Large portal crane beam deformation measuring method based on image and geometric contour

A technology of gantry cranes and crane girders, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of long measurement time, difficulty in matching points with the same name, lack of texture features, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

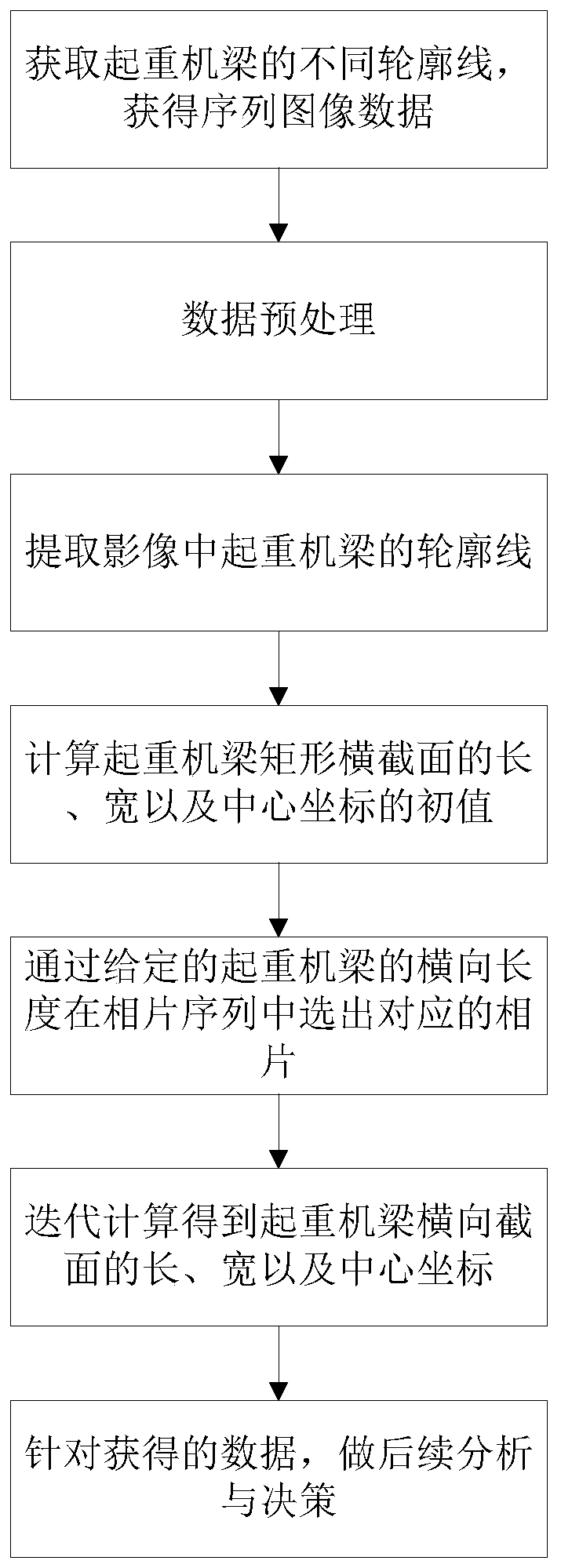

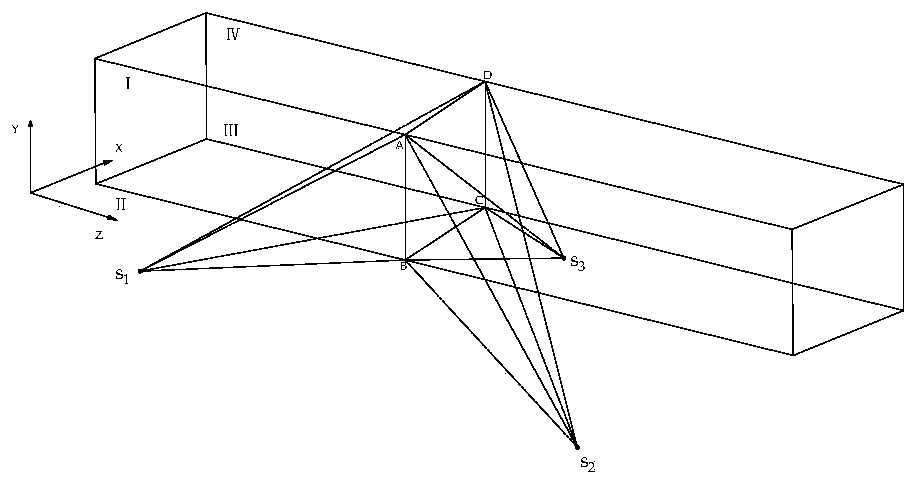

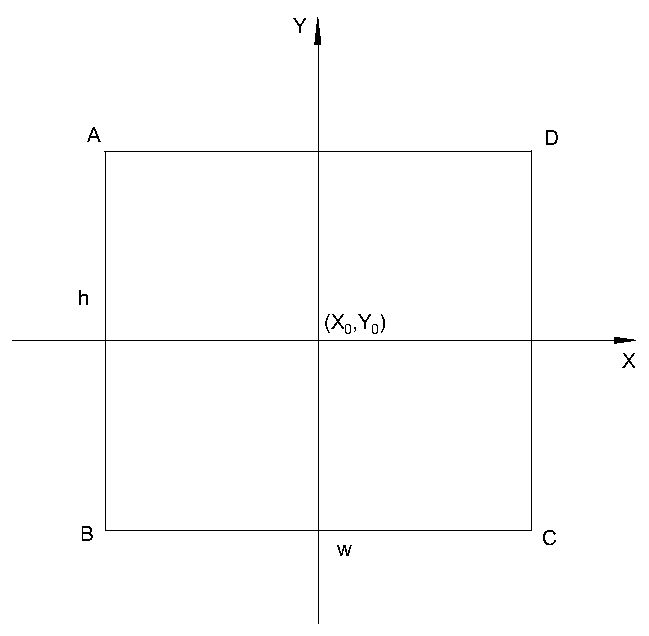

[0025] The present invention introduces photogrammetry and image recognition technology into the measurement field of mechanical engineering equipment, overcomes the strict correspondence between image points and space points required by traditional photogrammetry, introduces the contour constraints of measurement objects, and measures the size of large gantry cranes by taking pictures. deformation of the beam.

[0026] The present invention uses the Image Station 305 (IS) image total station produced by TOPCON Company to complete the work of shooting the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com