Annular piezoresistor ceramic and preparation method thereof, and annular piezoresistor and preparation method thereof

A varistor, varistor technology, applied in varistor cores, varistors, resistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

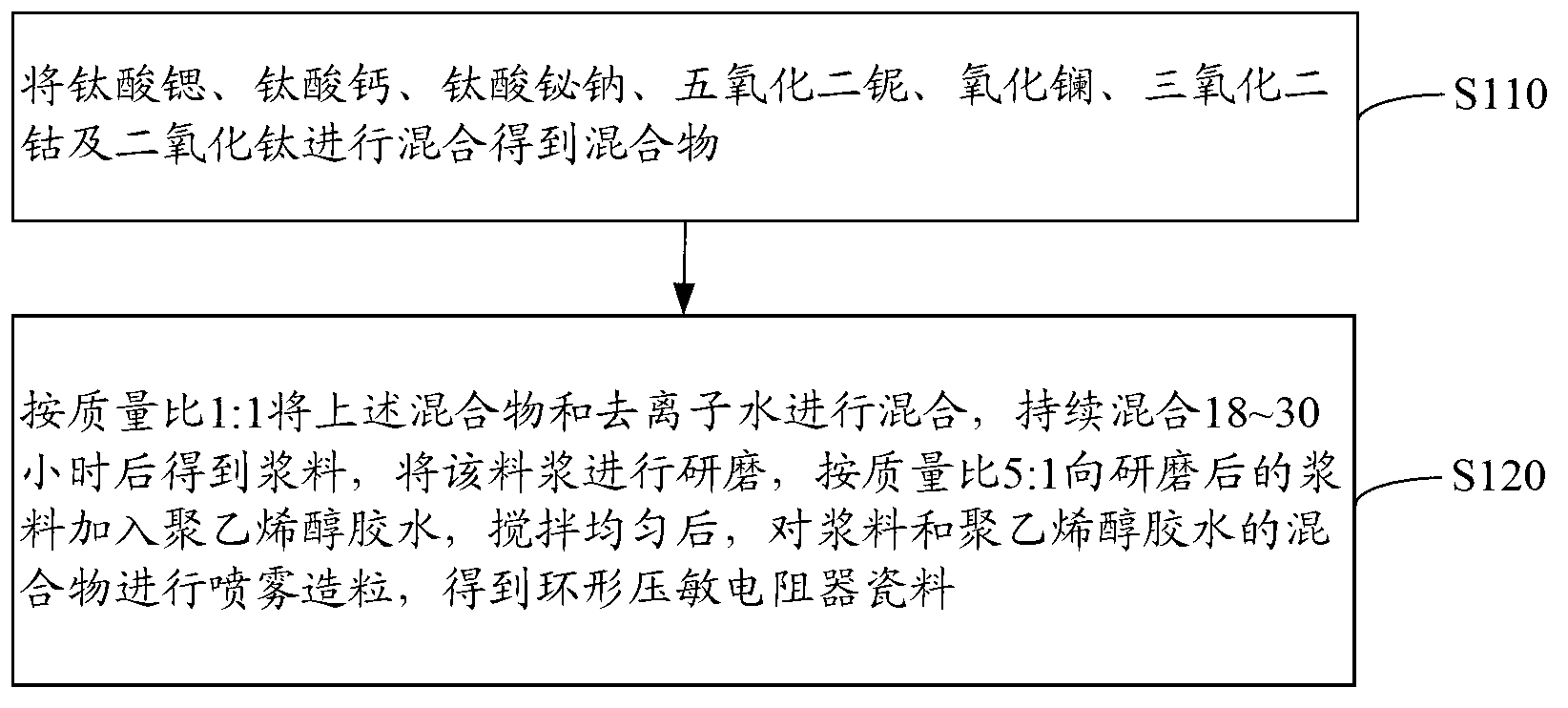

[0053] see figure 1 , the preparation method of ring-shaped piezoresistor ceramic material according to one embodiment, includes the following steps S110 and S120.

[0054] Step S110: mixing strontium titanate, calcium titanate, sodium bismuth titanate, niobium pentoxide, lanthanum oxide, cobalt trioxide and titanium dioxide to obtain a mixture.

[0055] In the above mixture, based on mole percentage, strontium titanate accounts for 50-70 mol%, calcium titanate accounts for 15-35 mol%, sodium bismuth titanate accounts for 7-12 mol%, niobium pentoxide accounts for 1-3 mol%, lanthanum oxide accounts for 0.1-1mol%, dicobalt trioxide accounts for 0.1-1.5mol%, and titanium dioxide accounts for 1-4mol%.

[0056] In a preferred scheme, the molar percentages of the above-mentioned components are respectively: strontium titanate (SrTiO 3 ) 55mol%, calcium titanate (CaTiO 3 ) 30mol%, sodium bismuth titanate ((BiNa)TiO 3 ) 10mol%, niobium pentoxide (Nb 2 o 5 ) 2mol%, lanthanum oxid...

Embodiment 1

[0102] Ceramic materials for ring varistors and preparation of ring varistors

[0103] 1. Preparation of ceramic materials for ring varistors

[0104] (1) will Bi 2 o 3 、Na 2 CO 3 and TiO 2 After weighing according to the molar ratio of 1:1:2, put it into the ball mill jar, add deionized water, and put the agate balls, so that the Bi in the ball mill jar 2 o 3 、Na 2 CO 3 and TiO 2 The ratio of the total mass of the total mass, the quality of the agate ball and the mass of deionized water is 1:2:1.5, and then ball milled for 30 hours to make Bi 2 o 3 、Na 2 CO 3 、TiO 2 Mix well with deionized water, and further use a spray drying tower to 2 o 3 、Na 2 CO 3 、TiO 2 Dry the mixture with deionized water to obtain a powder; put the powder into a tunnel-type high-temperature electric furnace, and keep it in air at 900°C for 2 hours. Mesh sieving to obtain bismuth sodium titanate ((BiNa)TiO 3 );

[0105] (2) SrTiO 3 , CaTiO 3 , Nb 2 o 5 , La 2 o 3 、Co 2 o 3 ...

Embodiment 2

[0115] Ceramic materials for ring varistors and preparation of ring varistors

[0116] 1. Preparation of ceramic materials for ring varistors

[0117] (1) will Bi 2 o 3 、Na 2 CO 3 and TiO 2 After weighing according to the molar ratio of 1:1:2, put it into the ball mill jar, add deionized water, and put the agate balls, so that the Bi in the ball mill jar 2 o 3 、Na 2 CO 3 and TiO 2 The ratio of the total mass of the total mass, the quality of the agate ball and the mass of deionized water is 1:2:1.5, and then ball milled for 20 hours to make Bi 2 o 3 、Na 2 CO 3 、TiO 2 Mix well with deionized water, and further use a spray drying tower to 2 o 3 、Na 2 CO 3 、TiO 2Dry the mixture with deionized water to obtain a powder; put the powder into a tunnel-type high-temperature electric furnace, and keep it in air for 3 hours at 850°C. Mesh sieving to obtain bismuth sodium titanate ((BiNa)TiO 3 );

[0118] (2) SrTiO 3 , CaTiO 3 , Nb 2 o 5 , La 2 o 3 、Co 2 o 3 、...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com