Method for preparing fly ash fluorine removal agent through two steps of hydrothermal reaction/acid leaching and application

A technology of fly ash and fluoride removal agent, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of secondary pollution, difficult to obtain, and high cost of raw materials, and achieve convenient treatment, Reduced preparation cost and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of hydrothermal / acid leaching two steps prepares the method for fly ash defluorination agent, comprises the following steps:

[0042] Put a certain amount of fly ash and 0.1, 1.5, 2.5mol / L NaOH solution into the autoclave at a solid-to-liquid ratio of 1:10, and react for 4 hours at a temperature of 180°C and a stirring speed of 350rpm. Then pulp washing and suction filtration. With 1.5mol / L of H 2 SO 4 The solution was stirred and soaked for 5 minutes at a solid-to-liquid ratio of 1:10, then suction filtered, and dried at 80°C for 2 hours to make a fly ash defluorination agent.

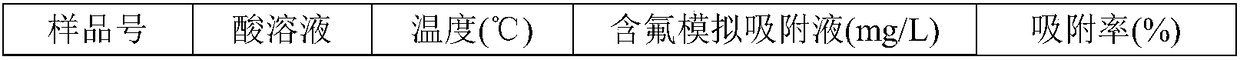

[0043] The fluoride ion adsorption capacity test was carried out with the defluorinating agent made in Example 1, and the results are shown in Table 1.

[0044] Table 1 Example 1 performance comparison of each sample

[0045] sample number

[0046] It can be seen from the data in Table 1 that when the alkali water is hot, the adsorption rate of the fly ash defluoridation ag...

Embodiment 2

[0048] A kind of hydrothermal / acid leaching two steps prepares the method for fly ash defluorination agent, comprises the following steps:

[0049] Put the fly ash and 2.5mol / L NaOH solution into the autoclave at a solid-to-liquid ratio of 1:10, and react for 2 hours at a temperature of 180°C and a stirring speed of 350rpm. Then pulp washing and suction filtration. With 1.5mol / L of H 2 SO 4 Stir and soak with HCl solution at a solid-to-liquid ratio of 1:10, then soak with suction for 5 minutes, and then dry at 80°C and 120°C for 1 hour to make a fly ash defluorination agent.

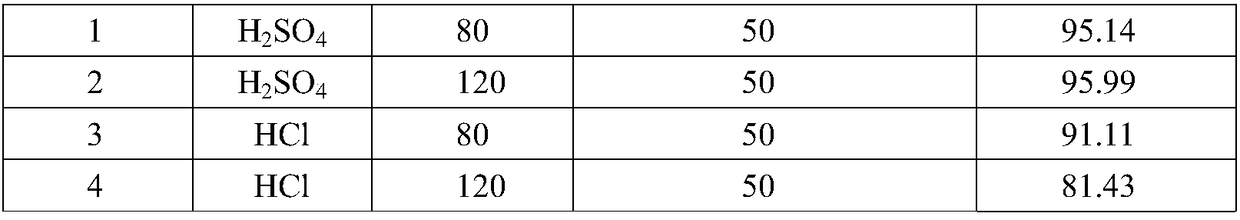

[0050] The fluoride ion adsorption capacity test was carried out with the defluorinating agent made in Example 2, and the results are shown in Table 2.

[0051] Table 2 Example 2 performance comparison of each sample

[0052]

[0053]

[0054] It can be seen from the data in Table 2 that the defluoridation agent prepared by using sulfuric acid and hydrochloric acid as the pickling solution in t...

Embodiment 3

[0056] A kind of hydrothermal / acid leaching two steps prepares the method for fly ash defluorination agent, comprises the following steps:

[0057] Put fly ash and 2.5mol / L NaOH solution into the autoclave at a solid-to-liquid ratio of 1:10, and react for 2h and 4h at a temperature of 180°C and a stirring speed of 350rpm. Then pulp washing and suction filtration. With 1.5mol / L of H 2 SO 4 The solution was stirred at a solid-to-liquid ratio of 1:10 for 5 minutes, then filtered with suction, and dried at 120°C for 1 hour to prepare a fly ash defluorination agent.

[0058] The fluoride ion adsorption capacity test was carried out with the defluorinating agent made in Example 3, and the results are shown in Table 3.

[0059] Table 3 Example 3 performance comparison of each sample

[0060] sample number

[0061] It can be seen from the data in Table 3 that the effect of hydrothermal time on the adsorption effect of the defluorinating agent of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com