Shore power supply for ship

A technology for shore power supply and ships. It is used in flexible AC power transmission systems, conversion equipment for intermediate conversion to DC conversion, and single-grid parallel feeding arrangements. It can solve the problems of low input power, equipment loss, and high voltage. , to achieve the effect of stable output performance, extended service life and less harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

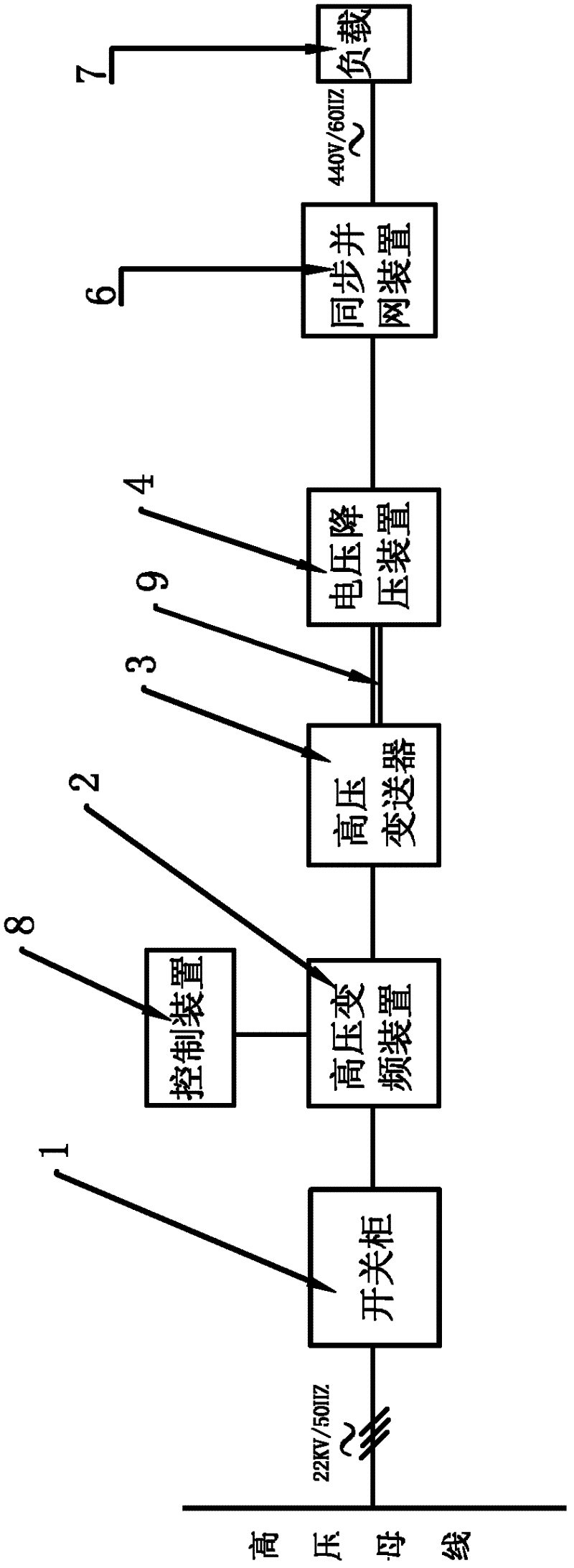

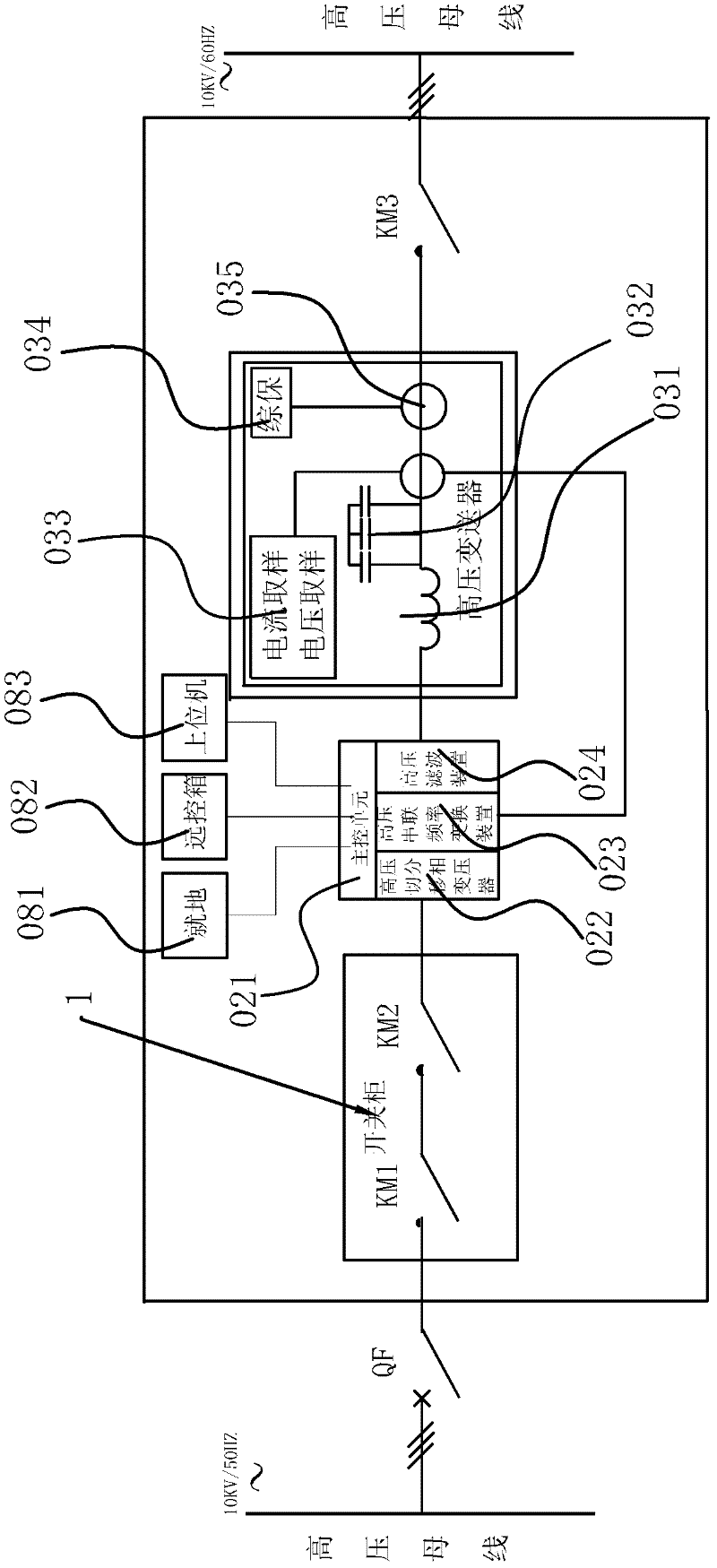

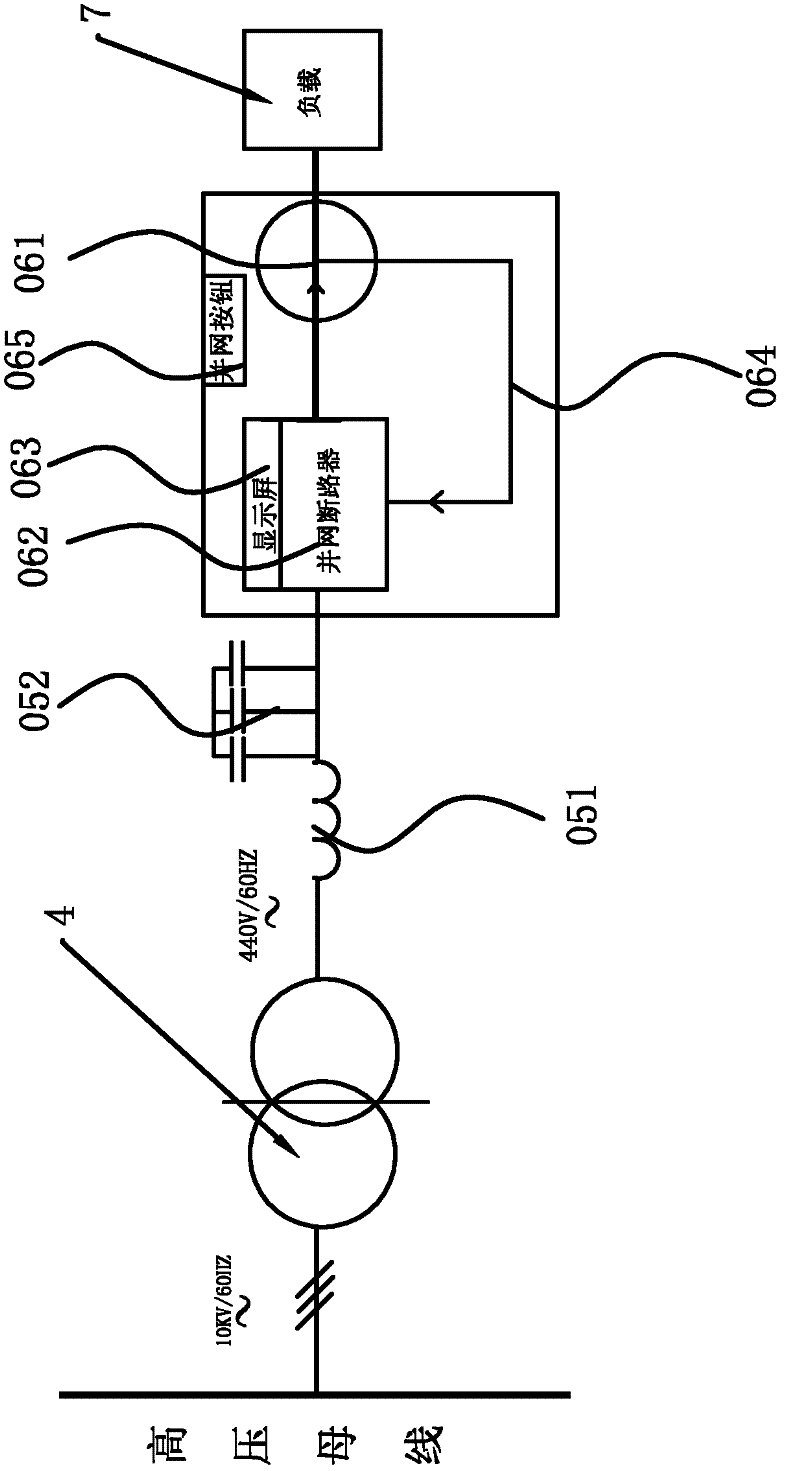

[0026] Such as figure 1 , 2 , 3, a shore power supply for ships, including a switchgear 1 placed on the shore and connected to the three-phase high-voltage bus, characterized in that the shore power supply for ships also includes a high-voltage switchgear connected to the switchgear 1 on the shore Frequency conversion device 2, voltage step-down device 4 and synchronous grid-connected device 6 placed on board. The high-voltage frequency conversion device 2 includes a main control unit 021, a high-voltage split phase-shifting transformer 022, a high-voltage series frequency conversion device 023, and a high-voltage filter device 024. The primary coil of the high-voltage split phase-shifting transformer 022 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com