Method for preparing propylene through ethylene/butylene disproportionation reaction

A technology of disproportionation reaction and ethylene, which is used in the fields of metathesis reaction to produce hydrocarbons, chemical recovery, organic chemistry, etc. It can solve the problems of easy deactivation of catalysts, harsh operating conditions and harsh regeneration conditions, and achieve the conversion rate and selectivity of the reaction. Good, mild process conditions, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

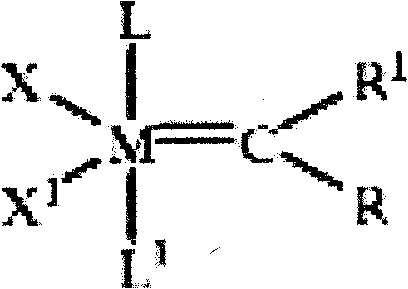

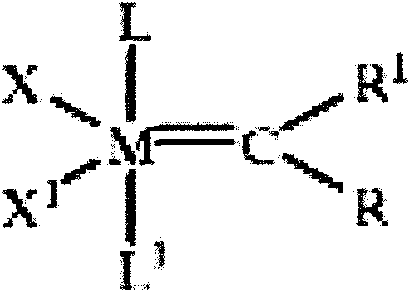

[0024] In the autoclave, a batch operation mode is adopted to replace the reaction system with high-purity nitrogen; under nitrogen protection, add the cooled catalyst solution (di-cyclohexylphosphine-benzylidene-ruthenium dichloride / ethylene dichloride solution ) 15ml and 2-butene 1.3g; start stirring and heat up to 20°C; after stabilization, fill with ethylene so that the molar ratio of ethylene / 2-butene is 3:1, and the reaction pressure is 1.09MPa. The reaction starts timing. No additional ethylene was added during the reaction. Gas phase samples were taken intermittently for GC analysis to monitor the progress of the reaction. The reaction was stopped after 60 min. GC analysis was performed on gas and liquid phase reaction products. The conversion rate in terms of 2-butene was 73.2%, and the propylene selectivity was 99.1%.

Embodiment 2

[0026] In the autoclave, a batch operation mode is adopted to replace the reaction system with high-purity nitrogen; under nitrogen protection, add the cooled catalyst solution (di-cyclohexylphosphine-benzylidene-ruthenium dichloride / ethylene dichloride solution ) 15ml and 2-butene 1.3g; start stirring and heat up to 35°C; after stabilization, fill with ethylene so that the molar ratio of ethylene / 2-butene is 3:1, and the reaction pressure is 1.09MPa. The reaction starts timing. No additional ethylene was added during the reaction. Gas phase samples were taken intermittently for GC analysis to monitor the progress of the reaction. The reaction was stopped after 30 min. GC analysis was performed on gas and liquid phase reaction products. The conversion rate in terms of 2-butene was 70.8%, and the propylene selectivity was 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com