Patents

Literature

147 results about "Cobalt(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt (III) oxide is the inorganic compound with the formula of Co₂O₃. Although only two oxides of cobalt are well characterized, CoO and Co₃O₄, procedures claiming to give Co₂O₃ have been described. Thus treatment of Co(II) salts such as cobalt(II) nitrate with an aqueous solution of sodium hypochlorite (also known as bleach) gives a black solid. Some formulations of the catalyst hopcalite contain "Co₂O₃".

Water purification ceramic material and preparation method thereof

InactiveCN102219498ATo promote metabolismEfficient dischargeWater/sewage treatment by irradiationWater/sewage treatment by substance additionCalciteRare earth

The invention discloses a water purification ceramic material and a preparation method thereof, relating to a ceramic material. The invention provides a water purification ceramic material capable of releasing negative ions, radiating far infrared rays, resisting bacteria, removing residual chlorine, removing heavy metal and purifying water, and a preparation method thereof. Main components of the water purification ceramic material are tourmaline, copper oxide and iron trioxide. Auxiliary components of the water purification ceramic material are at least one of quartz, calcite, kaolin, feldspar, talc, zirconium oxide, titanium oxide, manganese dioxide, cobalt trioxide and the like. The preparation method comprises the following steps of: mixing the main components; then, mixing the mixedmain components with at least one of the auxiliary components; crushing; screening; ball-milling to obtain a mixture; then sintering to synthesize a spinel type copper oxygen body substrate material;crushing and ball-milling the spinel type copper oxygen body substrate material to form a substrate material; with at least one of copper salt, zinc salt, inorganic silver salt and rare earth metal as a metal source, dissolving the metal source in water to prepare a solution; adding the copper oxygen body substrate material to the solution and adsorbing to form a combination body; after sintering, introducing reducing gas; and forming to obtain the water purification ceramic material.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

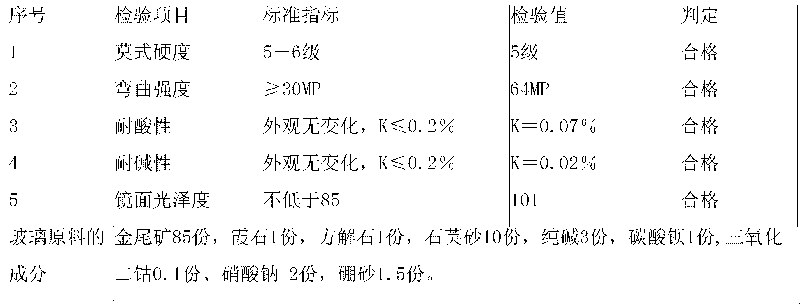

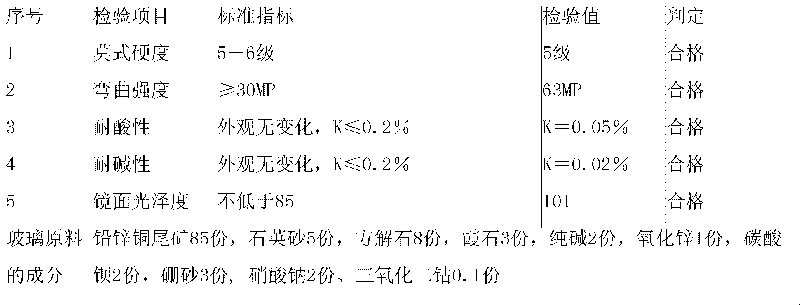

Black micro-crystalline glass plate made of gold ore tailings and manufacturing method thereof

The invention discloses a black micro-crystalline glass plate made of gold ore tailings, which is prepared from the following raw materials in part by mass: gold ore tailings 60-90, quartz sand 8-20, calcite 0.5-2, nepheline 1-2, sodium carbonate 2-5, borax 1-2, barium carbonate 1-8, sodium nitrate 2-6 and cobalt oxide 0.1-0.5. A manufacturing method comprises: crushing and screening the gold ore tailings, the quartz sand, the calcite and the nepheline; removing cyanides from the gold ore tailings by an iron exchange method; weighing the raw materials in proportion and preparing a mixed material; melting the mixed material at 1,250 to 1,350 DEG C to form vitreous humour; allowing molten vitreous humour directly to flow into water to be quenched by water into glass grains; flatly spreading the glass grains in a refractory mould for crystallization; and grinding and cutting an obtained black crystalline glass sample. Compared with the traditional black crystalline glass, the product has more higher quality, and has the advantages of high Mohs' hardness, high bending strength, high chemical stability and pure color.

Owner:君达环保科技(宝鸡)有限公司

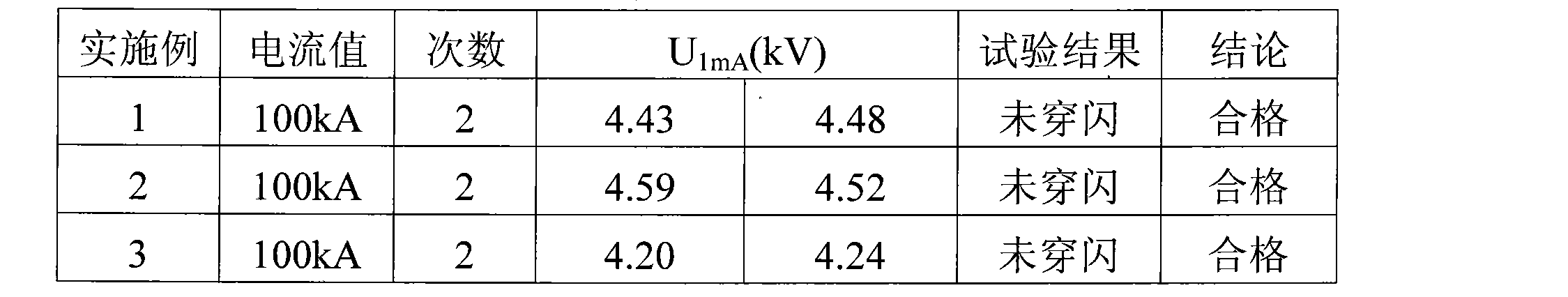

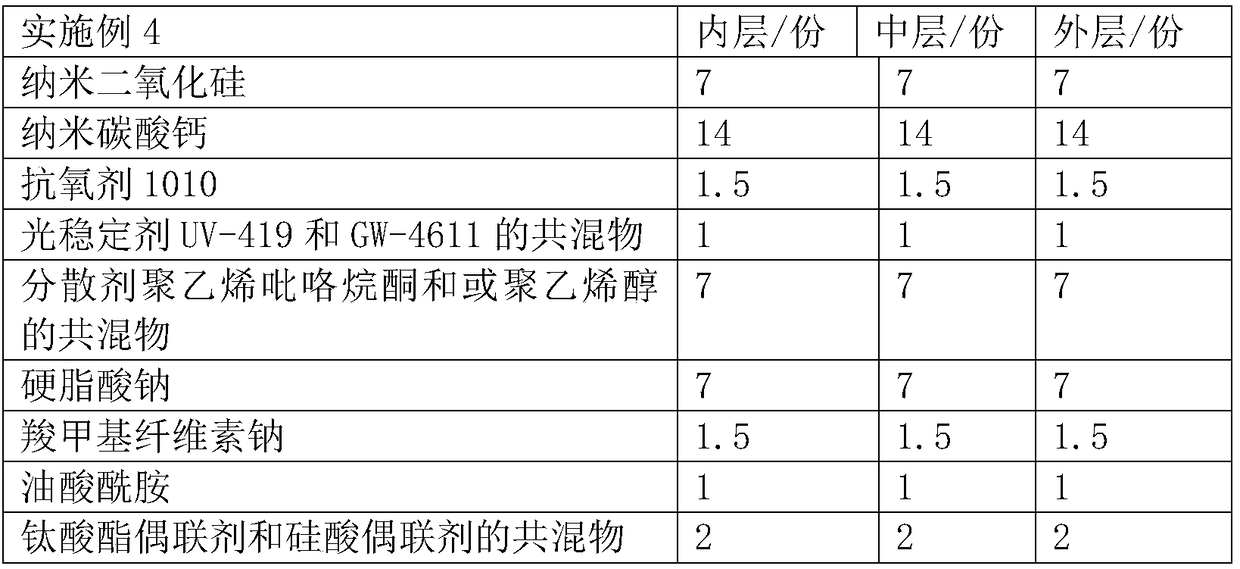

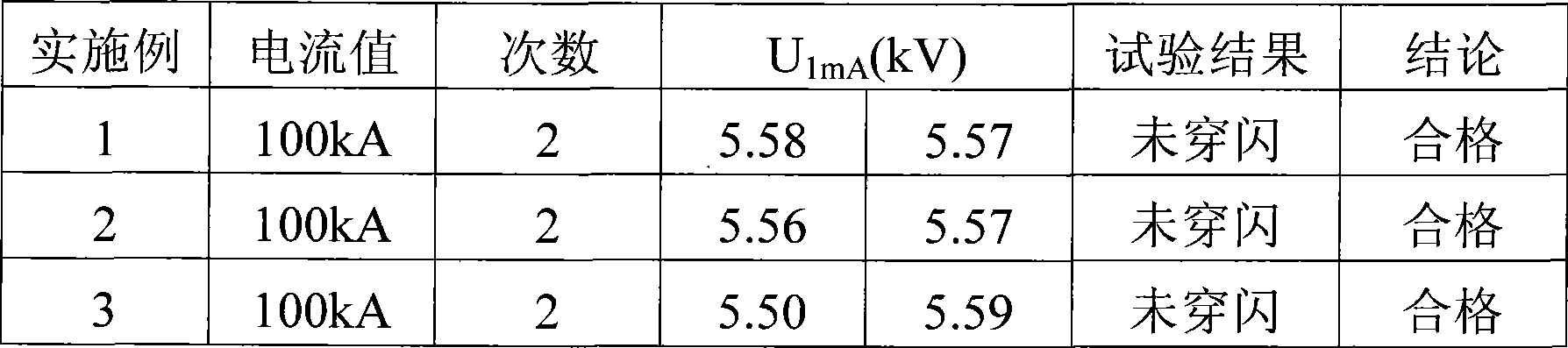

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

Composition for preparing zirconia ceramics and ceramics

The invention discloses a composition for preparing zirconia ceramics, which comprises zirconia, a sintering auxiliary agent and a pigment, wherein the pigment contains cobalt oxide. The invention also provides ceramics, which is prepared by die forming the composition provided by the invention and then sintering the composition. The ceramics prepared from the composition provided by the invention has bright color after being polished and high hardness and bending strength.

Owner:BYD CO LTD

Method for preparing foamed glass by using waste fiberglass products

InactiveCN101955319AEfficient use ofImprove structural strengthAntimony trioxideSodium hexafluoroaluminate

The invention relates to a method for preparing foamed glass by using waste fiberglass products, which comprises the following steps of: firstly, airing collected waste fiberglass mats and fiberglass meshes, manually sorting out the impurities of metal, organic matter and the like, cutting into fragments smaller than 20 mm*20 mm, and ball-milling to 200 meshes to form glass powder; loading the glass powder, silicon carbide, diantimony trioxide, sodium sulfate, sodium fluoaluminate, sodium nitrate and cobalt oxide into a ball mill, and ball-milling to form a batch; loading the batch into a heat-resisting mold, and firing into foam glass. In the invention, the waste fiberglass products are used as a main raw material to produce foam glass, and the prepared foam glass has low density, high strength, small heat conductivity and low water absorption rate. The preparation method has simple operation process, low founding temperature and low cost, not only changes wastes into valuables, but also protects the environment, and is applicable to industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Blue zirconium oxide ceramic and preparation method thereof

The invention provides blue zirconium oxide ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing cobalt sesquioxide, aluminium oxide, silicon dioxide, a dispersing agent and water to obtain primary slurry; performing sanding treatment on the primary slurry to obtain first-level slurry; drying the first-level slurry and roasting to obtain a blue base material of a cobalt aluminum spinel structure; mixing the blue base material of the cobalt aluminum spinel structure, zirconium oxide, yttrium oxide, the dispersing agent and water to obtain second-level slurry; performing sanding treatment on the second-level slurry to obtain third-level slurry; mixing the third-level slurry and an adhesive, and pelleting, forming, discharging glue and roasting to obtain the blue zirconium oxide ceramic. The grain size of the materials obtained in each step can be fined to be below 80 nm by a sanding technology, the activity of powder materials is improved, the mass transfer distance between particles is shortened, and the cobalt aluminum spinel blue base material can be mixed uniformly, so that the color uniformly of the blue zirconium oxide ceramic is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

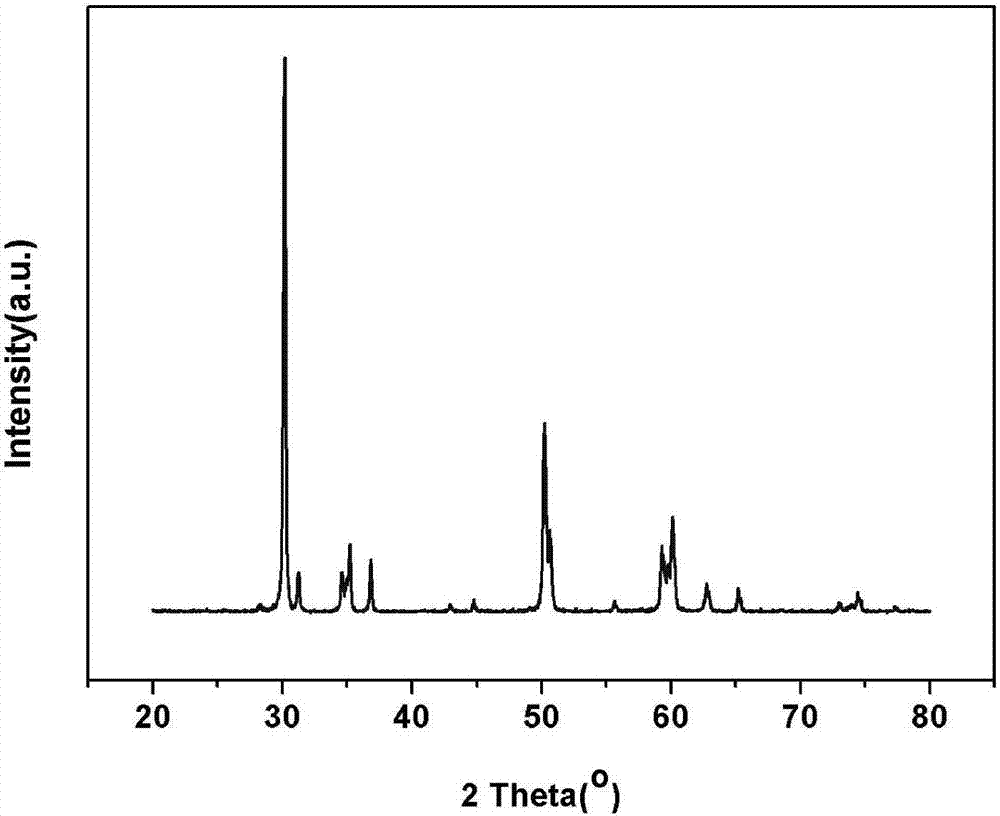

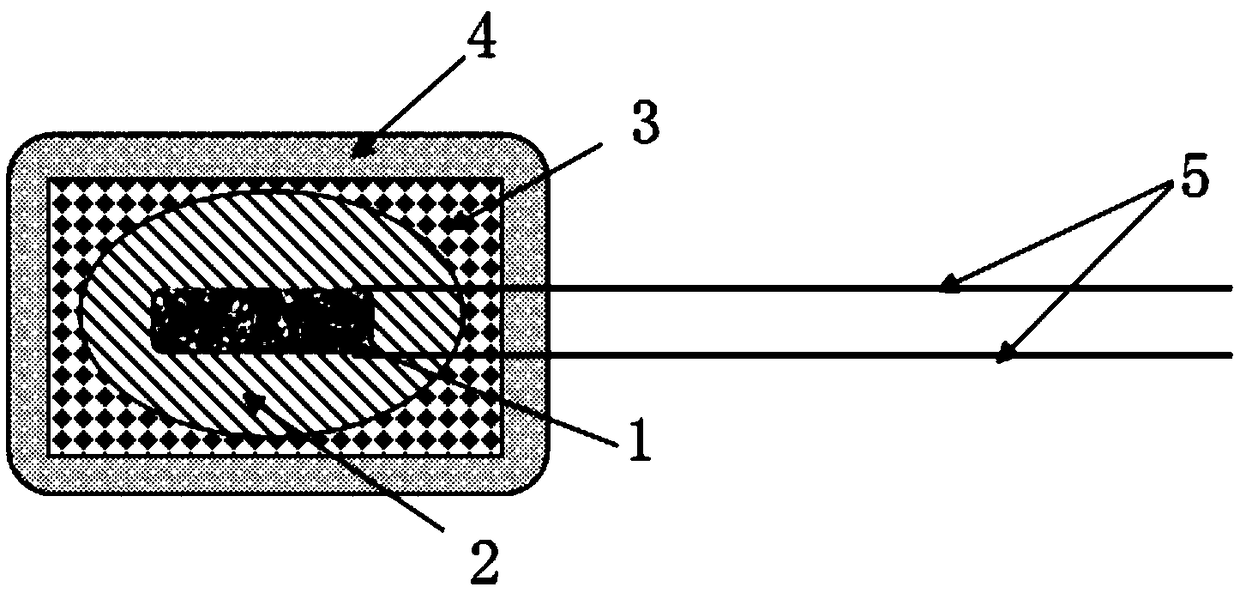

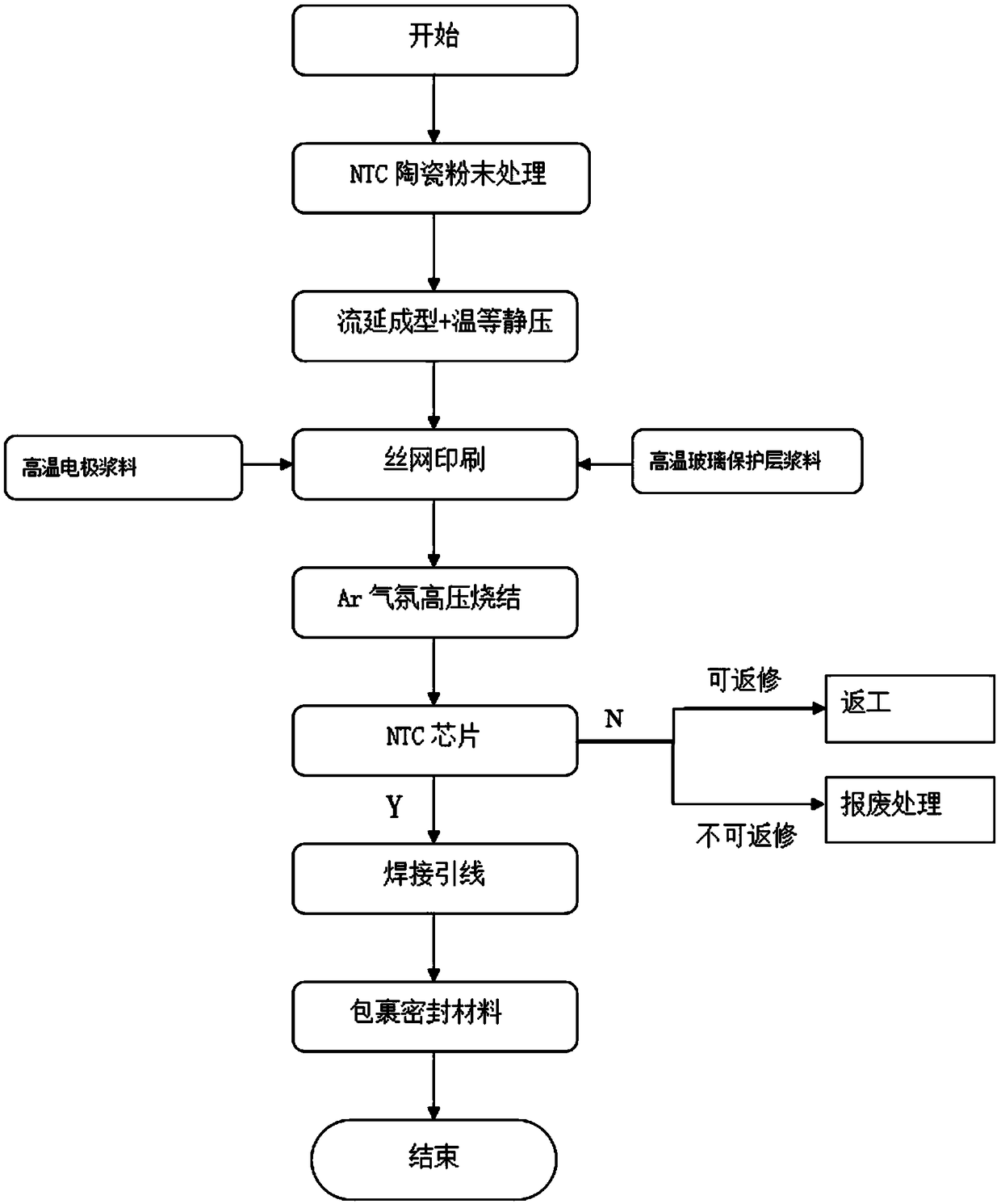

Thermosensitive ceramic powder, NTC thermosensitive chip, temperature sensor and preparation method

ActiveCN109053158AStrong reliabilityNo breakageThermometers using electric/magnetic elementsUsing electrical meansRare earthMechanical pressure

The invention discloses thermosensitive ceramic powder, a NTC thermosensitive chip, a temperature sensor and a preparation method. The ceramic powder disclosed by the invention is prepared from the following components in percentage by weight: 18-38% of manganese dioxide powder, 12-20% of cobalt oxide powder, 4-14% of iron oxide powder, 21-41% of nickel oxide powder and 2-10% of rare earth oxide powder. The temperature sensor disclosed by the invention has the advantages of perfect softness, bending resistance, vibration resistance, wear resistance, corrosion resistance and the like, and is adapted to quite harsh environment of oil stain, EMI, mechanical pressure and the like in a motor; the temperature sensor is required to work stably for a long time in bad conditions.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

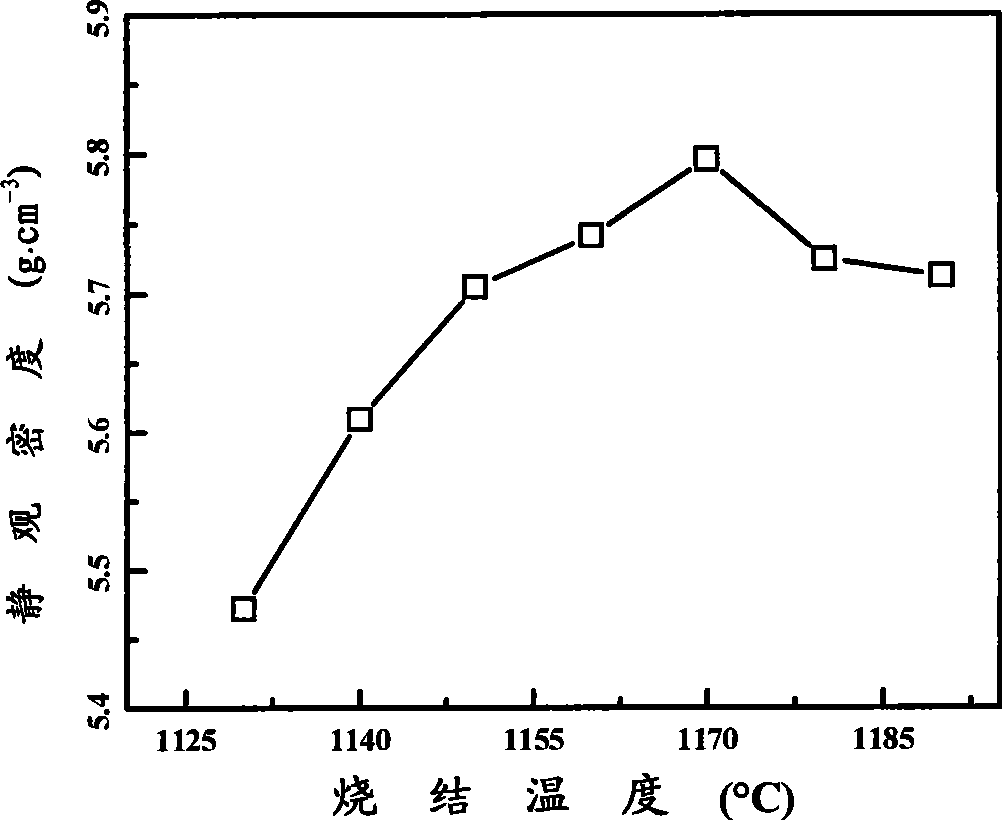

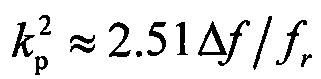

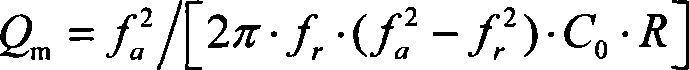

Ternary system sodium bismuth titanate base leadless piezoelectric ceramics material and preparation method thereof

InactiveCN101381231AHigh depolarization temperatureGood piezoelectricSesquioxideIntermediate frequency

The invention discloses a trinary sodium bismuth titanate based lead-free piezoelectric ceramic material and a method for preparing the same, and belongs to the field of functional ceramics and manufacture thereof. The invention aims to improve the depolarization temperature and mechanical quality factor of the prior trinary sodium bismuth titanate based lead-free piezoelectric ceramic material. The component of ceramic material of the invention is (100-x)Bi1 / 2Na1 / 2TiO3-xBaTiO3-yCo2O3, wherein x is more than or equal to 2 and less than or equal to 4, and y is more than or equal to 0.25 and less than or equal to 2.0. The method is to prepare the ceramic material from raw materials of natrium carbonicum calcinatum, anhydrous potassium carbonate, bismuth oxide, titanium dioxide, barium carbonate and cobalt sesquioxide through pre-synthesis, roll forming and sintering. The ceramic material prepared by the method has high depolarization temperature which is 157 DEG C, high mechanical quality factor which is 626, and excellent piezoelectric and dielectric properties and can be used for manufacturing intermediate frequency ceramic filters, resonators, piezoelectric gauges and actuators.

Owner:BEIJING UNIV OF TECH

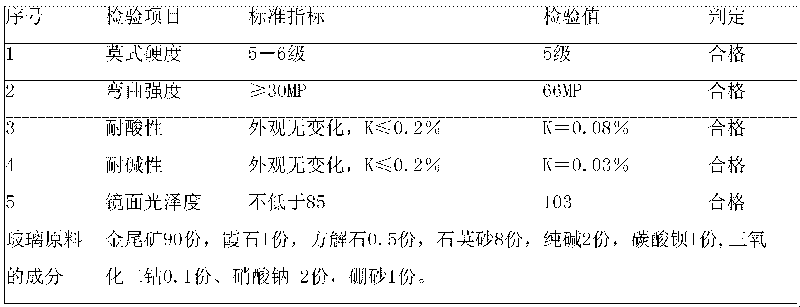

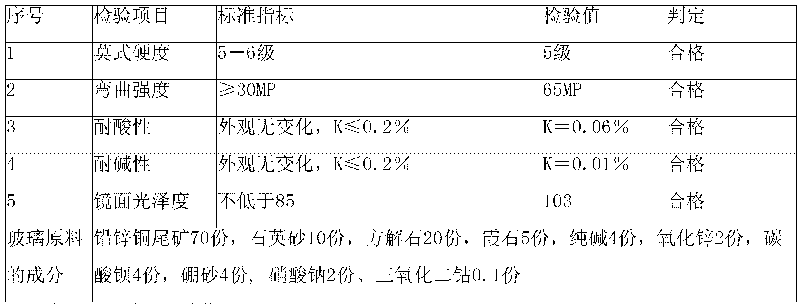

Black micro-crystal glass plate manufactured from lead-zinc-copper tailings and manufacturing method thereof

The invention relates to a black micro-crystal glass plate manufactured from lead-zinc-copper tailings, which is manufactured from the following raw materials in parts by weight: 60-90 parts of lead-zinc-copper tailings, 5-10 parts of quartz sand, 8-20 parts of calcite, 3-7 parts of nepheline, 2-4 parts of soda, 1-6 parts of zinc oxide, 2-8 parts of barium carbonate, 2-5 parts of borax, 2-6 parts of sodium nitrate and 0.1-0.5 part of cobalt oxide. The manufacturing method of the black micro-crystal glass plate comprises the following steps: grinding the lead-zinc-copper tailings, the quartz sand, the calcite and the nepheline into powder; removing cyanides from the lead-zinc-copper tailings by using an ion exchange method; weighing in proportion and preparing into a mixture; melting at 1250 DEG C-1350 DEG C; pouring the mixture into water for water quenching to obtain glass particles; horizontally laying the glass particles into a fire-resistant mold for crystallization treatment; and grinding and cutting black micro-crystal glass samples. The invention can relieve the harm of the tailings to the environment, reduce the cost of raw materials, and improve the product quality.

Owner:君达环保科技(宝鸡)有限公司

Optical pigment and its preparation method

ActiveCN103911023AReduce dosageReduce thicknessInorganic pigment treatmentSesquioxideSilicon dioxide

The invention relates to an optical pigment comprising a substrate and a coating layer coating the substrate. The substrate is at least successively coated with three coating matters. The three coating matters are successively selected from titanium dioxide, stannic oxide, ferric oxide, ferroferric oxide, cobaltous oxide, cobalt sesquioxide, zirconium dioxide, chromic oxide or a mixture and a compound thereof; silicon dioxide; and aluminum oxide, bismuth trioxide or a mixture or compound thereof. The optical pigment provided by the invention overcomes the defects of small particle diameter reflecting surface and low color saturation due to small pigment particles in the prior art. At the same time, the invention also relates to a preparation method of the optical pigment, the preparation method overcomes the defects of ''layer lamination '' of the coating layer in the prior art, meanwhile the coating amount of the coating layer is reduced, and the number of particles per unit weight is increased, so that color of the prepared pigment is more full, rich and varied.

Owner:SHANTOU LONGHUA PEARL LUSTRE PIGMENTS CO LTD

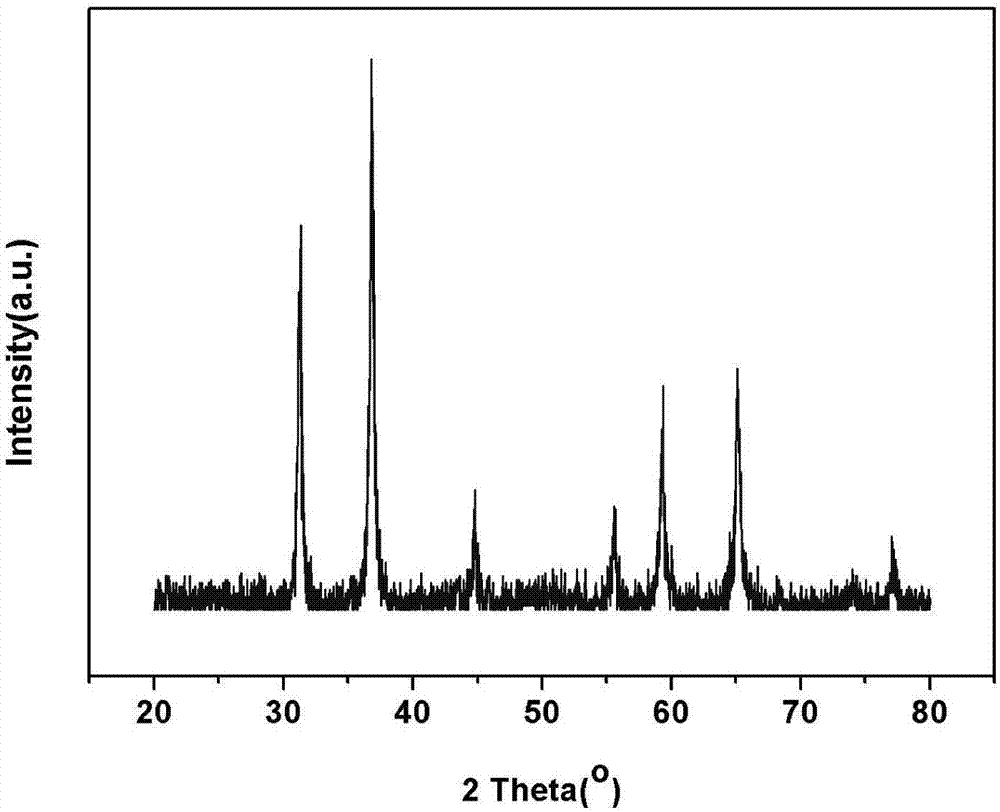

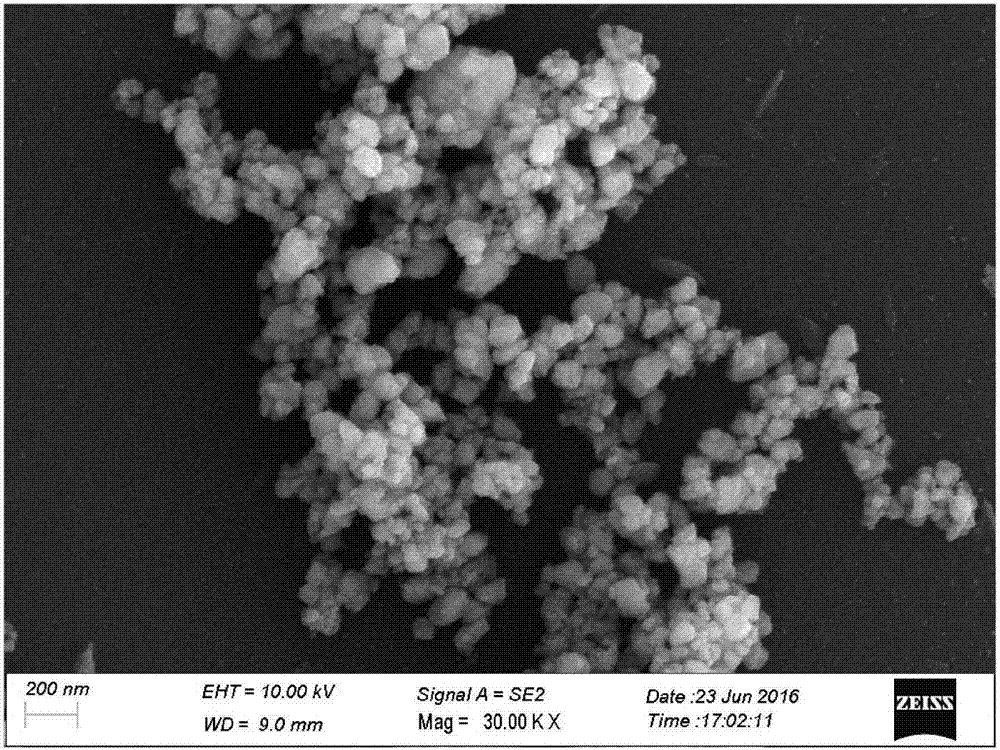

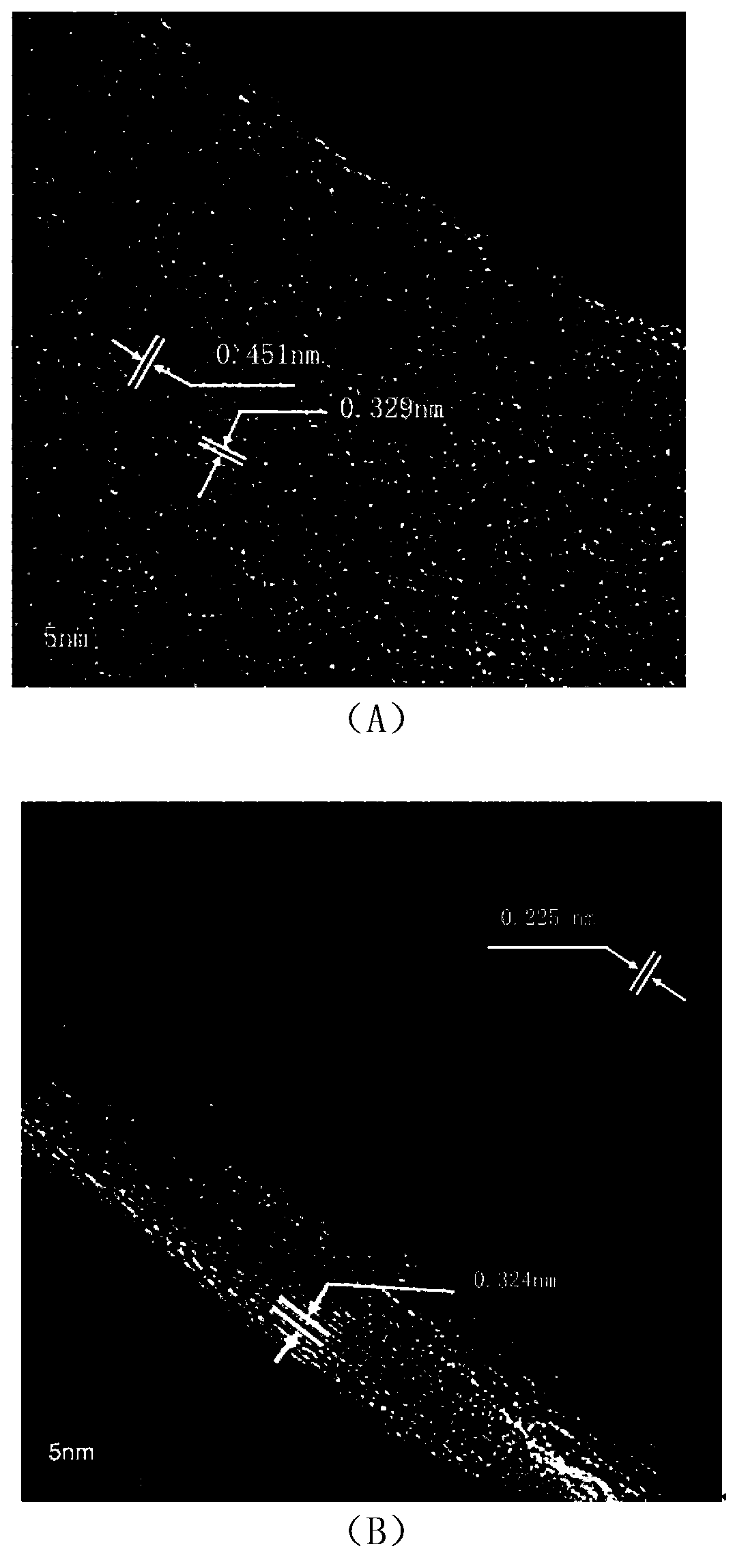

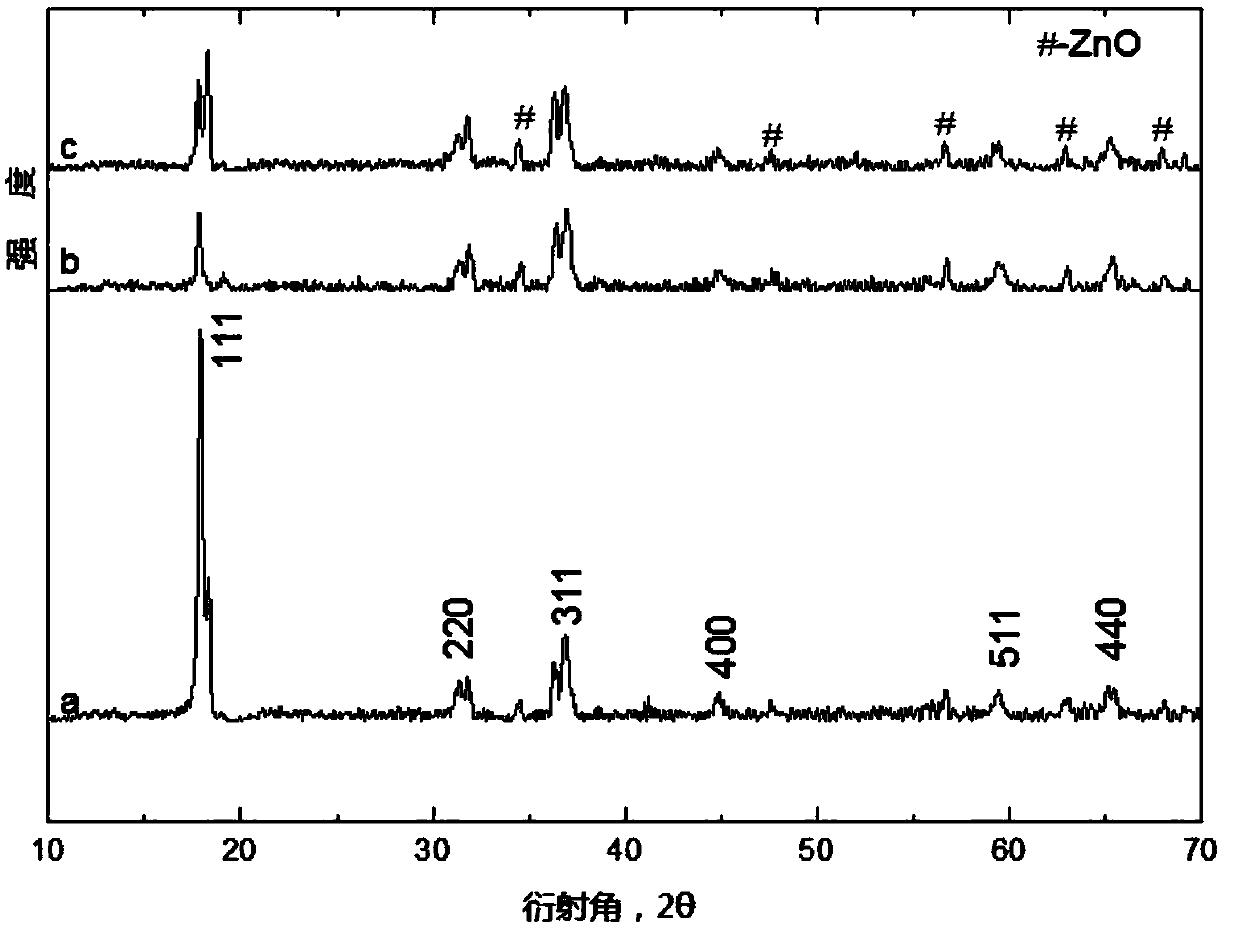

Preparation method ofzinc cobaltatenanometer material doped with zinc oxide

InactiveCN103420431AEasy to operateSimple processMaterial nanotechnologyCobalt compoundsConcentration ratioReaction temperature

A preparation method of a zinc cobaltate nanometer material doped with zinc oxide comprises the following steps: dispersing the zinc oxide and cobaltic oxide in deionized water according to a certain molar ratio, so as to obtain a first solution; heating the first solution for a certain time at a first constant temperature, so as to obtain a second solution; cooling the second solution until the temperature of the second solution to be the room temperature, and performing rinsing and low-temperature drying, so as to obtain the zinc cobaltate nanometer material; wherein the certain molar ratio is (1:2)-(2:1), the first constant temperature is 120-180 DEG C, and the certain time is 12-48 hours. The preparation method adopts a hydro-thermal synthesis system, and directly takes the oxide (i.e. the zinc oxide) as the reactant to prepare the zinc cobaltate nanometer material; the reaction time, reaction temperature and reactant concentration ratio are regulated; the variety and using amount of additive are changed. Therefore, the morphology and grain sizes of the particles are controlled. The preparation method has the advantages of low raw material and equipment costs, simple process, easiness in operation, relatively-low reaction temperature and low environment pollution.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

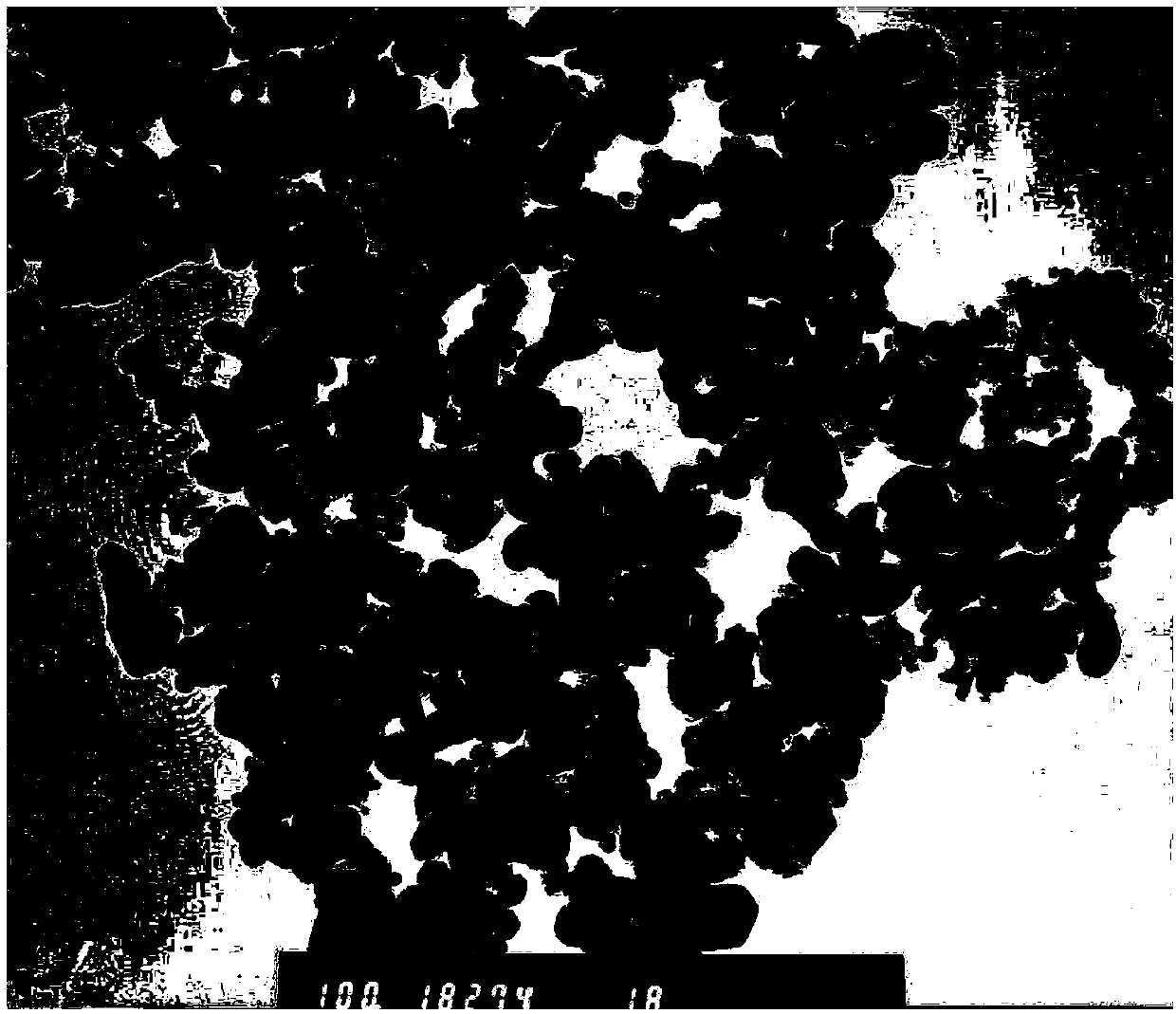

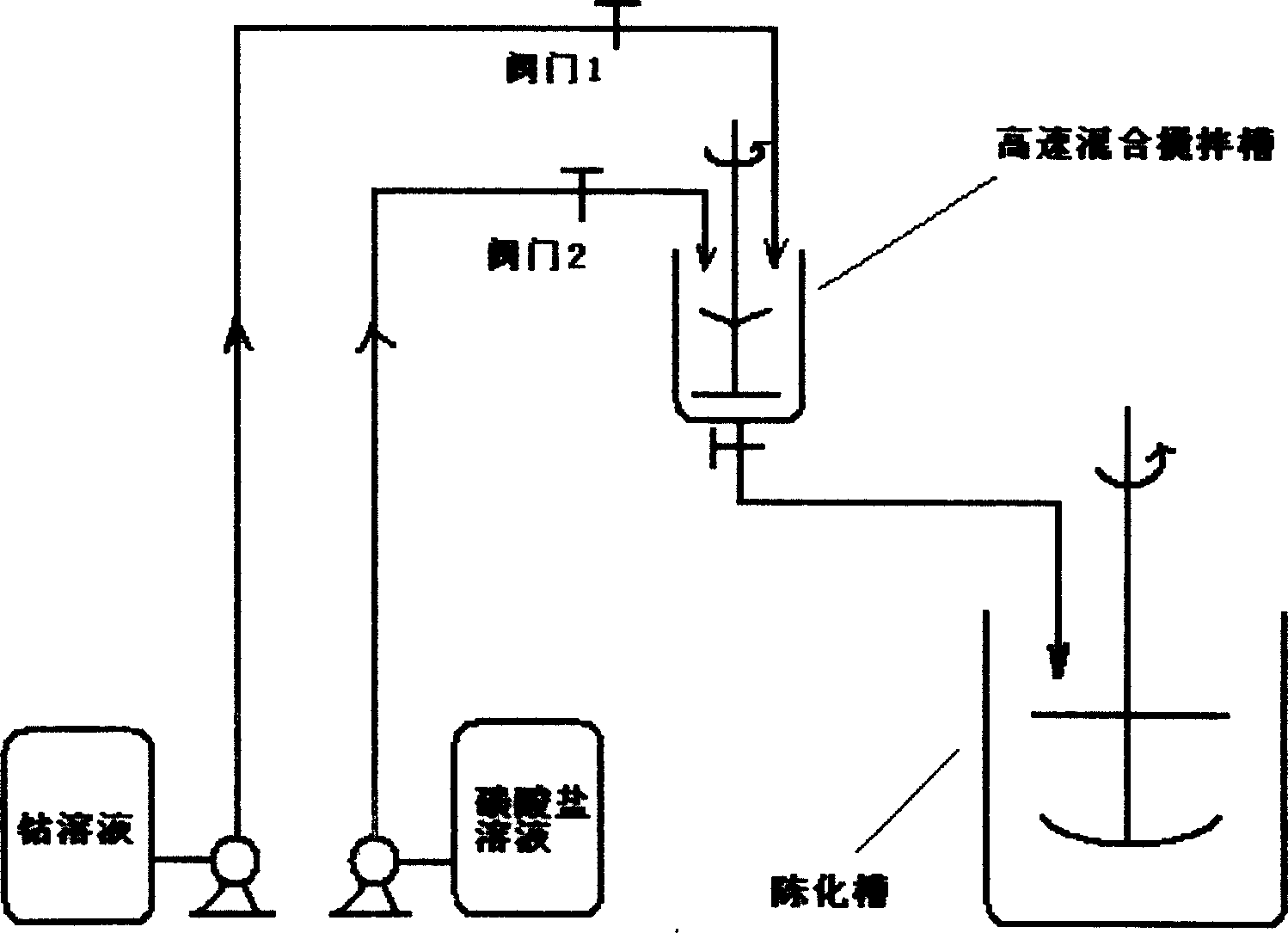

Process for preparing superfine cobalt oxide powder by booster parallel-flow precipitation

InactiveCN1693213AUltrafine particle sizeSmall granularityCobalt oxides/hydroxidesCobalt(II,III) oxideHigh intensity

A process for preparing the superfine cobalt oxide powder includes such steps as high-speed pumping the Co salt solution and carbonate precipitant into a small-volume intermediate reactor with strong stirrer for mixing, stirring in a large-volume stirrer, ageing, drying and calcining at 300-900 deg.C for 4-15 hr.

Owner:CENT SOUTH UNIV +1

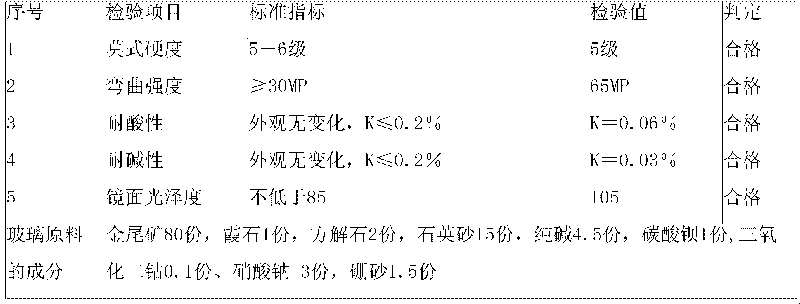

Black high-strength microcrystalline glass and its preparation method

The invention discloses a black high-strength microcrystal glass, which comprises the following parts: 70% SiO2, 3. 5% Lithia, 17% alumina, 0.1%-0.5% ferric trioxide, 0.5%- 1% cobalt trioxide, 0.5%-1% nickel trioxide, 3. 1% -3. 5% at least one of titania, zirconia and phosphorus pentoxide, 1%-1. 5% at least one of magnesia, zinc oxide, barium oxide and boric oxide, 2. 0%-2. 1% potassium oxide and or sodium oxide and 1% arsenic oxide and or antimony oxide. The making method of microcrystal glass comprises the following steps: grinding evenly; adding reducer to allocate composite material; fusing under 1580 -1650 deg. c; shaping; annealing; coring under 600-800 deg. c for 1-4h; heating to 700-1000 deg. c to crystallize for 1-12h.

Owner:ZHEJIANG UNIV

High energy type zinc oxide piezoresistor material and preparation method thereof

InactiveCN102515740AReduce the residual pressure ratioReduce leakage currentVaristor coresOvervoltage protection resistorsTin dioxideHigh energy

The invention relates to a high energy type zinc oxide piezoresistor material and a preparation method thereof, which belong to the technical field of piezoresistor material preparation. The preparation method comprises (1) enabling manganese carbonate, barium carbonate and strontium carbonate to be mixed, ball-milled and calcined to obtain mixture A; (2) enabling titanium oxide, antimony pentoxide, bismuth trioxide, cobalt oxide, nickel oxide, silica and stannic oxide to be mixed in submicron-sized zinc oxide powder to obtain mixture B which is mixed and ball-milled with the mixture A to obtain mixture C; and (3) adding aluminum nitrate, silver nitrate, magnesium nitrate, a dispersing agent and an antifoaming agent in the mixture C, ball-milling and drying to obtain high energy type zinc oxide piezoresistor composite powders which are formed in a pressing mode and sintered to obtain a high energy type zinc oxide piezoresistor. The high energy type zinc oxide piezoresistor material is simple in preparation method, prepared zinc oxide piezoresistor has high energy density, low leakage current and residual voltage ratio, batch of products is stable, acceptability is high, and the high energy type zinc oxide piezoresistor material is applicable to scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

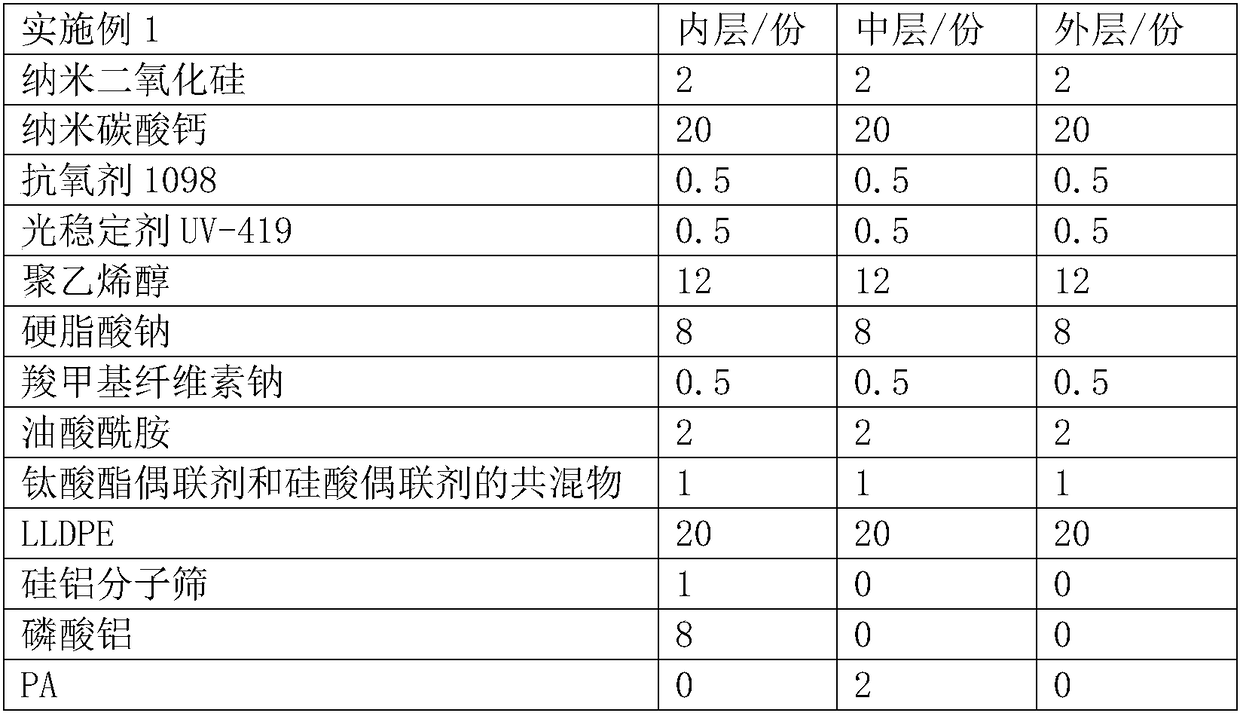

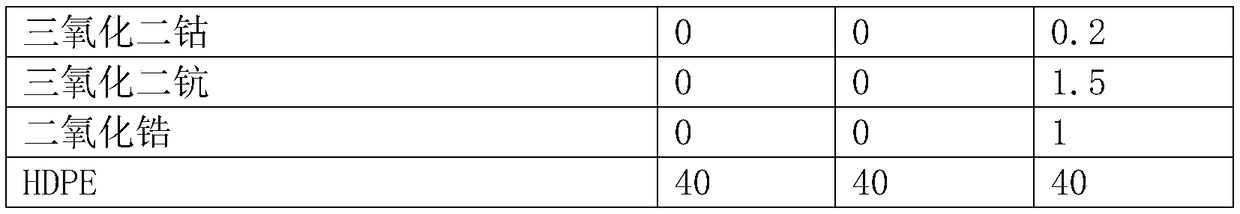

Extinction casting PE (polyethylene) film and preparation method thereof

ActiveCN108314818AImprove uniformityGood flexibilityFlexible coversWrappersAntioxidantALUMINUM PHOSPHATE

The invention discloses an extinction casting PE (polyethylene) film and a preparation method thereof. The extinction casting PE film has a three-layer structure of an inner layer, a middle layer andan outer layer; the PE film comprises the following preparation raw materials: nanometer silicon dioxide, nanometer calcium carbonate, an antioxidant, a light stabilizer, a dispersing agent, a lubricating agent, a tackifier, a slipping agent, a coupling agent, LLDPE, a silicon aluminum molecular sieve, aluminum phosphate, PA, cobalt oxide, scandium oxide, zirconium dioxide and HDPE; and the PE film is prepared by the steps of preparing an inner-layer film-forming material, a middle-layer film-forming material and an out-layer film-forming material by selecting different raw materials, and adding the above three layers of film-forming materials into a co-extrusion casting stretcher to prepare the PE film. The casting PE film prepared by the method has extinction property and has high tensile strength, anti-puncture strength and flame resistance.

Owner:四川厚诚新材料有限公司

High-strength and high-abrasion-resistance brown aluminum oxide ceramic and preparation method thereof

PendingCN108793974ABeautiful and generous colorQuality improvementSilicon dioxideMechanical property

The invention discloses a high-strength and high-abrasion-resistance brown aluminum oxide ceramic and a preparation method thereof and belongs to the technical field of aluminum oxide ceramics and aims to solved the technical problems and remarkably improving the mechanical property of the ceramic under the situation that the firing temperature is not improved, decreasing raw materials, reducing the manufacturing cost and improving the production efficiency. According to the adopted technical scheme, the high-strength and high-abrasion-resistance brown aluminum oxide ceramic is prepared from,by weight, 1-3.5 parts of manganese dioxide, 1-3 parts of iron trioxide, 0.1-0.5 part of magnesium oxide, 0.5-1.5 parts of silicon dioxide, 0.5-2 parts of kaoline, 2-8 parts of calcium oxide, 2-5 parts of zirconium oxide, 0.3-0.8 part of cobaltic oxide, 1-3 parts of barium carbonate, 0.3-0.8 part of chromic oxide and 100 parts of aluminum oxide. The prepared high-aluminum ceramic product has darkand light-toned brown colors due to different ingredient contents and is attractive in appearance.

Owner:河津市锦浩特种陶瓷有限公司

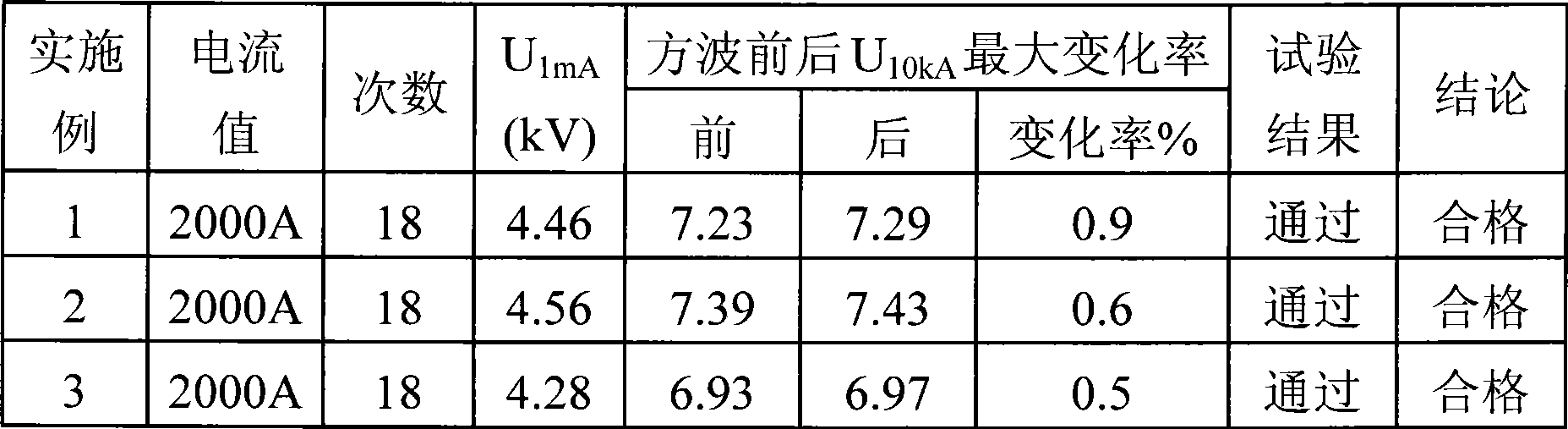

Formula of high pressure AC zinc oxide resistance chip

ActiveCN101503291AUniform and stable structureImproved energy toleranceVaristor coresSesquioxideCarbide

The invention discloses a formulation of a high-voltage AC zinc oxide resistance chip. The formulation comprises the following additives and a main material ZnO by weight percentage: 4.5 to 5.5 percent of Bi2O3, 5.0 to 6.0 percent of Sb2O3, 0.8 to 1.2 percent of Co2O3, 0.9 to 1.1 percent of MnCO3, 1.0 to 1.5 percent of NiO, 0.02 to 0.04 percent of aluminum nitrate, 0.010 to 0.050 percent of glass dust and 85.0 to 87.5 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: 1, the formulation is a new formulation system using the zinc oxide, dibismuth trioxide, diantimony trioxide, nickel protoxide, cobalt sesquioxide and manganous carbide as main compositions, so that the internal structure of the resistance chip is more uniform and stable, and the energy endurance capability is greatly improved; and 2, the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the resistance chip is more excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

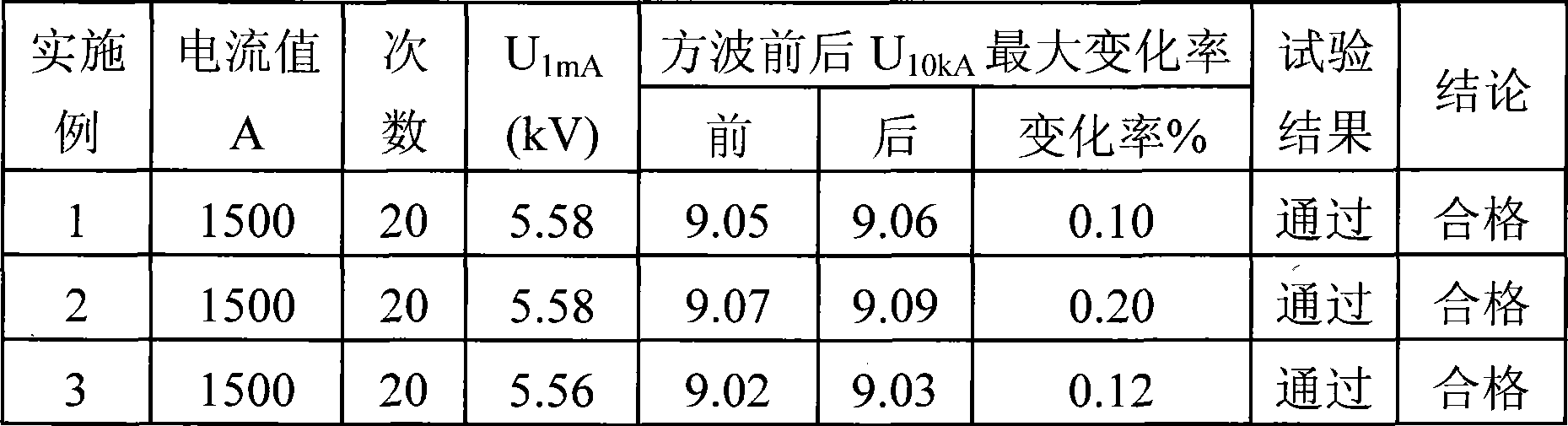

Large-capacity small-size high-gradient alternating current zinc oxide resistor sheet and preparation process thereof

ActiveCN106803449AGrowth inhibitionImprove microstructureResistor manufactureOvervoltage protection resistorsAlternating currentAntimony trioxide

The invention provides a large-capacity small-size high-gradient alternating current zinc oxide resistor sheet and a preparation process thereof; the product is prepared by, with a zinc oxide powder as a main material, properly adding antimonous oxide, bismuth trioxide, cobaltic oxide, cobaltosic oxide, silicon dioxide, manganese dioxide, chromic oxide and other metal oxides, and carrying out weighing, ball-milling mixing, drying, granulation, dry pressing molding, pre-sintering, high temperature sintering, sheet grinding, heat treatment, electrode spraying, glaze coating and other processes. The product has the advantages of large capacity, small size, high electric potential gradient, safety and reliability and the like, and is suitable for use of small-sized large-capacity lightning arresters; and the preparation process is simple and convenient, and is suitable for industrialized production.

Owner:STATE GRID CORP OF CHINA +2

Nanometer intelligent cleaning antibacterial pearl ceramic glaze

A nanometer intelligent cleaning antibacterial pearl ceramic glaze comprises the following components in parts by weight: 200 parts of common ceramic glaze, 0-10 parts of zinc oxide, 0.7-1.0 part of bismuth trioxide, 1.5-1.8 parts of diantimony trioxide, 0.7-1.0 part of manganese dioxide, 1.5-1.8 parts of cobalt oxide, 0.7-1.0 part of chromium oxide, 1.5-1.8 parts of nickel monoxide, 2.0-2.8 parts of silicon dioxide, 0.15-0.2 part of boron trioxide, 0-0.2 part of aluminium nitrate nonahydrate and the balance inorganic nanometer material. The production process of the ceramic glaze comprises the following steps: transferring the raw materials into a plant; inspecting the appearances of raw materials, performing chemical examinations, performing calcination tests; determining the raw material proportionings; milling with a ball mill; sieving the finished glaze to remove impurities; sending the sieved glaze to a glaze slurry storage pool to mix evenly with a mixer; spraying; and calcining to obtain the finished product. The preparation process of the invention is simple, water-saving, environmentally friendly and economical; the ceramic glaze has high glaze density, fewer tiny holes, high brightness and smoothness, large scope of heat resistance, good acid resistance and alkali resistance and self-cleaning and antibacterial effects.

Owner:陈干礼

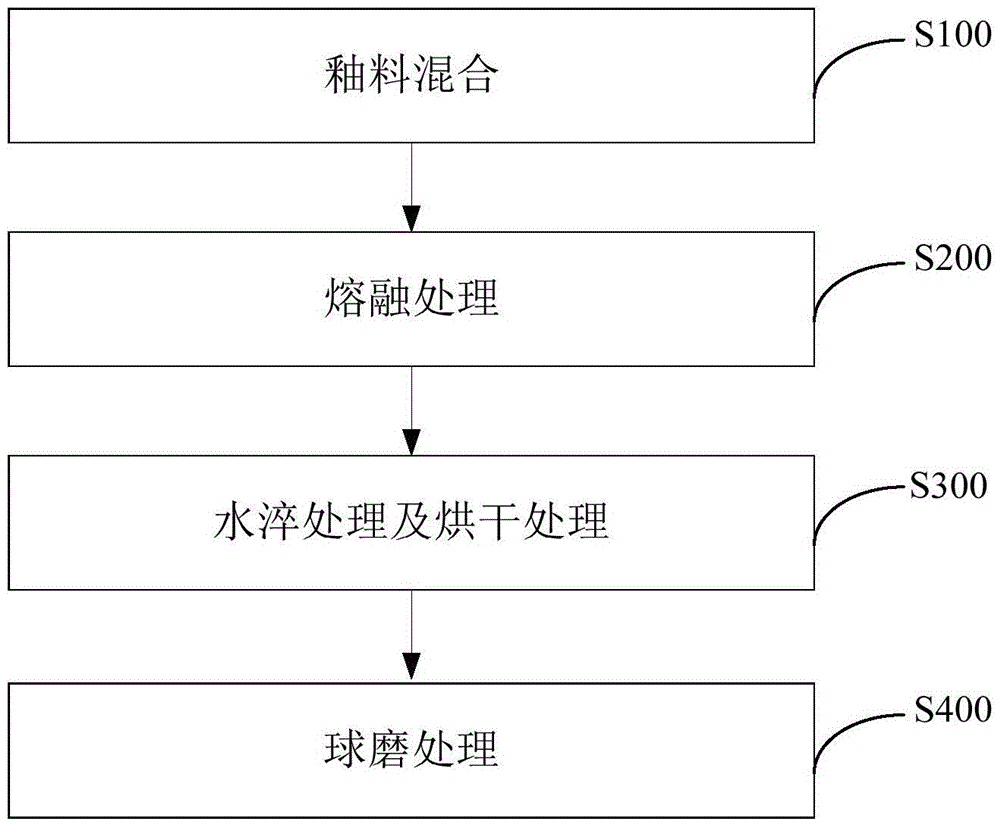

Method for preparing thick-film dielectric glass powder

The invention relates to a method for preparing thick-film dielectric glass powder. The method comprises the following steps: adopting pyrophyllite and limestone as main raw materials, adding small amounts of boric acid, titanium dioxide, zirconium dioxide, cobalt sesquioxide and industrial alumina, and then performing mixing, high-temperature smelting, water quenching and grinding to prepare the thick-film dielectric glass powder. The method for preparing the thick-film dielectric glass powder has the benefits that the thick-film dielectric glass powder prepared by the method can reduce the smelting temperature of glass, can reduce energy consumption, and can reduce defects of blending impurities, local micro-cracks and the like caused by introducing a heterogeneous nucleating agent, and the insulating property and thermal shock resistance of glass media are further improved; the method is simple in operation and is easy to realize industrialization, and the thick-film dielectric glass powder has a good using effect and is beneficial to promote.

Owner:青田县南方玻纤原料有限公司

Deep low temperature oxide thermosensitive resistor material

InactiveCN1744240AWide temperature rangeLow costNegative temperature coefficient thermistorsOxide conductorsRare-earth elementLiquid hydrogen

The material is nonstoichiometric oxide material in structure of perovskite SrCoO1-xNixO3-5 (delta is larger than and equal to 0, and less than and equal to 0.1, delta is larger than and equal to 0, and less than and equal to 0.5). Through testing shows that the disclosed material is comparable to approved products used under temperatures of liquid oxygen, liquid nitrogen or liquid hydrogen. Component parts obtained is operable at temperature 4.2K-20K. Advantages are: wide workable temperature region; cost is lowered since the disclosed material does not contain rare earth element.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Desulphurizer for high-sulphur coal coke making and preparation method and applications

The invention discloses a desulfurizing agent for coke making of high-sulfur coal, which comprises the following compositions: the mass ratio of a main desulfurizing agent to a desulfurizing auxiliary agent is between 100 to 5 and 30, wherein the main desulfurizing agent consists of Fe2O3 and Ni2O3, and the compositions with mass percentages are 10 to 90 percent of Fe2O3 and 10 to 90 percent of Ni2O3. The desulfurizing auxiliary agent is one or more of titanium dioxide, manganese dioxide, cobalt sesquioxide, chromium acetate or ammonium molybdate. The compositions are mixed, then are sent into a crushing machine, and are crushed to the size below 74mu to obtain the desulfurizing agent. The desulfurizing agent has the advantages of good desulfurization effect and no influence on the quality of molten iron.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

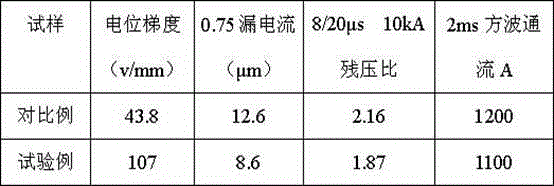

Manufacturing method for medium-voltage high-energy zinc oxide resistor disc

InactiveCN102723157AEffective control of average particle sizeControl average particle sizeResistor manufactureVaristor coresHigh energySilver carbonate

Disclosed is a manufacturing method for a medium-voltage high-energy zinc oxide resistor disc. The manufacturing method includes: adding, by mole percentage, 0.5-1.2% of antimonous oxide, 0.1-0.6% of titanium dioxide, 0.5-1.3% of bismuth oxide, 0.8-2.1% of cobaltic oxide, 0.6-1.3% of manganese carbonate, 0.001-0.003% of silver carbonate, 0.3-0.6% of stannic oxide, 0.002-0.005% of strontium carbonate, 0.001-0.006% of boric acid and balance of zinc oxide serving as the major ingredient, ball-milling, mixing, spraying for granulation, water-containing, forming and sintering. The medium-voltage resistor manufactured by the method is lowered in residual voltage ratio and improved in through-flow performance, and the gradient reaches to 100-120V / mm, 10Ka residual voltage ratio can be controlled within 1.85-1.90 when a phi 60 resistor disc is taken as an example.

Owner:扬州发运电气有限公司

Blue composite transmutation glaze material and method for preparing transmutation glaze ceramic by adopting glaze material

The invention discloses a blue composite transmutation glaze material and a method for preparing transmutation glaze ceramic by adopting the glaze material. A ground coat is prepared from the following materials in percentage by weight: 18 to 38% of feldspar, 0 to 20% of frit, 5 to 14% of calcite, 10 to 12% of calcined kaolinite, 6 to 12% of raw kaolinite, 4 to 13% of quartz, 12 to 18% of wollastonite, 6 to 12% of talc, 3.5 to 6.5% of aluminum oxide, 6 to 12% of ferric oxide, and 0.5 to 3.5% of cobalt sesquioxide; a surface coat is prepared from the following materials in percentage by weight:10 to 30% of feldspar, 0 to 30% of frit, 3 to 20% of calcined zinc oxide, 5 to 12% of calcite, 0 to 10% of dolomite, 6 to 12% of raw kaolinite, 8 to 22% of quartz, 10 to 23% of calcined kaolinite, and 2 to 8% of titanium dioxide; a blank is prepared from the following materials in percentage by weight: 5 to 20% of albite, 10 to 30% of potassium feldspar, 5 to 25% of quartz, 40 to 60% of kaolin, 0to 10% of aluminum oxide, and 0 to 7% of a plasticizer; during preparation, the blank is subjected to ball milling, filter pressing and dehydration to obtain a mud cake, then a rough blank is obtained according to the shape of the ceramic, and finally the rough blank is subjected to firing, ground coat soaking and surface coat soaking to obtain a glaze blank.

Owner:CHONGQING JINHUI CERAMICS

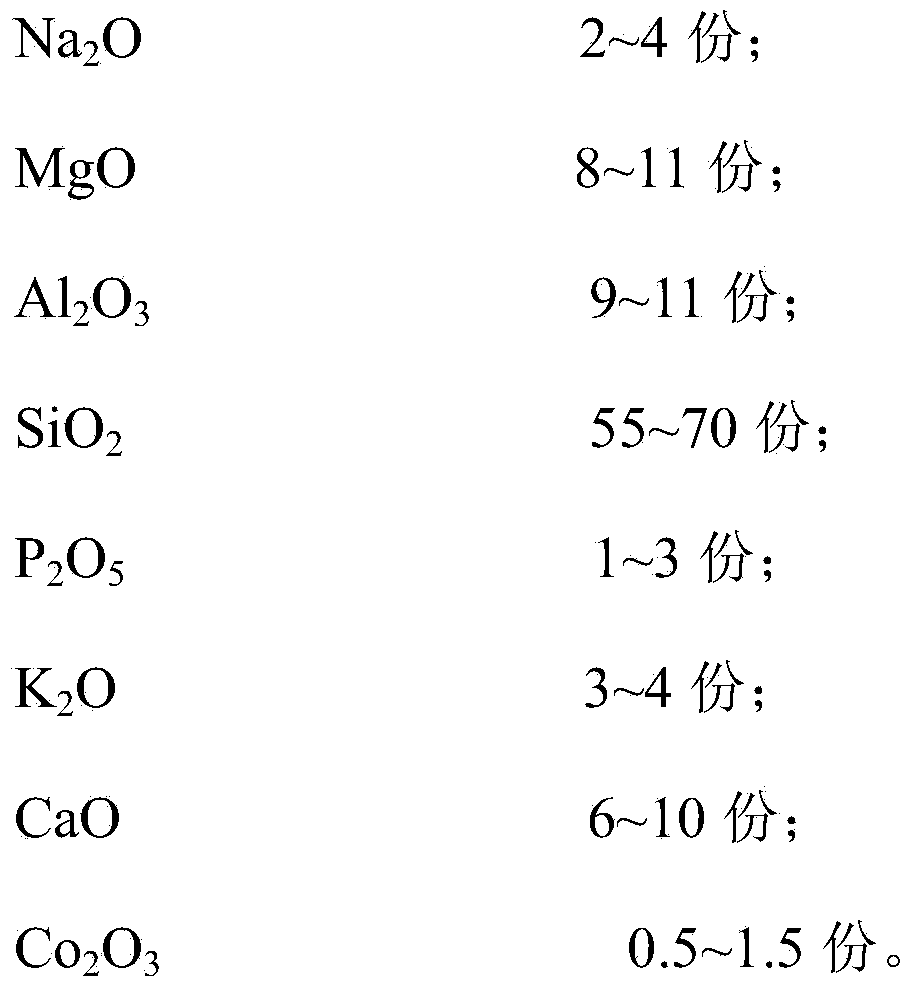

Pink glass-ceramic plate and production method thereof

ActiveCN104071981ABreak through the situation of single colorRaw materials are easy to getSesquioxideDolomite

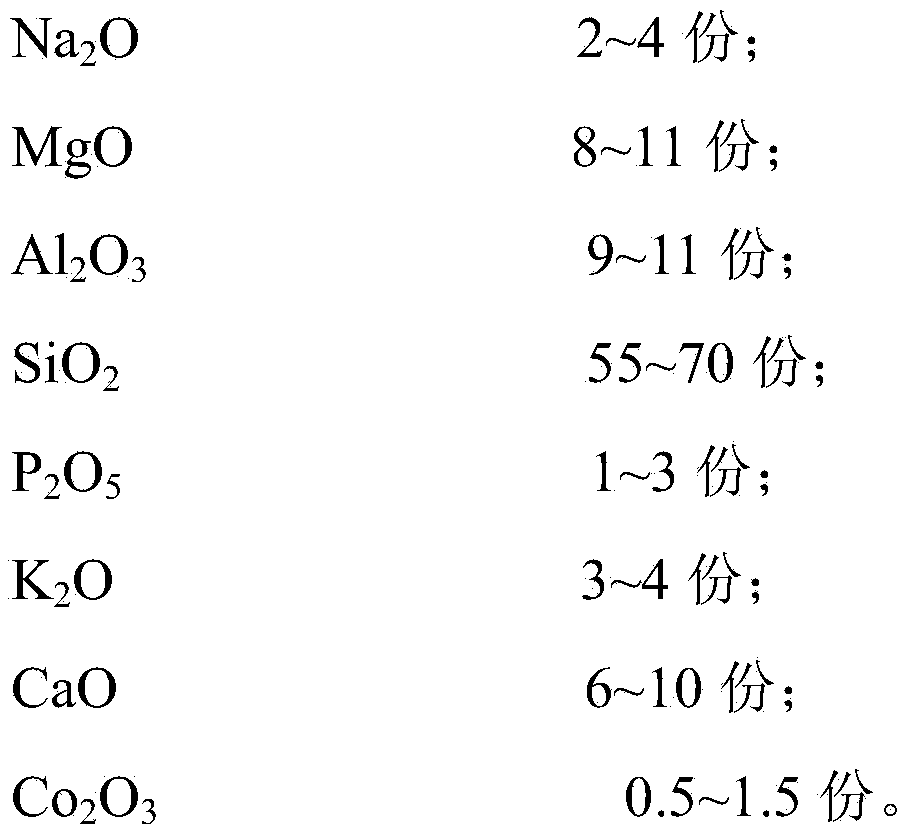

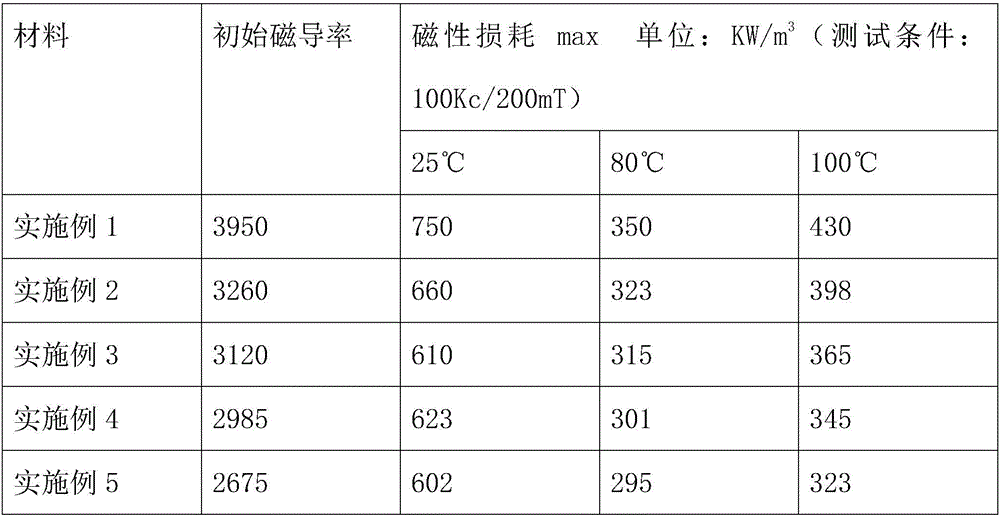

The invention discloses a pink glass-ceramic plate and a production method thereof. The pink glass-ceramic plate comprises the following components in parts by weight: 2-4 parts of Na2O, 8-11 parts of MgO, 9-11 parts of Al2O3, 55-70 parts of SiO2, 1-3 parts of P2O5, 3-4 parts of K2O3, 6-10 parts of CaO and 0.5-1.5 parts of Co2O3. The production method comprises the following steps: mixing the following materials in parts by weight: 24-31 parts of dolomite, 65-78 parts of granite, 2-6 parts of calcium dihydrogen phosphate, 0.5-1 part of cobalt sesquioxide and 2-4 parts of caustic calcined magnesite, and then producing by adopting all-electric melting calendering. According to the invention, the formula of the pink glass-ceramic plate is obtained by researching the proportion of a glass-ceramic plate for a long term, and the production method for producing the pink glass-ceramic plate is obtained. The pink glass-ceramic plate disclosed by the invention breaks through the condition of single color of the traditional glass-ceramic plate.

Owner:四川一名微晶科技股份有限公司

Wide-temperature and wideband zinc-nickel soft magnetic ferrite material and preparation method thereof

The invention disclsoes a wide-temperature and wideband zinc-nickel soft magnetic ferrite material. The wide-temperature and wideband zinc-nickel soft magnetic ferrite material is prepared from a main material and an auxiliary material at the weight ratio of 1 to (0.3 to 0.5), wherein the main material comprises: chromium oxide, zinc oxide, nickel carbonate, iron oxide, copper oxide, manganese carbonate and the balance of iron powder; by taking the weight of the main material as the basis, the auxiliary material comprises aluminum sesquioxide, vanadium oxide, zirconium oxide, tungsten trioxide, bismuth oxide, cobalt sesquioxide, a sintering auxiliary agent and a polyvinyl alcohol water solution. The invention further provides a preparation method of the wide-temperature and wideband zinc-nickel soft magnetic ferrite material. The zinc-nickel soft magnetic ferrite material prepared by the preparation method has wide-temperature and wideband properties.

Owner:ZHONGDE ELECTRONICS

Stray light absorbing glass for optical fiber image inverter and preparation method of stray light absorbing glass

ActiveCN109851218AHigh glossStrong anti-devitrification abilityGlass shaping apparatusGlass productionNickel sesquioxideSpectral transmittance

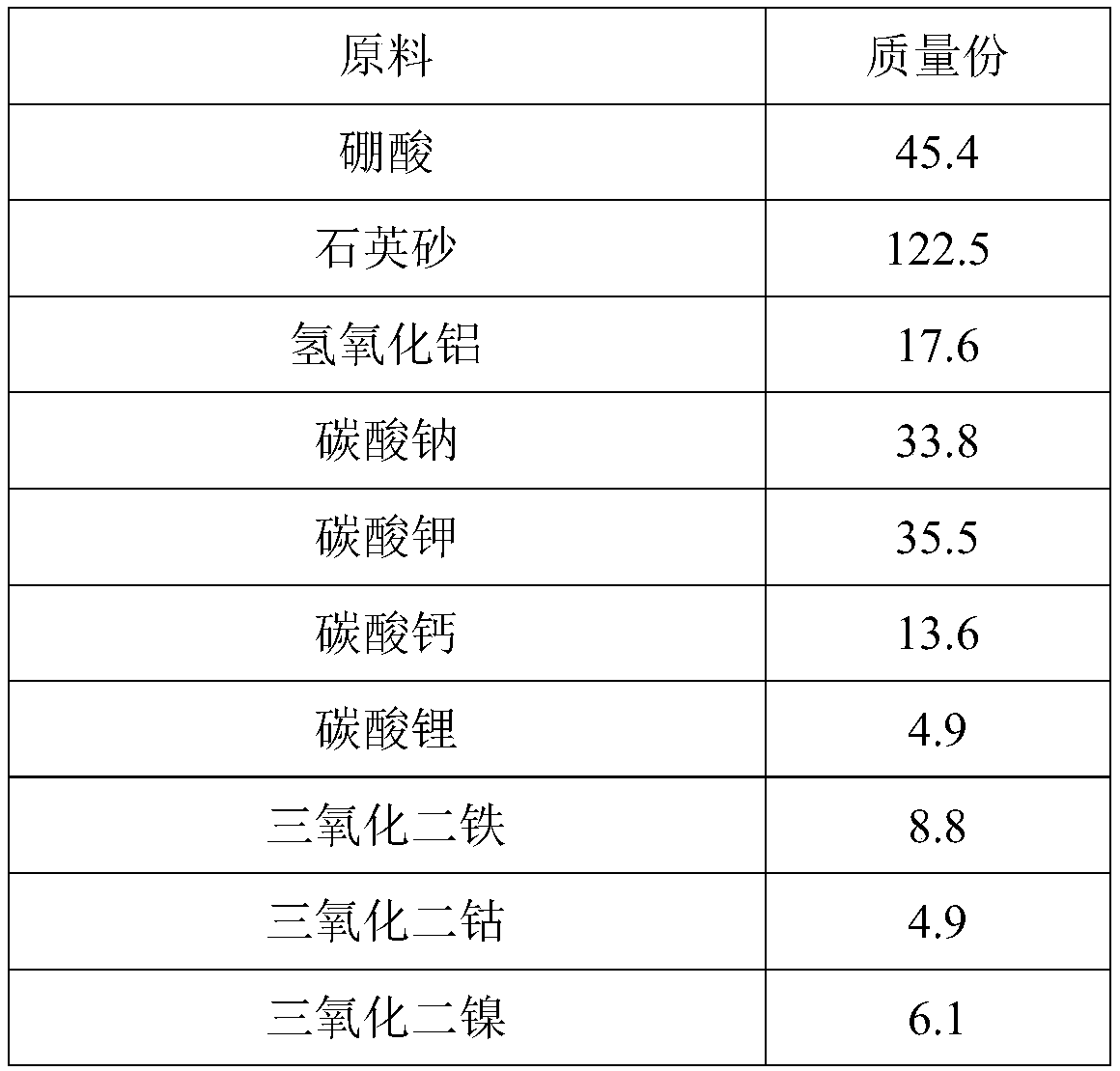

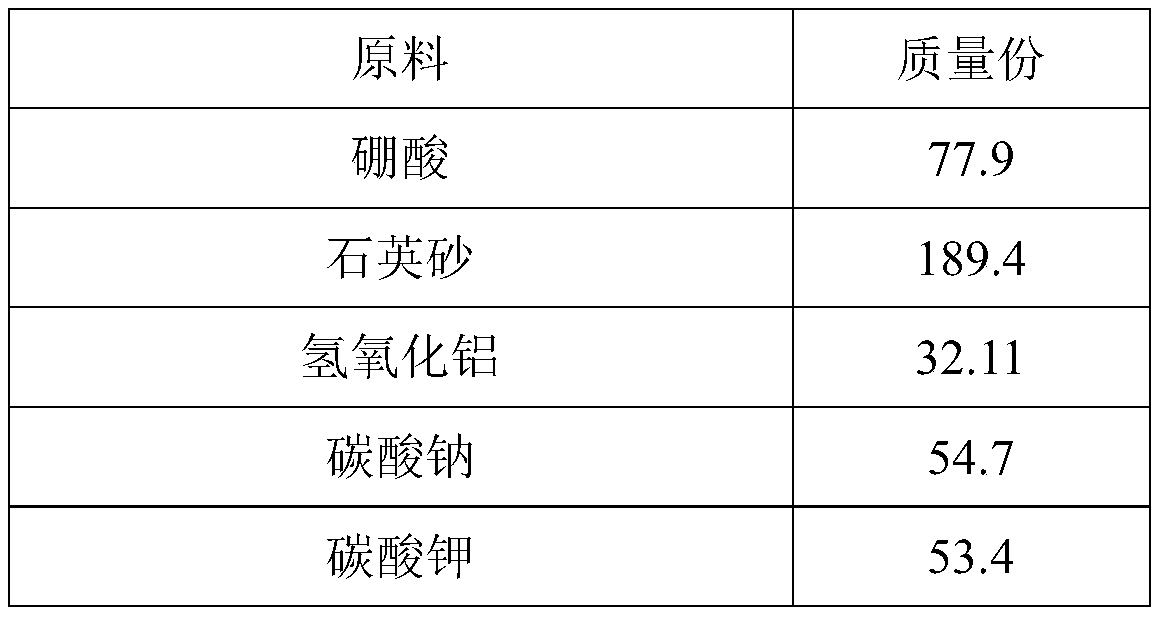

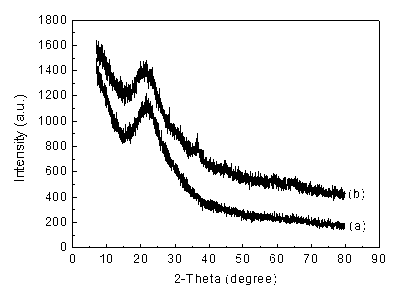

The invention discloses stray light absorbing glass for an optical fiber image inverter and a preparation method of the stray light absorbing glass. The stray light absorbing glass for an optical fiber image inverter is prepared from the raw materials: boric acid, quartz sand, aluminum hydroxide, potassium carbonate, sodium carbonate, calcium carbonate, lithium carbonate, titanium dioxide, ferricoxide, cobalt oxide, nickel sesquioxide, manganese dioxide, sodium sulfate and arsenic trioxide. A preparation method of the stray light absorbing glass for the optical fiber image inverter is also disclosed. The black absorbing glass which can be applied to the optical fiber image inverter has a spectral transmittance of 5-10% at wavelengths of 350-900 nm under the control condition of a thickness of 1.00+ / -0.01 mm, meanwhile, the smelt glass has no stone, and the glass has high glossiness; and meanwhile the glass has a softening temperature range of 620-750 DEG C, the crystallization lower-limit temperature is >= 850 DEG C, and the glass has high anti-crystallization ability and good chemical stability, and can meet the requirements of the optical fiber inverter for the process performance of the black absorbing glass.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

SBA-15 supported cobalt oxide catalyst as well as preparation method and application thereof in wastewater treatment

InactiveCN103301869AEasy to prepareLow priceMolecular sieve catalystsWater/sewage treatment with mechanical oscillationsSesquioxideCobalt(II,III) oxide

The invention relates to a SBA-15 supported cobalt oxide catalyst as well as a preparation method and an application thereof in wastewater treatment. Cobalt oxide is loaded on an SBA-15 mesoporous material, the cobalt oxide is one or more of cobaltous oxide, cobalt sesquioxide and cobaltosic oxide. The SBA-15 supported cobalt oxide catalyst is used for activating peroxymonosulfate, and in combination with ultrasonic and electrochemical technologies, the SBA-15 supported cobalt oxide catalyst has a better degradation effect on organic pollutants in wastewater, the technical process is simple, and the implementation cost is low, so that the SBA-15 supported cobalt oxide catalyst has better generalization foreground.

Owner:WUHAN UNIV

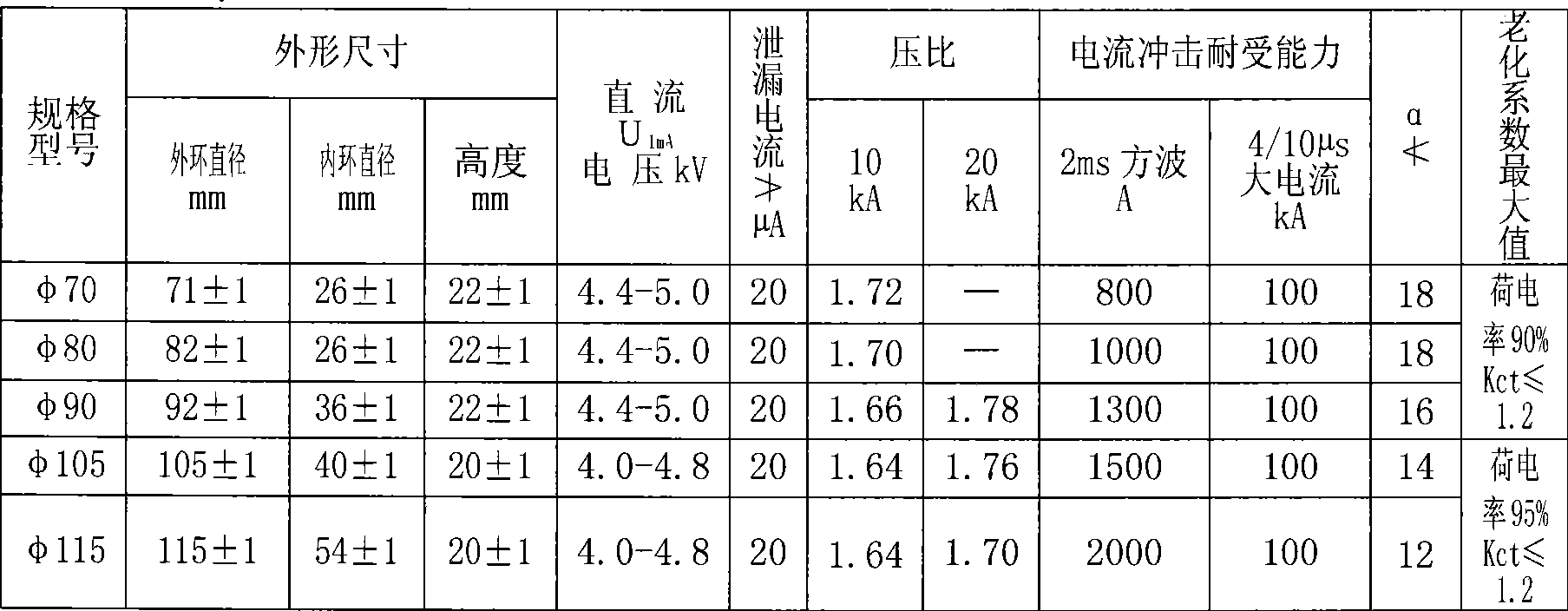

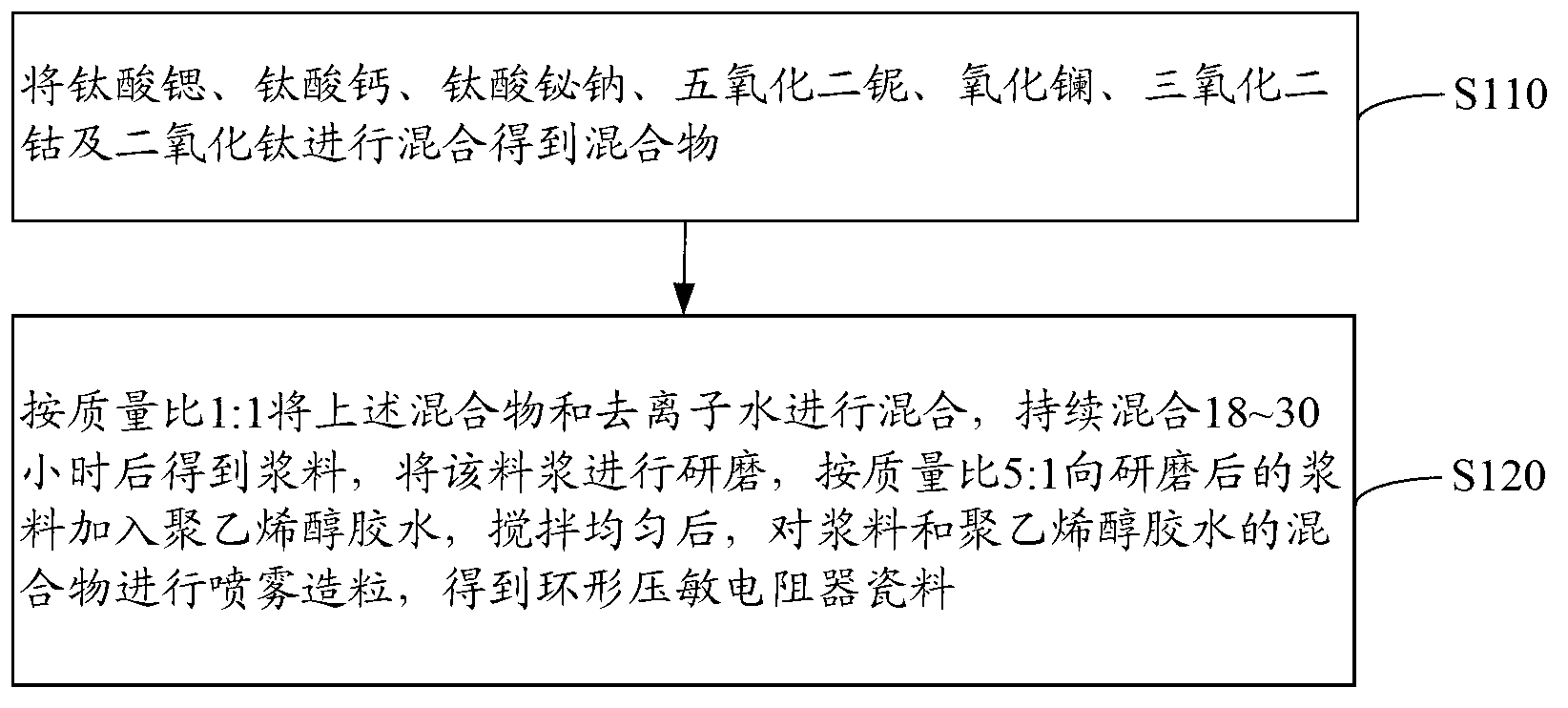

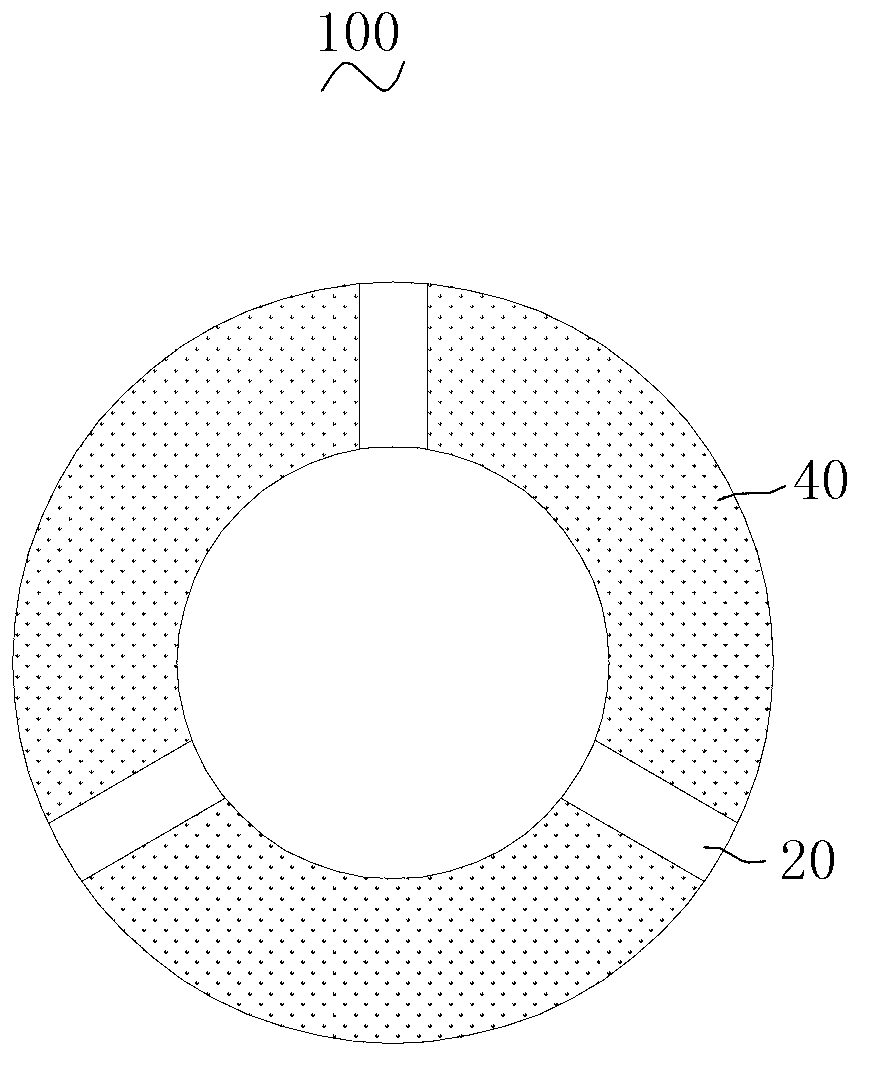

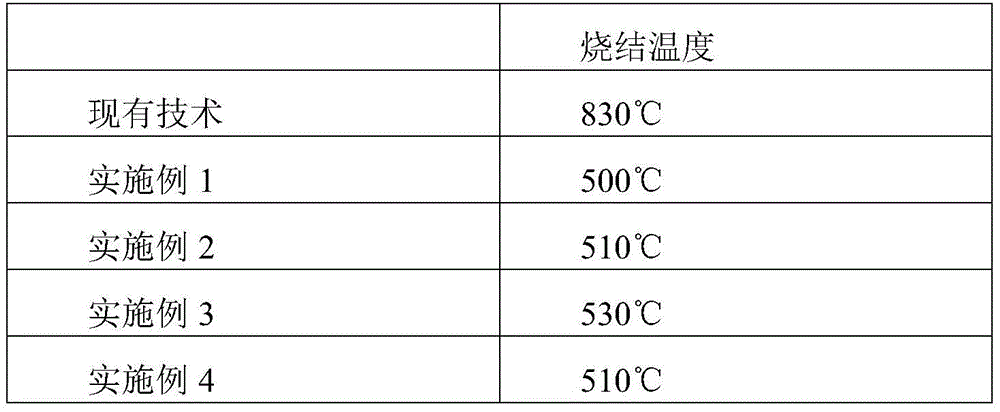

Annular piezoresistor ceramic and preparation method thereof, and annular piezoresistor and preparation method thereof

The invention relates to an annular piezoresistor ceramic and a preparation method thereof, and an annular piezoresistor and a preparation method thereof. The annular piezoresistor ceramic comprises 50-70 mol% of strontium titanate, 15-35 mol% of calcium titanate, 7-12 mol% of sodium bismuth titanatee, 1-3 mol% of niobium pentaoxide, 0.1-1 mol% of lanthanum oxide, 0.1-1.5 mol% of cobaltic oxide and 1-4 mol% of titanium dioxide. The composition and ratio of the host crystal material, semiconducting material and combustion-supporting material are optimized to obtain the annular piezoresistor ceramic. The voltage variation of the annular piezoresistor prepared from the annular piezoresistor ceramic does not exceed 10% in a 0-125 DEG C temperature rise environment; and thus, the annular piezoresistor can be used in a motor working at higher environment temperature, thereby widening the application temperature range of the annular piezoresistor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Far-infrared enamel material and preparation method and application thereof

The invention provides a far-infrared enamel material and a preparation method and application thereof. The far-infrared enamel material comprises a matrix agent, an adhesive agent, an assistant agent and far-infrared powder. The far-infrared powder is selected from at least one of silicon carbide, iron oxide, manganese dioxide, cobalt oxide and molybdenum oxide. The far-infrared enamel material has good high temperature resistance, acid resistance, alkali resistance, scraping resistance, corrosion resistance and other performance, has a low sintering temperature, is good in adherence and binding force for metal base materials, and has ideal far-infrared performance.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com