Method for removing sulfate ions by high-temperature membrane method

A sulfate ion, high temperature membrane technology, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, high cost, and great harm to humans and animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

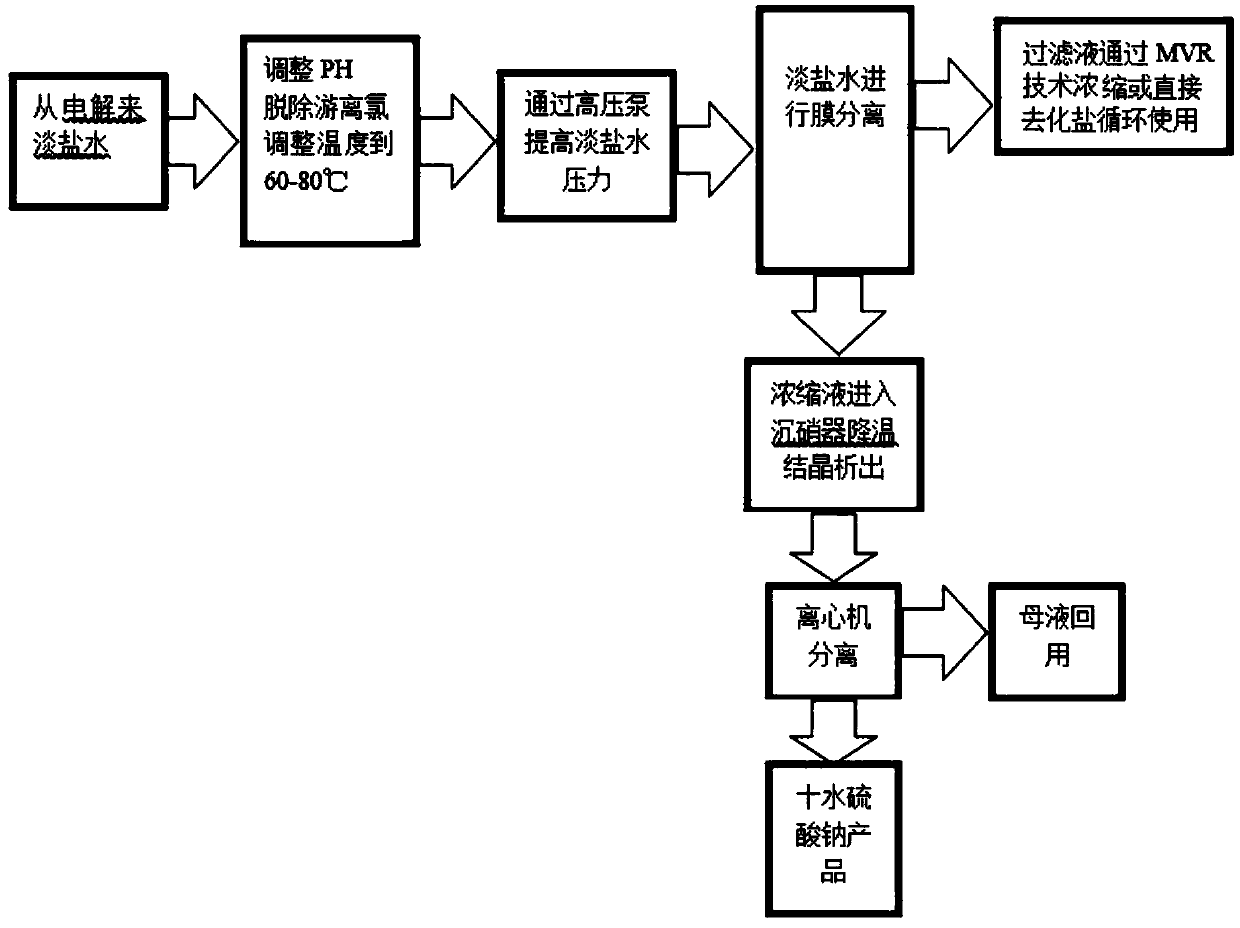

[0117] 1. Pretreatment of light brine

[0118] Pretreatment of chlor-alkali industrial ion membrane electrolysis light brine, removal of free chlorine (i.e. dechlorination treatment), pH adjustment (i.e. pH adjustment treatment), fine-tuning temperature (i.e. temperature adjustment treatment) and filtration to remove impurities, to obtain high temperature pretreatment Treat brackish water, where:

[0119] In the process of pretreatment to remove free chlorine, adjust the free chlorine content in the light brine to be zero, and the known dechlorination methods in the art are applicable to the present invention;

[0120] In the process of adjusting the pH, adding alkali or hydrochloric acid to adjust the pH of the light brine to 4-7, the existing methods for adjusting the pH of the solution known in the art are applicable to the present invention;

[0121] In the process of adjusting the temperature, fine-tune the temperature of the light brine to 60-80°C to obtain a slightly l...

Embodiment 2

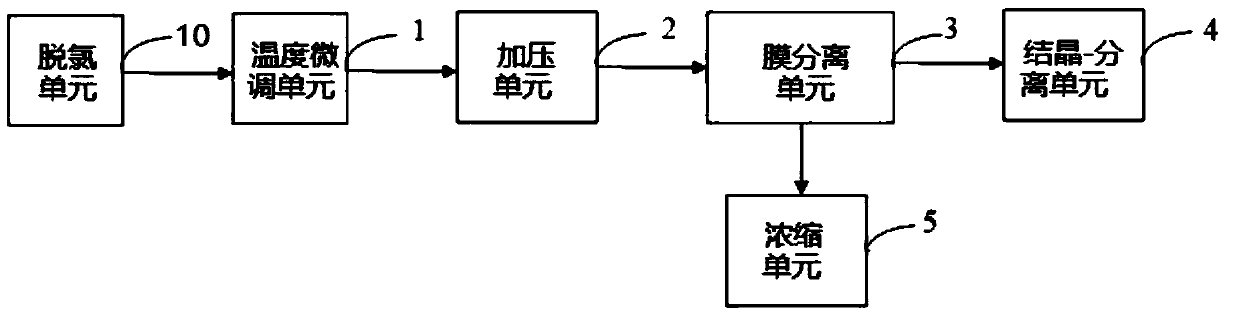

[0134] Such as figure 2 , 2A , ion membrane electrolysis light brine sulfate removal system, according to the process requirements of high-temperature membrane denitrification at least includes light brine dechlorination unit 10, light brine temperature fine-tuning unit 1, light brine pressurization unit 2, membrane separation unit 3, crystallization- Separation unit 4, MVR concentration unit 5 or dilute brine direct desalination unit.

[0135] Chlor-alkali industrial ionic membrane electrolysis light brine is input into the light brine pretreatment unit for free chlorine removal, pH adjustment, temperature fine-tuning treatment (that is, temperature adjustment treatment), and filtration and impurity removal treatment.

[0136] 1. Dechlorination treatment of light brine

[0137] The chlor-alkali industrial ion membrane electrolysis light brine is dechlorinated, free chlorine is removed (i.e. dechlorination treatment), pH is adjusted (i.e. pH adjustment treatment), temperatu...

Embodiment 2A

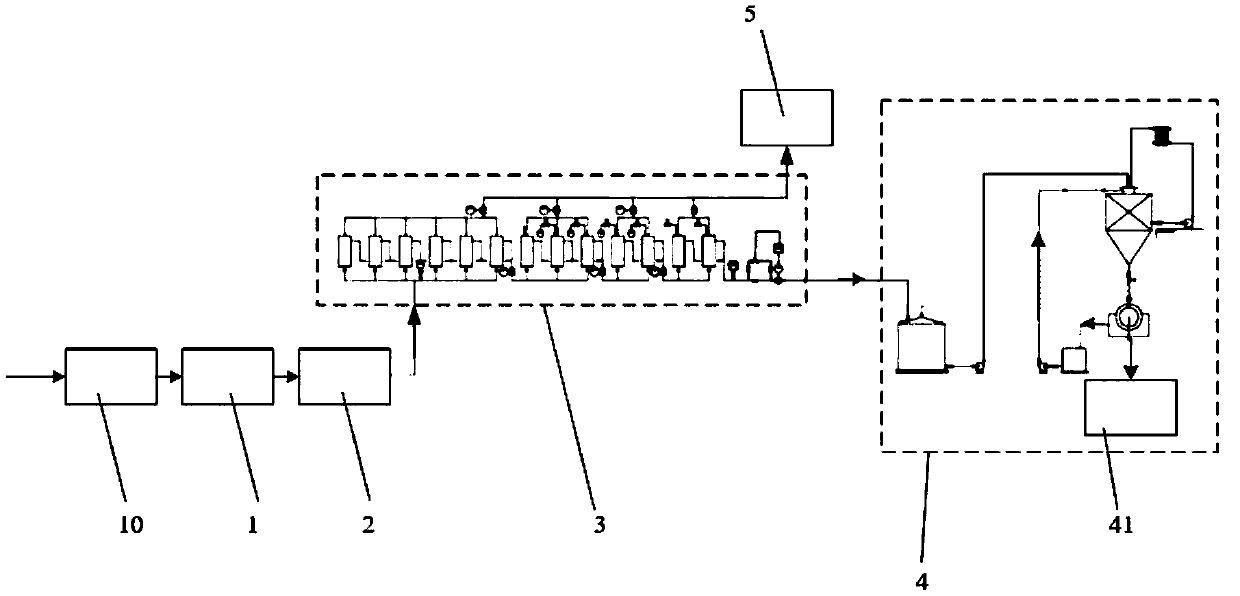

[0161] Such as image 3 The ionic membrane electrolysis light brine desulfation treatment system includes a dechlorination purification unit 10, a pressurization unit 2, and a membrane separation unit 3 connected in sequence through pipelines; and a crystallization-separation unit 4 connected to the outlet of the concentrated solution of the membrane filtration unit , the concentrating unit 5 connected to the fresh water outlet of the membrane filtration unit, except that the temperature fine-tuning unit is not included, the rest are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com