Patents

Literature

60results about How to "Process condition control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for recovering lithium from waste lithium iron phosphate battery

ActiveCN109207730AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium iron phosphate

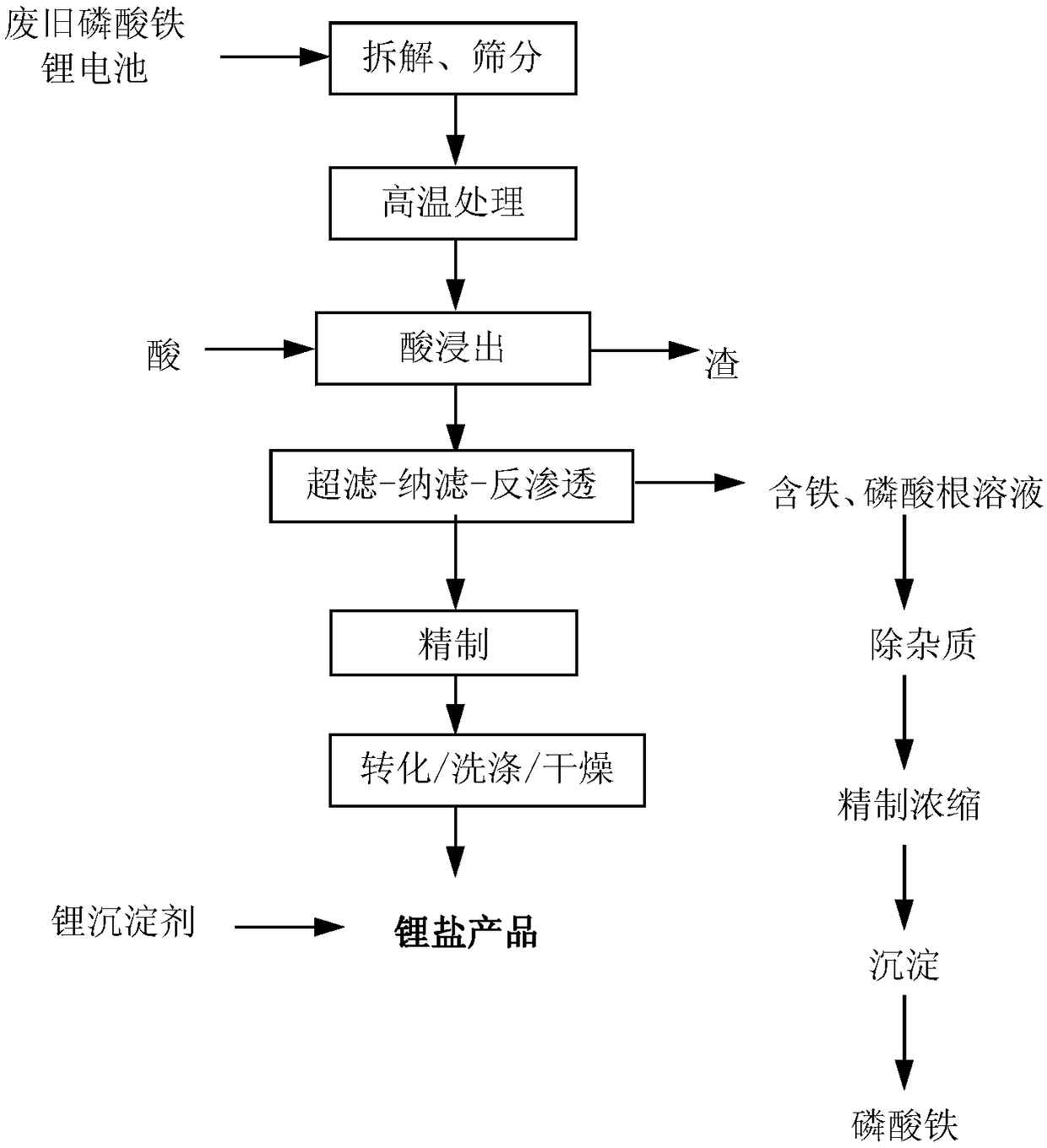

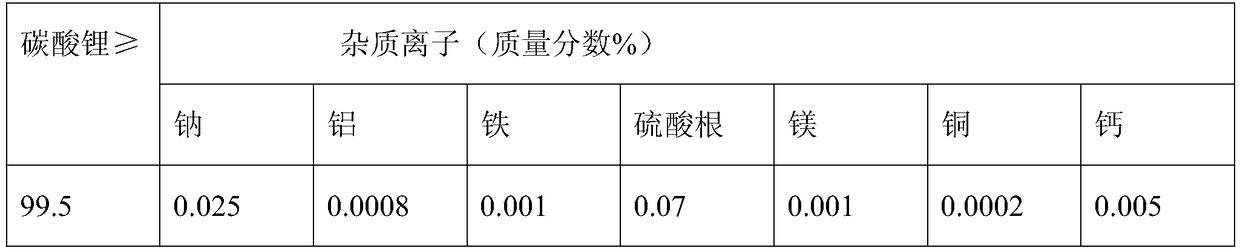

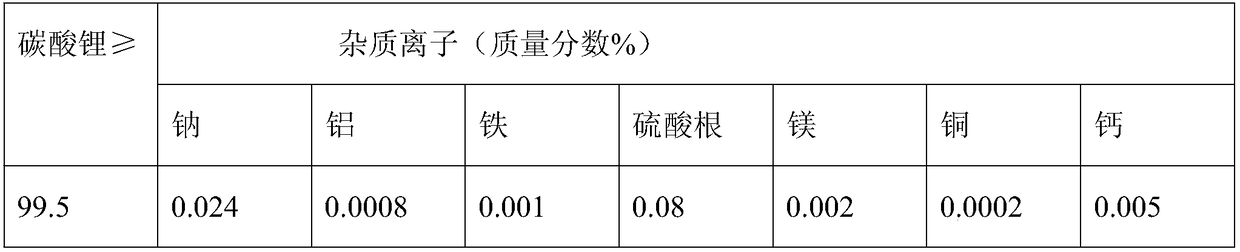

The invention discloses a method and system for recovering lithium from a waste lithium iron phosphate battery. The method comprises the following steps that a positive plate is disassembled from thewaste lithium iron phosphate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by an acid solution, and an acidified leaching solution is obtained; ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise iron ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution, alkaline substances are adopted to precipitate and separate iron ions in the solution containing other cations, and lithium recovery is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse-osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for preparing strontium titanate nanometer powder of one-dimensional structure

InactiveCN101311376AProcess conditions are easy to controlProcess condition controlPolycrystalline material growthFrom normal temperature solutionsStrontium titanateNanowire

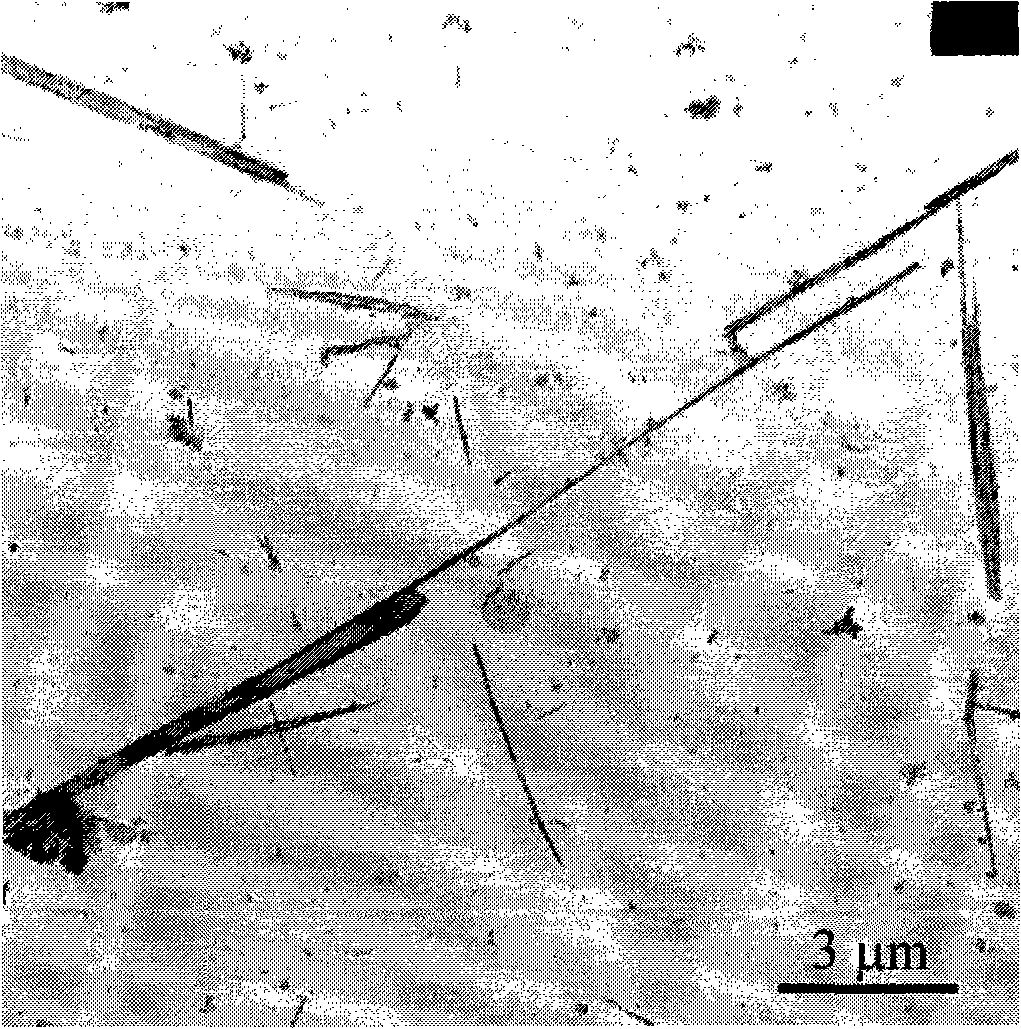

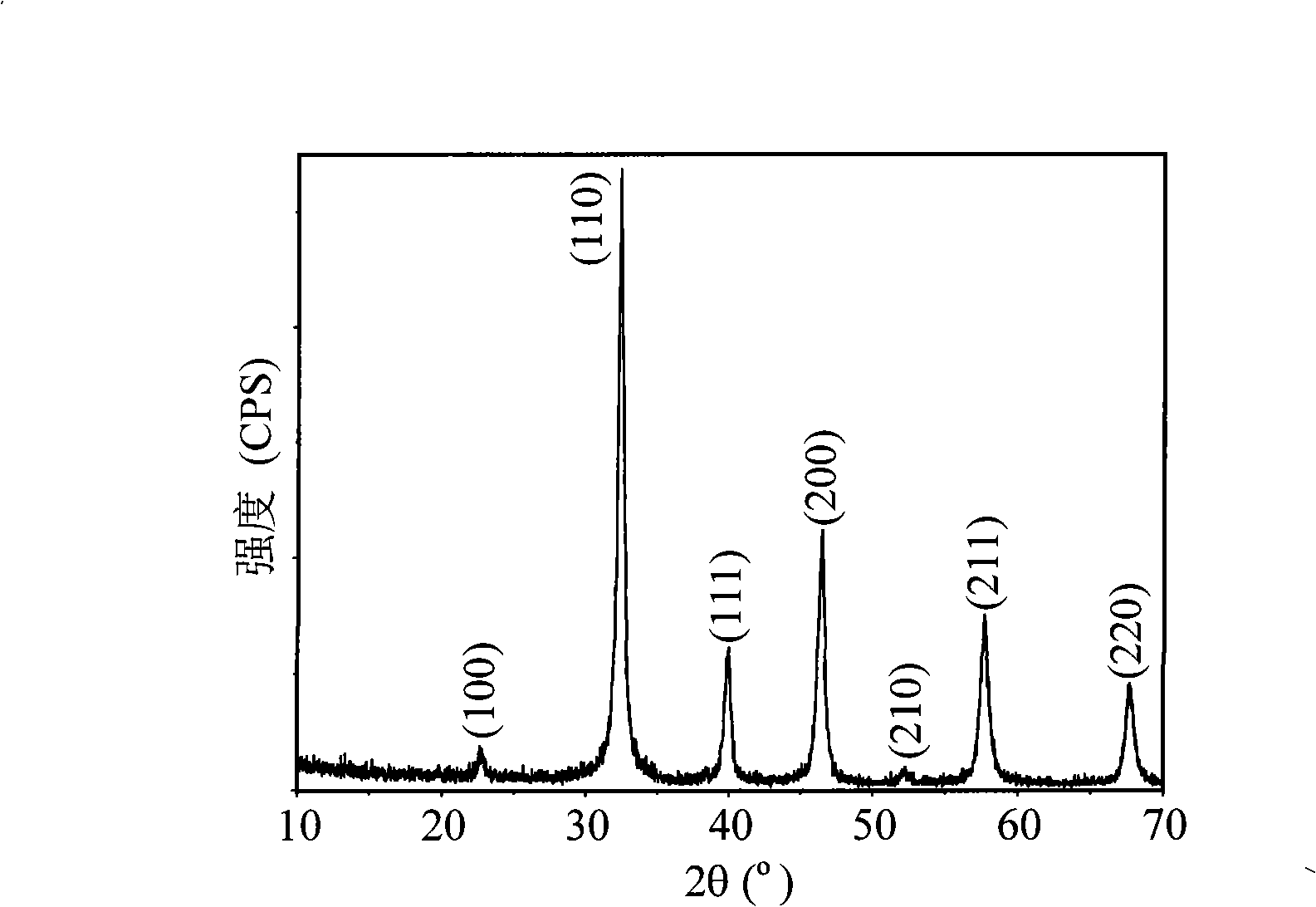

The invention discloses a method for preparing strontium titanate nanometer powder with one-dimension structure, which consists of procedures of preparing the oxyhydroxide precipitate of titanium and the deionized aqueous solution of barium acetate as reaction materials, adding a feasible quantity of potassium hydroxide to promote crystallization, and appending a suitable viscosity of patterned vertical alignment polymer surfactant to control the feature; under the temperature of 100-150 DEG C, strontium titanate nanowire and a branched crystal structure are obtained after a hydrothermal reaction. The craftwork of the invention is simple; the micro feature of the product is easy to control, the pollution is free; the cost is low; a large-scale production is suitable. The quality of the crystallization of the prepared product is stable; the specific surface is big. A broad application prospect is possessed in fields of micro electronic devices, EO devices, storage devices, oxygen sensors, photocatalyst, and solar battery, etc.

Owner:ZHEJIANG UNIV

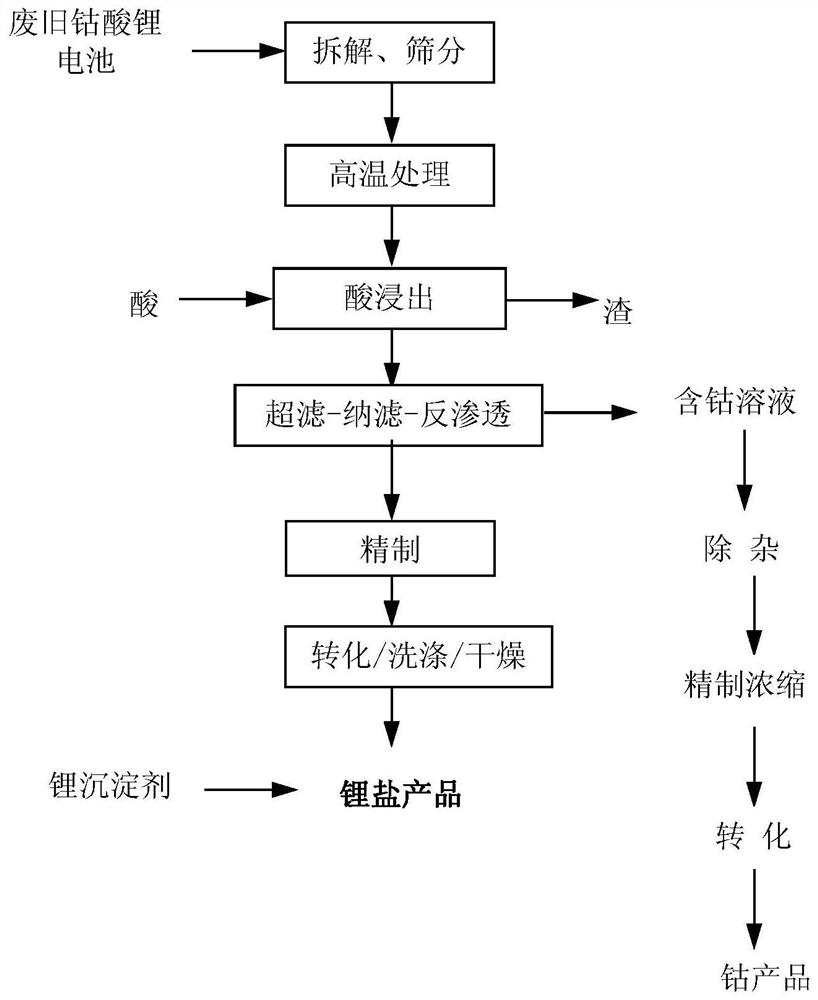

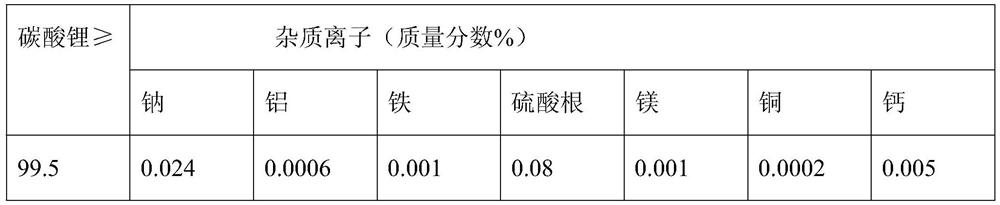

A method and system for recovering lithium and cobalt from spent lithium cobalt oxide batteries

ActiveCN109256597AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium

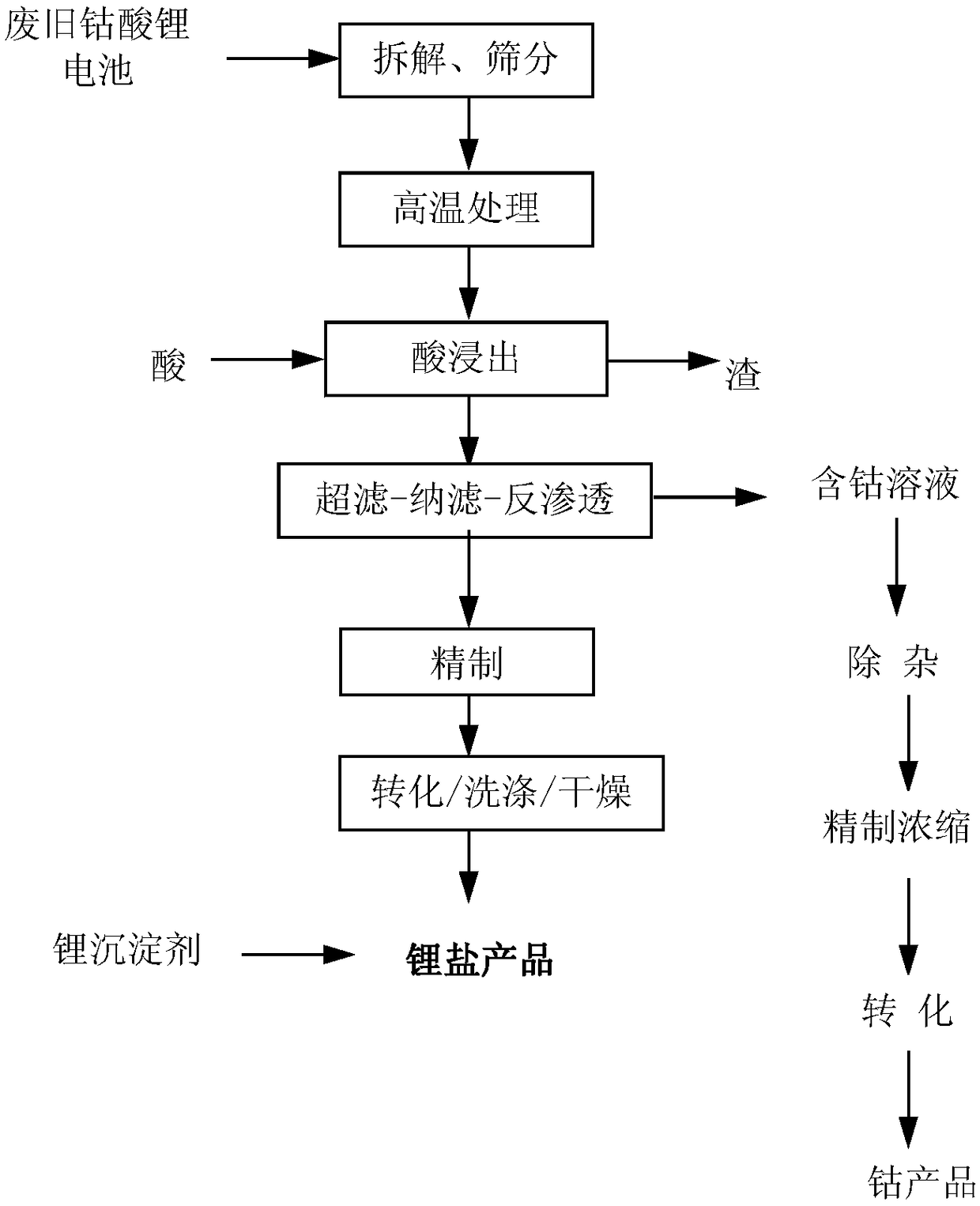

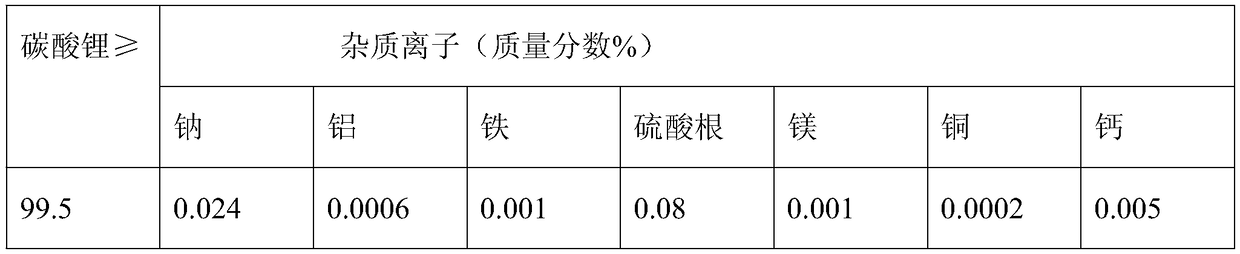

The invention discloses a method and a system for recovering lithium and cobalt from waste lithium cobalt oxide batteries. The method comprises the following steps of: disassembling a positive electrode sheet from a waste lithium cobalt oxide battery; Removing the binder in the positive electrode sheet, and then acid leaching the valuable metal elements in the positive electrode sheet to obtain anacidizing leaching solution; The acidified leachate was treated by ultrafiltration membrane. Separating lithium ions in acidified leaching solution from other cations different from lithium ions by using nanofiltration membrane technology to obtain lithium-containing solution and solution containing other cations, and concentrating and enriching the lithium-containing solution and the solution containing other cations respectively by reverse osmosis technology, wherein the other cations include cobalt ions; And a lithium precipitant is used to precipitate lithium ions from a lithium-containing solution, and an alkaline substance is used to precipitate cobalt ions from a solution containing other cations, thereby realizing the recovery of lithium and cobalt. The adoption of ultrafiltration-Nanofiltration-Reverse osmosis combined technology has the characteristics of simple process, less acid and alkali consumption, good and stable membrane separation effect and so on.

Owner:青海中科德方能源科技研究有限公司

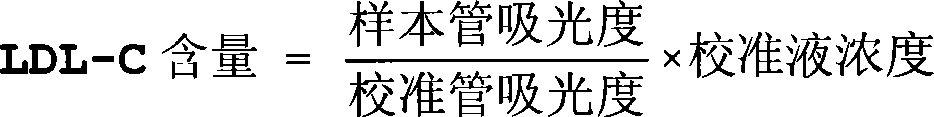

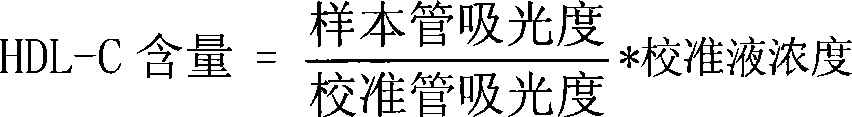

Surface fixed taurine ligand porous membrane material, preparation method and its application in blood fat adsorption separating

InactiveCN101058058AAchieve adsorptionAchieve separationSemi-permeable membranesOther chemical processesLipid compositionBlood plasma

It is aimed to provide a porous carrier surface fixed with taurine absorbed sulfo group. Its average hole radius is made by 0. 05-100mum medical polymer nonwoven cloth modified by 60Cogammacoradiated the polyacrylic acid surface together with porous film, with the help of one aminopropancdiol, 3 EDC activated carboxy group coupling with biologically compatible taurine absorbed sulfo group with the surface fixed with porous film carrier material reinforcing selective absorption and separation effect. It is simple, safe and effective. The material is compatible with blood, with excellent use in plasma absorption separation, clinical blood dynamic purification and waste plasma regeneration and utilization.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

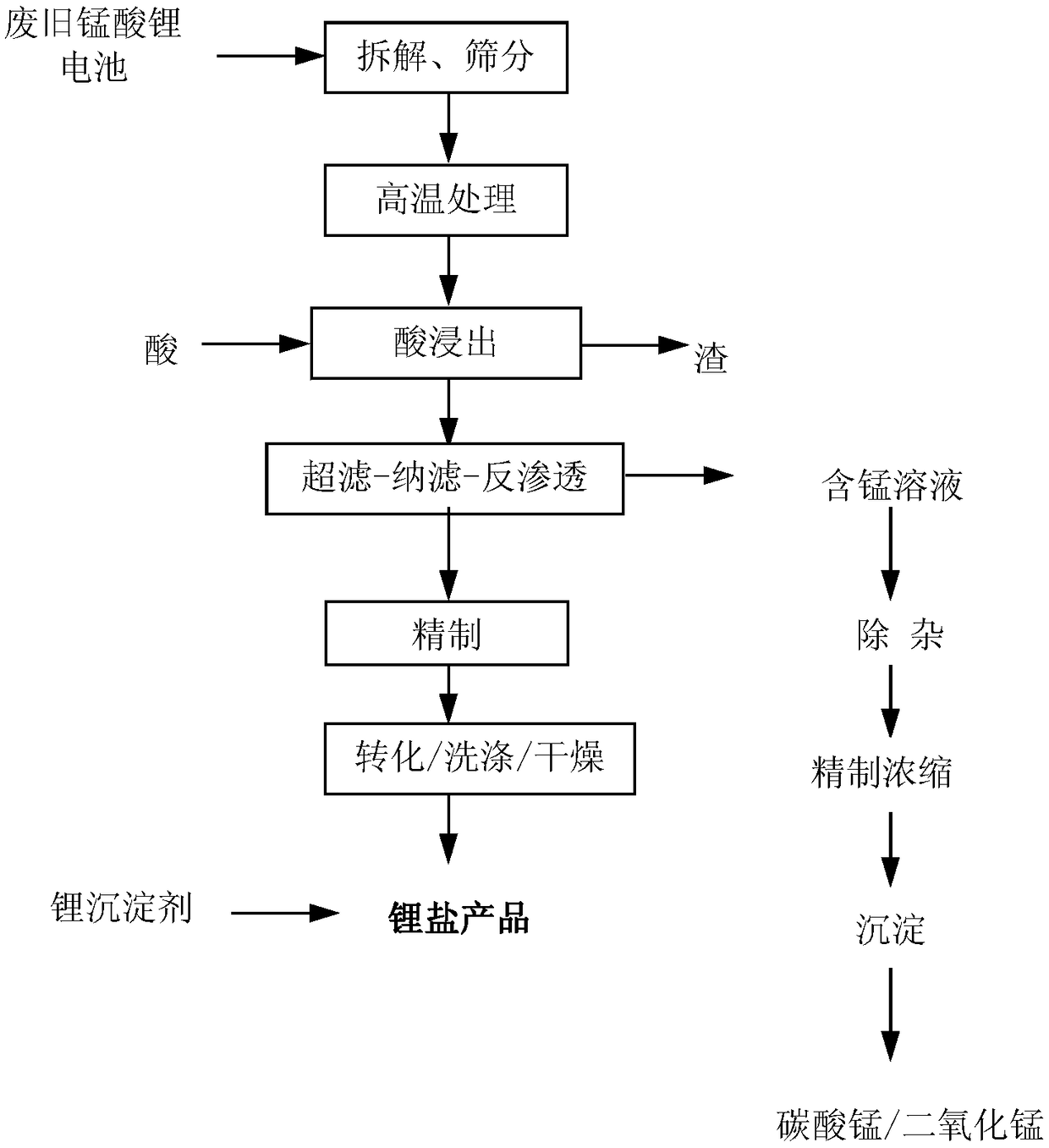

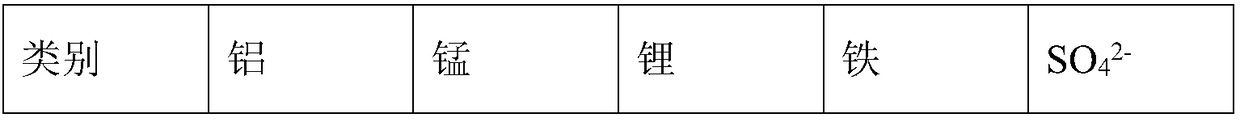

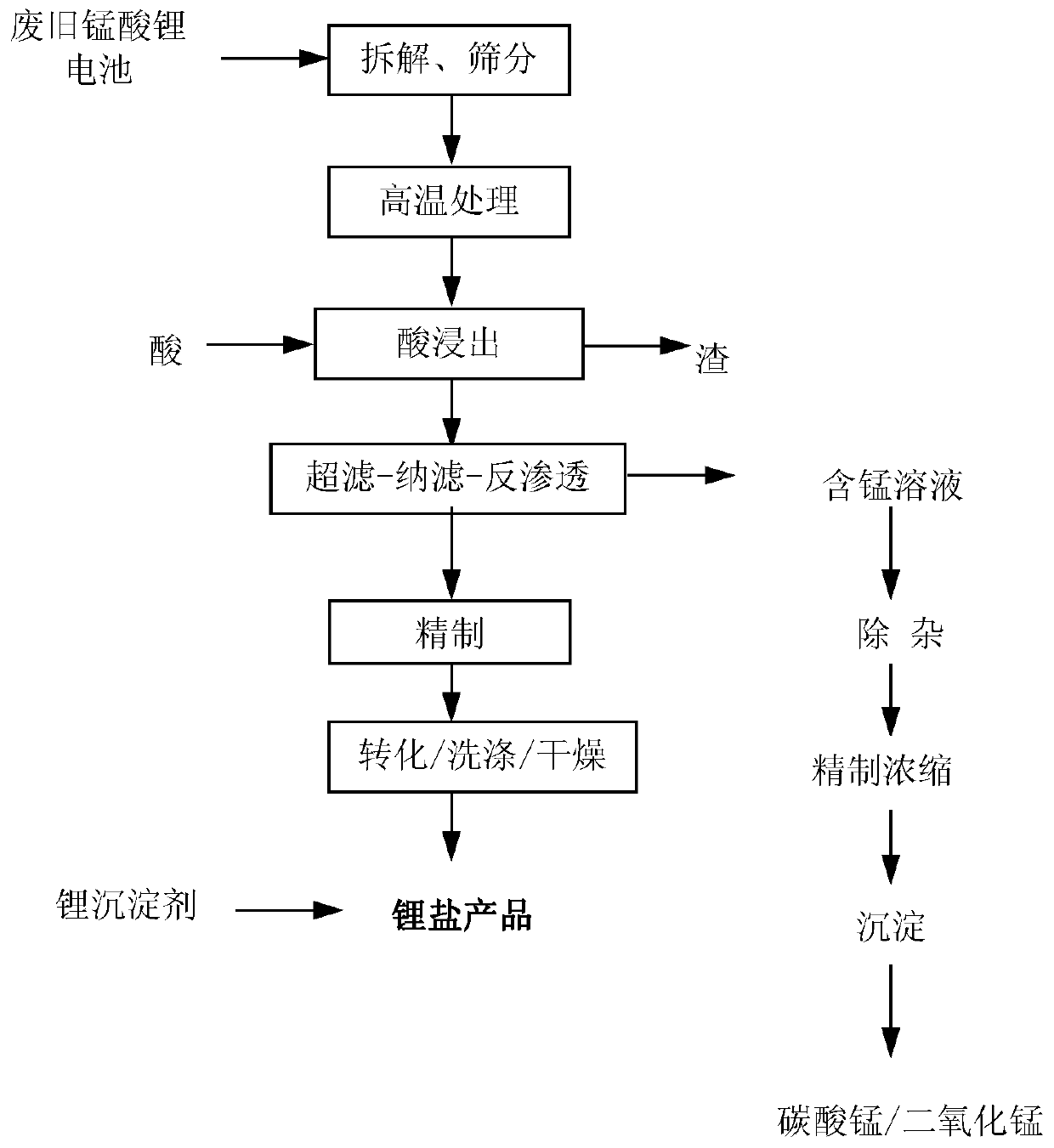

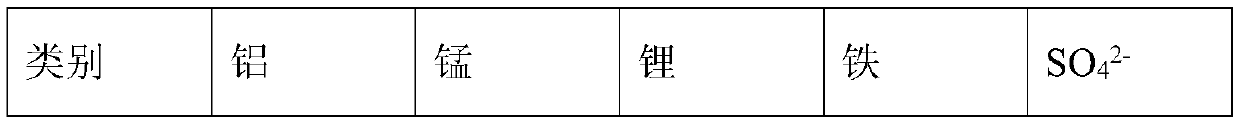

Method and system for recovering lithium and manganese from waste lithium manganate battery

ActiveCN109207725AAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyManganese

The invention discloses a method and system for recovering lithium and manganese from a waste lithium manganate battery. The method comprises the following steps that a positive plate is disassembledfrom the waste lithium manganate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by acid dissolution, and acidified leachate is obtained;ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise manganese ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution,and alkaline substances are adopted to precipitate and separate manganese ions in the solution containing other cations, so that the recovery of lithium and manganese is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:青海中科德方能源科技研究有限公司

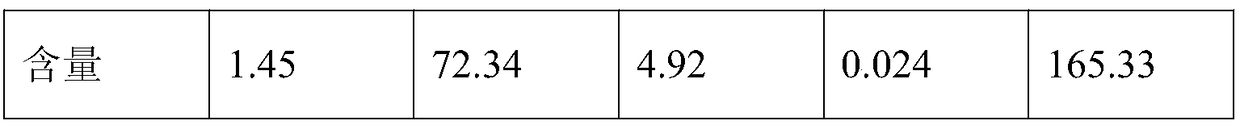

Wood waterproof agent, method for preparing wood waterproof agent, and method for preparing waterproof wood by utilizing wood waterproof agent

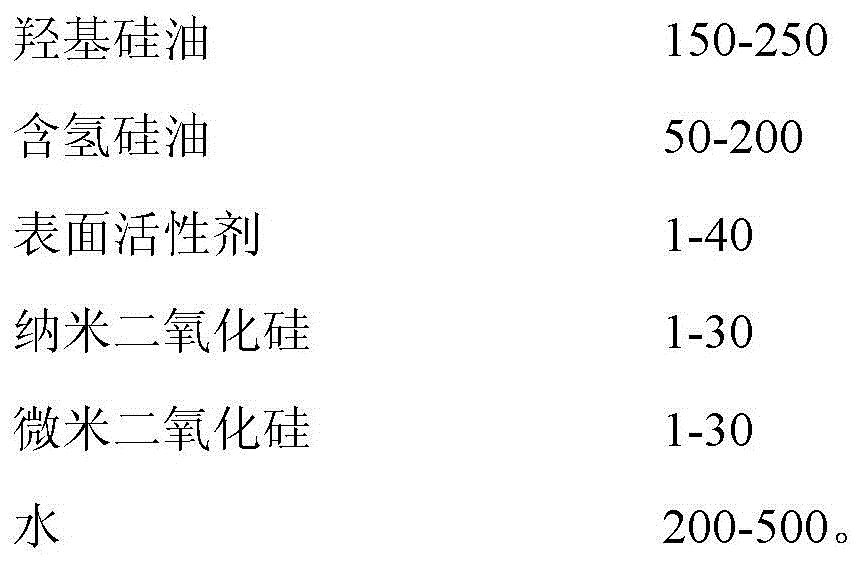

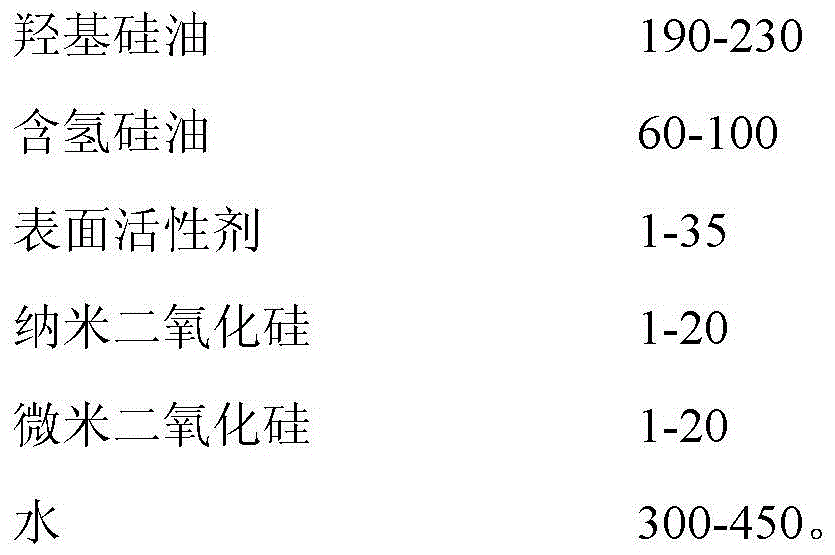

ActiveCN105729600AReduce treatment concentrationLow costWood treatment detailsPressure impregnationEmulsionHydrogen

The invention provides a wood waterproof agent adopting a silicone emulsion, a method for preparing the wood waterproof agent, and a method for preparing waterproof wood by utilizing the wood waterproof agent. The method for preparing the wood waterproof agent comprises the following steps: first, preparing a silicone oil emulsion primary liquid which contains hydroxyl silicone oil, hydrogen-containing silicone oil, a surfactant, nano-silicon dioxide, micron-silicon dioxide and water; then, diluting the silicone oil emulsion primary liquid into silicone oil emulsions of different concentrations; and finally, adding a catalyst for uniform dissolution and mixing. When the silicone oil emulsion wood waterproof agent provided by the invention is utilized for vacuum-pressurization pretreatment of wood, the waterproof performance and size stability of the wood can be improved, the hygroscopicity of the wood can be reduced, and the contact angle between the treated wood surface and water is larger than 140-150.

Owner:BEIJING FORESTRY UNIVERSITY +1

Process for extracting pachyman from poria coccus wolf

The invention discloses a process for extracting pachyman from poria coccus wolf. The process comprises the following steps: (1) selecting a poria coccus wolf raw material, and conducting ultrafine grinding to obtain poria coccus wolf coarse powder; (2) adding water into the poria coccus wolf coarse powder for soaking, and placing the soaked poria coccus wolf coarse powder in 40000 Hz ultrasonic waves to be treated for 20-25 min; (3) conducting water bathing and then conducting centrifugal separation; (4) conducting enzymolysis separation by adopting a compound enzyme to obtain a filtrate; (5) conducting protein precipitation and filtration, and centrifugally collecting a supernate; (6) concentrating a pachyman extract to be 10 to 20% of the original volume to obtain a pachyman concentrate, and conducting spray drying to obtain coarse pachyman; (7) conducting ultrafiltration, then conducting column chromatography to obtain purified pachyman, and conducting freeze drying so as to obtain the pachyman. According to the process, an ultrasonic-assisted extraction method is utilized, the process steps are simple, the pachyman leaching rate can be obviously increased, the extracted pachyman is low in possibility of stereostructure damage and high in biological activity, and the advantages that the leaching time is shortened, the extraction conditions are mild, and the reaction product is free of toxic or side effect are achieved.

Owner:潜山市三新茶叶专业合作社

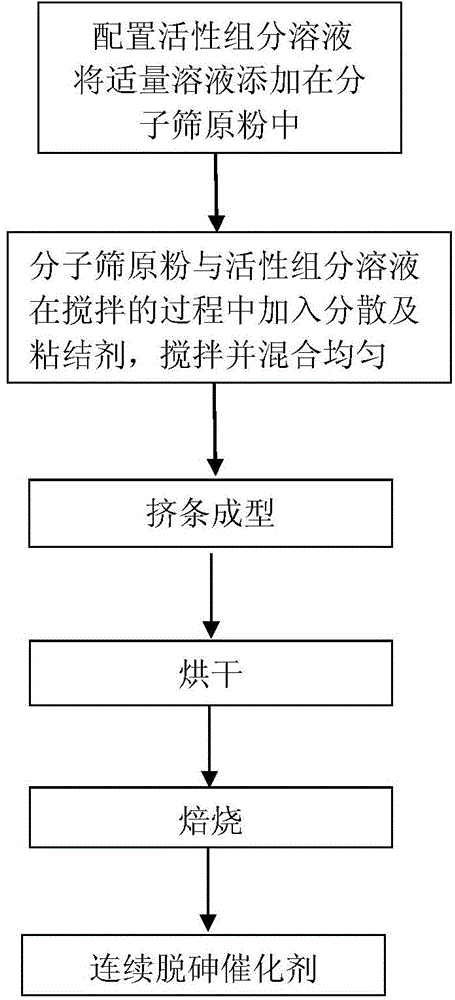

Continuous arsenic removal catalyst for industrial tail gas purification and preparation method thereof

ActiveCN104624223APhosphorus tolerance is goodSimple preparation processMolecular sieve catalystsDispersed particle separationMolecular sieveCopper salt

The invention discloses a continuous arsenic removal catalyst for industrial tail gas purification. The continuous arsenic removal catalyst is prepared by mixing a solution of an active component, raw powder of a molecular sieve and a binding dispersant and moulding by extruding, wherein the molecular sieve serves as a carrier, the active component is a cupric salt, the carrier is a molecular sieve of 13X-grade particles, the effective micropore size of the molecular sieve is 0.8-1.5nm, and the volume ratio of micropores is over 80%. The continuous arsenic removal catalyst is prepared as follows: weighing the raw powder of the molecular sieve, stirring, adding the solution of the active component, adding the binding dispersant after the material is wetted, mixing the materials uniformly, molding by extruding, drying and calcining. The continuous arsenic removal catalyst is used for removing hydrogen arsenide from tail gas of calcium carbide, tail gas of yellow phosphorus and other atmospheres. Hydrogen arsenide is subjected to hydration reaction after being subjected to catalytic oxidation, and then is discharged in the form of arsenic acid or arsenious acid. The active component of the continuous arsenic removal catalyst does not change obviously before and after catalytic oxidation, and the requirement that CO in tail gas serves as a product with high additional value can be met.

Owner:BEIJING PEKING UNIV PIONEER TECH

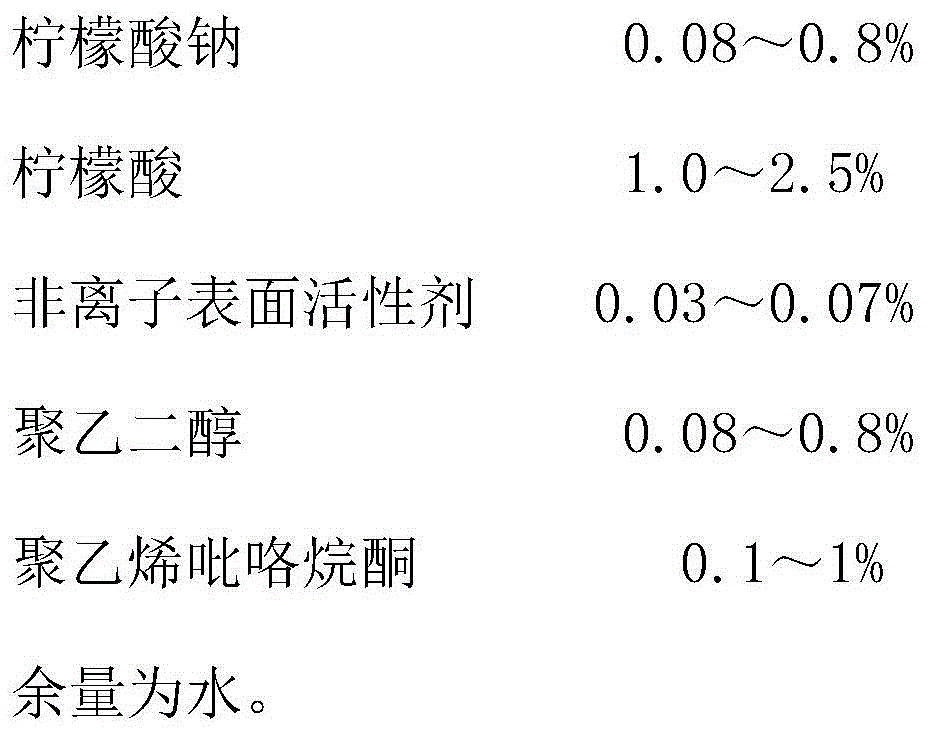

Multi-crystalline silicon wafer texturization additive

ActiveCN104651949AImprove wettabilityImprove the environment of acid textureAfter-treatment detailsFinal product manufacturePolyethylene glycolOptoelectronics

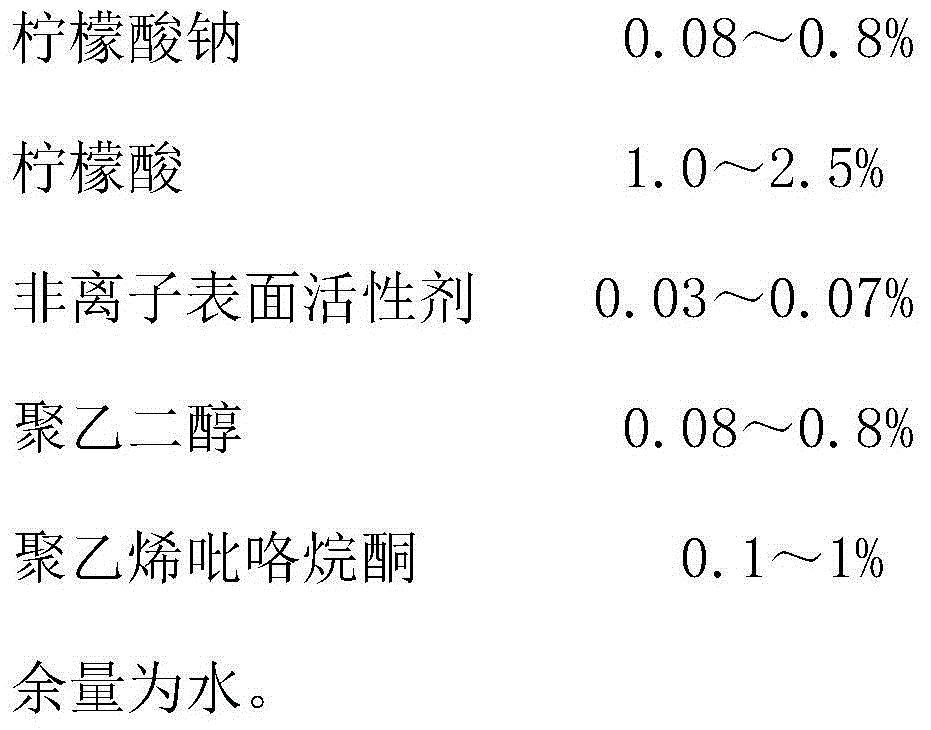

The invention discloses a multi-crystalline silicon wafer texturization additive, which comprises the following components in percentage by mass: 0.08-0.8% of sodium citrate, 1.0-2.5% of citric acid, 0.03-0.07% of non-ionic surfactant, 0.08-0.8% of polyethylene glycol, 0.1-1% of polyvinylpyrrolidone and the balance of water. After being texturized through using the prepared multi-crystalline silicon wafer texturization additive, the multi-crystalline silicon wafer has an even surface, the reflective rate is reduced by 3-5%, and a battery conversion rate is promoted by 0.1-0.2%.

Owner:CHANGZHOU JUNHE TECH

Leaching method for indium in waste liquid crystal panel and leaching agent

The invention relates to a leaching method for indium in a waste liquid crystal panel and a corresponding leaching agent, and belongs to the technical field of solid waste recycling. Eutecticevaporate ionic liquid formed through choline chloride and diacid substances serves as the leaching agent, after a liquid crystal panel glass substrate is crushed into powder with the granularity of 50-200 meshes, the powder is immersed through the eutecticevaporate ionic liquid, the immersing temperature is 50-90 DEG C, the immersing time is 12-48 h, the solid and liquid mass ratio of the glass powder to the eutecticevaporate ionic liquid is 1:0.5-1:2, and the indium leaching rate is higher than 95%. The leaching method has the advantages that the leaching agent preparing method is simple, the leaching agent is environment-friendly and capable of being circularly used, the leaching method operation technology is simple, the indium leaching rate is high, and selectivity is high, and an effective method for recycling indium from the waste liquid crystal panel is provided.

Owner:YUNNAN UNIV

Blood plasma lipide component adsorbing separation polymer porous film material, its preparing and use

InactiveCN101024149AGood reproducibilityEasy to prepareSemi-permeable membranesOther blood circulation devicesPerfusionSelective adsorption

This invention aims at providing a plasma lipid composition selective adsorption separation porous membrane carrier materials, preparation methods and related applications. The porous membrane carrier used the average pore size of 0.05 m ~ 100 u medical nonwoven polymer as the starting raw materials, through a total of 60 Co-ray irradiation grafting copolymerization polyacrylic acid surface modification, it further fixed the cholesterol ligand by carboxyl and containing 0 to 10 carbon atoms hand cholesterol arm of covalent ligand, finally get the polymer porous membrane carrier materials of plasma lipid selective adsorption separation ability. The invention related to the preparation method is simple, safe, effective and easy to promote large-scale production. With good material blood compatibility, it can be used as a plasma lipid composition adsorption separation of hyperlipidemia, dynamic perfusion of clinic high plasma patients blood purification and waste blood separation renewable auxiliary materials.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of trimethyl borate

InactiveCN102002064AEasy to implementProcess condition controlGroup 3/13 element organic compoundsReaction speedRaffinate

The invention discloses a preparation method of trimethyl borate. The method comprises the following steps of: (1) heating and dehydrating a boric acid solid to prepare metaboric acid and pyroboric acid solids; (2) adding the metaboric acid and pyroboric acid solids which are obtained in the step (1) to methanol to make the mixture react under a stirring state; (3) heating and distilling the reaction solution obtained in the step (2) to obtain an azeotrope solution of the methanol and the trimethyl borate, distilling and cooling raffinate to obtain boric acid; and (4) separating the azeotrope solution of the methanol and the trimethyl borate, which is obtained in the step (3), to obtain a trimethyl borate product. In the invention, by firstly heating and dewatering the boric acid to prepare the metaboric acid and the pyroboric acid and then making the metaboric acid and the pyroboric acid react with the methanol to prepare trimethyl borate, the reaction speed is accelerated, the conversion per pass is improved, the reaction conditions are mild and no risks exist.

Owner:SHANDONG GUOBANG PHARMA

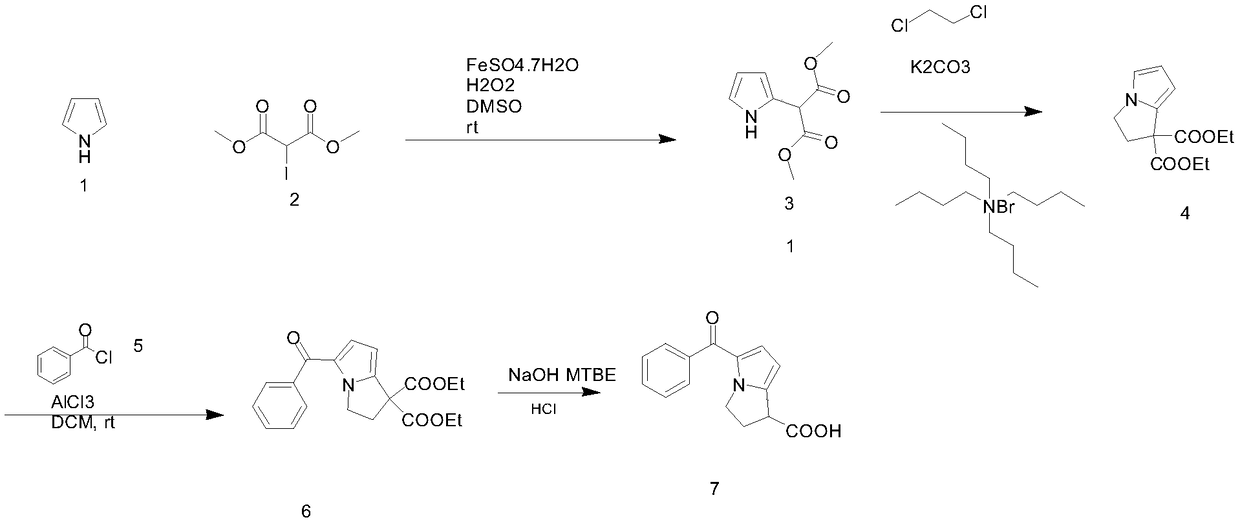

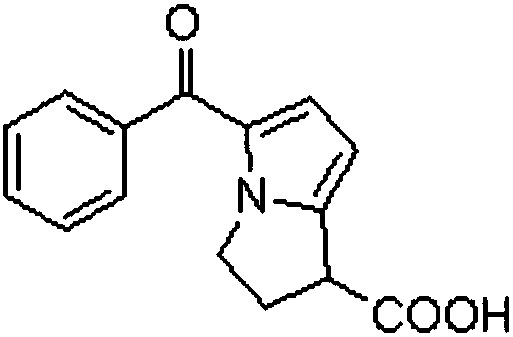

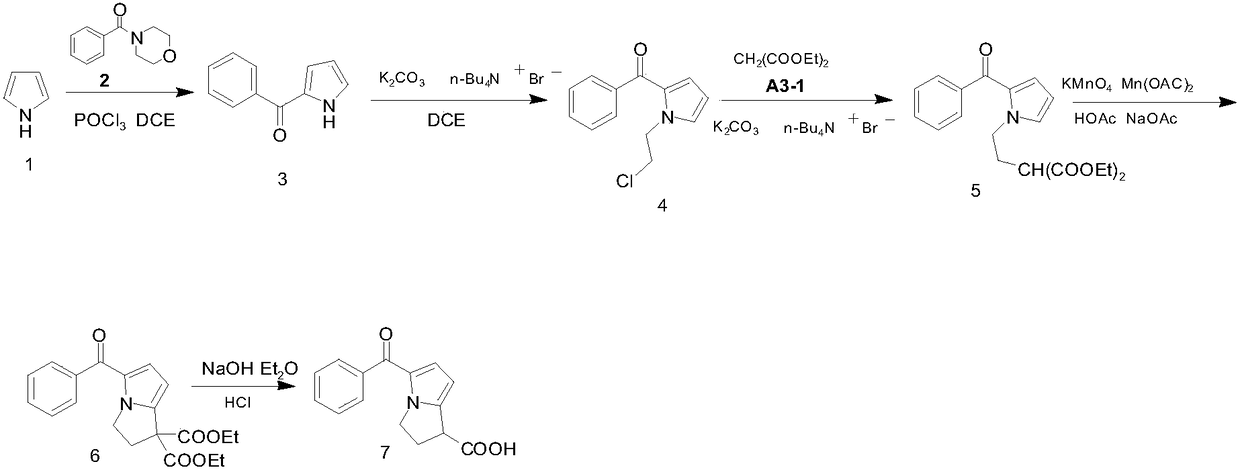

Synthesis process of ketorolac

InactiveCN108191876AEmission reductionThe synthesis process is environmentally friendlyOrganic chemistryKetorolacManganese

The invention discloses a synthesis process of ketorolac, and relates to the technical field of medicine synthesis. The synthesis process solves the technical problems that the existing process can generate a large amount of liquid and solid wastes, and the environment protection is not facilitated. Hydrogen peroxide with side products being water is used as an oxidizing agent; malysite is used asa catalyst; a large number of manganese salts are replaced; when 1kg of ketorolac is reduced, 3.5 to 6.1kg of discharged liquid and solid wastes are reduced; the green and environment-friendly effects are achieved. Benzoyl chloride is directly used as raw materials; the one-step reaction is reduced; the synthesis process is simpler; the methyl tertiary butyl ether is used for replacing the flammable and combustible diethyl ether; the process production safety is improved. The synthesis process has the advantages that the operation is easy; the process conditions can be easily controlled; thefinal product purification and aftertreatment are simple.

Owner:上海仁实医药科技有限公司

Method of producing cutting tool steel board with three layer complex blades

ActiveCN101032793AHigh composite strengthProcess conditions are easy to controlRoll mill control devicesHeat treatment process controlSheet steelMaterial Perforation

The process of making three-layered composite steel plate for cutting tool includes the following steps: taking one thin rod of cutter edge steel and one thick rod of cutter body steel, coaxially compounding these two rods through drilling hole and embedding, heating the compounded rod and forging and welding radially in a forging machine in the deformation of 50 %, heating the forged and welded plate and rolling axially in a rolling mill for welding in the thickness deformation rate not lower than 80 %, heat treatment, rolling and fixing, and splitting the plate along the axis to obtain 2 three-layered composite steel plates for cutting tool. The present invention has high compounding strength, stable product quality, low product cost.

Owner:辽宁新华阳伟业装备制造有限公司

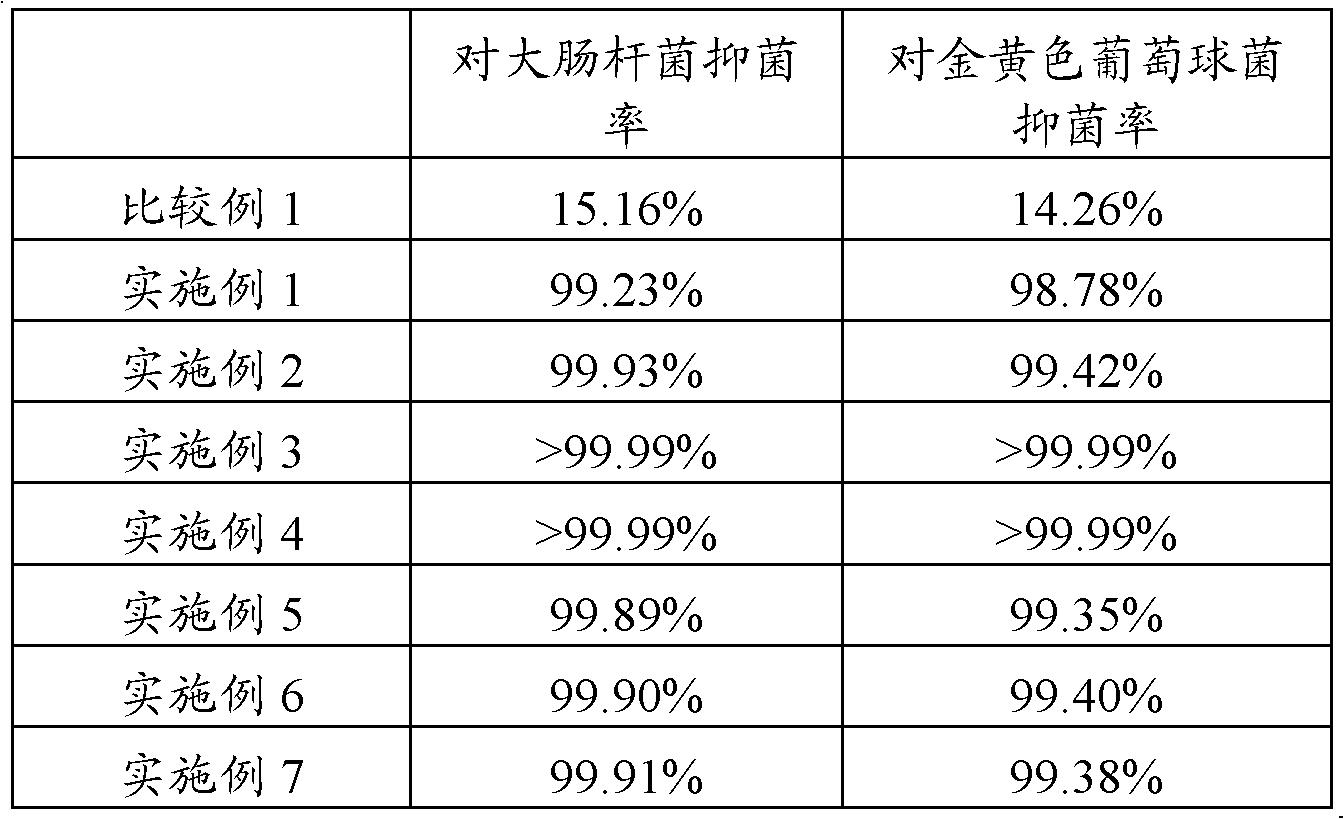

Anti-bacterial polythene foamed plastics and preparation method thereof

InactiveCN101967244AImprove antibacterial propertiesImprove the bactericidal effectFibre typesFiberPolymer science

The invention discloses anti-bacterial polythene foamed plastics. The anti-bacterial polythene foamed plastics is made from the following raw materials in percentage by mass: 80.5 to 96.5 percent of base material, 0.5 to 5 percent of silver-plated fibers, 0.5 to 2 percent of cross linking agent, 2 to 10 percent of foaming agent and 0.5 to 2.5 percent of foaming promoter, wherein the base material comprises two polymers, namely polythene and ethylene-vinyl acetate copolymer. The anti-bacterial polythene foamed plastics has high antibacterial property, mechanical property and wide application range. The invention also discloses a preparation method for the anti-bacterial polythene foamed plastics. Process conditions of the method are easy to control; equipment is simple and convenient to operate; and the method has low requirement on mechanical equipment and is suitable for industrial production.

Owner:ZHEJIANG SCI-TECH UNIV

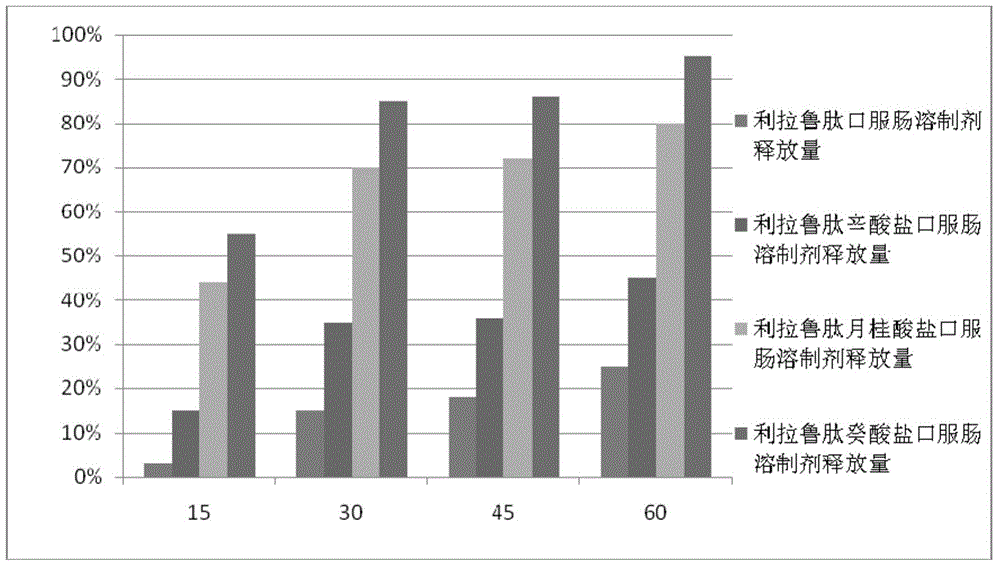

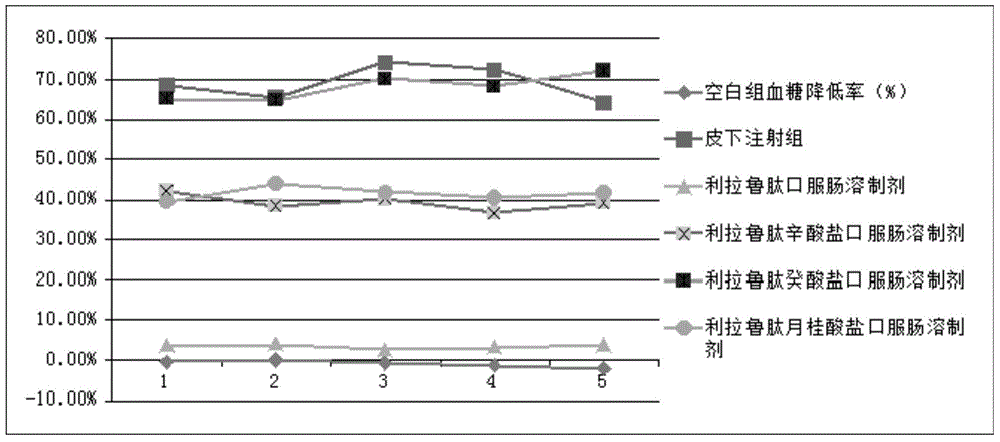

Intestinal absorption promoting liraglutide salt for preparing oral enteric-coated preparations

InactiveCN104998251AImprove bioavailabilityImprove stabilityPeptide/protein ingredientsMetabolism disorderPotassiumSodium octanoate

The invention discloses an intestinal absorption promoting liraglutide salt for preparing oral enteric-coated preparations, and belongs to the field of medicines. The liraglutide salt is selected from salts formed through reacting liraglutide with sodium caprate, potassium caprate, benzene sulfonic acid, sodium dodecyl benzene sulfonate, potassium dodecyl benzene sulfonate, sodium octanoate, potassium octanoate, sodium laurate, potassium laurate, sodium oleate and potassium oleate.

Owner:哈尔滨吉象隆生物技术有限公司

Preparation method of food additive grade tricalcium phosphate

InactiveCN101654236ALow impurity contentGood removal effectPhosphorus compoundsFood additiveAlkalinity

The invention provides a preparation method of food additive grade tricalcium phosphate, which comprising the following steps: using an aqueous calcium chloride solution and an aqueous sodium hydroxide solution to prepares fresh lime cream, aging, subsiding, filtering and washing the fresh lime cream to obtain calcium hydroxide precipitates; aging, centrifugalizing, drying and smashing tricalciumphosphate generated during reaction of the calcium hydroxide precipitates and phosphoric acid to obtain the product. The preparation method of the food additive grade tricalcium phosphate is easy to eliminate impurities through washing in such a way that the coacervation and sedimentation effect of calcium hydroxide particles is better than that of the phosphoric acid under the condition of high alkalinity and the calcium hydroxide particles wrap and absorb few impurities. The tricalcium phosphate product prepared by the method accords with China HG 2789-1996 and America FCC food additive standards in quality. The preparation method has extensive material source and easy technology condition control and is especially suitable for large-scaled industrialized production.

Owner:GUANGDONG GUANGHUA SCI TECH +1

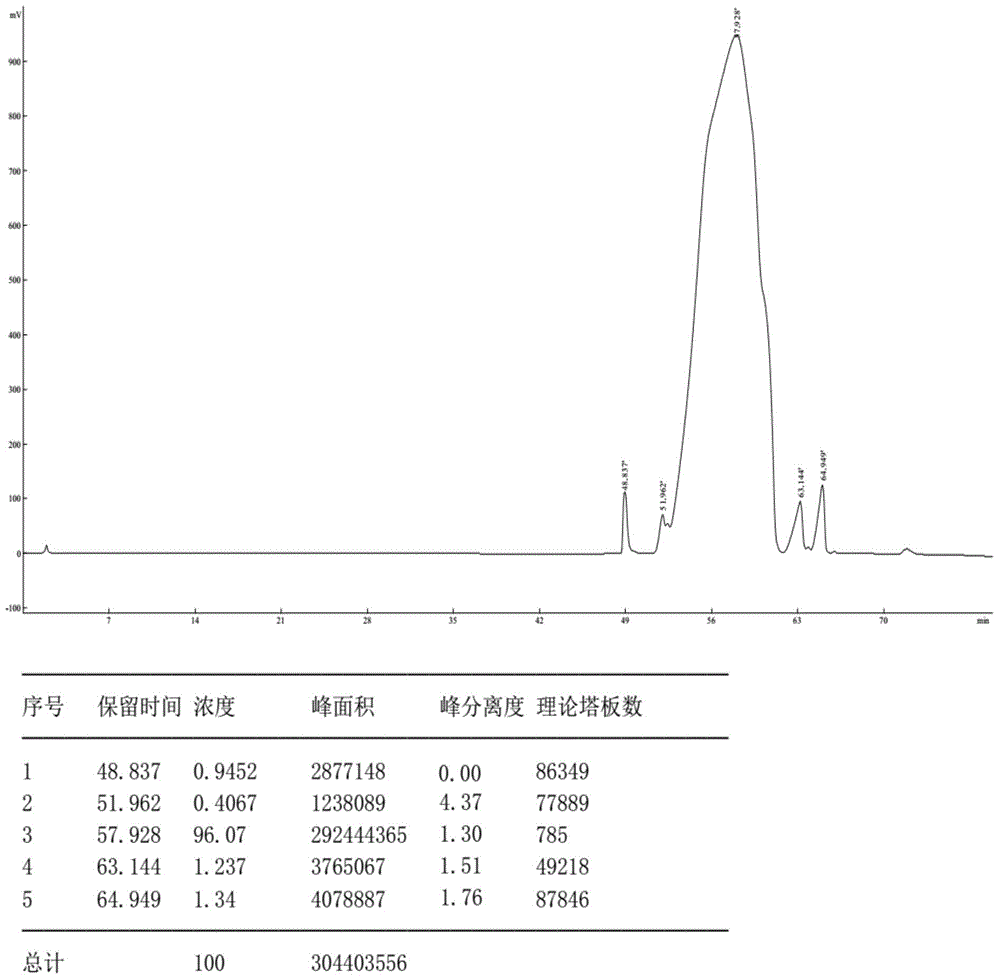

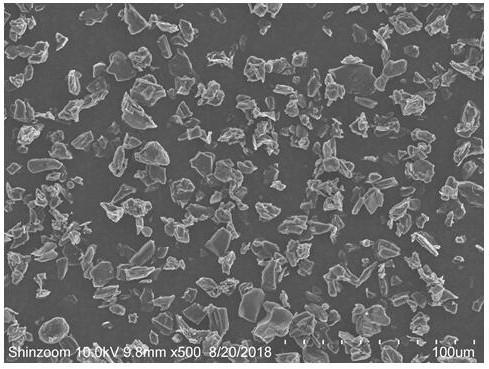

Preparation method of low-cost composite particle graphite cathode material

InactiveCN109748274AImprove charge and discharge performanceSmooth de-embeddingCarbon compoundsCell electrodesMetallurgyMixed materials

The invention provides a preparation method of a low-cost composite particle graphite cathode material. The preparation method includes the steps: mixing coke materials and asphalt powder according tothe weight ratio of 100:1 to 100:20 to obtain mixed materials; placing the mixed materials into a graphitization furnace for graphitization to obtain the composite particle graphitization materials;grading the composite particle graphitization materials to obtain graded materials; screening and demagnetizing the graded materials to obtain the composite particle graphite cathode material. A composite granulating process and a graphitization process are integrated, the cost of the composite granulating process is saved, and the charge and discharge performance of the material is improved.

Owner:HUNAN SHINZOOM TECH

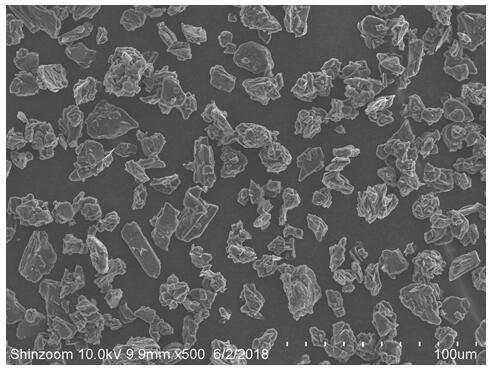

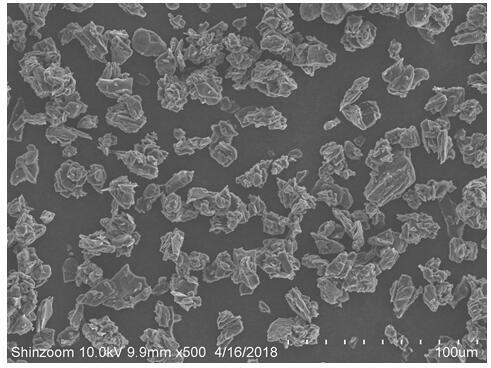

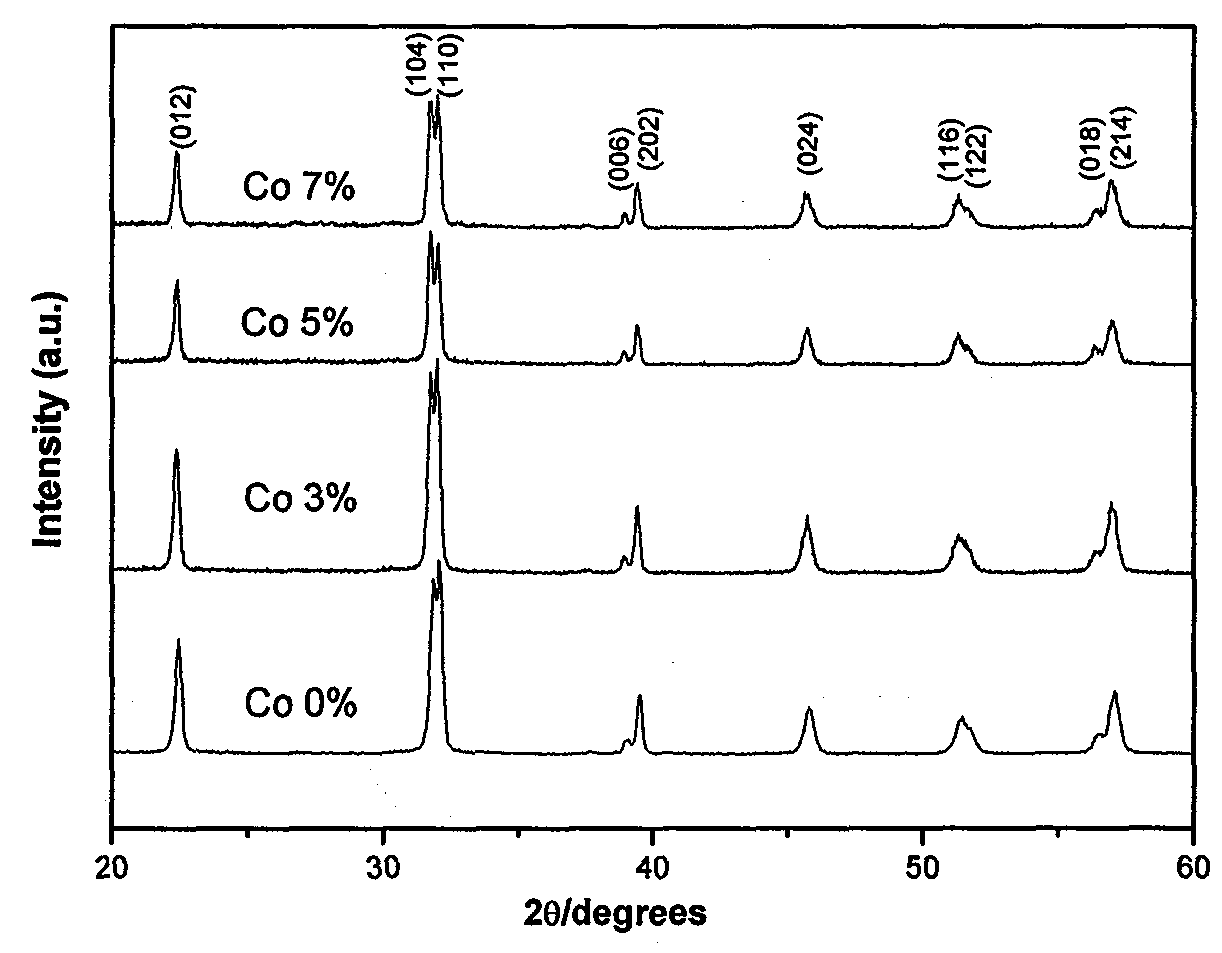

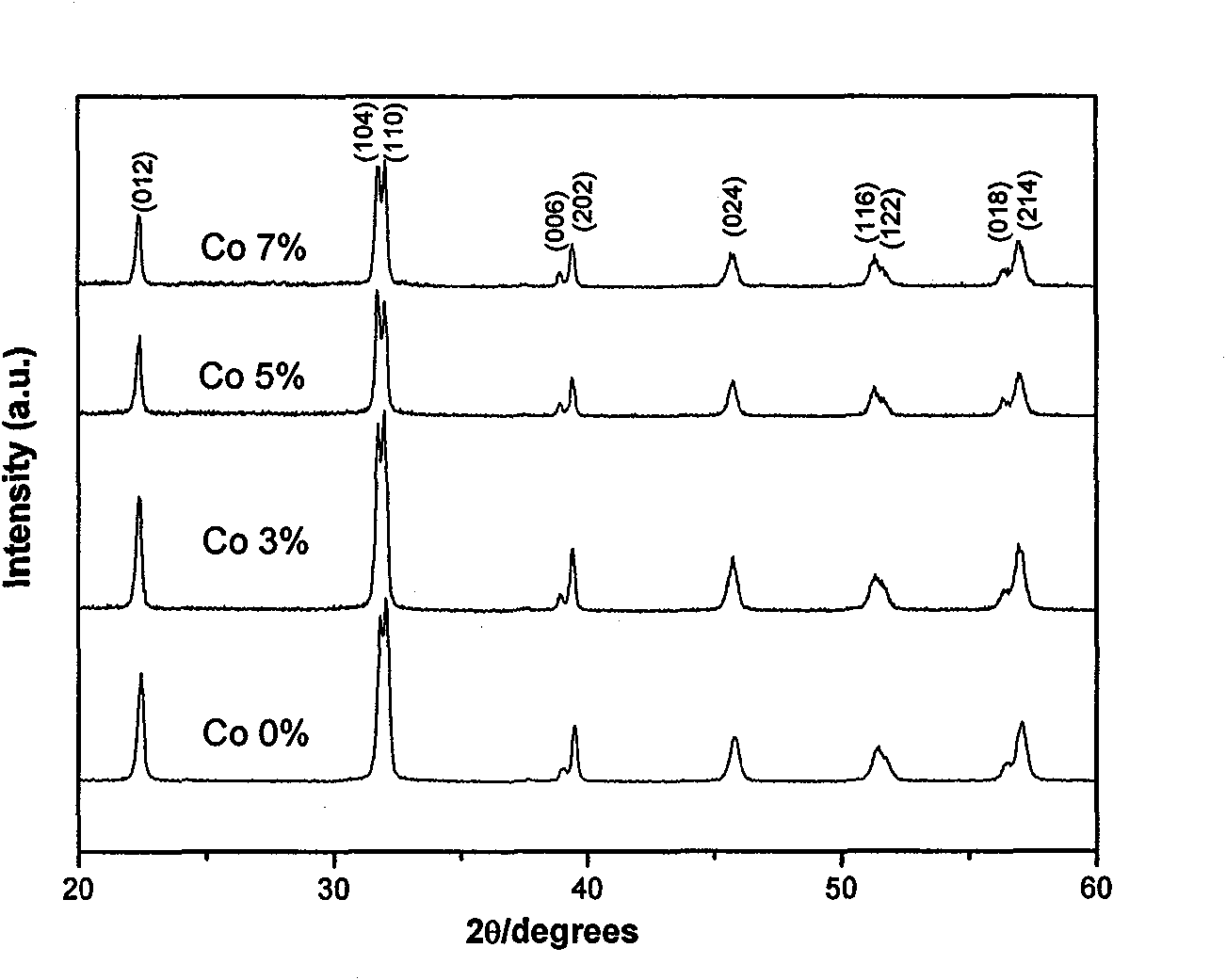

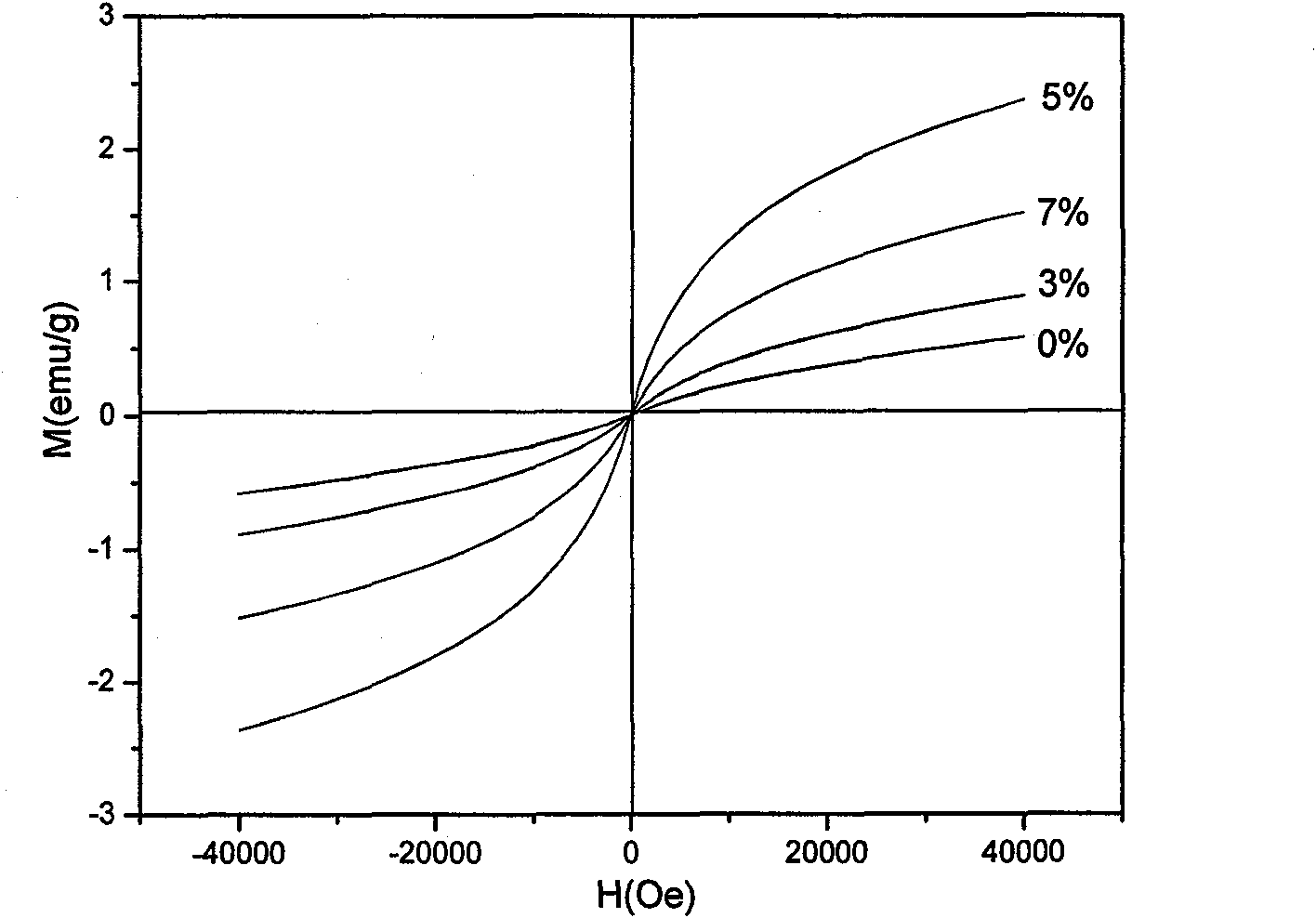

Cobalt material doping with ferrous acid bismuth multi-iron and preparation method thereof

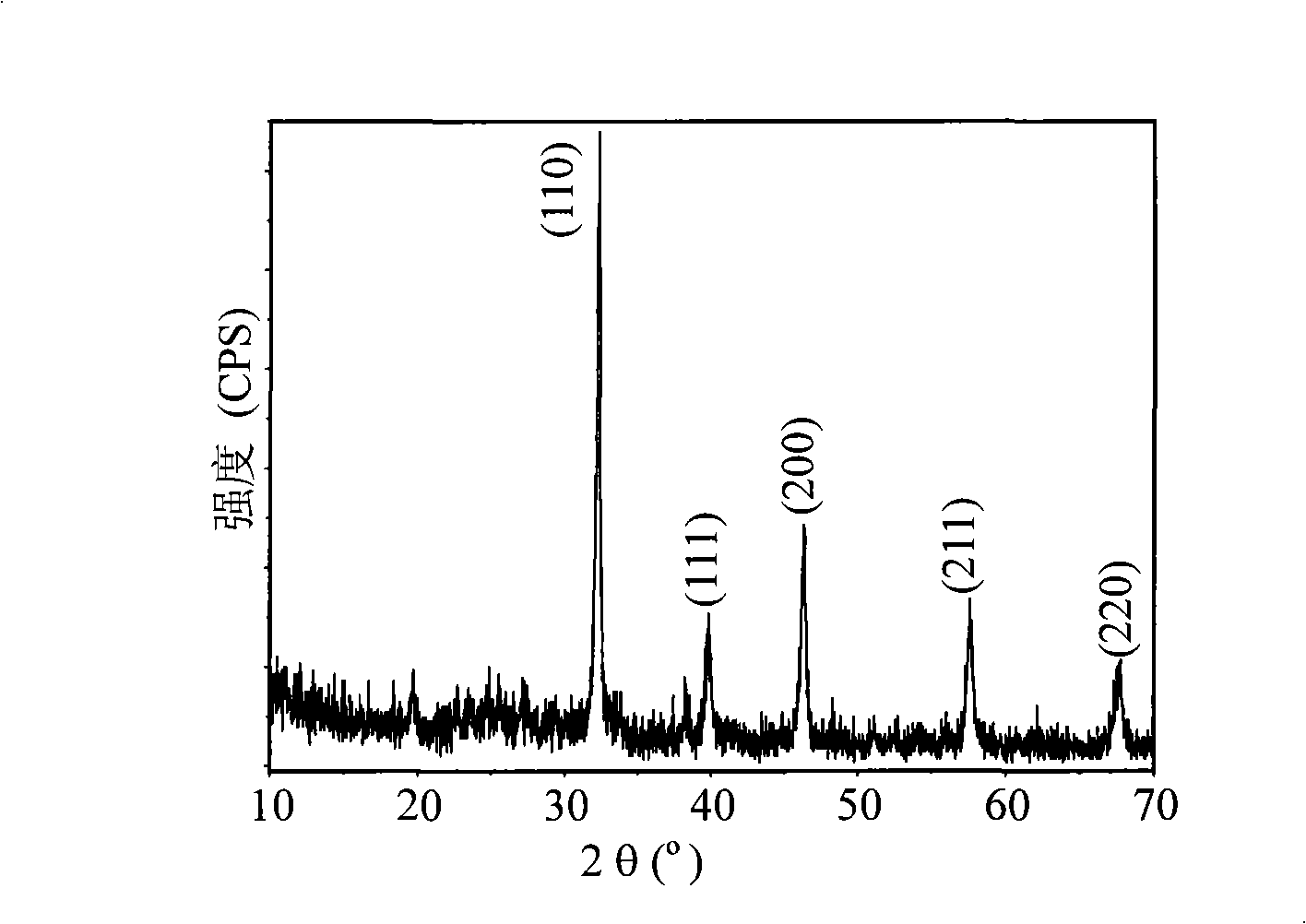

InactiveCN101303928BImprove magnetismImprove crystal qualityInorganic material magnetismPotassium hydroxideCobalt

The invention discloses cobalt doping bismuth ferric material, the chemical formula of which is BicoxFe1-xO3; x is not more than 0.07 while is more than 0. The preparation method is that: oxyhydroxide precipitation of iron, bismuth and cobalt is made as the reaction material; potassium hydroxide with suitable concentration is added to promote crystallization; cobalt doping bismuth ferric powder is then obtained by hydrothermal reaction under the temperature of 120 degrees to 200 degrees. The invention dramatically enhances the magnetism of the bismuth ferric by doping cobalt; furthermore, theinvention has simple technique, has no pollution, low cost and is suitable for mass production. The cobalt doping bismuth ferric material of the invention has stable crystallization quality and has wide application prospect in the fields such as information storage, satellite communication, precise control, circuit measurement of high voltage transmission lines and magnetoelectric sensors.

Owner:ZHEJIANG UNIV

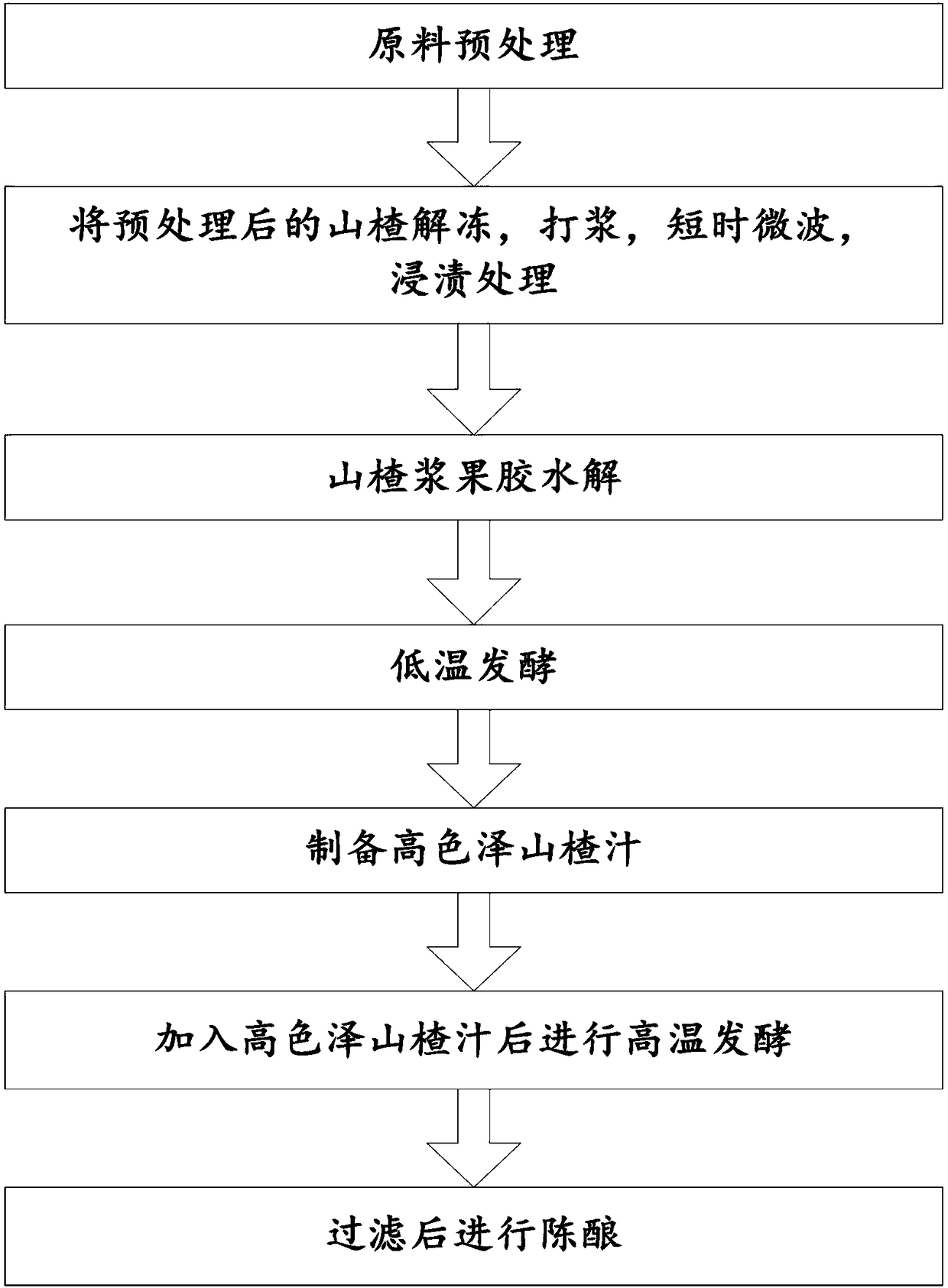

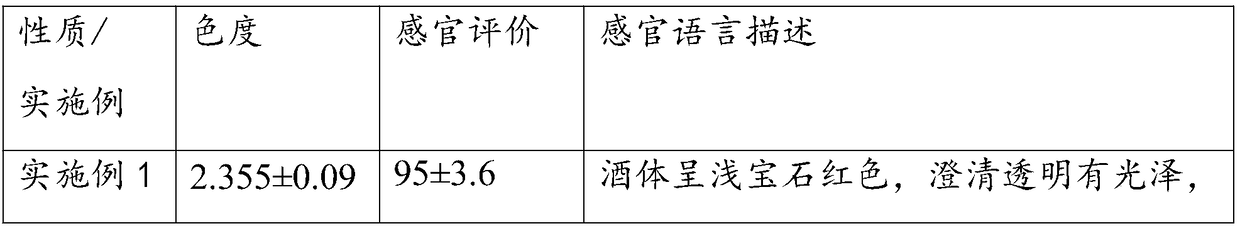

High-chroma dry type hawthorn fruit wine and preparation method thereof

ActiveCN108220070AEnsure safetyGuaranteed contentAlcoholic beverage preparationMicrowaveHawthorn fruit

The invention discloses a high-chroma dry type hawthorn fruit wine and a preparation method thereof. The preparation method comprises the following steps of selecting purple-pulp hawthorn fruit with high content of anthocyanin; cleaning fruit of hawthorn wine, crushing, freezing, impregnating by microwaves for a short time, adding sugar to adjust, and fermenting at low temperature in a light shielding way; adding high-chroma hawthorn fruit juice, fermenting, aging, and filtering, so as to obtain the high-chroma dry type hawthorn fruit fermenting wine. The prepared high-chroma dry type hawthornfruit wine has the advantages that the color, fragrance, taste, mouth feel, and acidity are mutually coordinated; the mouth feel is soft, the rich nutrients are contained, the edible and health-carefunctions can be simultaneously realized, the high-chroma dry type hawthorn fruit wine is suitable for the public taste, and the requirement on higher-quality foods by people can be met.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of producing cutting tool steel board with three layer complex blades

ActiveCN100482406CHigh composite strengthProcess conditions are easy to controlRoll mill control devicesHeat treatment process controlSheet steelMaterial Perforation

Owner:辽宁新华阳伟业装备制造有限公司

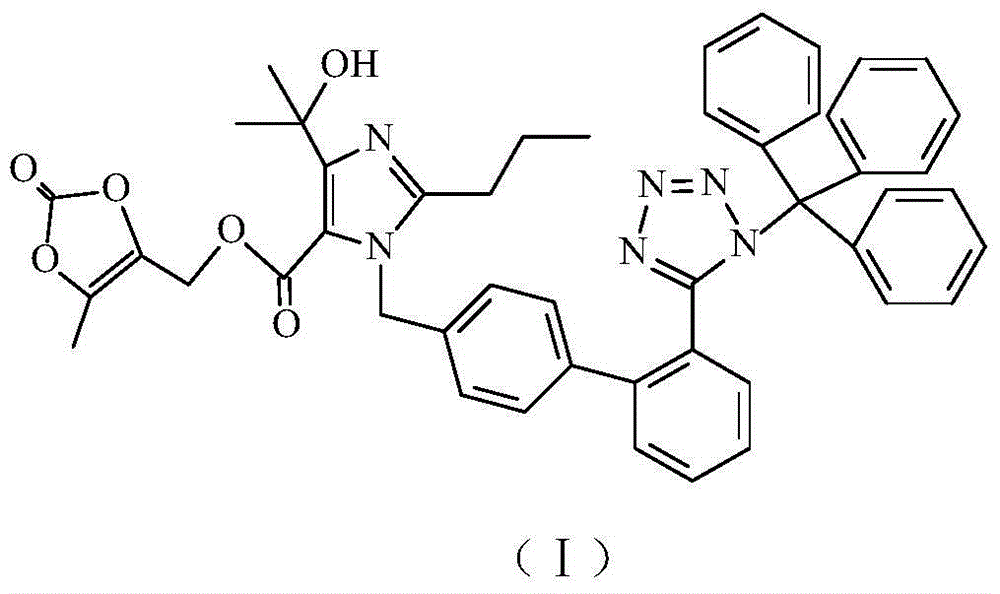

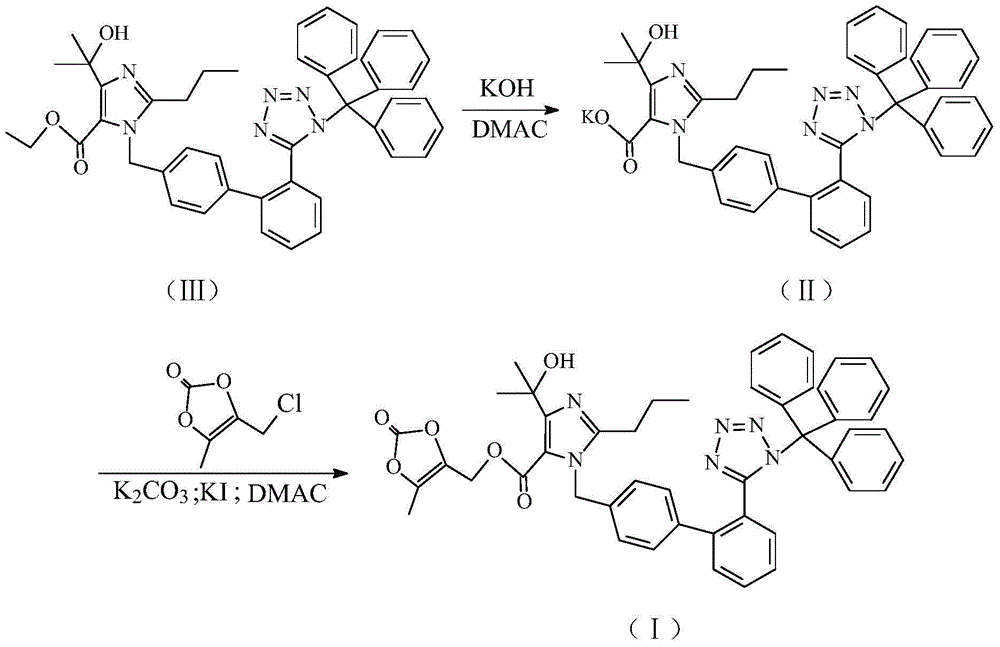

Preparation method of olmesartan intermediate

The invention belongs to the technical field of medicament synthesis, and in particular relates to a preparation method of an olmesartan intermediate. The preparation method comprises the following steps: enabling a compound (III) to react with a strong base in the presence of an organic solvent under the protection of nitrogen to generate a compound (II), enabling the compound (II) to react with 4-chloromethyl-5-methyl-1,3-dioxole-2-one under the catalysis of potassium carbonate and potassium iodide without separation, performing extraction with an organic solvent after reaction, and performing brine washing, concentration, crystallization, centrifuging and drying to obtain a crude product of a compound (I); and recrystallizing the crude product of the compound (I) by using the organic solvent, then centrifuging, and finally performing vacuum drying under the condition of alternate replacement of nitrogen and vacuum, thereby obtaining a high-quality product of the compound (I). The preparation method provided by the invention is stable in process and simple in operation, the process condition is easy to control, the after treatment is simple and convenient, less three wastes are generated, a mother solution can be continuously and circularly used, the product quality is good, the yield is high, the production cost is low, and a pilotscale experiment validates that the preparation method is suitable for industrial production.

Owner:SHANDONG XINHUA PHARMA CO LTD

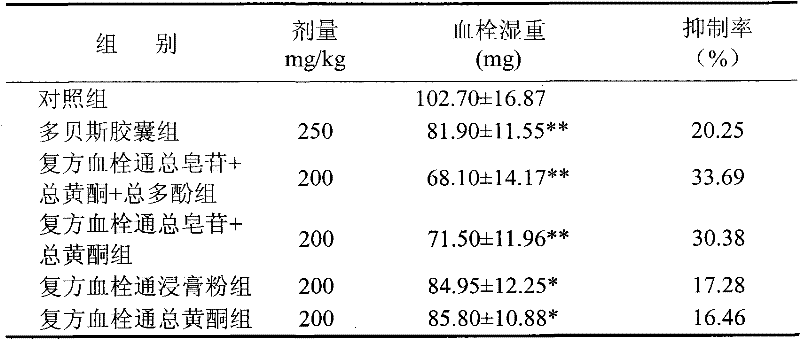

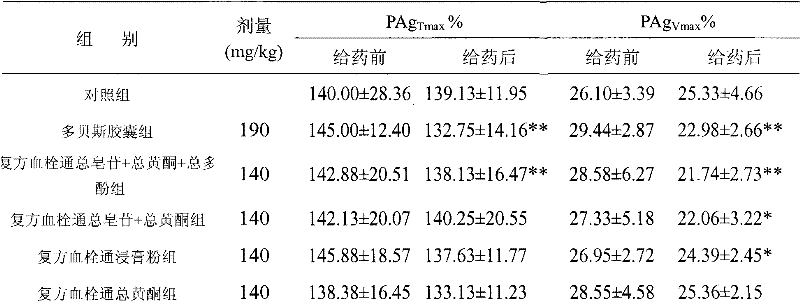

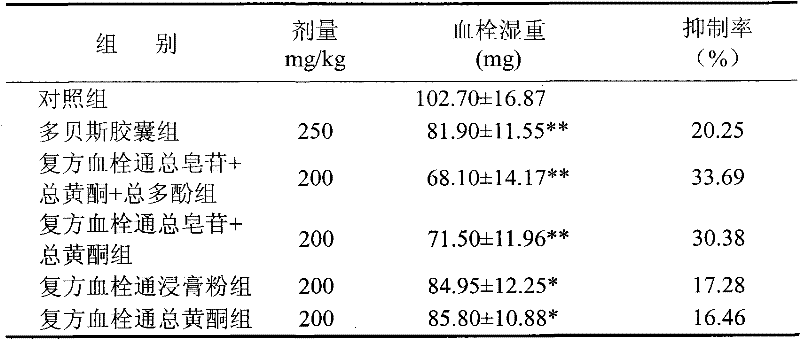

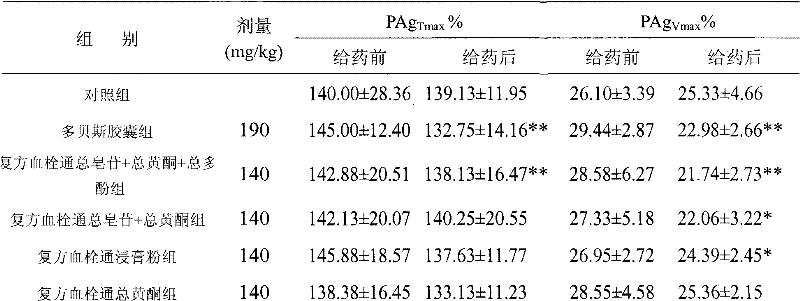

Pharmaceutical composition and preparation method thereof

ActiveCN101744938BLittle side effectsImprove bioavailabilitySenses disorderMetabolism disorderMedicinal herbsDisease

The invention provides a pharmaceutical composition and preparation method and application thereof in curing cardio-cerebrovascular diseases. The invention adopts the scheme that the pharmaceutical composition is prepared by taking 25 parts of pseudo-ginseng, 8 parts of Astragalus mongholicus, 8 parts of radix scrophulariae and 5 parts of roots of red-rooted salvia as materials, and the weight ratio of the total flavonoids extracts, the total saponin extracts and the total polyphenolic acid extracts extracted from the four Chinese medicinal herbs is 1-5:1-5:1, wherein the total flavone accounts for more than 80% of the total flavonoids extracts, the total saponin accounts for more than 70% of the total saponin extracts, the total polyphenolic acid accounts form more than 85% of the total polyphenolic acid extracts, and the total content of the flavone, saponin and polyphenol is more than 80%.

Owner:广州威斯宝药业有限公司

Method of producing cutting tool steel board of complex blades

ActiveCN100462192CUniform tissueReasonable structureRoll mill control devicesHeat treatment process controlSheet steelMiddle line

The process of making double composite steel plate for cutting tool includes the following steps: taking one large cutter body steel plate and one small cutter edge steel plate in the same length, shaving one slot in the cutter body steel plate and embedding the cutter edge steel plate in the slot, heating to the eutectic temperature and forging and welding in a forging machine in the thickness deformation of 48-52 %, heating to 1100-1200 deg.c and rolling in a rolling mill for welding in the deformation rate of 70-90 %, heat treatment, rolling and fixing, and splitting along the central line to obtain two double composite steel plates for cutting tool. The present invention has high compounding strength, stable product quality, low product cost, and may be used in producing shears and planer tool.

Owner:辽宁新华阳伟业装备制造有限公司

A method and system for recovering lithium and cobalt from waste lithium cobalt oxide batteries

ActiveCN109256597BAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementMembrane technologyReverse osmosis

Owner:青海中科德方能源科技研究有限公司

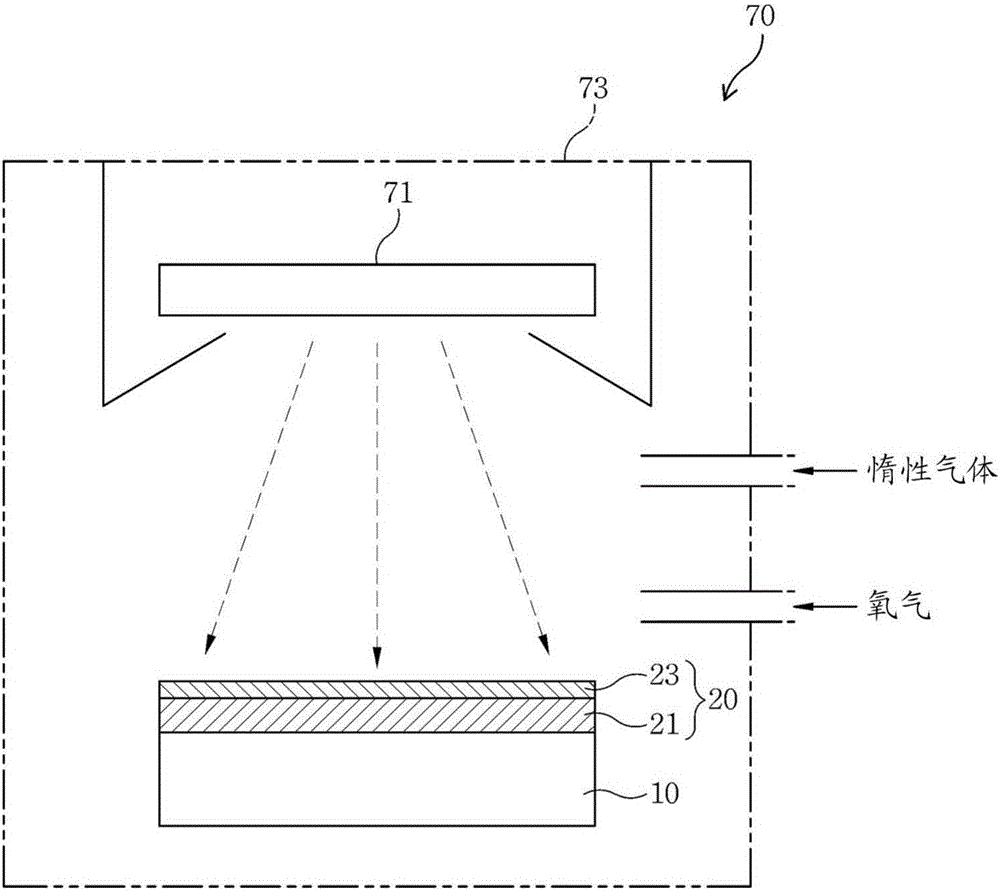

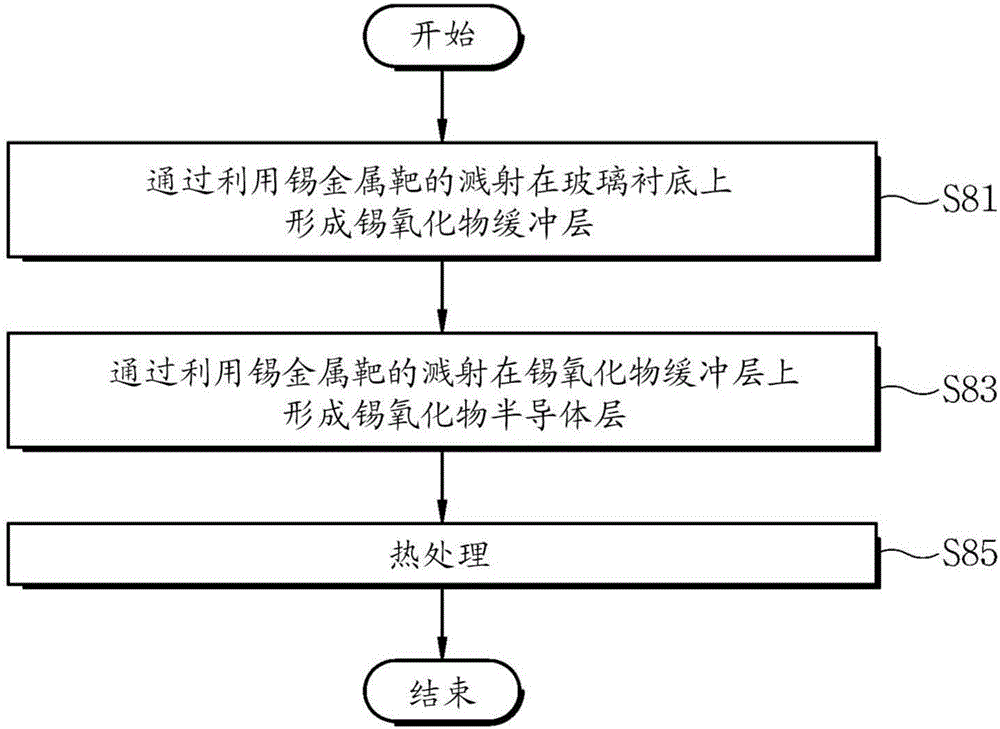

Method for forming tin oxide layer by means of tin metal target

InactiveCN106661714AWell formedProcess condition controlSolid-state devicesVacuum evaporation coatingSputteringSemiconductor

The present invention relates to a method for forming a tin oxide layer by means of a tin metal target, the method forming the tin oxide layer on a glass substrate by means of a tin metal target. Provided is a method for forming a tin oxide layer by means of a tin metal target, the method comprising the steps of: forming a tin oxide buffer layer (SnO2) on a glass substrate by means of sputtering using a tin metal target; and forming a tin oxide semiconductor layer (SnO2-x where 0 < x <= 0.01) on the tin oxide buffer layer by means of sputtering using a tin metal target.

Owner:RFTRON

Methanol fuel specially used for boiler combustion

InactiveCN105820849AReduce consumptionEnsure quality equalizationLiquid carbonaceous fuelsFuel additivesZinc peroxideActive agent

The invention relates to methanol fuel specially used for boiler combustion. The methanol fuel comprises the following components in percentage by mass: 85% of methane, 1-7% of acetone and 8-14% of a component A, wherein the component A is one or mixture of more than one of zinc peroxide, diethyl ether, dimethyl methane, a fat type active agent, methyl tertiary-butyl ether and normal octane. The methanol fuel provided by the invention has the advantages that caloric value of the methanol fuel can be beneficially improved, a preparation technology is simple, period is short, and technological conditions are controlled, so that non-renewable boiler fuel at present can be conveniently replaced, tail gas discharged through boiler combustion is cleaner, and carbon monoxide in exhaust gas emission is reduced by at least 95%.

Owner:王菊林

A method and system for recovering lithium and manganese from waste lithium manganese oxide batteries

ActiveCN109207725BAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyPhysical chemistry

The invention discloses a method and a system for recovering lithium and manganese from waste lithium manganate batteries. The method includes: dismantling the positive electrode sheet from the waste lithium manganese oxide battery; removing the binder in the positive electrode sheet, and then leaching the valuable metal elements in the positive electrode sheet through acid solution to obtain an acidified leachate; using an ultrafiltration membrane to The acidified leachate is subjected to ultrafiltration treatment; the lithium ions in the acidified leachate are separated from other cations different from lithium ions by using nanofiltration membrane technology to obtain a lithium-containing solution and a solution containing other cations, which are then concentrated and enriched by reverse osmosis technology. set, the other cations include manganese ions; and, the lithium ions in the lithium-containing solution are precipitated by using a lithium precipitant, and the manganese ions in the solution containing other cations are precipitated by using an alkaline substance, so as to realize the separation of lithium and manganese Recycle. The invention adopts ultrafiltration-nanofiltration-reverse osmosis combined technology, and has the characteristics of simple and environmentally friendly process, less acid and alkali consumption, good and stable membrane separation effect, and the like.

Owner:青海中科德方能源科技研究有限公司

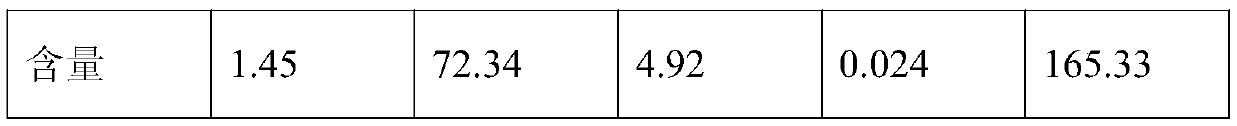

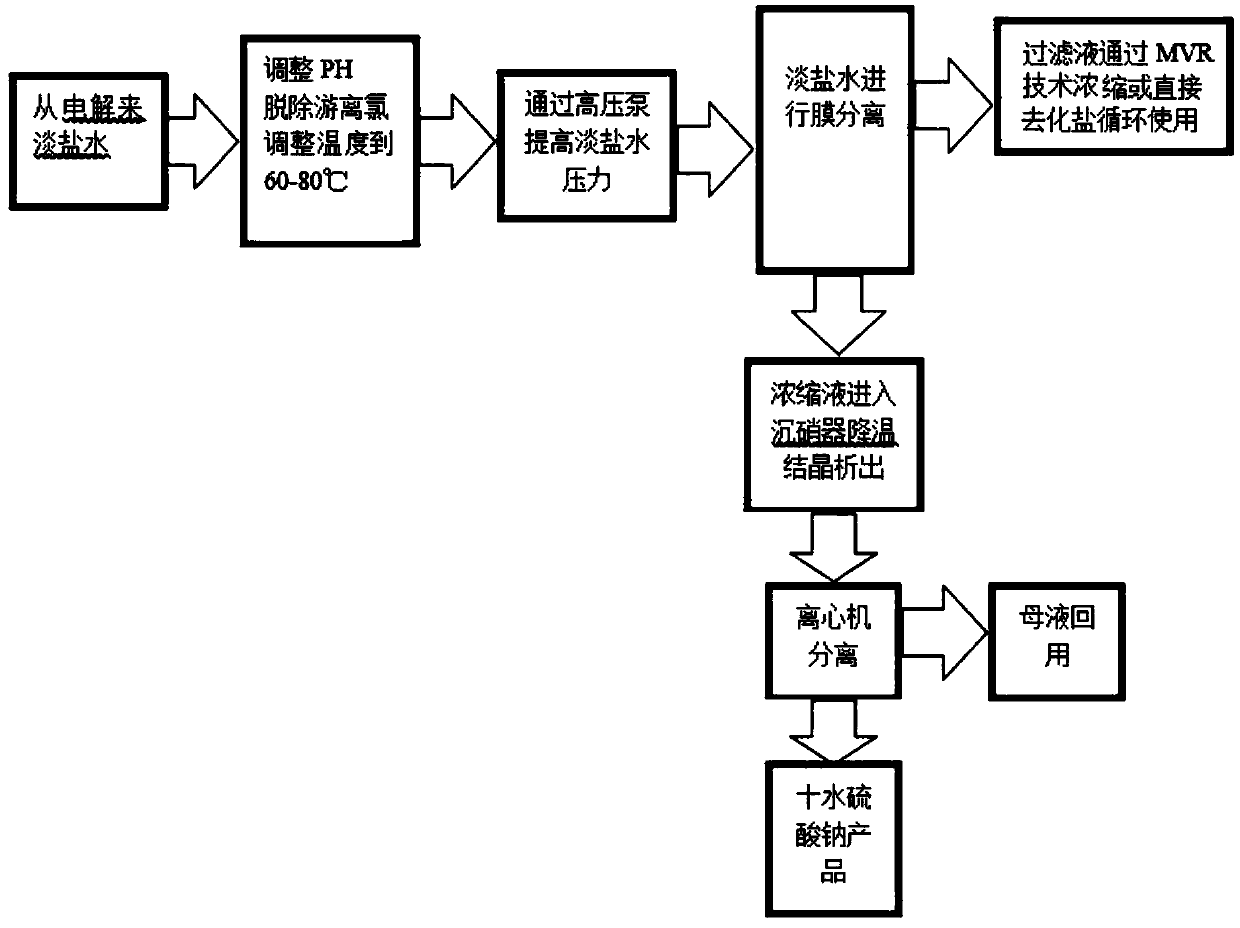

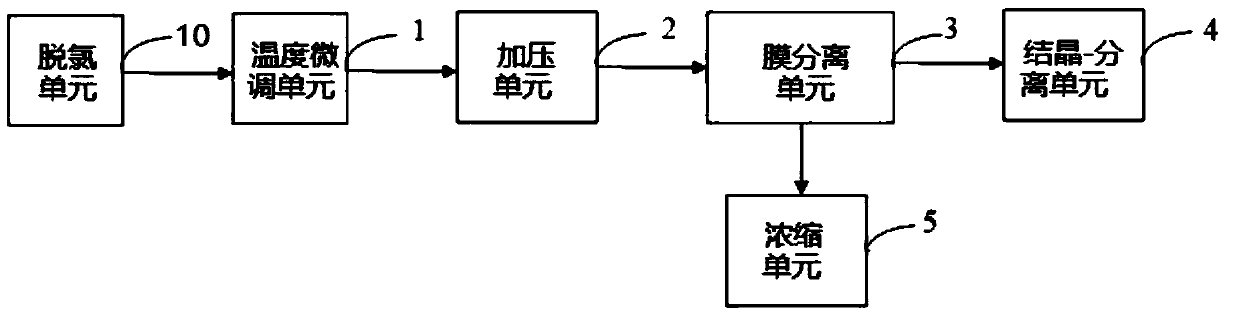

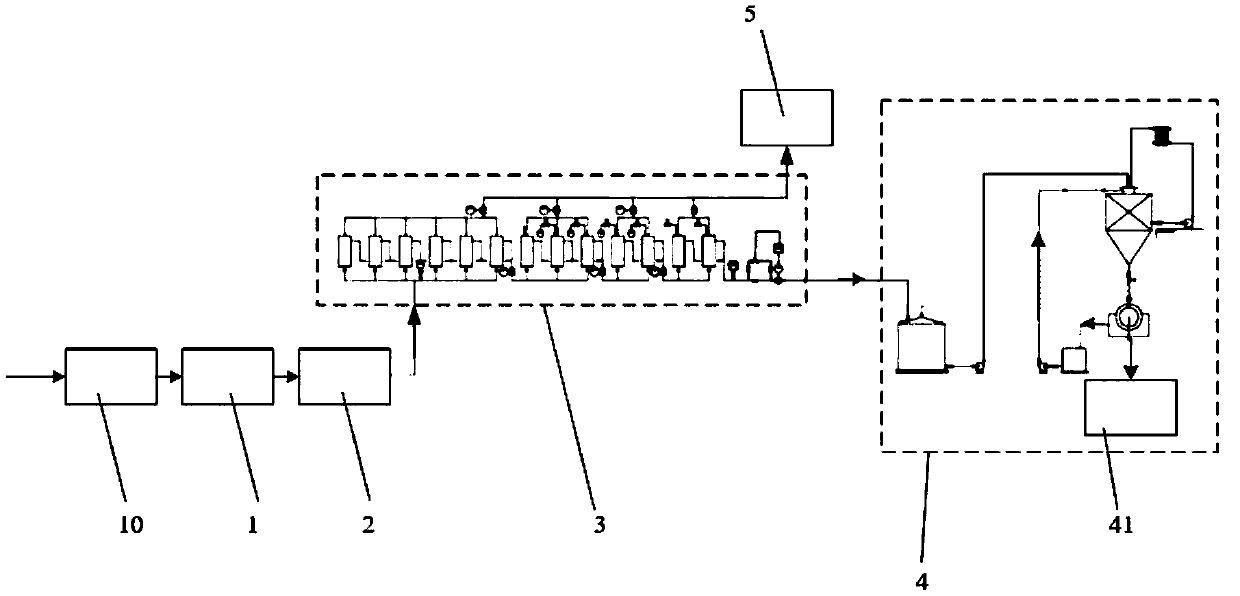

Method for removing sulfate ions by high-temperature membrane method

PendingCN111484177AReduce energy consumptionSave energyWater treatment parameter controlWater contaminantsSaline waterSulfate radicals

The invention discloses a method for removing sulfate ions by a high-temperature membrane method. The method comprises the following steps: pretreating high-temperature electrolyzed light salt brine;performing dechlorination treatment on the high-temperature electrolyzed light salt brine in the pretreatment process; adjusting the pH value of the high-temperature electrolyzed light salt brine; finely adjusting the temperature of the high-temperature electrolyzed light salt brine to slightly reduce the temperature of the high-temperature electrolyzed light salt brine; and then carrying out membrane separation treatment, crystallizing and separating the saline water with high sulfate ion concentration after membrane separation, and concentrating the saline water with low sulfate ion concentration after membrane separation or returning the saline water with low sulfate ion concentration to a saline water process for salt melting. According to the method, sulfate radicals in the electrolyzed light salt brine are removed through a high-temperature nanofiltration process, the treatment temperature of the light salt brine treated by the system is high, desulfurization acid radical treatment can be carried out without cooling to 45 DEG C or below, and the use amount of cooling water is remarkably reduced; and in addition, the temperature of filtrate obtained after membrane filtration is high, heat consumption during MVR evaporation or salt melting is reduced, energy consumption is reduced in the MVR concentration process, and energy is saved.

Owner:HENGXINGRUNFENG TECH DEV BEIJING

Pharmaceutical composition and preparation method thereof

ActiveCN101744938ALittle side effectsImprove bioavailabilitySenses disorderMetabolism disorderMedicinal herbsDisease

The invention provides a pharmaceutical composition and preparation method and application thereof in curing cardio-cerebrovascular diseases. The invention adopts the scheme that the pharmaceutical composition is prepared by taking 25 parts of pseudo-ginseng, 8 parts of Astragalus mongholicus, 8 parts of radix scrophulariae and 5 parts of roots of red-rooted salvia as materials, and the weight ratio of the total flavonoids extracts, the total saponin extracts and the total polyphenolic acid extracts extracted from the four Chinese medicinal herbs is 1-5:1-5:1, wherein the total flavone accounts for more than 80% of the total flavonoids extracts, the total saponin accounts for more than 70% of the total saponin extracts, the total polyphenolic acid accounts form more than 85% of the total polyphenolic acid extracts, and the total content of the flavone, saponin and polyphenol is more than 80%.

Owner:广州威斯宝药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com