Continuous arsenic removal catalyst for industrial tail gas purification and preparation method thereof

A technology for industrial exhaust gas and catalyst, which is used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high toxicity of metal ions, limited life of purifiers, and many types of oxidants, so as not to produce secondary The effect of pollution, good control of process conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

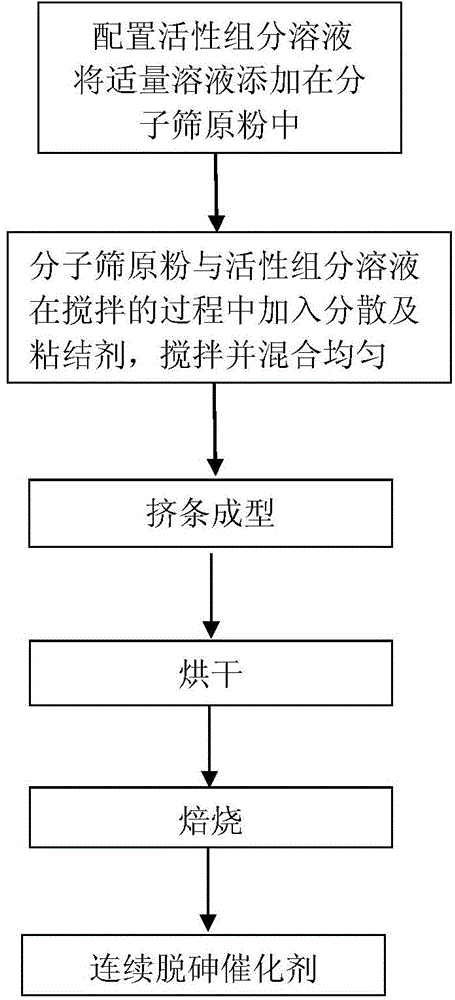

[0044] Embodiments specifically adopt the following preparation process conditions to realize the preparation of the above-mentioned continuous arsenic removal catalyst:

[0045] a) The catalyst carrier is prepared by 13X molecular sieve raw powder, its bulk specific gravity is 0.38g / ml, the pore distribution is mainly 0.8-1.5nm, CO 2 The adsorption capacity is 22.5ml / g.

[0046] b) Proportion ratio of catalyst active components: calculated according to the ratio of aqueous solution, Cu 2+ The concentration is 0.3M, 1Kg molecular sieve raw powder needs to add 0.5L Cu(NO3) 2 Solution, add the solution while stirring during the addition process.

[0047] c) In order to increase the dispersion and molding strength of the copper salt during the preparation of the catalyst, high-dispersion aluminum sol needs to be added, and about 0.2L of aluminum sol needs to be added to 1Kg of molecular sieve raw powder.

[0048] d) Forming of the catalyst: Extrusion forming is carried out aft...

Embodiment 1

[0051] Take by weighing 36.24g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) it is uniformly dissolved, and prepared as 500ml aqueous solution, in order to prevent the hydrolysis of copper nitrate, add 5 drops of nitric acid. Weigh 1Kg of 13X molecular sieve raw powder, mix the prepared solution with the raw powder, add 0.2L of highly dispersed aluminum sol to help molecular sieve forming, and stir evenly. Extrude the material into strands using an extruder. After drying the strips in the shade, put them into an oven and bake them at 120°C for 3 hours, then transfer them to a roasting furnace and bake them at 250°C for 2 hours, and finally get the finished arsenic removal catalyst.

[0052] This catalyst was packed in a fixed bed reactor. The reactor temperature is set at 220°C; the space velocity is set at 10000h -1 ; The reaction pressure is normal pressure. The yellow phosphorus tail gas is prepared by simulating the yellow phosphorus tail gas components in the laboratory, and...

Embodiment 2

[0054] Weigh 51.15g copper chloride (CuCl 2 2H 2 (2), it is uniformly dissolved, and it is prepared as 1L aqueous solution; the 13X molecular sieve former powder of 2Kg is weighed, and the solution is stirred evenly with it, and 0.4L of highly dispersible aluminum sol solution is added during the stirring process, and the stirring is continued until uniform. Extrusion molding is carried out on the extruder. After drying in the shade, it was baked at 120°C for 3 hours, and then fired in a baking furnace at 250°C for 2 hours to obtain a finished arsenic removal catalyst.

[0055] The prepared catalyst was packed in a fixed bed reactor. The reactor temperature is set at 200°C; the space velocity is set at 5000h -1 ; The reactor pressure is at normal pressure. Simulation preparation of calcium carbide tail gas, in which the arsenic content before purification is 750mg / m 3 . After passing through the fixed bed reactor for purification, the arsenic content in the outlet gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Effective aperture | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com