permanent magnet speed regulating device

ActiveCN107612276BDoes not affect production operationsImprove work efficiencyAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorContact type

The invention discloses a hanging-cone disc-type permanent-magnet speed regulator. The hanging-cone disc-type permanent-magnet speed regulator comprises a disc-type permanent-magnet speed regulator and a support seat, wherein a hanging cone device is arranged on the disc-type permanent-magnet speed regulator, an alarm device is arranged on the support seat, a spring on the hanging cone device canbe compressed or stretched when an input shaft or an output shaft moves, a conical head can be driven to move in a sliding groove, a contact type sensor is arranged on the support seat according to anaxial endplay setting value, the conical head slides in the sliding groove and contacts an induction head when the input shaft or the output shaft reaches the axial endplay setting value, the contacttype sensor can give out a warning signal to a corresponding alarm, the alarm which receives the signal gives out a warning, a motor and a conductor rotor or a speed regulation device and a permanent-magnet rotor are detected by a worker according to the position of the alarm, the problem range is shortened, the reason of excessively large axial endplay also can be timely and rapidly found out and solved, normal production operation is not affected, monitoring of the axial endplay is achieved, and the hanging-cone disc-type permanent-magnet speed regulator is a novel permanent-magnet speed regulator.

Owner:ANHUI WOLF POWER TECH

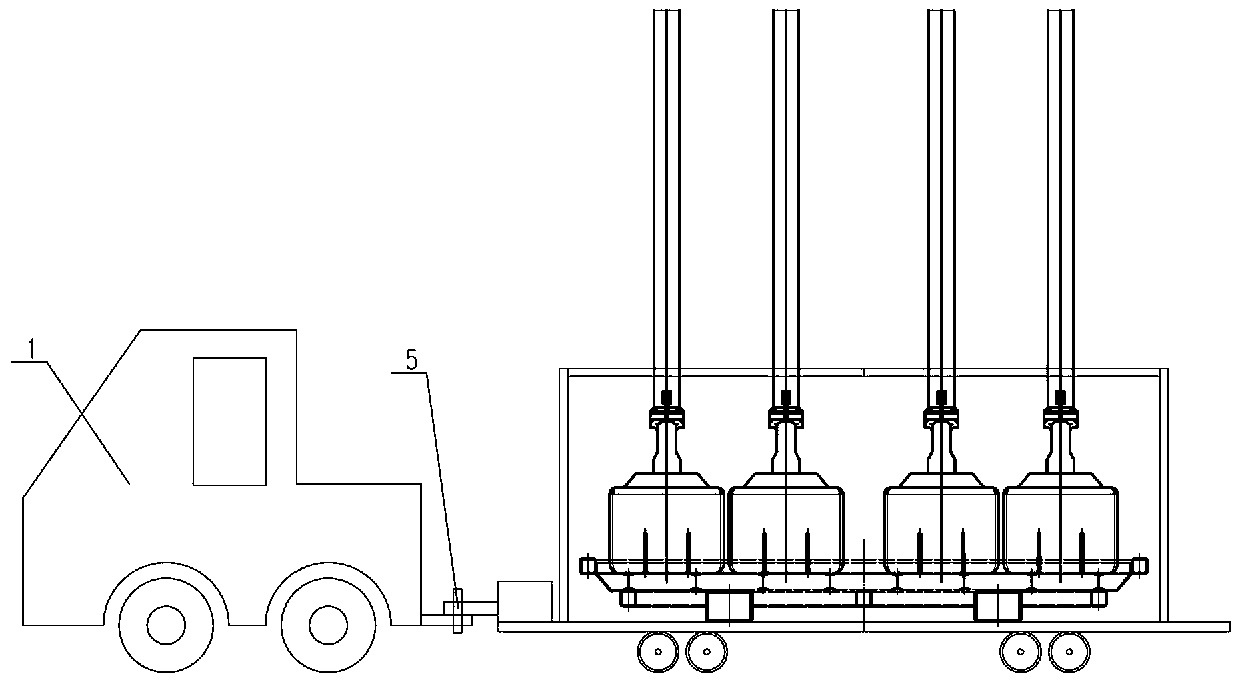

Anode set transportation and residual anode cooling pollutant collection transportation vehicle and use method

InactiveCN110552023ADoes not affect production operationsEmission reductionItem transportation vehiclesElectrolysisTransport engineering

The invention relates to a transportation vehicle, in particular to an anode set transportation and residual anode cooling pollutant collection transportation vehicle and a use method. The anode set transportation and residual anode cooling pollutant collection transportation vehicle comprises a towing vehicle and a trolley connected with the towing vehicle. A cooling tank is arranged on the trolley. A connector flange connected with a purification pipeline is arranged on the upper portion of one side of the cooling tank, and a detachable front cover is arranged on the other side of the cooling tank. A tray containing anodes is arranged on the trolley. The anode set transportation and residual anode cooling pollutant collection transportation vehicle and the use method have the beneficialeffects that inorganized discharge of pollutant such as HF is reduced; and after anode sets are preheated in an assembly workshop, the device can also be used as a heat preservation box, and the temperature of the anode sets is kept in the transportation process from the anode assembly workshop to an electrolysis workshop.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

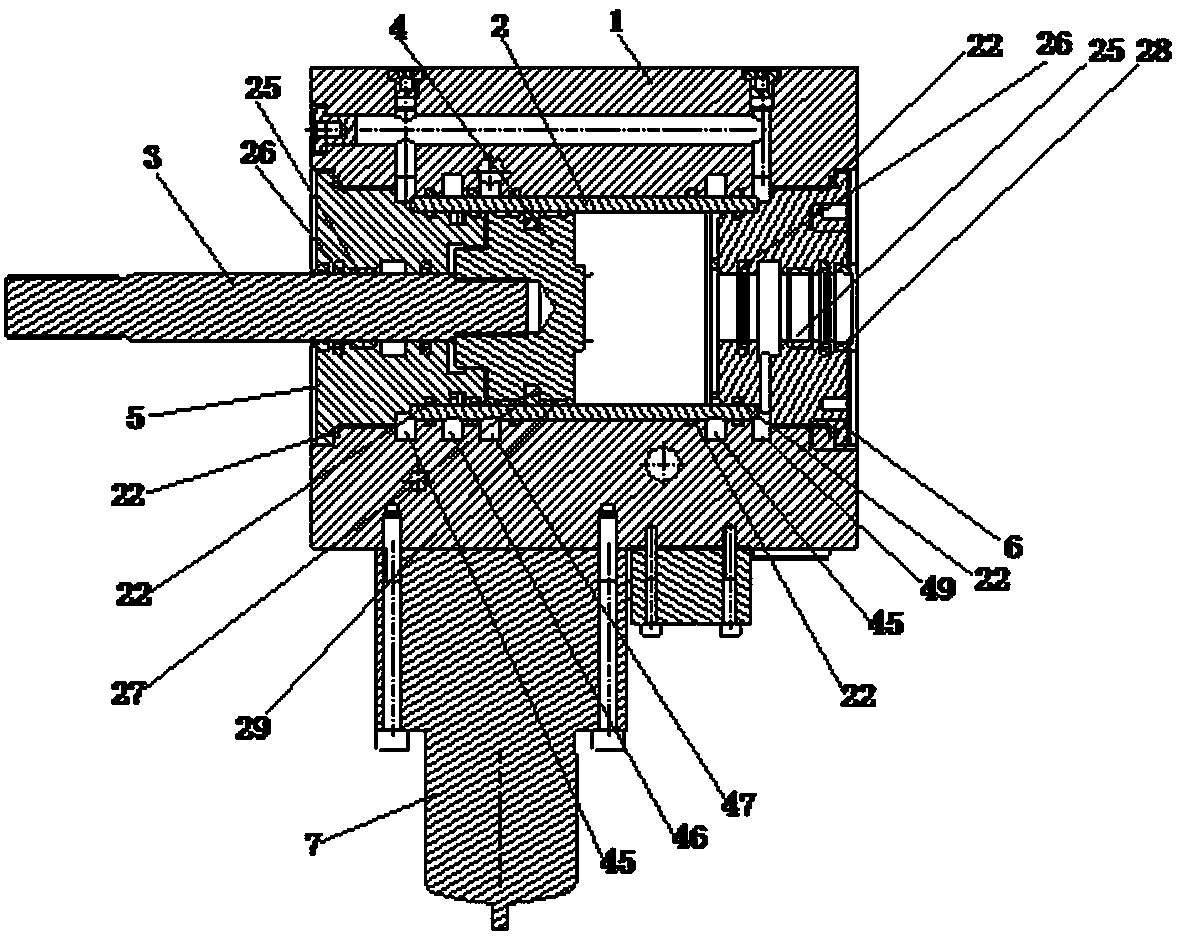

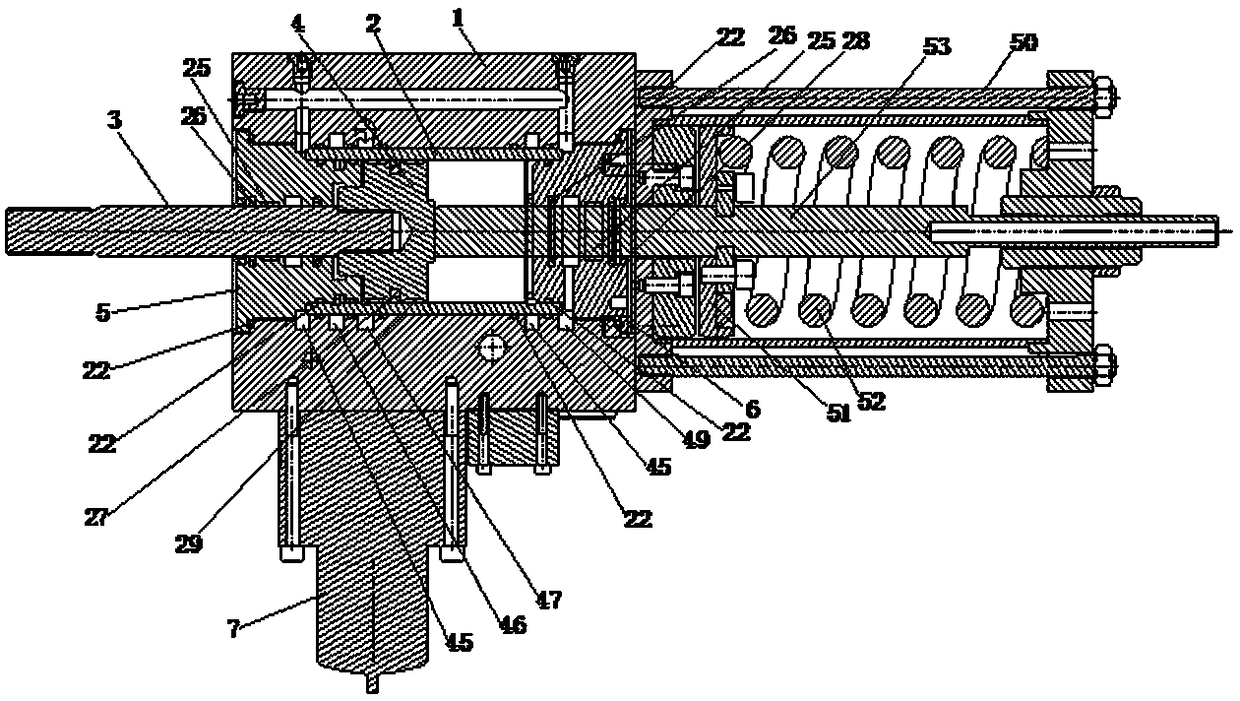

Straight stroke spring return hydraulic actuator

ActiveCN106090401BSimple structureCompact structureOperating means/releasing devices for valvesFluid-pressure actuatorsLinear motionPiston Guide

The invention discloses a hydraulic reset actuator adopting a linear motion spring. The hydraulic reset actuator has characteristics that reset is quick and convenient and the structure is simple. The hydraulic reset actuator comprises a main manifold block, wherein an oil cylinder is arranged in the main manifold block and is matched with a corresponding upper oil cylinder cover and lower oil cylinder cover; a piston is arranged in the oil cylinder in a matched manner, and a piston rod of the piston extends out of the lower oil cylinder cover and the main manifold block; oil passages communicated with the outside and the oil cylinder respectively are arranged on the main manifold block and are matched with corresponding plugs; a piston seal and a piston guide ring are arranged in a matched position of the piston and the oil cylinder, and a shaft seal and a shaft guide ring are matched between the piston rod and the lower oil cylinder cover; a reset mechanism matched with the piston is arranged on the upper oil cylinder cover. According to the hydraulic reset actuator adopting the linear motion spring, through the matching of the main manifold block, the piston, the oil cylinder, the reset mechanism and the like, an actuator component connected with the reset mechanism can be conveniently and rapidly reset, and the hydraulic reset actuator has the characteristic of simple structure.

Owner:成都赛来科技有限公司

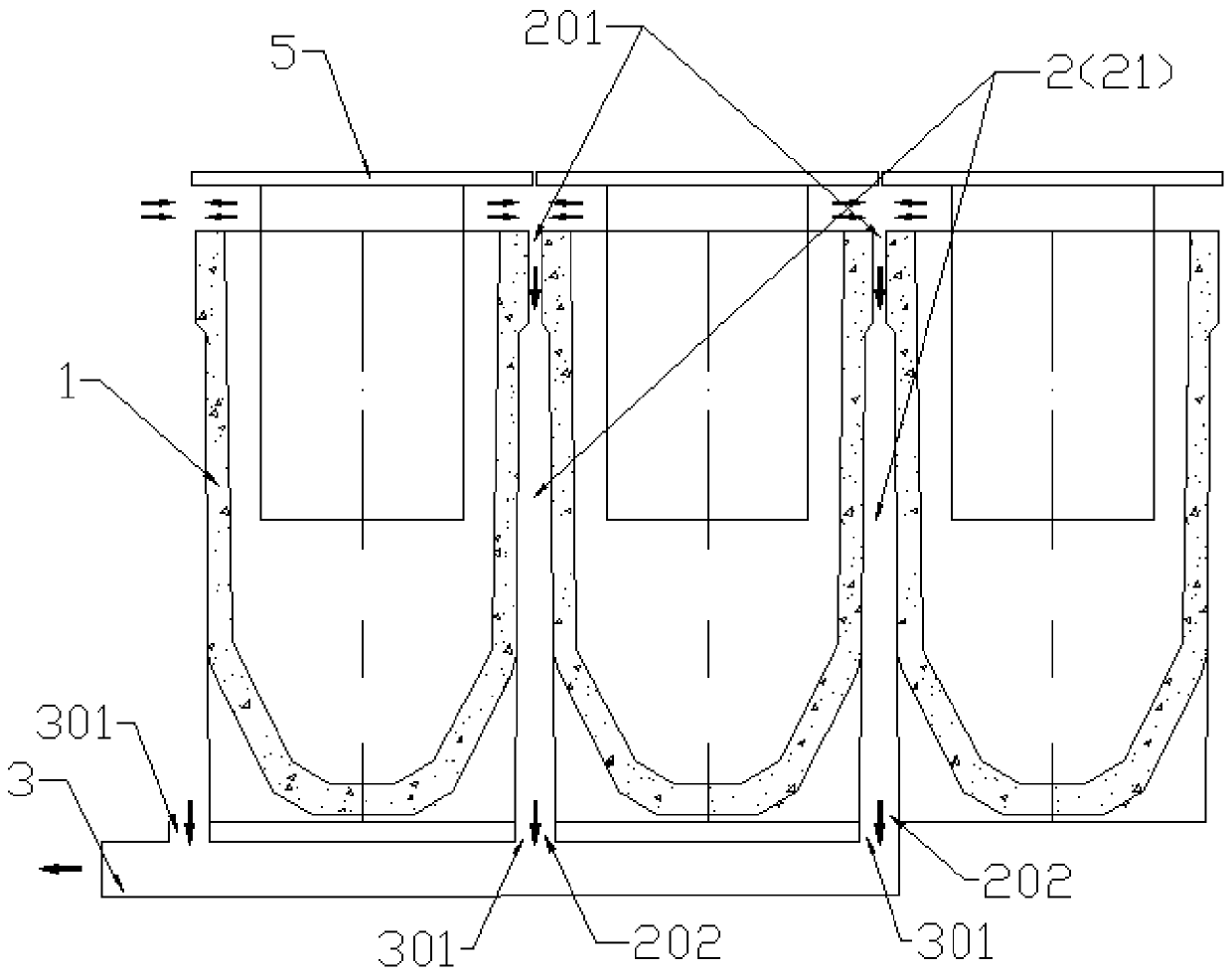

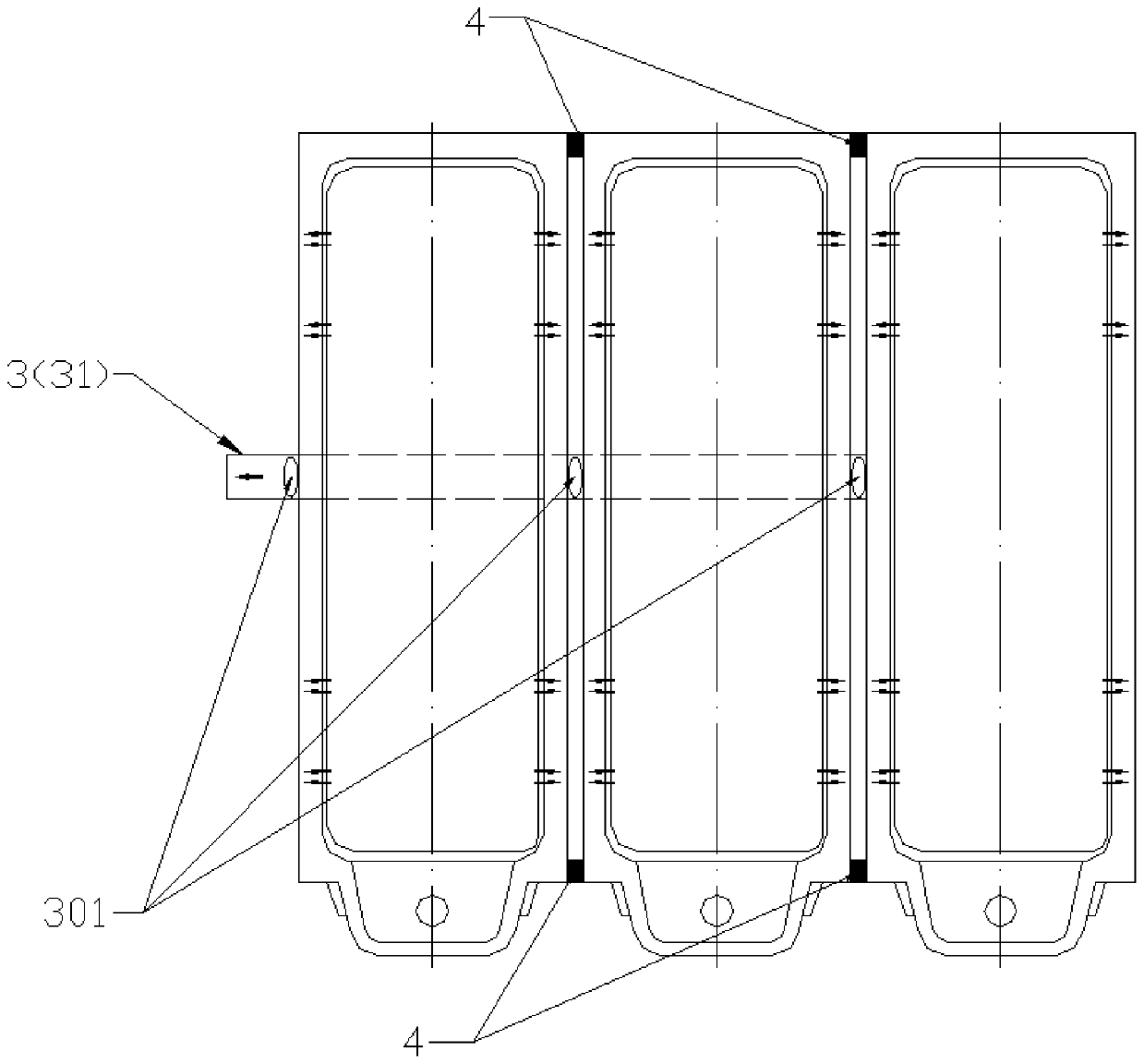

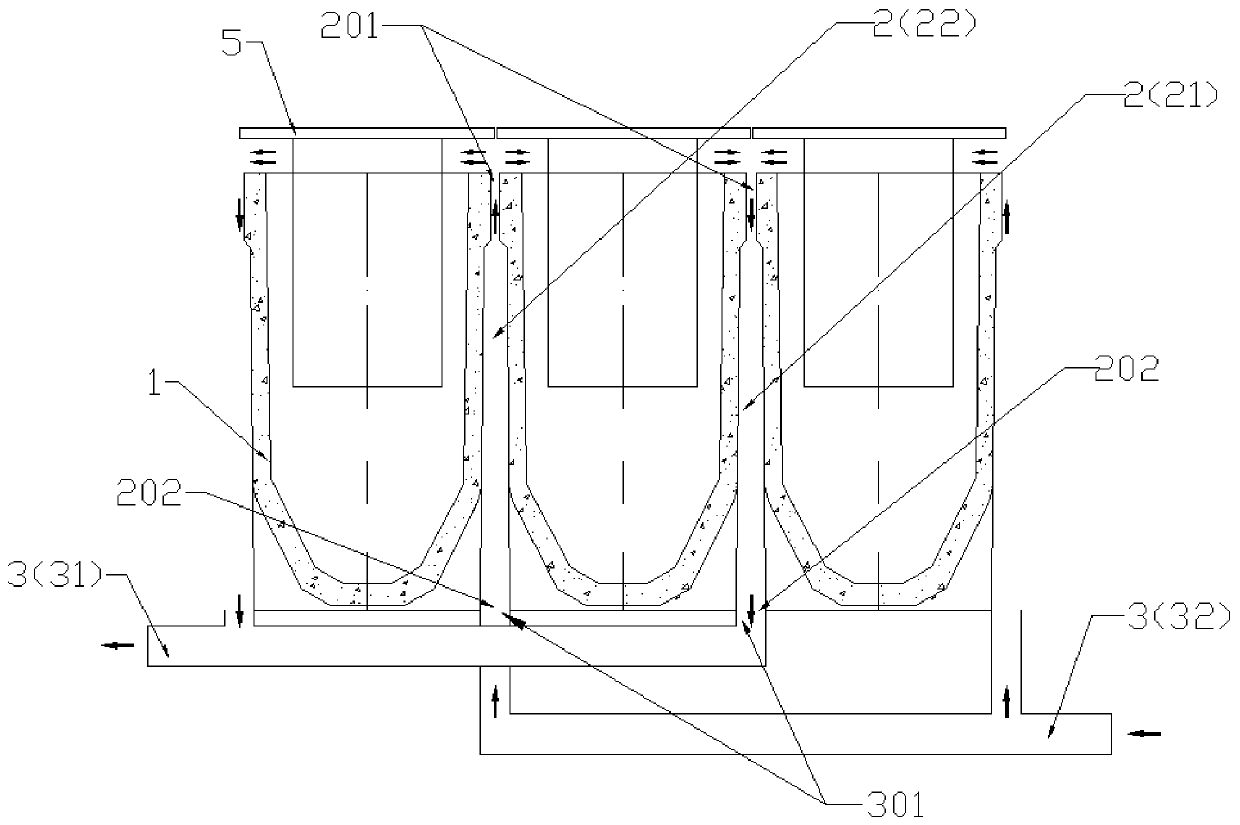

Electrolyzer device and electrolytic acid mist treatment method using same

The invention discloses an electrolytic cell device and an electrolytic acid mist treatment method applying the electrolytic cell device. The electrolytic cell device comprises at least three electrolytic cell bodies and a pipe body located at the bottoms of the electrolytic cell bodies; the electrolytic cell bodies are arranged at intervals; a channel is formed between every two adjacent electrolytic cell bodies; the bottom and the two sides of each channel are each of a closed structure; a first opening is formed in the upper end of each channel; the lower end of the bottom of each channel is provided with a second opening; and the pipe body is provided with through holes and communicates with the second openings of the channels through the through holes. Thus, the electrolytic cell device of the structure is provided with the multiple channels, the bottoms of the channels communicate with the pipe body, the whole electrolytic cell device has high suction capacity, acid mist can be fast trapped, and the acid mist pollution is effectively eliminated. Besides, the pipe body is fixed to the bottoms of the electrolytic cell bodies and has good stability, the whole device is simple in structure, and the acid mist trapping efficiency is high.

Owner:HANGZHOU SANAL ENVIRONMENTAL TECH

An activated carbon fluidized bed adsorption combined device containing dust and organic waste gas

ActiveCN106166431BReduce labor operation intensityEasy to operateCombination devicesGas treatmentModular compositionActivated carbon

The invention relates to a device for treating dust and organic waste gas, in particular to a combined device for treating dust and organic waste gas that can be adsorbed by an activated carbon fluidized bed. area, purified gas buffer zone, activated carbon distribution area, swirl uniform gas distribution area, waste gas gas-solid swirl separation area, and activated carbon feeding area with saturated adsorption; the last six areas are located in the working cylinder, and the working cylinder It consists of a head, cylinder and conical hopper from top to bottom; the working cylinder is installed on the legs. The activated carbon fluidized bed adsorption combination device is a series modular combination structure. It can carry out gas-solid cyclone separation, activated carbon particle adsorption, fresh activated carbon feeding, and adsorption saturated activated carbon discharge recovery operations at the same time, which is conducive to reducing the labor and operation intensity of operators, simplifying the operation steps, and can adsorb organic waste gas continuously. .

Owner:江苏江大环境工程有限责任公司

A fixed-point multi-stage fracturing method for vertical wells and its application

ActiveCN106761642BRealize vertical effective useIncrease productionFluid removalWell cementingMaterial Perforation

The invention provides a vertical-well fixed-point multistage fracturing method. The method includes the following steps: according to a plurality of fracturing segments divided from the reservoir stratum, when a casing is setting into a casing seat, performing well cementing and completion; putting a gauge cutter to the artificial well bottom; setting an elastic ring releasing tool and a perforation combined operation tool string to the position of the casing seat at the lowest end through a cable; energizing the cable to enable gunpowder in the elastic ring releasing tool to burn, and pushing an elastic ring out of the releasing tool to be seated on the casing seat; lifting the tool string through the cable to the perforation position for perforation, and pulling out the tool string; throwing in a soluble ball which is seated on an elastic ring to plug the lower layer, and performing fracturing through a polished casing to complete fracturing of this layer; repeating the above operation, and completing operation of multiple intervals from bottom to top in sequence till well completion. Polished casing injected fracturing is adopted, construction displacement is large, and technical requirements for volume fracturing are met; the bottom layer is plugged by the aid of the soluble ball, the soluble ball is dissolved after fracturing without drilling, the problem of drilling plug of the conventional bridge-plug separate-layer fracturing process is solved, construction is safe, and cost is low.

Owner:PETROCHINA CO LTD

A waste heat power generation device based on organic flash cycle on the side wall of aluminum electrolytic cell

ActiveCN106591887BImprove energy conversion efficiencyLow costSteam engine plantsBoiling pointEngineering

Owner:武汉光谷环保科技股份有限公司 +1

Extraction method of effective components of isatis roots

The invention discloses an extraction method of effective components of isatis roots. The method particularly includes the steps: pre-extraction; microwave extraction; ultra-filtration, separation andpurification; freeze drying. According to the method, a traditional extraction process of a water-extraction and alcohol-precipitation method is improved, isatis roots are decocted and pre-extractedand then further extracted, the microwave radiation process includes that high-frequency electromagnetic wave penetrate extracting media to reach microtubule bundles and glandular cell systems insidethe isatis roots, microwave energy is absorbed, so that the temperature in cells rapidly rises, the pressure in the cells exceeds bearable capacity of cell wall expansion, the cells are fractured, effective components in the cells freely flow out and are dissolved in the extracting media at low temperature, and the effective components in the isatis roots are sufficiently extracted in a short time.

Owner:ANHUI YONSENT PHARMA

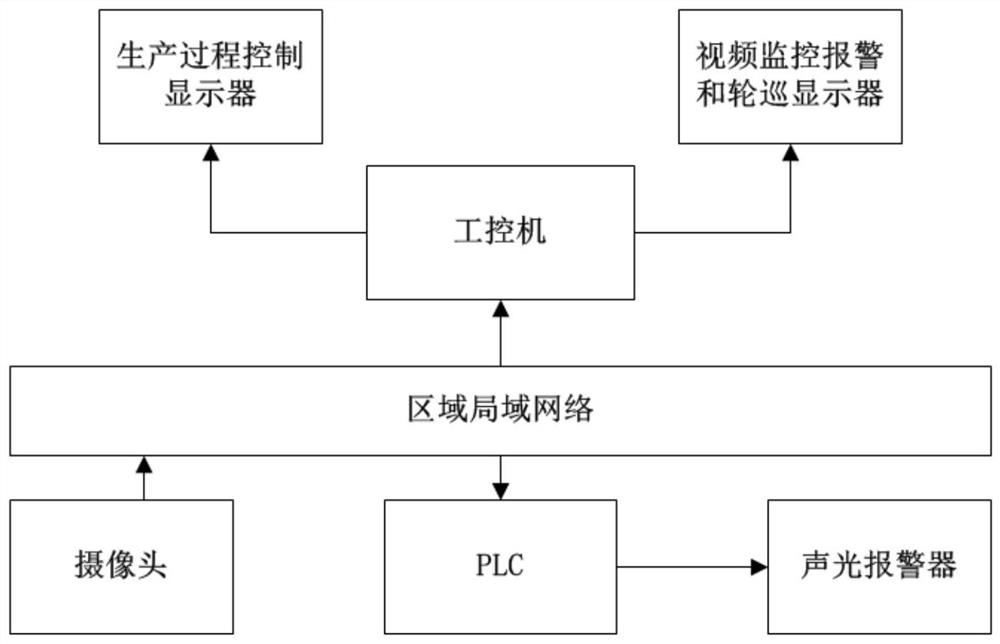

Production process control and alarm linkage system and method based on video images

InactiveCN112415960AReduce workloadLow efficiencyProgramme total factory controlVideo monitoringControl data

The invention discloses a production process control and alarm linkage system based on video images. The production process control and alarm linkage system is characterized by comprising a productionprocess control module, a video monitoring module and an alarm module; the production process control module is used for receiving the control data sent by production process control equipment, displaying the control data, receiving an abnormal alarm signal, sending an alarm to the alarm module and calling the data of the video monitoring module; the video monitoring module is used for collectingvideo monitoring data of key equipment in a production area, displaying the video monitoring data and receiving data calling of the production process control module; and the alarm module is used forreceiving the alarm information sent by the production process control module and carrying out sound-light alarm. According to the invention, through linkage between production process control and video monitoring, visual production monitoring and linkage alarm of production process control are realized.

Owner:YUNNAN DAHONGSHAN PIPELINE

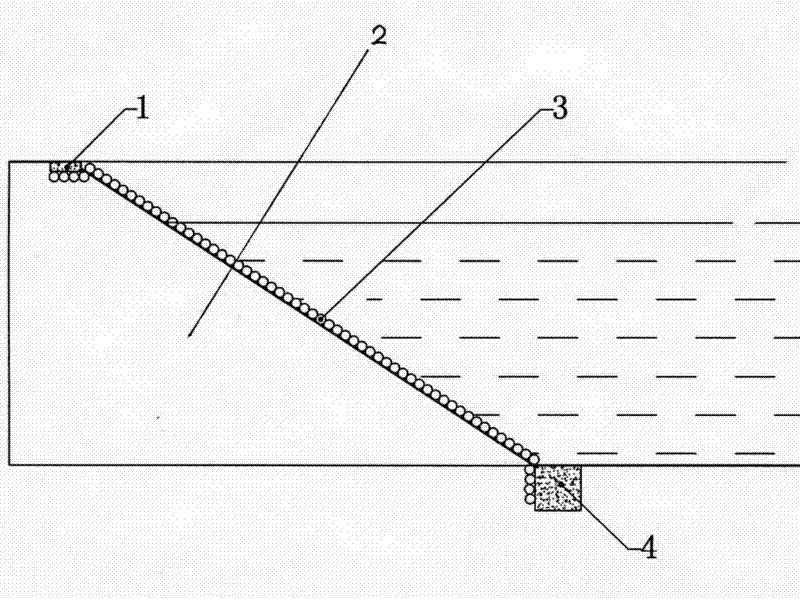

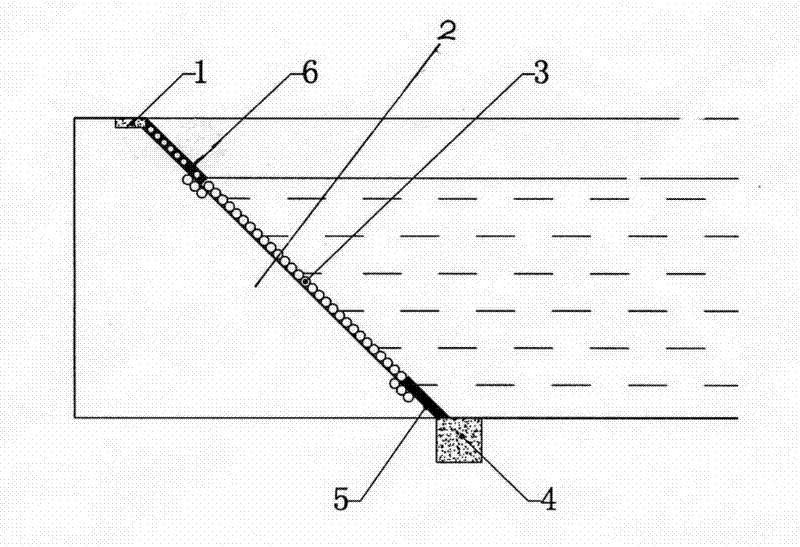

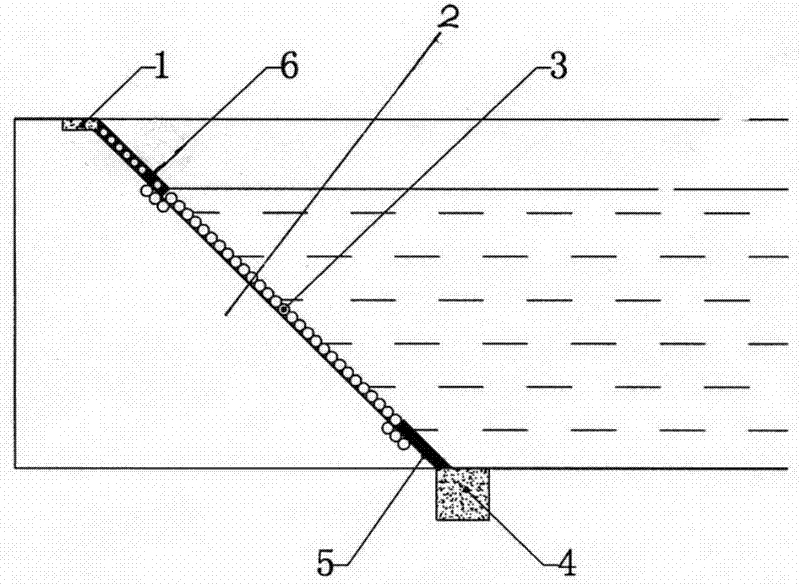

Method for building fishpond protecting slope

The invention provides a method for building a fishpond protecting slope. The method comprises the following specific steps of: (1) building the fishpond protecting slope according to the ratio of height to bottom length, i.e., 1:(1-1.5); (2) making 370*370 mm rectangular feet by using concrete at the bottom of the fishpond protecting slope; (3) laying reticular glass fiber geogrids along the fishpond protecting slope, and burying 30-40 cm reticular glass fiber geogrids below the foot part, laying the reticular glass fiber geogrids to 20-30 cm at the top end of a pond ridge at the upper part,and compacting the geogrids by using compression concrete; (4) spreading 0.5-1 cm floating soil on the laid reticular glass fiber geogrids, and compacting the floating soil with small force; (5) planting herbaceous plants with prosperous root systems on the laid interface, and cutting surface plants along with the interface after the herbaceous plants grow mature naturally; and (6) after the surface plants are cut, introducing water into the fishpond normally to perform aquaculture production. Through the method, the collapse problem of the fishpond ridge in China is solved, the service life of the fishpond is prolonged, the production efficiency is increased, and the ecological environment of the original pond is maintained.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A modification method for obstructing the installation of medium pipes in steel columns of expanded factory buildings

ActiveCN109356398BSolve the installation spaceDoes not affect production operationsBuilding repairsStructural engineeringSteel columns

The invention discloses a transformation method for blocking of an expanded plant steel column installing a medium pipeline, and belongs to the technical field of pipeline transformation. According tothe longitudinal axis of a medium pipeline and the transverse dimension of the blocking part of the expanded plant steel column longitudinal contour line, a pipeline bracket at the blocking part of the medium pipeline is structurally transformed, then the medium pipeline at the blocking part is translated to the right side of the longitudinal position of the expanded plant steel column to make the space needed to install the expanded plant steel column, and thus the problem of the installation space of the expanded plant steel column and the medium pipeline at the blocking part is solved.

Owner:CHINA MCC17 GRP

Repair method for ore slurry chute

ActiveCN104589487AReduced removal stepsShorten the timeSurface layering apparatusWear resistantEngineering

The invention discloses a repair method for an ore slurry chute, wherein the method comprises the following steps that 1, repair wear-resistant inner lining layers (5) are paved on the outer surfaces of the two side parts and the bottom of the ore slurry chute; 2, first repair bonding layers (6) are paved on the outer surfaces of the two side parts and the bottom of the repair wear-resistant inner lining layers (5); 3, repair support plates (7) are paved and fixed on the outer surfaces of the two side parts and the bottom of the first repair bonding layers (6). Through the technical scheme, under the condition of not dismounting the original ore slurry chute, the repair work is carried out outside the ore slurry bottom, the dismounting step is omitted, time is reduced, particularly, the method can be used for the ore slurry chute conveying ore slurry, the production and the operation are not influenced, and the production efficiency is improved.

Owner:PANGANG GRP MINING

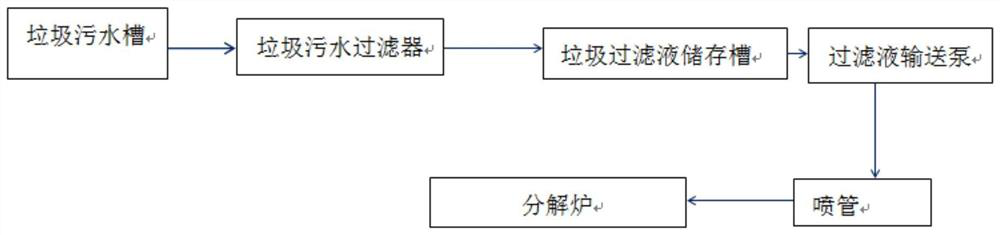

Device used for conveying garbage filtrate into decomposing furnace and garbage filtrate treatment method

PendingCN111609414AEasy maintenanceNo loss of productivityRotary drum furnacesIncinerator apparatusProcess engineeringRefuse Disposals

The invention discloses a device used for conveying garbage filtrate into a decomposing furnace and a garbage filtrate treatment method. The device comprises a sleeve pipe and a spraying pipe, whereinone end of the sleeve pipe is arranged on the furnace wall of the upper end of the decomposing furnace, and the other ends extend to the outer side of the furnace wall of the decomposing furnace, a spraying head with multiple penetrating holes is formed at one end of the spraying pipe, and the spraying pipe can penetrate through the sleeve pipe and extend the spraying head into a furnace body ofthe decomposing furnace, and is used for spraying garbage filtrate into the furnace body. The spraying pipe is detachably connected with the sleeve pipe. The device further comprises a blind plate. The blind plate is detachably connected with the end, on the outer side of the furnace wall, of the sleeve pipe in a sealed manner. By using the device, the garbage filtrate can be sprayed into the furnace body of the decomposing furnace through the spraying head from the upper end of the decomposing furnace, 100% decomposing of garbage filtrate is achieved, the efficiency of the decomposing is notlowered, the garbage filtrate can be decomposed, and zero discharge of garbage treatment liquid is achieved.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com