Patents

Literature

59results about How to "No need to regenerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A recapitalization generating oil hydrogenation catalysts and its preparing method

ActiveCN101157031ANo need to regenerateReduce lossesHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

The invention discloses reformate hydrogenation catalyst and the production method thereof. The invention is characterized in that the catalyst consists of a main active component, auxiliary agent, and carriers, the structural formula is Pd-Ma (Mb) / carriers; the main active component is a double noble metal component Pd, and the content is 0.01 to 0.5 wt percent; Ma is one of Au, Ag, Pt, Rh, and Ir, and the content is 0.01 to 0.5 wt percent; Mb is one of Sn, Pb, Sb, and Bi, and the content is 0.2 to 1.0 wt percent; the rest are carriers; inorganic acid or organic acid is taken as competitive adsorption auxiliary agent to achieve that the active component presents the distribution of an eggshell-shaped shallow layer, the active metal and the auxiliary agent are loaded by a distribution impregnation method or a co-impregnation method, and then the hydrogenation catalyst is produced through drying and roasting.

Owner:CHINA NAT OFFSHORE OIL CORP +1

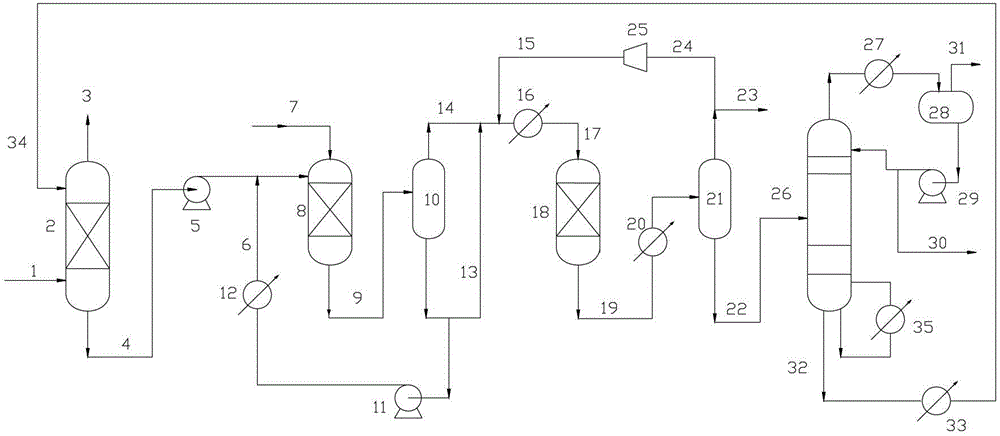

Method for removing olefins from reformate through liquid phase circulation selective hydrogenation

ActiveCN102911721AGood dispersionImprove hydrogenation activityTreatment with hydrotreatment processesReaction temperatureHydrogenation process

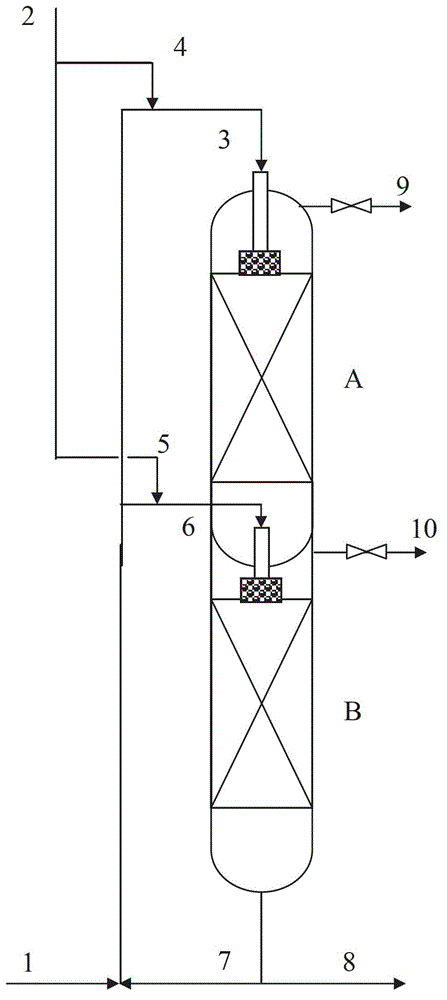

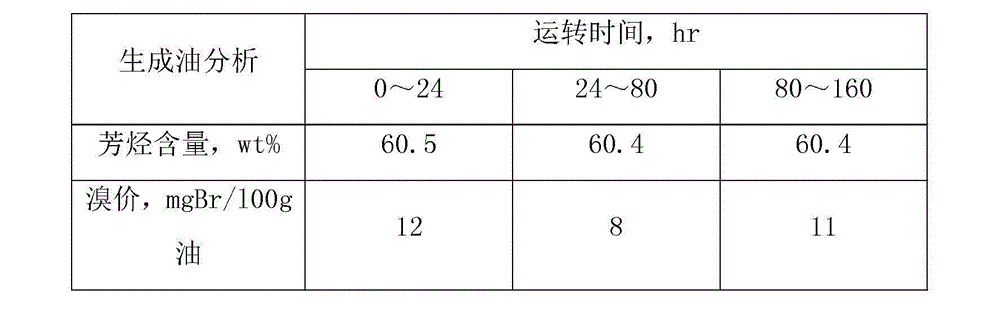

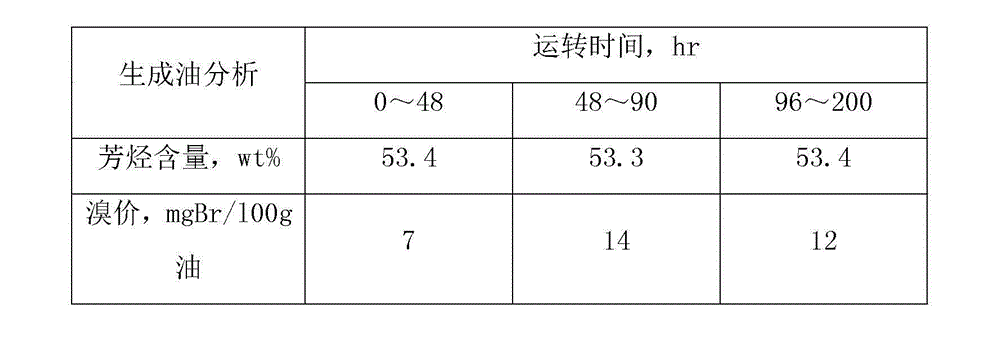

The invention relates to a method for removing olefins from reformate through liquid phase circulation selective hydrogenation. The method is characterized in that performing hydrogen saturation in a pipeline to form a raw material / hydrogenation product / hydrogen liquid phase mixture, and adding the liquid phase mixture to a multistage conventional hydrogenation reactor in sections under the hydrogenation condition; and entering a catalyst bed area in sections for reaction, wherein part of reaction products discharged from the bottom of the reactor circulate and are mixed with fresh raw materials, and part of reaction products discharged from the reaction system enter a follow-up separating device, the ratio of the circulation volume and the raw materials in the circulating liquid hydrogenation products is 1: (1-5): 1 by volume, the hydrogenation process conditions include that the reaction temperature is 80-180 DEG C, the pressure is 1.5-2.0MPa, and the fresh feed volume space velocity is 2.0-4.0hr-1.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Continuous arsenic removal catalyst for industrial tail gas purification and preparation method thereof

ActiveCN104624223APhosphorus tolerance is goodSimple preparation processMolecular sieve catalystsDispersed particle separationMolecular sieveCopper salt

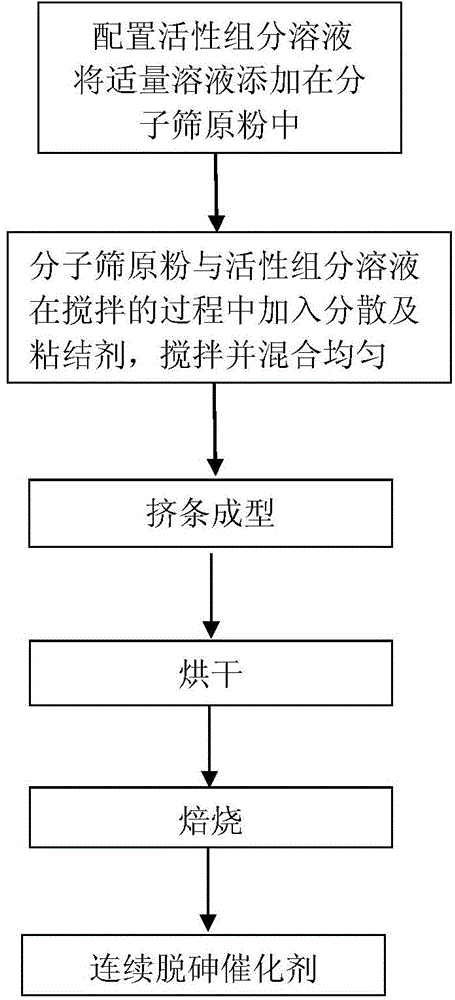

The invention discloses a continuous arsenic removal catalyst for industrial tail gas purification. The continuous arsenic removal catalyst is prepared by mixing a solution of an active component, raw powder of a molecular sieve and a binding dispersant and moulding by extruding, wherein the molecular sieve serves as a carrier, the active component is a cupric salt, the carrier is a molecular sieve of 13X-grade particles, the effective micropore size of the molecular sieve is 0.8-1.5nm, and the volume ratio of micropores is over 80%. The continuous arsenic removal catalyst is prepared as follows: weighing the raw powder of the molecular sieve, stirring, adding the solution of the active component, adding the binding dispersant after the material is wetted, mixing the materials uniformly, molding by extruding, drying and calcining. The continuous arsenic removal catalyst is used for removing hydrogen arsenide from tail gas of calcium carbide, tail gas of yellow phosphorus and other atmospheres. Hydrogen arsenide is subjected to hydration reaction after being subjected to catalytic oxidation, and then is discharged in the form of arsenic acid or arsenious acid. The active component of the continuous arsenic removal catalyst does not change obviously before and after catalytic oxidation, and the requirement that CO in tail gas serves as a product with high additional value can be met.

Owner:BEIJING PEKING UNIV PIONEER TECH

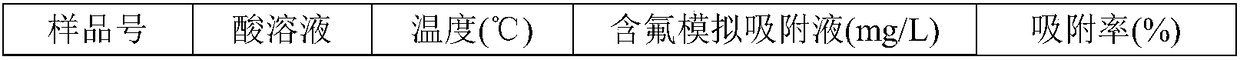

High performance agent for removing fluorin, preparation method, and application

InactiveCN101091903ARaise the pHGood defluoridation effectOther chemical processesWater/sewage treatment by sorptionBrickSorbent

The invention relates to a fluorine-removing agent with high efficiency and its preparation method and application. The invention includes the raw material agitation, the formation and the roasting which contains laterite, the aluminum salt, of which the weight dosage of the aluminum salt is 0-30% according to the gross weight of the raw material, the fluorine-removing agent can widely used in the profession of the fluorine sewage treatment, the high fluorine surface water purification. The invention is simple craft, and operation.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

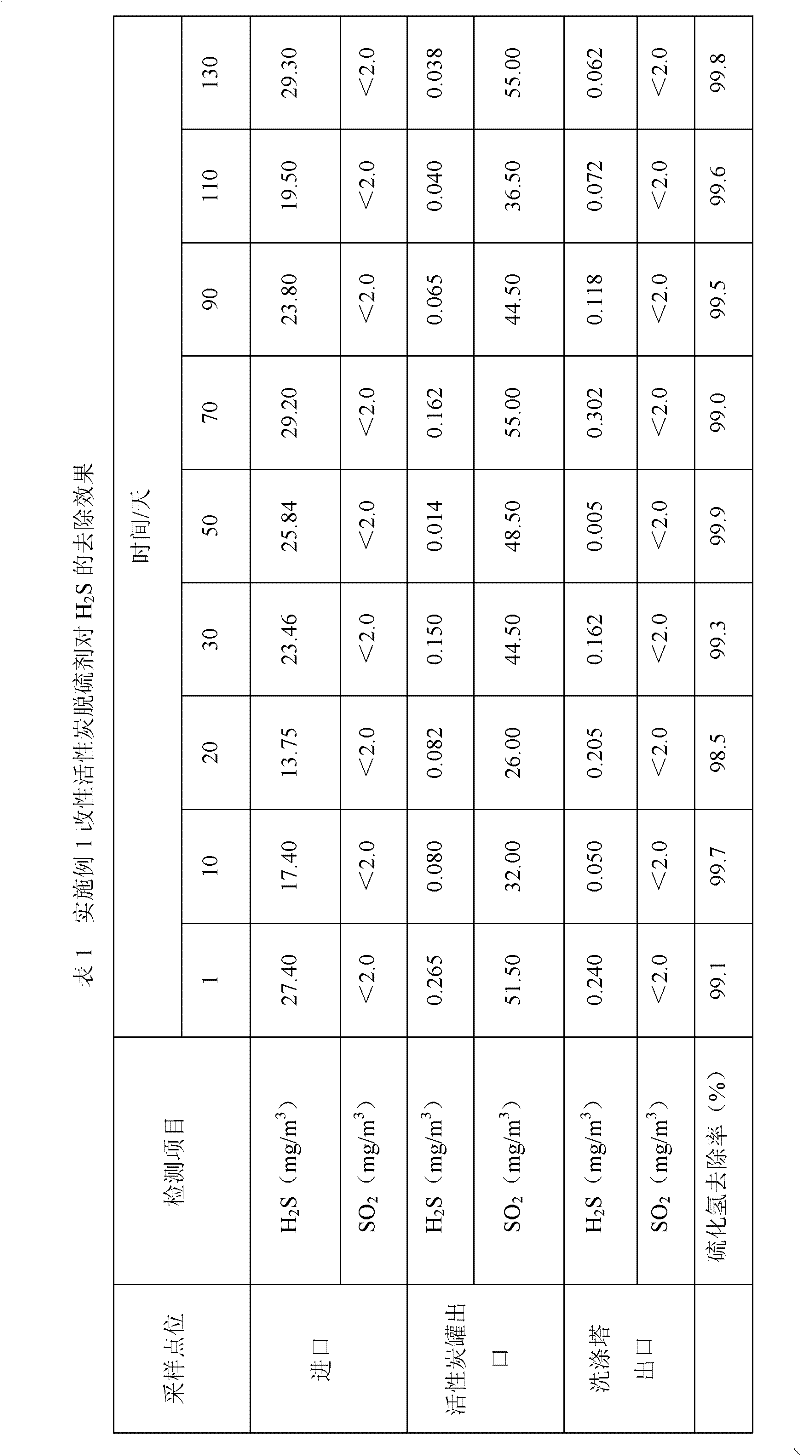

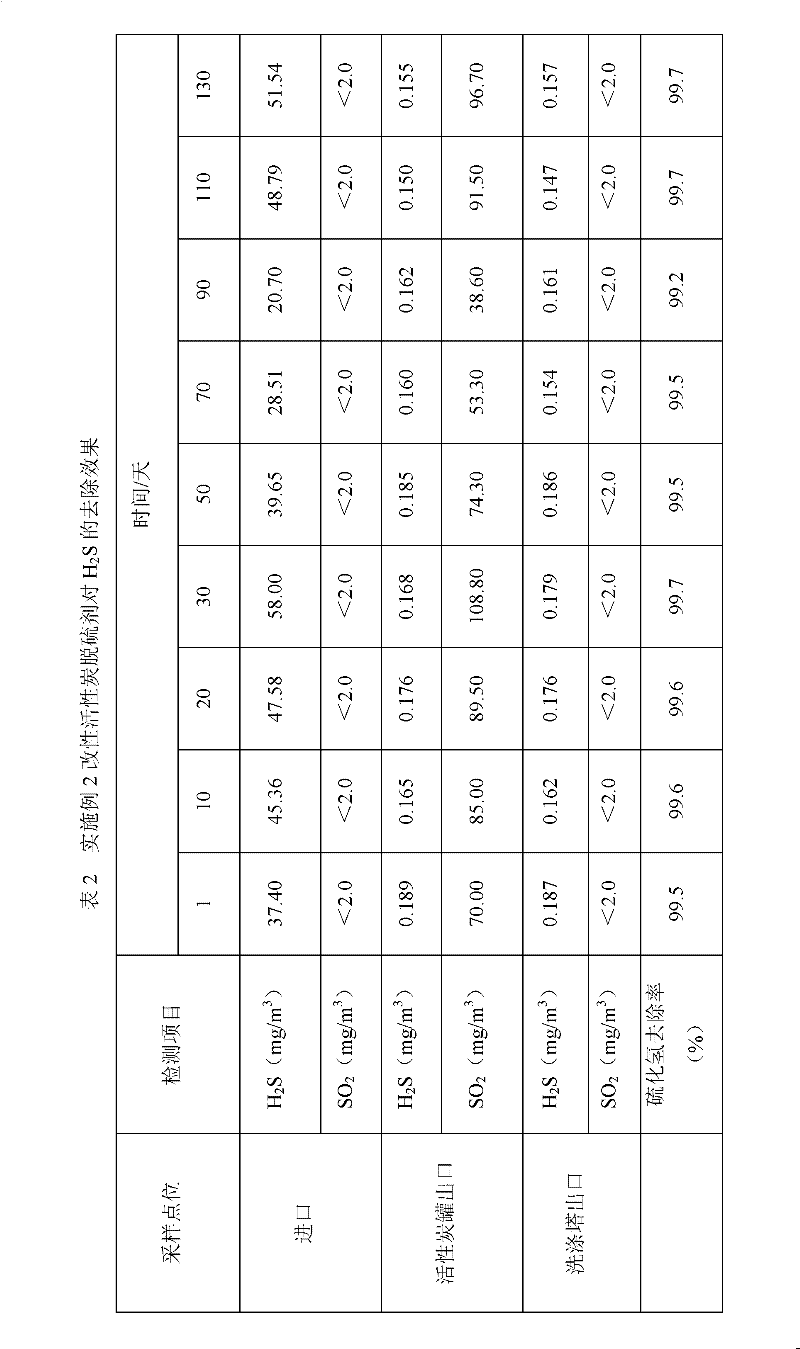

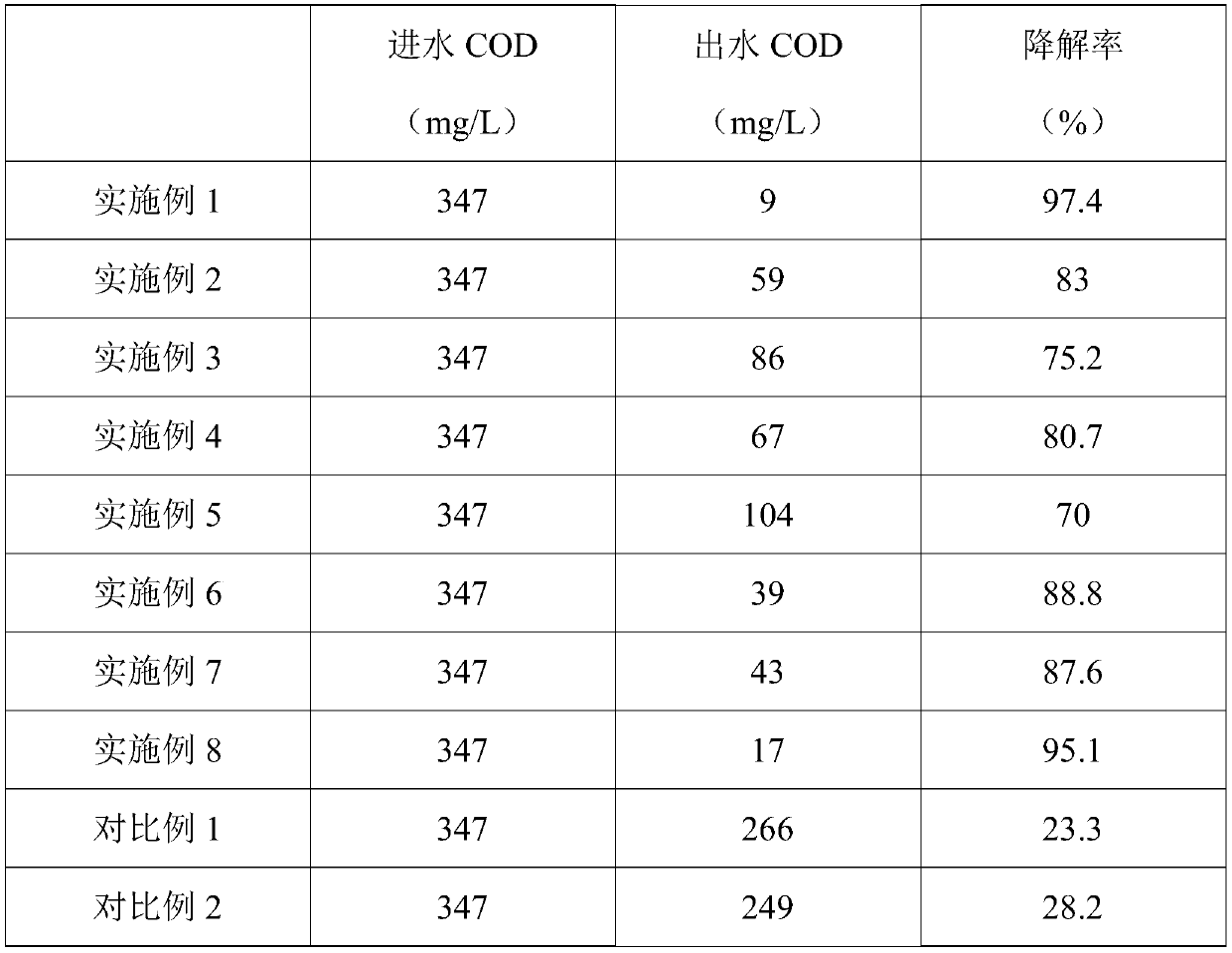

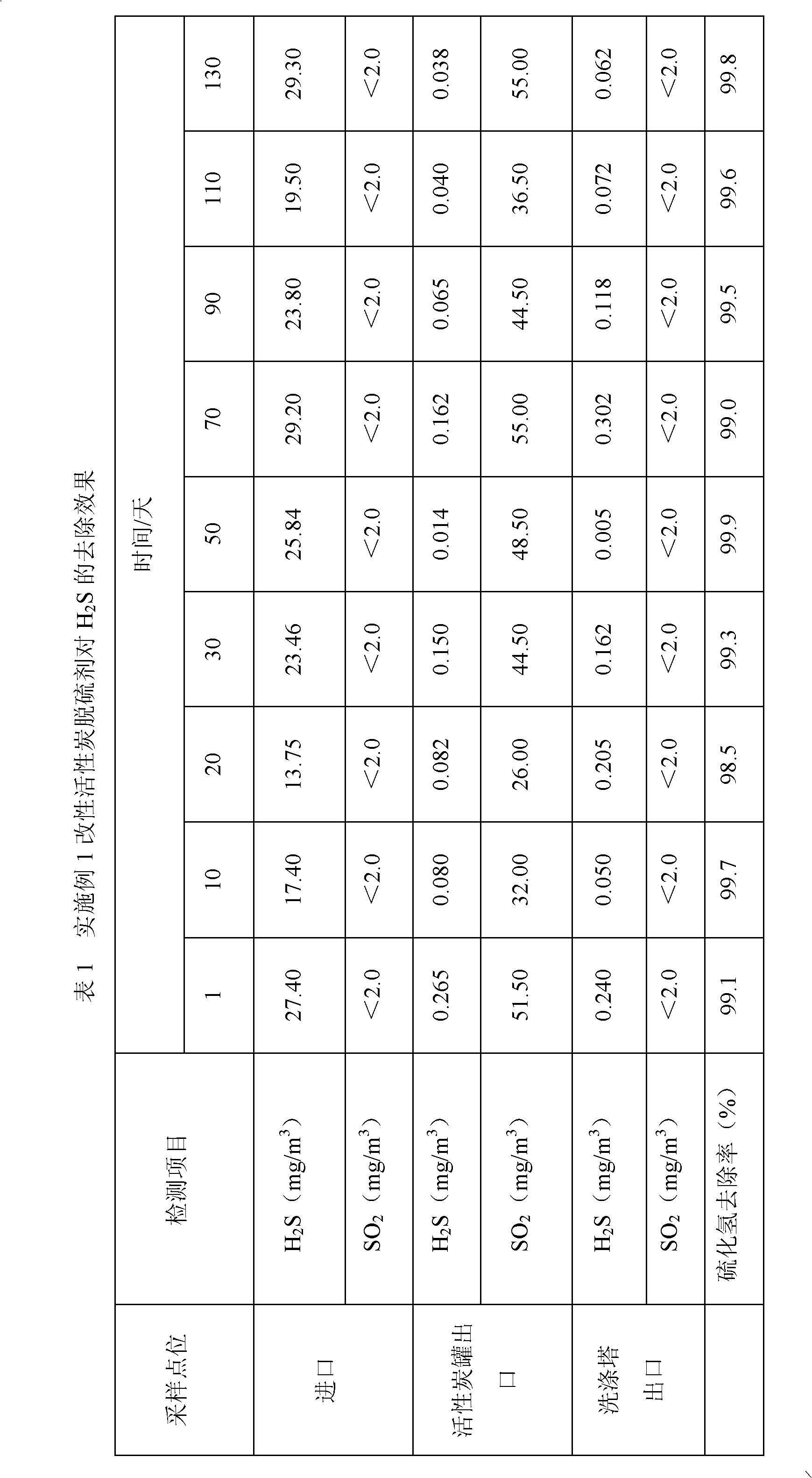

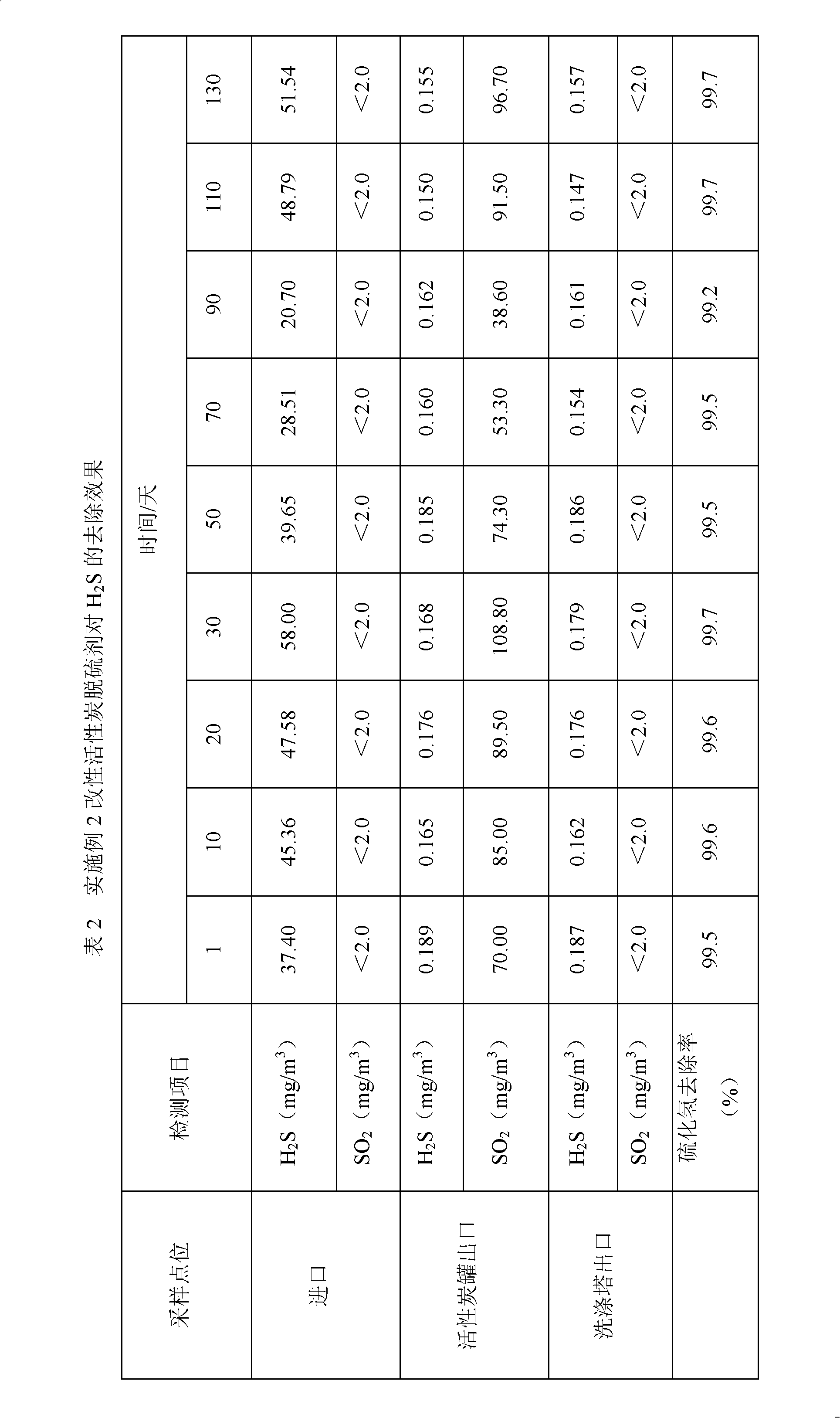

Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

InactiveCN102500323AEasy accessLow costPhysical/chemical process catalystsOther chemical processesActive agentCatalytic oxidation

The invention belongs to the technical field of waste gas desulfurization and purification, particularly provides a modified active carbon desulfurizer and a preparation method thereof, and a hydrogen sulfide waste gas treatment method using the desulfurizer. The modified active carbon desulfurizer is prepared from impregnating activated carbon with active agent mixed solution comprising phenol, acetone, sodium carbonate, ferric nitrate and organic solvent, and drying and roasting the mixture. The modified active carbon desulfurizer converts the hydrogen sulfide in the waste gas into sulfur dioxide at atmospheric temperature and pressure under the absorption and catalytic oxidation action, and the sulfur dioxide is converted into SO42- in water phase by washing and removed. The waste gas treatment method uses the modified active carbon desulfurizer, and prevents the defects that the desulfurizer needs to be regularly desorbed and regenerated due to blockage caused by adsorption saturation and generated elemental sulfur. Compared with an ordinary activated carbon desulfurization process, the process has the advantages of high hydrogen sulfide removal rate, long service life of the desulfurizer, low operation cost, simplicity in operation and management and the like.

Owner:北京天灏柯润环境科技有限公司

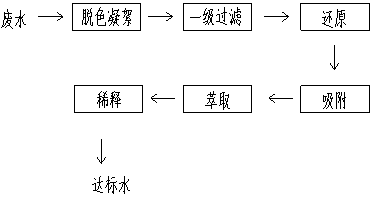

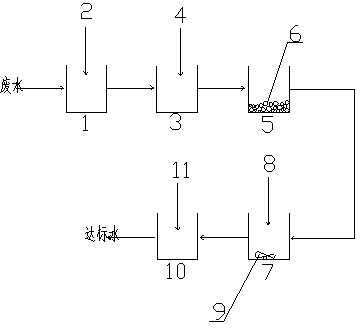

Printing and dyeing wastewater treatment process

InactiveCN104071920ARapid responseHigh decolorization rateMultistage water/sewage treatmentFiltrationDyeing wastewater

The invention discloses a printing and dyeing wastewater treatment process which comprises the following steps: adding a filter aid into wastewater, flocculating the wastewater, filtering to remove suspended matters from the wastewater, and reserving small suspended matters with colors and dissolved matters; adding a reducing decolorizer into the wastewater subjected to primary filtration for treating dyeing wastewater of direct dyes, so that dye molecules in the wastewater form a reductive degradation product; enabling the wastewater containing the reductive degradation product to pass through an adsorption material for adsorbing the reductive degradation product or other materials in the wastewater to the solid surface due to the adsorption effect; pouring a non-water-soluble organic solvent into the wastewater subjected to adsorption, and vibrating the solvent and the wastewater together, wherein the water phase is colorless when two phases are separated, and the dyes are accumulated on the upper-layer organic phase; and pouring a certain quantity of clean water into the wastewater subjected to extraction for diluting the wastewater. The process has the advantages that the pH value of the wastewater does not need to be adjusted, the effect is good, and the cost is low.

Owner:HUBEI CHUANDONG ENVIRONMENTAL ENERGY DEV CO LTD

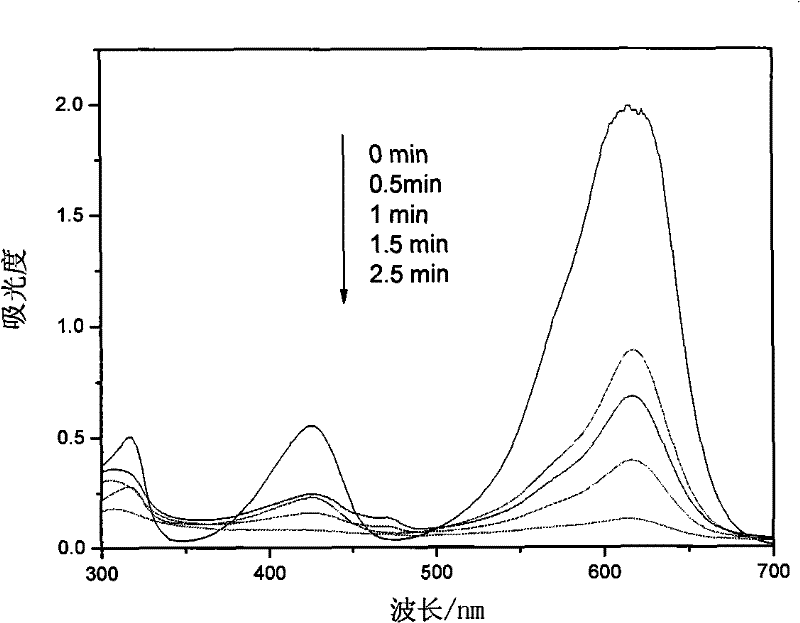

Active carbon fiber-loaded NaBiO3-based composite oxide and preparation method thereof, and method for degrading organic dye waste water by using composite oxide

InactiveCN103623805ASimple equipment requirementsSimple requirementsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsEpoxyFiber

The invention discloses an active carbon fiber-loaded NaBiO3-based composite oxide and a preparation method thereof and a method for degrading organic dye waste water by using the composite oxide. The preparation method comprises the following steps: successively cleaning an active carbon fiber with ammonia water, nitric acid, acetone and deionized water and drying the active carbon fiber for subsequent usage; synthesizing BSO from NaBiO3 and AgNO3 in a liquid phase and preparing a composite function material according to a mass ratio of BSO to NaBiO3 of 1: 1-3; and placing an epoxy resin and the composite function material according to a weight ratio of 1.5-2.5: 1 into a container containing acetone, carrying out high speed stirring, dipping the active carbon fiber 5 to 10 times of the mass of the composite oxide function material into an acetone solution for 2 h and successively subjecting the active carbon fiber to vacuum drying and then to heat treatment under the protection of N2 so as to obtain the composite oxide. The degradation method comprises the following steps: adding 2 to 5 g / L of the composite oxide into the organic dye waste water under irradiation by visible light; carrying out stirring at room temperature and normal pressure; and discharging waste water through centrifugation after basic decolouring of the waste water. The degradation method provided by the invention has the advantages of simple requirements on equipment, low energy consumption, convenient operation and capacity of achieving the purposes of decolouring, degradation and mineralization of the dye waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

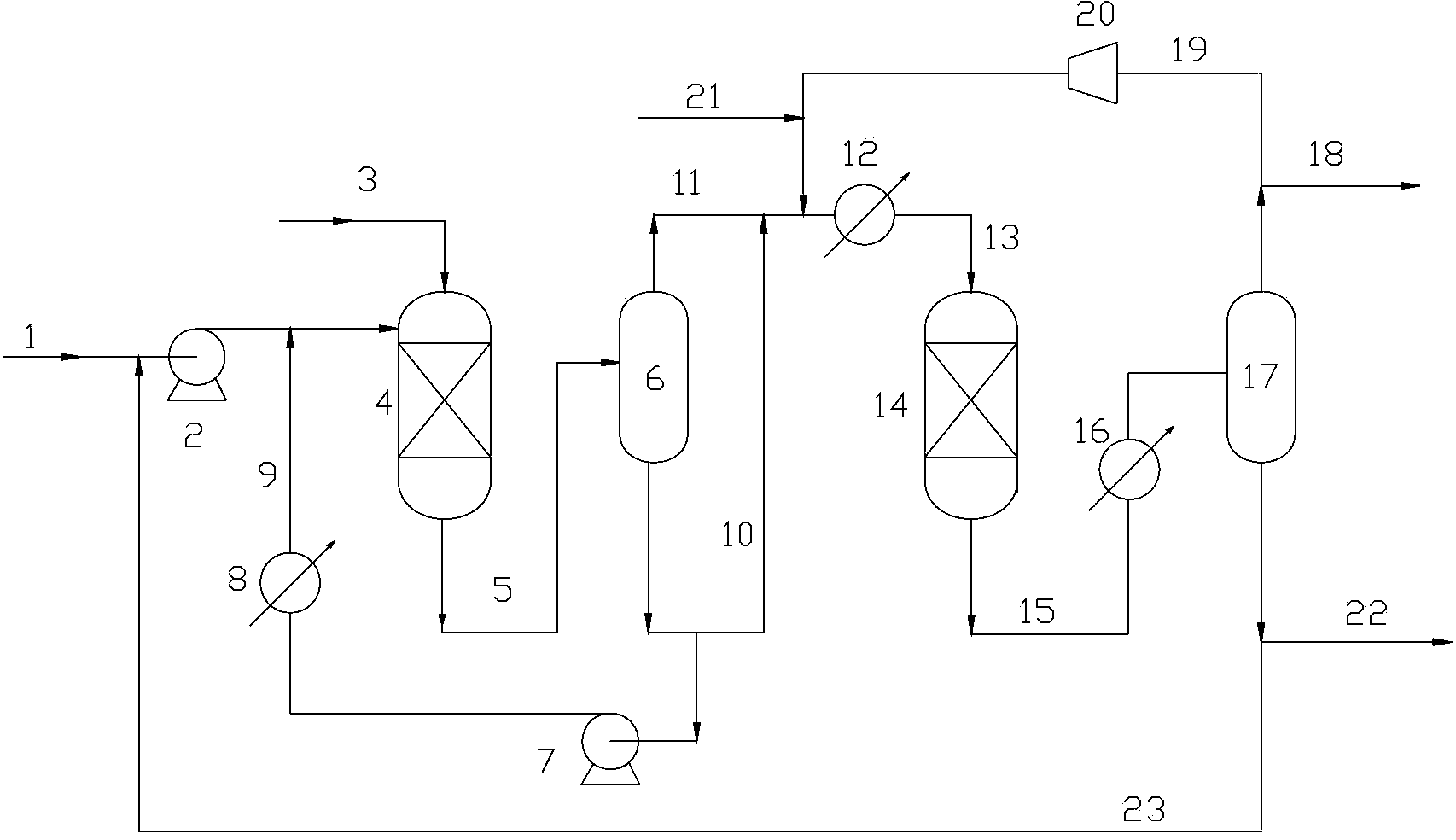

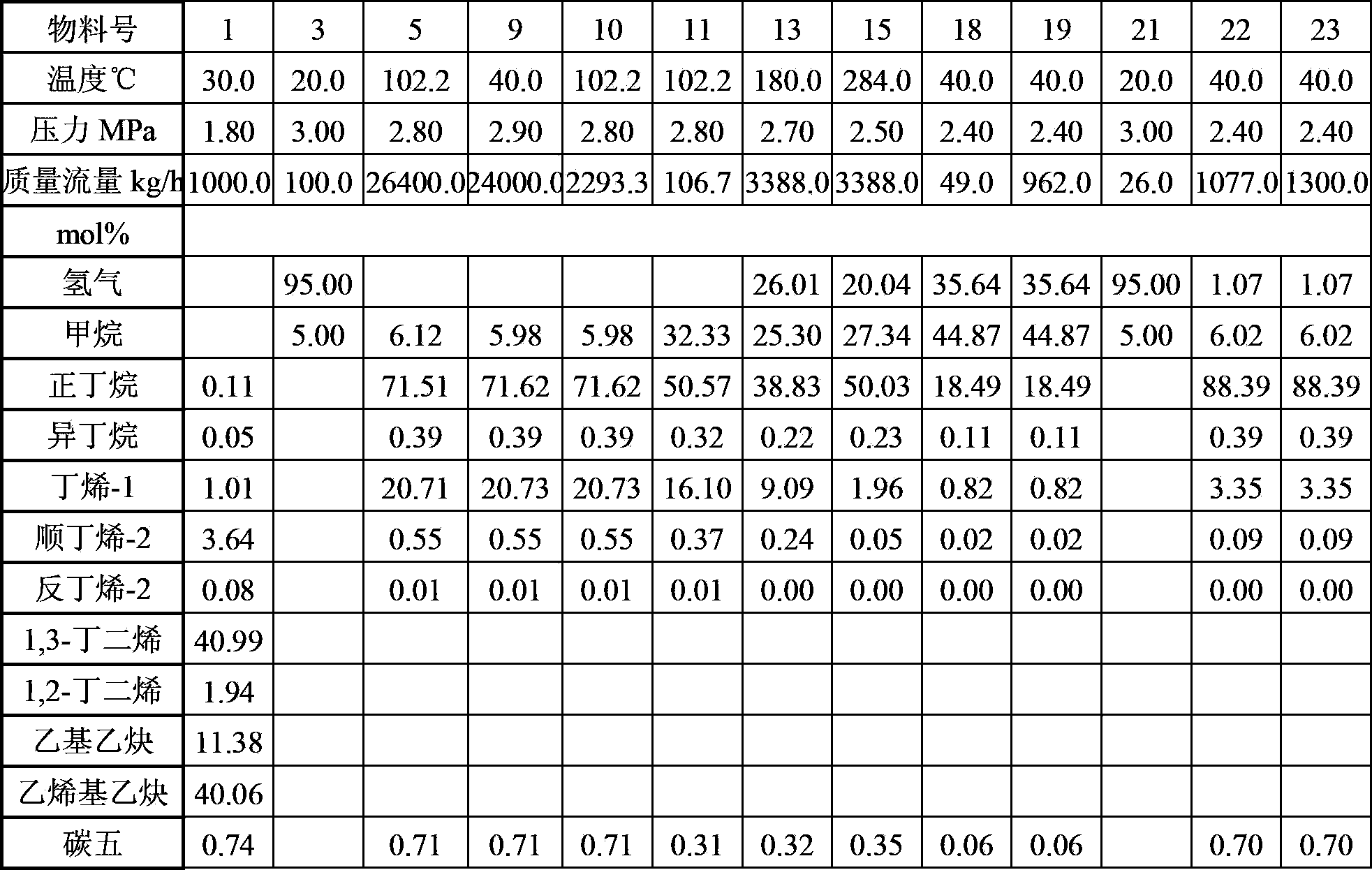

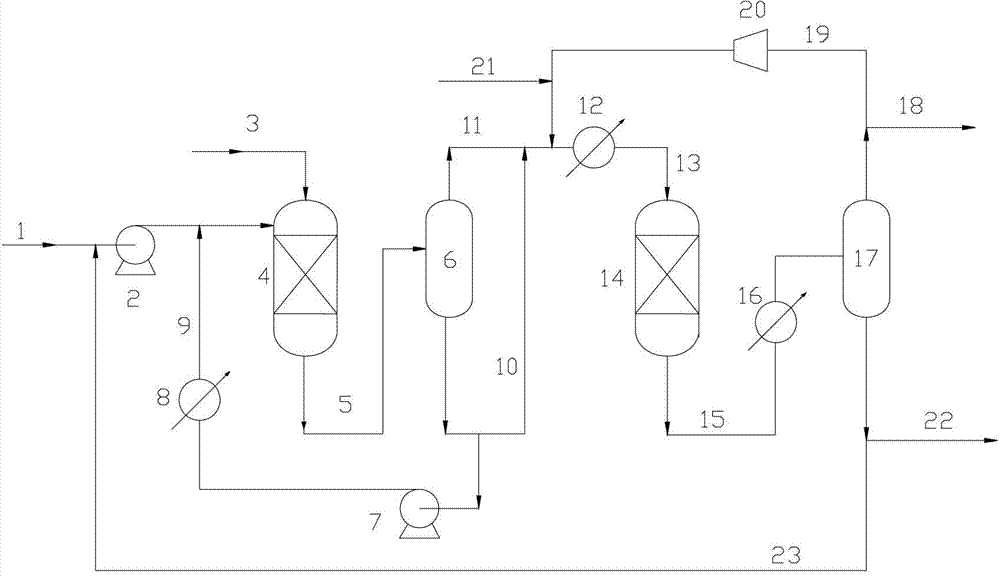

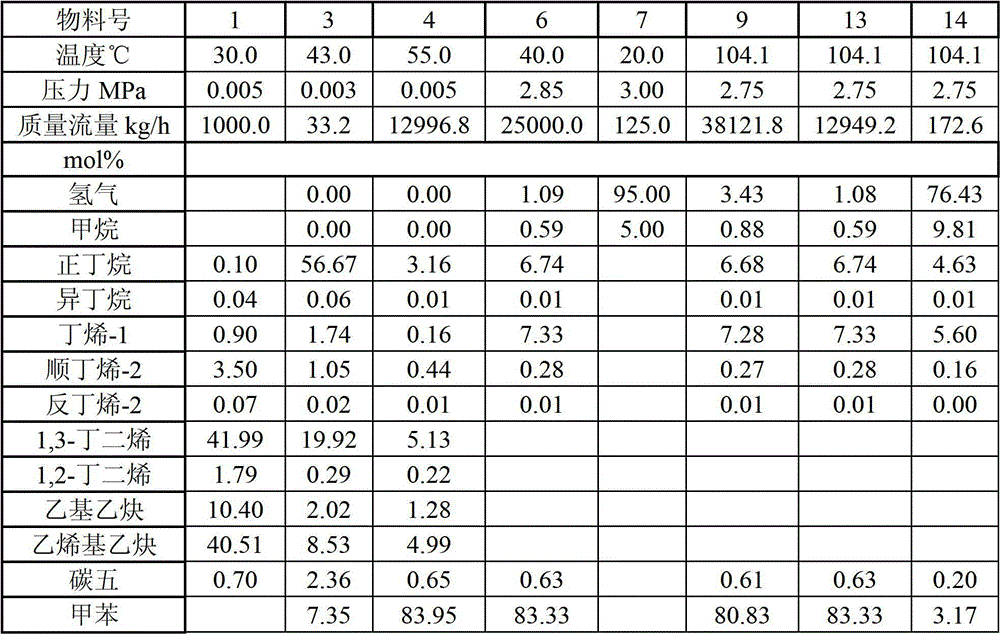

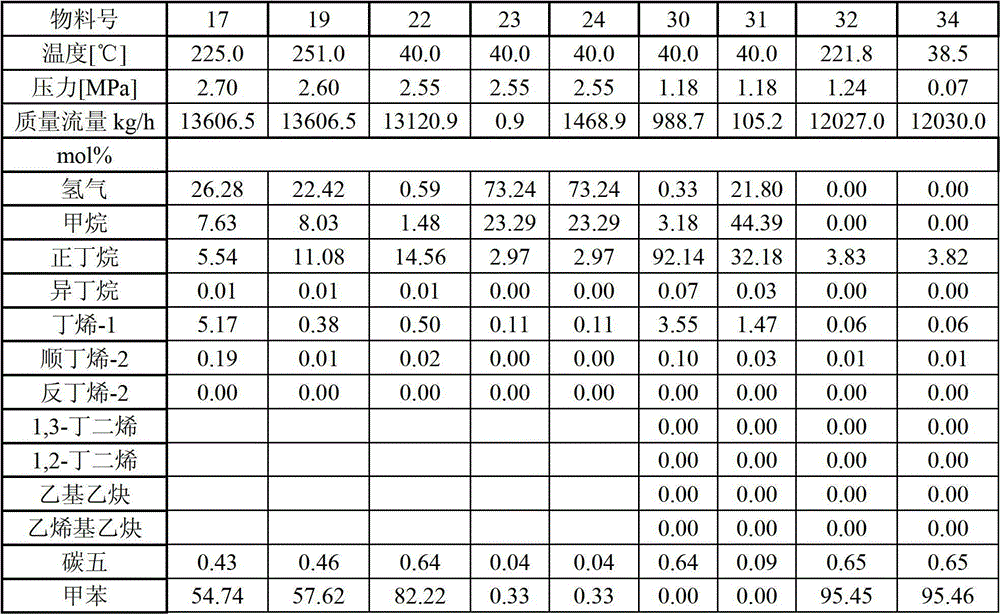

Butadiene tail gas hydrogenation device and method

ActiveCN103787813AExtended service lifeReduce olefin contentHydrocarbon by hydrogenationButadiene DioxideGas phase

The invention provides a method for hydrogenation of alkyne-rich tail gas of a butadiene extraction device. The alkyne-rich tail gas of a butadiene extraction device undergoes a liquid-phase hydrogenation reaction in the presence of an Ni-based catalyst using a titanium oxide-alumina compound as a carrier and undergoes a gas-phase hydrogenation reaction in the presence of an Ni-MO-based catalyst so that all alkynes and dialkenes in the raw material are subjected to hydrogenation conversion and most olefins are hydrogenated to form alkanes. The method realizes continuous and stable operation of the device and obviously reduces olefin content of the hydrogenation products to less than 5% so that requirements on cracking of the raw material of an ethylene production device are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

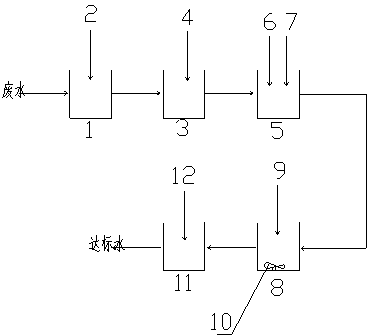

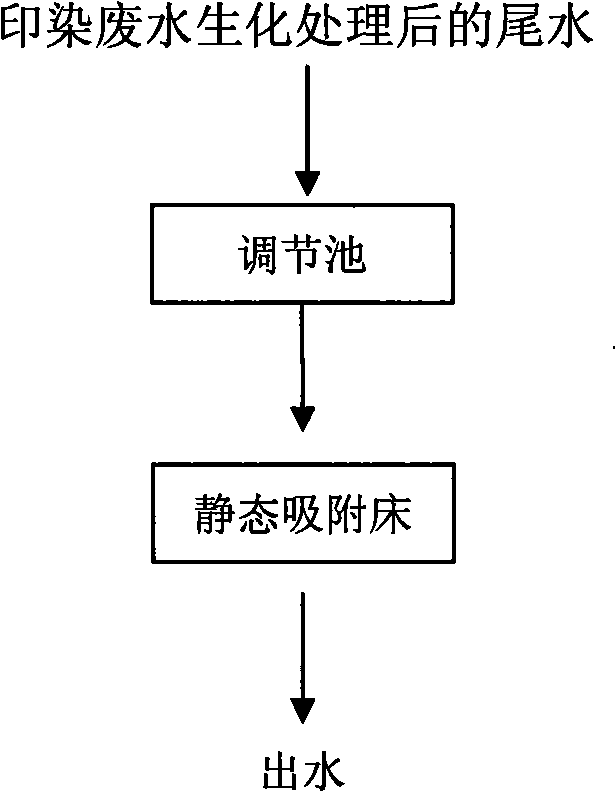

Advanced treatment method for printing and dyeing wastewater

InactiveCN101402505ALow running costNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by sorptionReclaimed waterSmall footprint

The invention discloses a method which aims at the deep treatment of dyeing wastewater and has the advantages of simple operation, low cost and no secondary pollution. The method comprises the following steps: based on the biochemical-physical and chemical treatment of the dyeing wastewater, tail water obtained after treatment is lifted by a pump and enters a static adsorption bed for filling fine coal particles, the stay time is controlled to between 2 and 4 hours, difficultly degraded organic matters in the tail water are removed by adsorption, and the discharged water meets the discharge standards and is discharged or reutilized. The method has the advantages of unnecessary addition of other chemical agents, low operational cost and no secondary pollution; the stay time is short with no more than 4 hours, and the reactor occupies small areas; the pH value of the tail water does not need to be adjusted, and the tail water after treatment can be reutilized as reclaimed water; and saturated adsorbing materials are unnecessarily regenerated, and can be continuously used as fuel.

Owner:NANJING UNIV

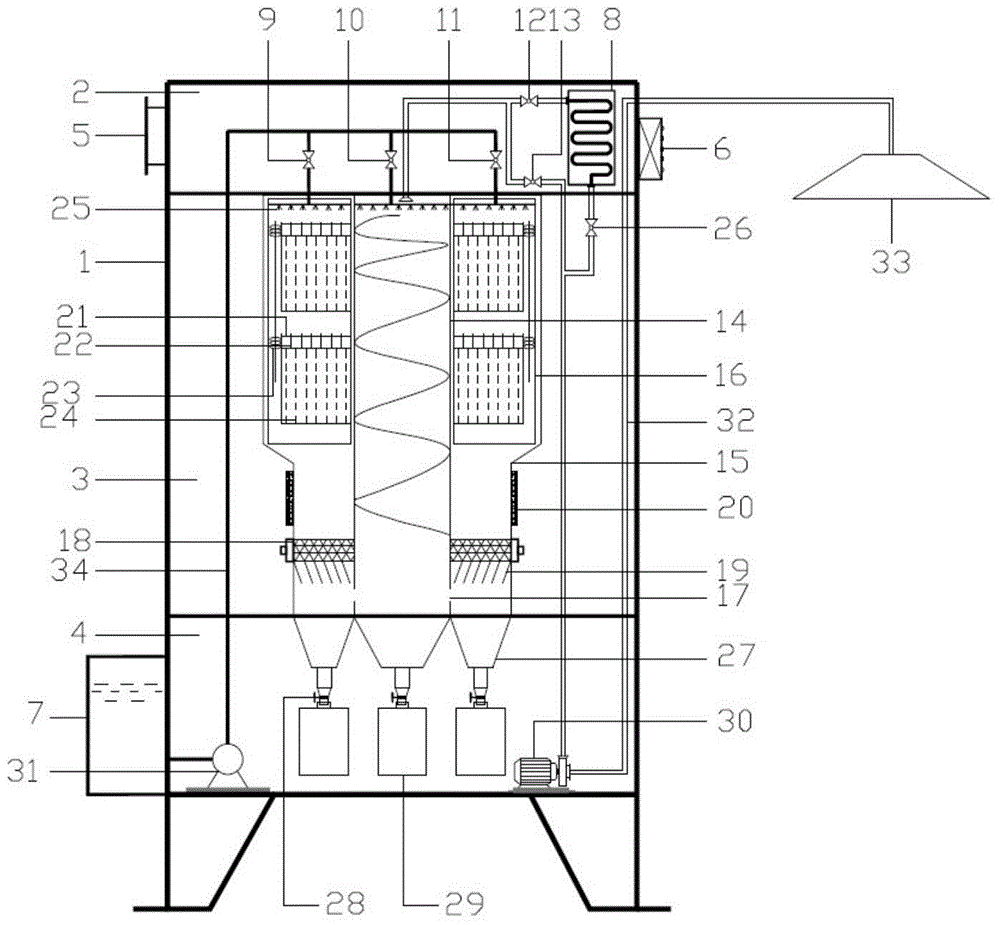

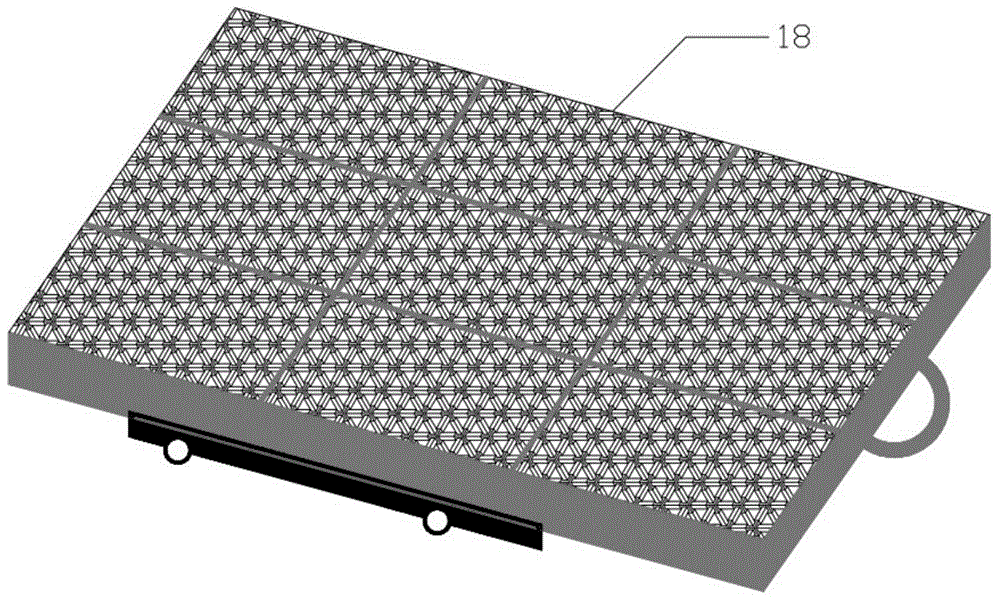

Integrated compound fume purification system

InactiveCN103949126ASmall footprintImprove purification efficiencyCombination devicesDomestic stoves or rangesElectrostatic precipitatorAir heater

The invention relates to an air purification system, and concretely relates to an integrated compound fume purification system. The system comprises a box body, and a clean air chamber, a fume purification chamber and a waste oil collecting chamber which are individual spaces obtained through the separation of separators, wherein the upper portion of the outer wall of the box body is provided with an exhaust port and a power supply controller, and the bottom of the box body is provided with a washing liquid storage tank; the clean air chamber, the fume purification chamber and the waste oil collecting chamber are connected in sequence from top to bottom; an air heater and solenoid valves with different uses are arranged in the clean air chamber; a solenoid valve II, a water distributor, and a cyclone separation chamber, a filtering chamber and an electrostatic purification chamber which are mutually connected through a flange are arranged in the fume purification chamber; and an oil collecting hopper, an oil discharging valve, an oil collecting barrel, a fan and a water pump are arranged in the waste oil collection chamber. The system adopting a 'cyclone separation + adsorption filtration + electrostatic dust removal' integrated compound design mode overcomes the defects of traditional purification methods, and has the advantages of small occupied area, safety, high efficiency, stable operation, low noise and convenient maintenance and management.

Owner:安徽锋亚环境技术有限公司

Processing method of explosive wastewater

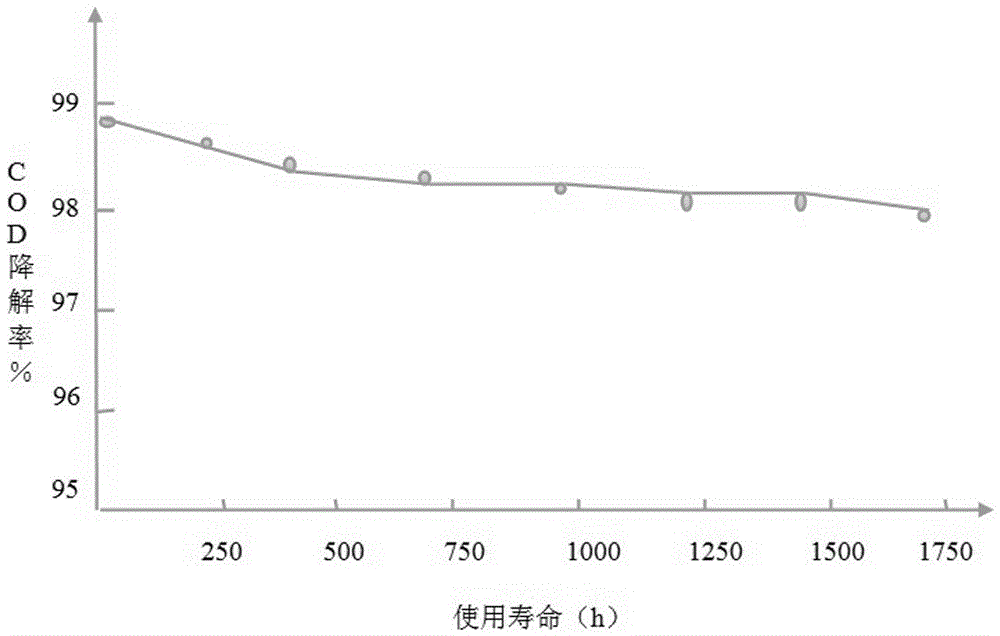

ActiveCN105936561AEnergy savingChemically stableWater/sewage treatment by irradiationWater treatment compoundsChemistryTitanium dioxide

The invention provides a processing method of explosive wastewater. The processing method comprises the following steps: (1) adjusting the pH value of explosive wastewater to 1-4 by acid, adding 0.05 to 0.5 M of persulfate, wherein persulfate accounts for 1 to 10 wt% of explosive wastewater, and evenly mixing; (2) placing an UV lamp in the explosive wastewater or on the surface of explosive wastewater, adding a copper-cerium modified titanium dioxide catalyst accounting for 5 to 30 wt% of explosive wastewater, carrying out aeration at the same time, and carrying out reactions for 2 to 12 hours; wherein the copper-cerium modified titanium dioxide catalyst is prepared by doping titanium dioxide by copper and cerium, and copper and cerium respectively account for 5 to 10 wt% and 10 to 20 wt% of titanium dioxide. The processing technology is simple, the cost is low, the maintenance is convenient, and the explosive wastewater can be recycled only through one step. Moreover, persulfate is taken as the oxidant, no secondary pollution or solid waste is generated; the service life of catalyst is long, and the catalyst can be continuously used and does not need regeneration.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST +1

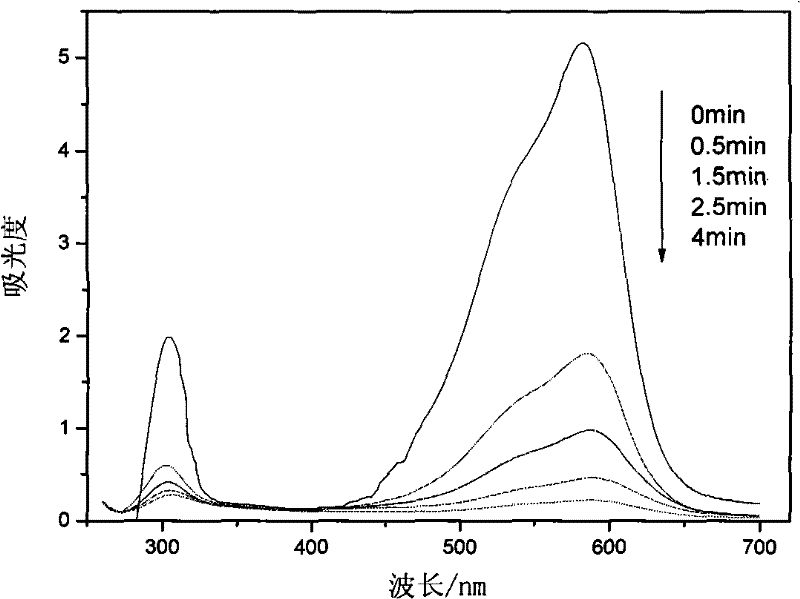

Sodium bismuthate/epoxy resin/glass fiber composite material, preparation method thereof, and application method for composite material in degradation of organic waste water

ActiveCN103623868AImprove stress shock resistancePromote absorptionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyUltrasonic dispersion

The invention discloses a sodium bismuthate / epoxy resin / glass fiber composite material, a preparation method thereof and an application method for the composite material in degradation of organic waste water. The preparation method comprises the following steps: soaking sodium bismuthate powder in an aqueous solution of a silane coupling agent for treatment, then taking out the sodium bismuthate powder and drying the sodium bismuthate powder for subsequent usage; adding methyl tetrahydrophthalic anhydride into an epoxy resin and carrying out uniform mixing so as to obtain an epoxy resin glue solution; and mixing the treated sodium bismuthate with the epoxy resin glue solution, carrying out ultrasonic dispersion, coating an obtained mixture on glass fiber cloth, folding the glass fiber cloth three to five times in a die, carrying out curing, cooling and demolding and cutting the glass fiber cloth to a certain shape and a certain size. The application method comprises the following steps: uniformly putting the composite material with an appropriate shape and an appropriate size between jacket layers of a glass tube reactor and installing a visible light lamp at the center of an inner tube; allowing organic waste water to enter into a glass jacket, pass through the composite material and undergo a visible light catalytic degradation reaction with sodium bismuthate under irradiation by visible light. The preparation method has the advantages of low requirements on equipment, simple procedures, low energy consumption and convenience in operation; and the composite material is capable of degrading organic waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Method used for treating highly concentrated ammonia-nitrogen in rare earth waste water

InactiveCN104907047ANothing producedWill not cause secondary pollutionOther chemical processesAlkali metal oxides/hydroxidesMass ratioRare earth

The invention relates to a method used for treating highly concentrated ammonia-nitrogen in rare earth waste water, and belongs to the field of highly concentrated ammonia-nitrogen treatment. According to the method, a sticky solution is prepared from a prepared organic composite denitrfying agent modified magnesium aluminum iron hydrotalcite magnetic nano adsorption material and an adhesion agent at a mass ratio of 7:1; the surfaces of adsorption rods are coated with the sticky solution, and the adsorption rods are dried under ventilation states and are delivered into an adsorption tower; a rare earth waste water penetrating fluid is delivered through the adsorption tower so as to adsorb 8000 to 12000mg / L highly concentrated ammonia-nitrogen in the rare earth waste water, wherein aging of adsorption material surface layers can be realized via adsorption saturation; under action of applied magnetic field and current scour, layer-by-layer falling of the adsorption material surface layers is realized, and at last the ammonia-nitrogen content of the rare earth waste water is detected. The method is capable of realizing adsorption material renewal; regeneration is not needed; the ammonia-nitrogen concentration of discharged waste water is controlled to be lower than 0.7mg / L; ammonia-nitrogen removing rate is higher than 99.99%; and no secondary pollution is caused to the environment.

Owner:CHANGZHOU UNIV

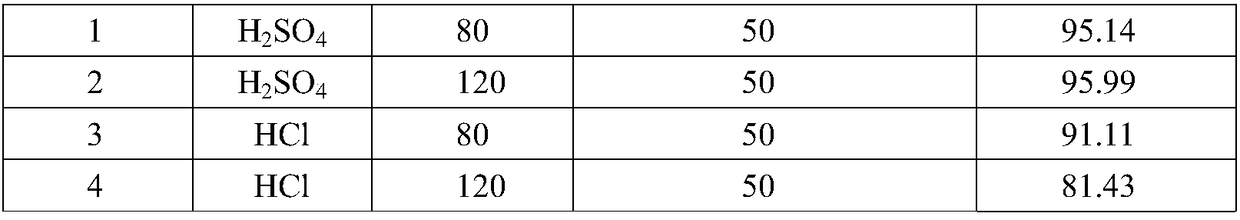

Method for preparing fly ash fluorine removal agent through two steps of hydrothermal reaction/acid leaching and application

ActiveCN108421526AReduce manufacturing costTo achieve the goal of "treating waste with waste"Other chemical processesAluminium silicatesSorbentWastewater

The invention relates to the field of preparation of fluorine removal agents, in particular to a method for preparing a fly ash fluorine removal agent through two steps of hydrothermal reaction / acid leaching and an application. According to the method for preparing the fly ash fluorine removal agent through two steps of hydrothermal reaction / acid leaching, fly ash and an alkaline solution are mixed and subjected to a hydrothermal reaction at the temperature of 35-200 DEG C for 0.5-6 h, washing and suction filtration are performed, and a filter cake is formed; the filter cake is soaked in an acid solution or subjected to magnetic stirring treatment for 5-10 min, and then, suction filtration is performed; the filter cake subjected to acid treatment is dried, and the fly ash fluorine removalagent is obtained. The fluorine removal agent is a novel adsorbent with great prospects, can be widely used in the industries of fluorine-containing wastewater treatment and high-fluorine surface water purification, can be put in a proper container for use and can be subjected to one-time batch-type treatment, that is, the fluorine removal agent is added to high-fluorine water and stirred to adsorb fluorine ions, and the purpose of fluorine removal is achieved. In a word, the fluorine removal agent has various application methods and can be selected and used according to actual conditions.

Owner:XILINGOL VOCATIONAL COLLEGE

Method used for treating high concentration ammonia nitrogen in metallurgical waste water

InactiveCN104909425AImplement updateNo need to regenerateOther chemical processesWater contaminantsHigh concentrationMagnetization

The invention discloses a method used for treating high concentration ammonia nitrogen in metallurgical waste water, and belongs to the field of metallurgical waste water treatment. According to the method, an organic composite denitrification agent modified magnesium aluminum iron hydrotalcite magnetic nano adsorptive material is prepared via magnetization, modification, drying, and activation, and then adsorption rods are prepared and are arranged in an adsorption tower to treat high concentration ammonia nitrogen in metallurgical waste water. In removing processes, high concentration ammonia nitrogen in waste water is absorbed, after saturation, aging of the surface layer of the adsorption material is realized, and updating of the adsorption material is realized under the action of an applied magnetic field and flow scour, and regeneration is not needed. After shedding, an obtained residue is waterless, and is small in volume; no ammonia gas is generated or released into the atmosphere; no precipitate is obtained; and no environmental secondary pollution is caused. Separation can be realized under the action of the applied magnetic field; ammonia nitrogen concentration is reduce to 0.45mg / L from 2000-6000mg / L; ammonia nitrogen removing ratio is higher than 99.99%; and the method can be used for treating waste water with high concentration ammonia nitrogen, and possesses a promising prospect.

Owner:CHANGZHOU UNIV

Method for treating highly concentrated ammonia nitrogen in petroleum refining wastewater

ActiveCN104925890AWill not cause secondary pollutionNo need to regenerateOther chemical processesWater/sewage treatment by sorptionHigh concentrationHydrotalcite

The invention discloses a method for treating highly concentrated ammonia nitrogen in petroleum refining wastewater and belongs to the field of environment-friendly ammonia nitrogen wastewater treatment. An organic composite denitrifier modified Mg-Al-Fe hydrotalcite magnetic nanometer adsorption material is obtained by steps of preparing, magnetizing, modifying, drying and activating Mg-Al-Fe hydrotalcite. The material is used for treating high-concentration ammonia nitrogen in the petroleum refining wastewater, the treatment efficiency is high, and ammonia gas and a precipitate are not generated; more importantly, after the modified hydrotalcite absorbs the ammonia nitrogen, the hydrotalcite can strip off automatically layer by layer without being regenerated, and the residue after stripping does not contain water and is small in size; the material is an environment-friendly ammonia nitrogen wastewater treating material; the finally measured ammonia nitrogen content in effluent of the wastewater is less than 0.2mg / L, and the denitrogenation efficiency is over 99.9 percent.

Owner:响水华清污水处理有限公司

Polypeptide-modified graphene oxide-modified composite antibacterial forward osmosis membrane and preparation method thereof

InactiveCN110548410AImprove antibacterial propertiesPrevent proliferationMembranesSemi-permeable membranesClick chemistrySolvent

The invention discloses a polypeptide-modified graphene oxide-modified composite antibacterial forward osmosis membrane and a preparation method thereof. The preparation method comprises the steps: mixing an aqueous solution containing a solvent with a silane coupling agent, carrying out backlight hydrolysis, then adding graphene oxide, and carrying out reaction, to obtain alkynylated graphene oxide; modifying antibacterial polypeptide on the surface of alkynylated graphene oxide by a click chemical technology, and connecting a carbon heteroatom and polypeptide, to obtain polypeptide-modifiedgraphene oxide; mixing polypeptide-modified graphene oxide, a high-molecular polymer and a solvent evenly, then coating a membrane by a liquid phase transformation method, and thus obtaining the polypeptide-modified graphene oxide-modified composite antibacterial membrane. By modifying graphene oxide with polypeptide, the antibacterial performance of graphene is effectively improved. The preparedforward osmosis membrane has the advantages of long-term antibacterial ability, no pollution, no regeneration, high permeability efficiency, stable operation, and wide application prospect.

Owner:宁波蓝盾新材料科技有限公司

A butadiene tail gas hydrogenation device and method

ActiveCN103787813BExtended service lifeReduce olefin contentHydrocarbon by hydrogenationAlkaneButadiene Dioxide

The invention provides a method for hydrogenation of alkyne-rich tail gas of a butadiene extraction device. The alkyne-rich tail gas of a butadiene extraction device undergoes a liquid-phase hydrogenation reaction in the presence of an Ni-based catalyst using a titanium oxide-alumina compound as a carrier and undergoes a gas-phase hydrogenation reaction in the presence of an Ni-MO-based catalyst so that all alkynes and dialkenes in the raw material are subjected to hydrogenation conversion and most olefins are hydrogenated to form alkanes. The method realizes continuous and stable operation of the device and obviously reduces olefin content of the hydrogenation products to less than 5% so that requirements on cracking of the raw material of an ethylene production device are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating high-concentration ammonia nitrogen in garbage leachate

InactiveCN104944502AWill not cause secondary pollutionNo need to regenerateOther chemical processesWater contaminantsViscous liquidHigh concentration

The invention relates to a method for treating high-concentration ammonia nitrogen in garbage leachate, belonging to the field of wastewater treatment. The method comprises the following steps: mixing an organic composite denitrifier modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorbing material and an adhesive in a mass ratio of 1:5 to obtain a viscous liquid, coating the viscous liquid to the surface layer of an adsorbing bar, drying, putting in an adsorption column, enabling the garbage leachate to flow through the adsorption column until the organic composite denitrifier modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorbing material on the adsorbing bar surface adsorbs ammonia nitrogen to the saturated state, aging the surface layer of the magnesium-aluminum-iron hydrotalcite magnetic nano material by the organic composite denitrifier so that the aged adsorbing material surface layer sheds layer by layer under the action of garbage leachate flow scour and external magnetic field, and finally, determining the ammonia nitrogen content in the wastewater. The method can not generate ammonia gas to enter the air or generate any precipitate, can not cause secondary environmental pollution, does not need to regenerate the adsorbing material, and is simple to operate. The ammonia nitrogen removal concentration is lower than 1 mg / L, and the removal rate is up to 99.99% above.

Owner:CHANGZHOU UNIV

A kind of hydrogenation method of butadiene tail gas

ActiveCN103787811BExtended service lifeReduce olefin contentHydrocarbon by hydrogenationGas phaseDesorption

The invention provides a method for hydrotreating alkynes-rich butadiene tail gas. The method comprises the following steps: butadiene tail gas is extracted, the tail gas is absorbed, a liquid phase of a Ni-based catalyst which takes a titania-alumina compound is performed with a hydrotreating reaction is employed, the gas phase hydrogenation reaction of a Ni-Mo catalyst is used, and steps of desorption and rectification are carried out. According to the invention, the hidden trouble when the liquefaction method of pressure rising and condensation are employed on the butadiene tail gas is eliminated by the method provided by the invention, alkene content in the hydrotreating products is obviously reduced, the alkene content is less than 5%, and the requirement for cracking the raw material can be reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating high-concentration ammonia nitrogen in urea

InactiveCN104876292AWill not cause secondary pollutionImplement updateOther chemical processesWater contaminantsViscous liquidHigh concentration

The invention relates to a method for treating high-concentration ammonia nitrogen in urea and belongs to the field of wastewater treatment. The method comprises the following steps: preparing a viscous liquid by using a prepared organic compound denitrification agent modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorption material and an adhesive in a mass ratio of 1:5, applying the viscous liquid to the surface of an adsorption rod, drying, putting the adsorption rod coated with the viscous liquid into an adsorption tower, enabling urea to flow through the adsorption tower until the organic compound denitrification agent modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorption material on the surface of the adsorption rod adsorbs urea to be saturated, enabling aged surface layers of the organic compound denitrification agent modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorption material one by one under the action of flashing of landfill leachate flow and an external magnetic field, and finally testing the content of ammonia nitrogen in wastewater. No ammonia gas can be generated to diffuse into the atmosphere, and no precipitate can be generated either, no secondary environment pollution can be caused, the adsorption material does not need to be regenerated, the ammonia nitrogen concentration is less than 1mg / L, and the removal rate is 99.99% or above.

Owner:CHANGZHOU UNIV

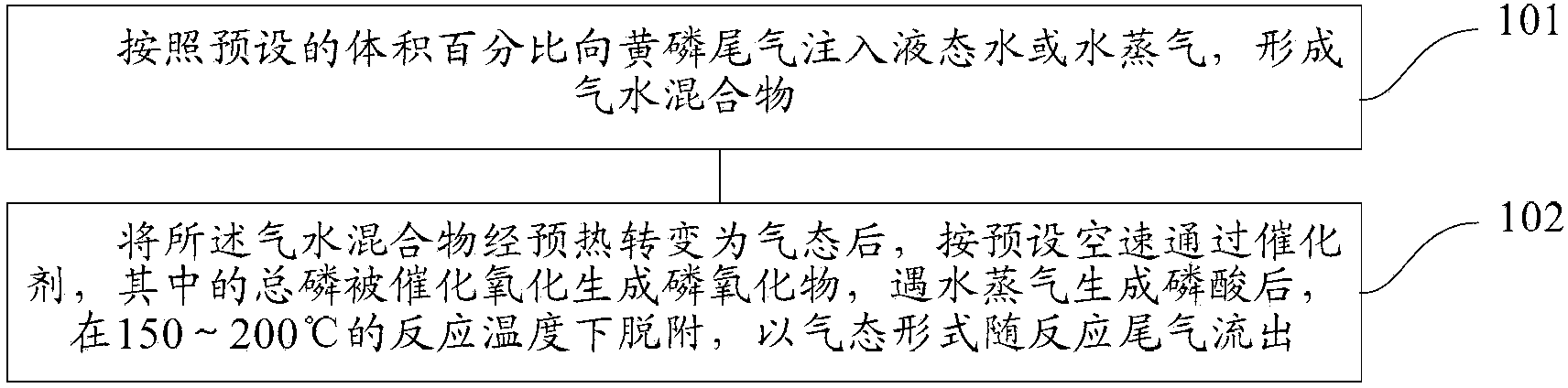

Dephosphorization catalytic reaction process and catalyst for yellow phosphorus tail gas

ActiveCN104069734ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporLiquid water

The invention provides a dephosphorization catalytic reaction process and a catalyst for yellow phosphorus tail gas. The dephosphorization catalytic reaction process includes: injecting liquid water or water vapor into the yellow phosphorus tail gas according to a preset volume percentage to form a gas-water mixture, and feeding the gas-water mixture though the catalyst according to a preset space velocity after the gas-water mixture is preheated to transform into a gas state, wherein the total phosphorus is subjected to catalytic oxidation to produce phosphoric oxides, and the phosphoric oxides produce phosphoric acid after contacting water vapor, are desorbed at a reaction temperature of 150-200 DEG C and flow out in a gas state along with the reaction tail gas. The reaction process and the catalyst can achieve continuous dephosphorization at a low reaction temperature, thus reducing energy consumption.

Owner:BEIJING PEKING UNIV PIONEER TECH

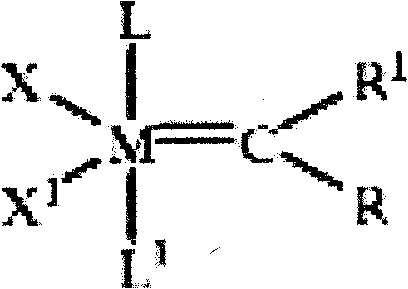

Method for preparing propylene through ethylene/butylene disproportionation reaction

ActiveCN102826948ANo need to regenerateSimple processHydrocarbon by metathesis reactionChemical recyclingCarbene2-Butene

The invention discloses a method for preparing propylene through an ethylene / butylene disproportionation reaction. The method is characterized in that ethylene and 2-butylene contact with a carbene catalyst solution containing metallic ruthenium or osmium to generate propylene; and especially, ethylene and 2-butylene contact with the carbene catalyst solution containing metallic ruthenium or osmium under conditions comprising that the temperature is 0-50DEG C and the pressure is 0.1-10MPa to generate propylene, wherein the molar ratio of ethylene to 2-butylene is 1:1-10:1. The method has the advantages of simple process, mild technological condition, high reaction conversion rate, high reaction selectivity, no need of the regeneration of the catalyst, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

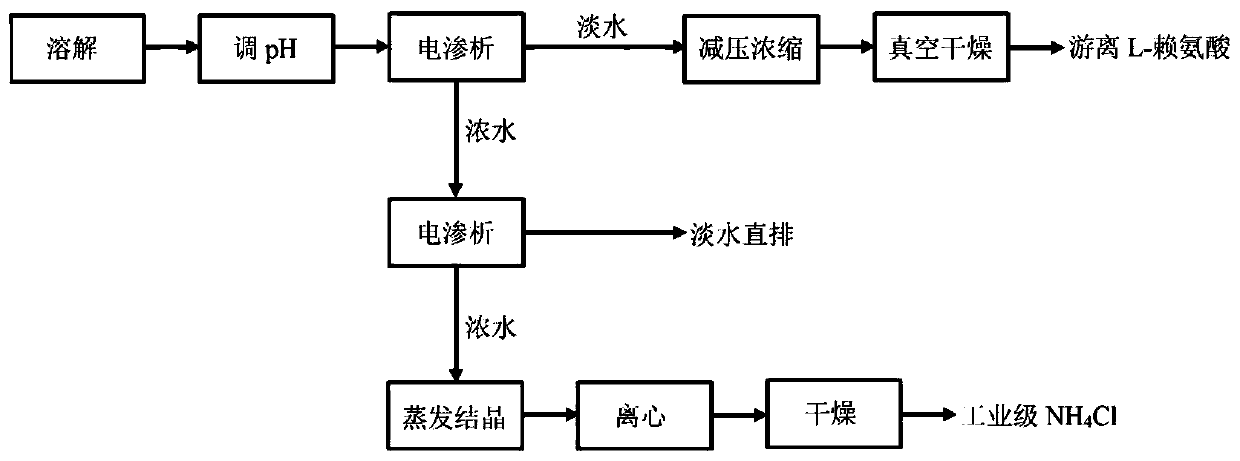

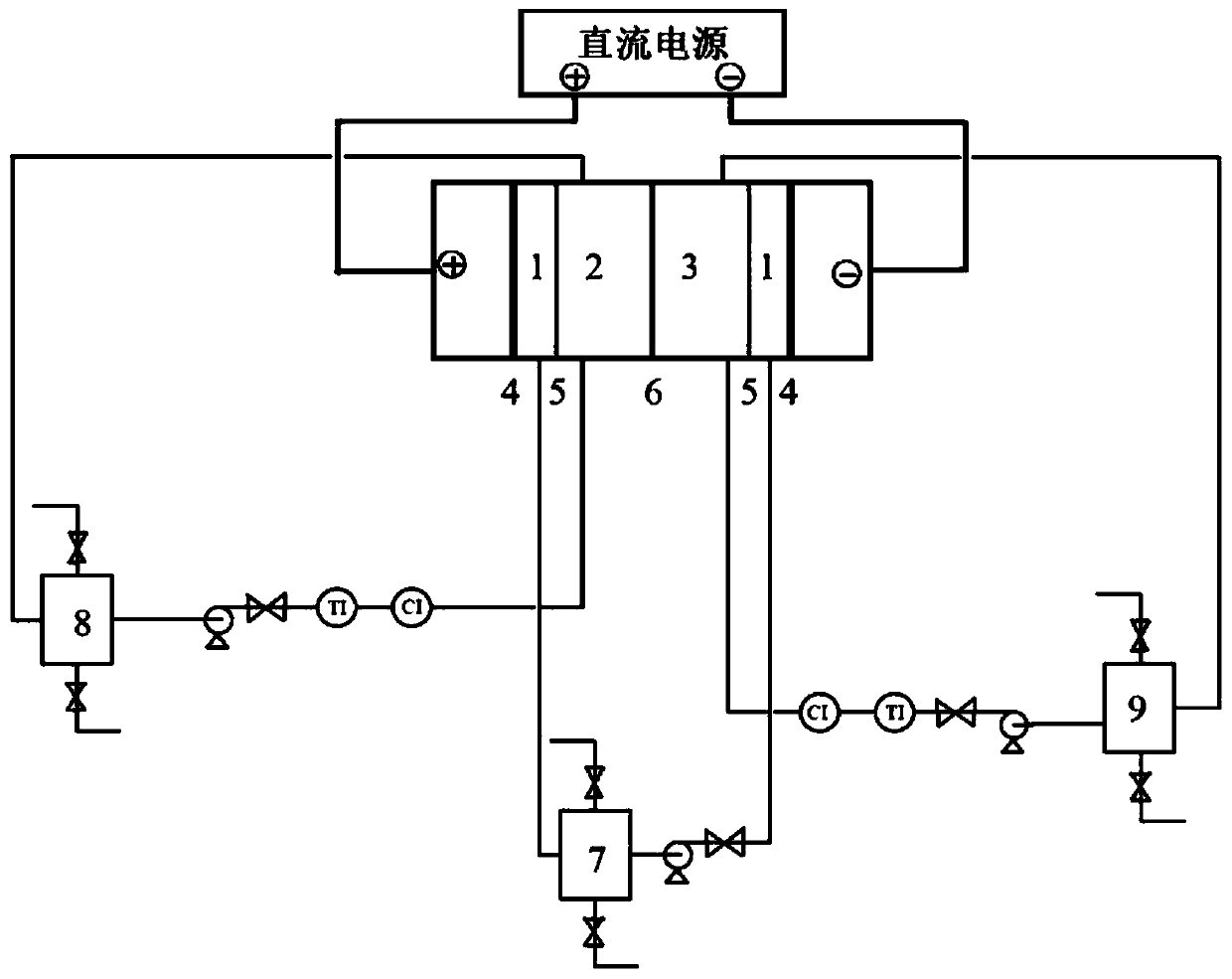

Method for extracting free L-lysine from ammonia water eluate by membrane method

InactiveCN110746019AExtend your lifeReduce water consumption and water productionOrganic compound preparationWater contaminantsIon-exchange membranesEnvironmental chemistry

The invention relates to the technical field of purification of free L-lysine and particularly relates to a method for extracting the free L-lysine from ammonia water eluate by a membrane method. According to the method, the free L-lysine is extracted by innovatively utilizing an electrodialysis plant, NH4Cl is effectively removed from the ammonia water eluate, and electrodialysis light water is subjected to depressurized concentration and vacuum baking, so as to obtain free L-lysine crystals; and a NH4Cl solution of electrodialysis concentrated water is subjected to electrodialysis concentrating of a section and then is evaporated, thereby obtaining an industrial grade NH4Cl product. According to the technology disclosed by the invention, the removal rate of Cl<-> reaches up to 99%, the recovery rate of the free L-lysine is higher than 95%, the traditional ion-exchange resin exchange method is replaced, the water consumption and water yield are reduced, the energy consumption is lowered, the operating cost is reduced; and the electrodialysis plant can be reused, and an ion exchange membrane has no need of regeneration and is relatively long in life.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Multistage reaction center oxidation catalyst as well as preparation method and application thereof

ActiveCN111229211AEfficient degradationIncrease concentrationWater treatment parameter controlWater contaminantsActivated carbonSilica particle

The invention provides a multistage reaction center oxidation catalyst. The catalyst comprises an activated carbon matrix, and metal colattice doped silicon dioxide particles which are adsorbed in gaps of the activated carbon matrix. By means of the adsorption function of the activated carbon and the microbattery function of the silicon dioxide particles, the catalyst, when being applied to the field of water treatment, achieves rapid degradation of pollutants, and a contact metal redox reaction is not generated in the system any more, so that the service life and the stability of the catalystare improved. The invention further provides a preparation method of the catalyst, a solvent method is adopted for preparing the metal colattice doped silicon dioxide particles, energy consumption islow, components are uniform, operation is easy, and wide application prospects are achieved.

Owner:天津市海跃水处理高科技有限公司 +1

Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

InactiveCN102500323BEasy accessLow costPhysical/chemical process catalystsOther chemical processesActive agentCatalytic oxidation

The invention belongs to the technical field of waste gas desulfurization and purification, particularly provides a modified active carbon desulfurizer and a preparation method thereof, and a hydrogen sulfide waste gas treatment method using the desulfurizer. The modified active carbon desulfurizer is prepared from impregnating activated carbon with active agent mixed solution comprising phenol, acetone, sodium carbonate, ferric nitrate and organic solvent, and drying and roasting the mixture. The modified active carbon desulfurizer converts the hydrogen sulfide in the waste gas into sulfur dioxide at atmospheric temperature and pressure under the absorption and catalytic oxidation action, and the sulfur dioxide is converted into SO42- in water phase by washing and removed. The waste gas treatment method uses the modified active carbon desulfurizer, and prevents the defects that the desulfurizer needs to be regularly desorbed and regenerated due to blockage caused by adsorption saturation and generated elemental sulfur. Compared with an ordinary activated carbon desulfurization process, the process has the advantages of high hydrogen sulfide removal rate, long service life of the desulfurizer, low operation cost, simplicity in operation and management and the like.

Owner:北京天灏柯润环境科技有限公司

Method for coating ozone catalytic decomposition material on electrostatic outdoor fresh air or indoor air purified dust collection pole plate

InactiveCN109013231AFully contactedReduce manufacturing costDispersed particle separationPretreated surfacesFresh airCatalytic decomposition

The invention discloses a method for coating an ozone catalytic decomposition material on an electrostatic outdoor fresh air or indoor air purified dust collection pole plate, and belongs to the technical field of indoor air purification. According to the method, the surface of a pre-treated pole plate is coated with ozone catalytic decomposition material slurry, pole plate roasting treatment is carried out, and the pole plate loaded with the ozone catalytic decomposition material is obtained. The method is applied to the pole plate with the narrow electrode spacing of an electrostatic dust removal device, dust-contained air flow can make sufficient contact with the pole plate, the ozone making contact with the pole plate can be efficiently removed under the room condition, the ozone catalytic decomposition reaction condition is moderate, no secondary pollution exists, and no safety hidden dangers exist. The method is simple and easy to implement, the production cost is low, the methodis applied to coat the n ozone catalytic decomposition material on the surface of the pole plate, and under the condition that the environment temperature of the pole plate ranges from 5 DEG C to 40DEG C, and the relative humidity ranges from 10% to 90%, the ozone removal rate can reach above 90%.

Owner:BEIHANG UNIV

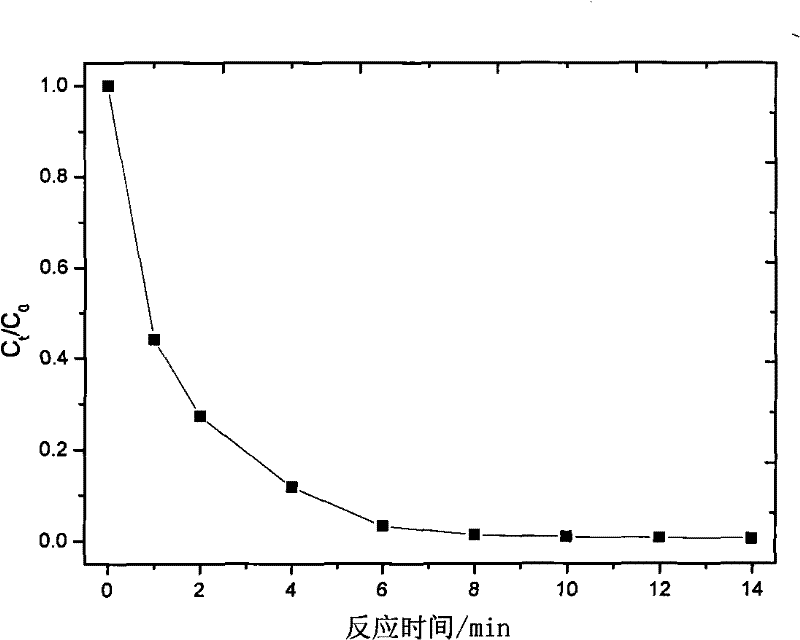

Method for rapid degradation of triphenylmethane dye waste water

InactiveCN101560027BStrong oxidation abilityImprove applicabilityWater contaminantsMultistage water/sewage treatmentTriphenylmethaneExternal energy

The invention discloses a method for rapid degradation of triphenylmethane dye waste water. The method firstly removes impurities by a grill, stands for precipitation and regulates pH, wherein, the pHvalue of the triphenylmethane dye waste water is controlled to be about 7-10; the waste water is introduced into a simple reaction container, then a mixture consisting of sodium bismuthate and silvernitrate is added, the multi-phase uniform mixing reaction is kept under the action of stirring, the temperature of the dye waste water during the process is kept at room temperature, the pressure isnormal pressure, and the waste water is discharged. The treatment method can high-efficiently degrade triphenylmethane dye which is typically difficult to biodegrade, the catalytic reaction can be realized without the use of any light source or other external energy, such as microwave and the like, and the treatment method has very low requirements on equipment, less energy consumption, low operation cost, convenient operation and no secondary pollution, thereby being the method which can realize the degradation at the room temperature.

Owner:NANJING UNIV

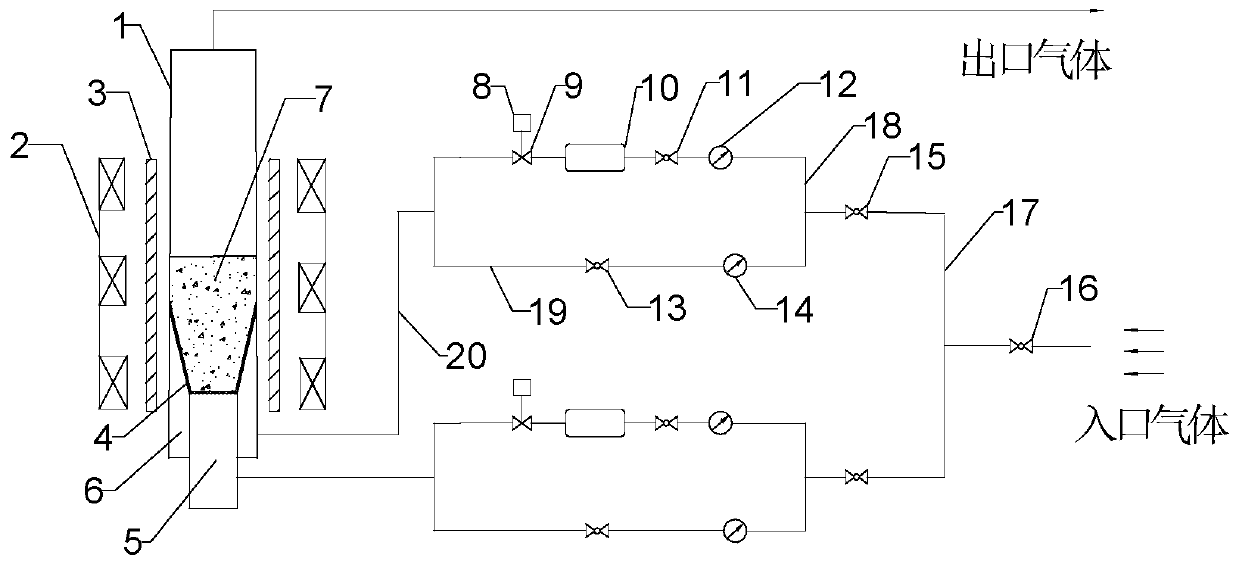

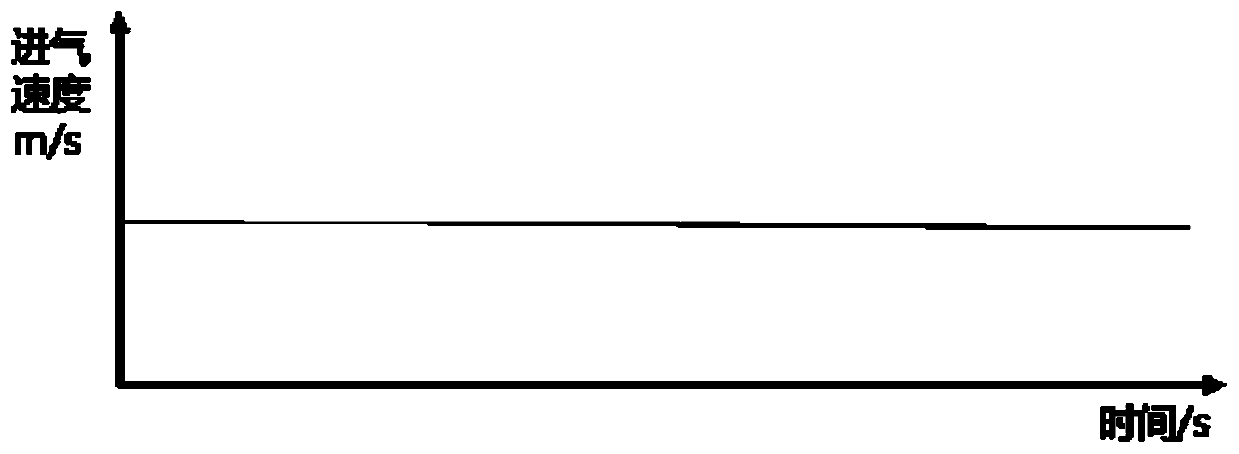

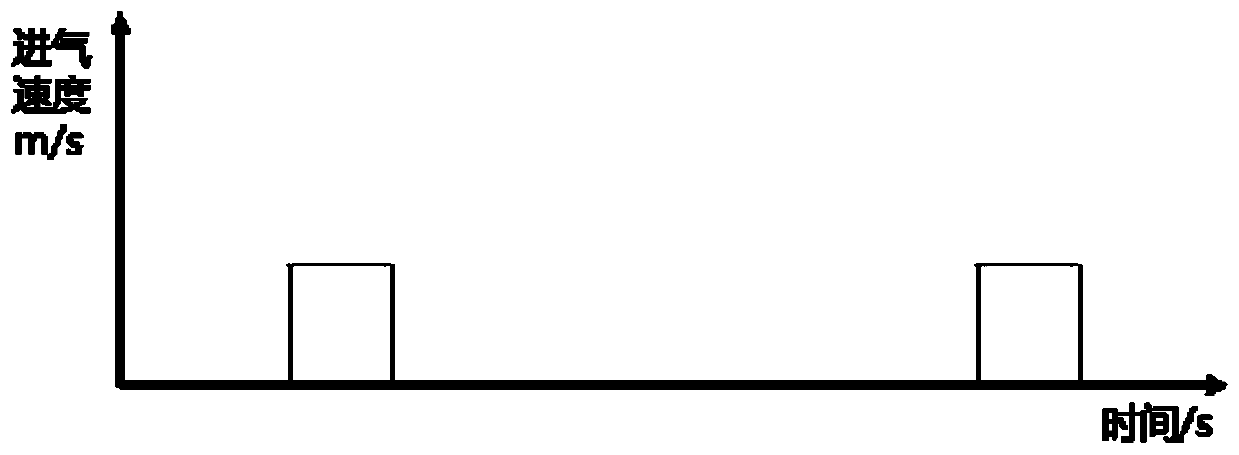

Pulsation gas flow and magnetic field combined enhanced methane catalytic reforming hydrogen production system and pulsation gas flow and magnetic field combined enhanced methane catalytic reforming hydrogen production method

ActiveCN109721029AExpand the scope of operationImprove the phenomenon of short circuitHydrogenCatalytic reformingReaction rate

The invention provides a pulsation gas flow and magnetic field combined enhanced methane catalytic reforming hydrogen production system and a pulsation gas flow and magnetic field combined enhanced methane catalytic reforming hydrogen production method, and relates to a fluidized bed methane catalytic reforming hydrogen production system and a fluidized bed methane catalytic reforming hydrogen production method. In the prior art, the utilization efficiency of the catalyst is low, the fluidization quality in the fluidized bed is low, the reaction rate is low, the catalytic reforming hydrogen production reaction-regeneration device is complicated, and other problems exist. A purpose of the present invention is to solve the problems in the prior art. According to the system, the lower portionof a fluidized bed reactor is provided with a conical wind distribution plate, an inner wind box is connected to the horizontal section of the conical wind distribution plate, an outer wind box is connected to the inclined section of the conical wind distribution plate, a heater is installed on the outer portion of the fluidized bed reactor, a stable magnetic field generator is installed on the outer portion of the heater, and the outlets of two independent gas flow generating devices are respectively connected to the inner wind box and the outer wind box. According to the method, the reduction of catalyst particles is firstly performed, than a catalytic reforming hydrogen production reaction is performed, and finally a coke deposition removing reaction is performed on the catalyst. The system and the method of the present invention are used for methane catalytic reforming hydrogen production.

Owner:HARBIN INST OF TECH

Method for treating high-concentration ammonia nitrogen in leather wastewater

InactiveCN104944499AWill not cause secondary pollutionImplement updateOther chemical processesWater contaminantsViscous liquidHigh concentration

The invention relates to a method for treating high-concentration ammonia nitrogen in leather wastewater, belonging to the field of wastewater treatment. The method comprises the following steps: mixing an organic composite denitrifier modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorbing material and an adhesive in a mass ratio of 1:5 to obtain a viscous liquid, coating the viscous liquid to the surface layer of an adsorbing bar, drying, putting in an adsorption column, enabling the leather wastewater to flow through the adsorption column until the organic composite denitrifier modified magnesium-aluminum-iron hydrotalcite magnetic nano adsorbing material on the adsorbing bar surface adsorbs ammonia nitrogen to the saturated state, aging the surface layer of the magnesium-aluminum-iron hydrotalcite magnetic nano material by the organic composite denitrifier so that the aged adsorbing material surface layer sheds layer by layer under the actions of leather wastewater flow scour and external magnetic field, and finally, determining the ammonia nitrogen content in the wastewater. The method can not generate harmful gas or cause secondary environment pollution, and does not need to regenerate the adsorbing material. The ammonia nitrogen concentration in the treated wastewater is lower than 0.6 mg / L, and the removal rate is up to 99.99% above.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com