Method for removing olefins from reformate through liquid phase circulation selective hydrogenation

A technology of reforming to generate oil and selectivity, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of high equipment construction cost and large cost ratio, and achieve short material contact time and flexible operation. Big, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

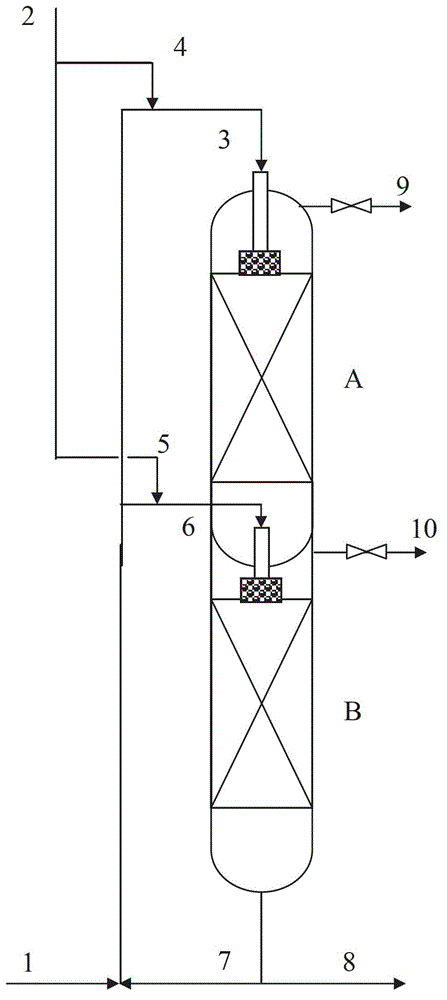

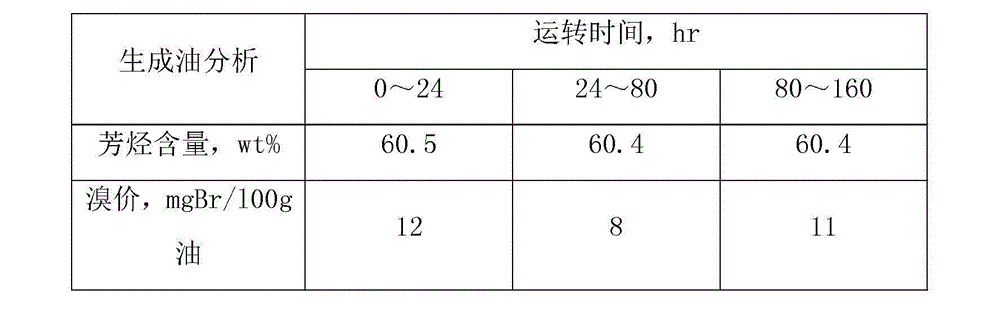

[0043] A two-stage series fixed-bed hydrogenation reactor is adopted, and the filling amount of the first reaction catalyst and the second reaction catalyst are both 100 mL. The raw material is the reformed oil from the continuous reformer, the distillation range is 26.2-218.2°C, the aromatic content is 60.5wt%, and the bromine value is 3640mgBr / 100g oil. According to the catalyst E prepared in Example 1 of CN100596285C, the catalyst was pre-reduced in hydrogen at 170°C for 8 hours, and then lowered to the reaction temperature for selective hydrogenation reaction. Control the circulation of product oil into the first and second reactors, the liquid hourly volumetric space velocity of the first and second reactors are 4.0 h respectively -1 , 6.0 h -1 , Process conditions are shown in Table 1-1, and the properties of refined reforming oil are shown in Table 1-2.

[0044] Table 1-1 Process conditions

[0045] Process conditions

Example 1

reactor

Two-stage series

Reacti...

Embodiment 2

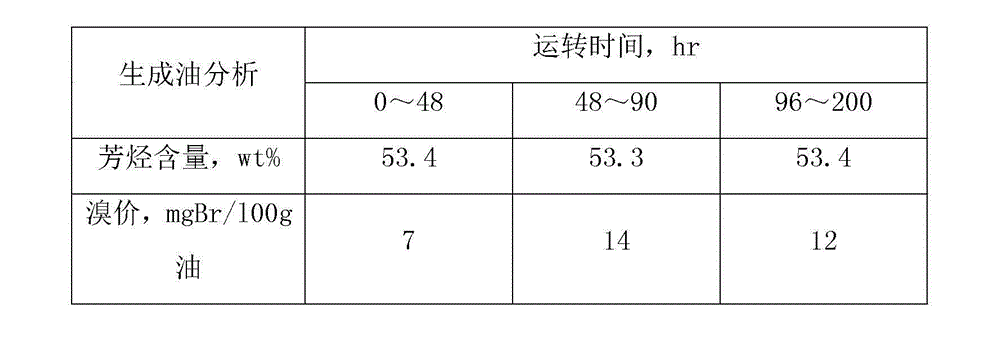

[0049] Two-stage series hydrogenation reactors are used, with 80 mL of the first reaction catalyst and 120 mL of the second reaction catalyst. The raw material used is a semi-regenerative fixed-bed reformer to reform the whole oil fraction, the distillation range is 46.2-167.5°C, the aromatic content is 53.4wt%, and the bromine value is 1870mgBr / 100g oil. The catalyst is based on the catalyst A prepared in Example 1 of CN100596285C, reduced in advance in hydrogen at 170°C for 8 hours, and then lowered to the reaction temperature for selective hydrogenation reaction. Control the circulation of product oil into the first and second reactors, the liquid hourly volumetric space velocity of the first and second reactors are 4.0 h respectively -1 , 6.0 h -1 , The process conditions are shown in Table 2-1, and the properties of refined reforming oil are shown in Table 2-2.

[0050] Table 2-1 Process conditions

[0051] Process conditions

Example 2

reactor

Two-stage series

...

Embodiment 3

[0055] A two-stage series hydrogenation reactor is used, and the loading capacity of the first reaction catalyst and the second reaction catalyst are both 100 mL. The raw materials used are the same as in Example 1. The catalyst was pre-reduced in hydrogen at 180° C. for 8 hours according to the catalyst E prepared in Example 1 of CN100596285C, and then lowered to the reaction temperature for long-term stability test. Control the circulation of product oil into the first and second reactors, the liquid hourly volumetric space velocity of the first and second reactors are 4.0 h respectively -1 , 6.0 h -1 , The process conditions are shown in Table 3-1, and the properties of refined reforming oil are shown in Table 3-2.

[0056] Table 3-1 Process conditions

[0057] Process conditions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com