Dephosphorization catalytic reaction process and catalyst for yellow phosphorus tail gas

A yellow phosphorus tail gas, catalytic reaction technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as increasing energy consumption, and achieve low preparation costs , to meet the requirements of combustion power generation, the effect of easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

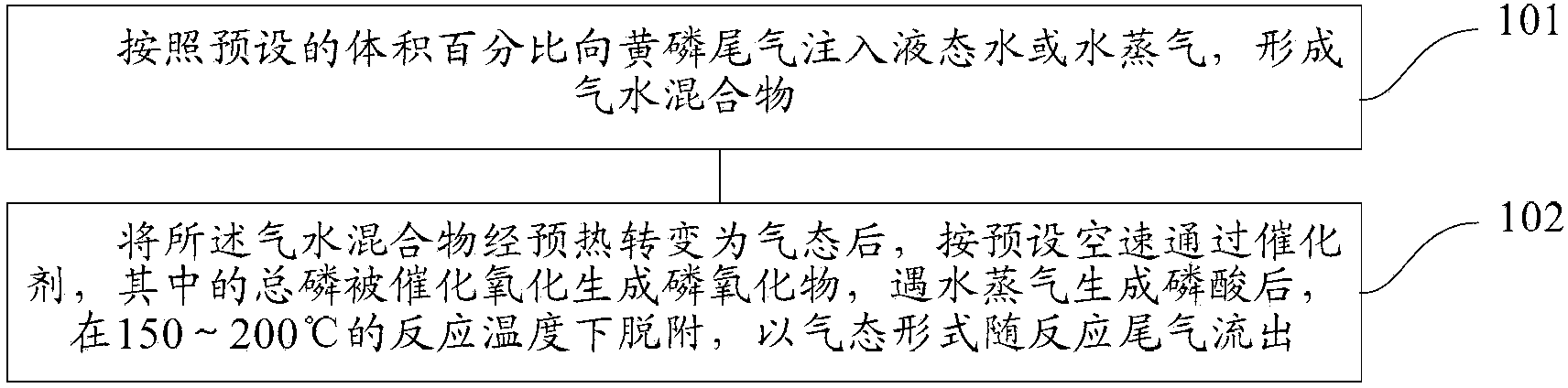

Method used

Image

Examples

example 1

[0062] Example 1: In this example, the supported active component of the catalyst is copper nitrate, and the catalyst carrier is an activated carbon fiber carrier. The specific preparation method is:

[0063] Weigh 34.10g of copper nitrate, dissolve it evenly, prepare it as 2L aqueous solution, add 800ml of activated carbon fiber carrier, impregnate it under vacuum for 4 hours, stop vacuuming, slowly add aqueous solution of potassium dihydrogen phosphate of saturated concentration to it 2L, adjust the pH value to about 9, filter after aging for 12 hours, and dry at 120°C.

[0064] This catalyst was packed in a fixed bed reactor. The temperature of the fixed bed catalytic reactor is set at 160°C; the space velocity is set at 6000h -1 , the water vapor content in the reaction gas is 25%. The total phosphorus before the yellow phosphorus tail gas purification is 770mg / m 3 , total sulfur 3500mg / m 3 . After passing through the fixed bed reactor for purification, the total phos...

example 2

[0065] Example 2: In this example, ferric chloride is used as the loaded active component of the catalyst, and the activated carbon carrier is a surface-treated activated carbon fiber carrier. The specific preparation method is:

[0066] Take by weighing 13.52g ferric chloride, be prepared as 500ml aqueous solution, add 200ml active carbon fiber carrier, after impregnating 4h under the vacuum condition, stop vacuuming, slowly add the potassium dihydrogen phosphate aqueous solution 500ml of saturated concentration therein, adjust the pH value to 10 or so, after aging for 12 hours, filter and dry at 120°C.

[0067] This catalyst was packed in a fixed bed reactor. The temperature of the fixed bed catalytic reactor is set at 180°C; the space velocity is set at 10000h -1 , The reaction gas contains 30% water vapor. Total phosphorus before purification of yellow phosphorus tail gas 890mg / m 3 , total sulfur 3000mg / m 3 . After passing through the fixed bed reactor for purificatio...

example 3

[0068] Example 3: In this example, the supported active component of the catalyst is copper chloride, and the catalyst carrier is an activated carbon fiber carrier. The specific preparation method is:

[0069] Weigh 13.64g copper chloride, prepare 1L aqueous solution, add 400ml activated carbon fiber carrier, and impregnate under vacuum condition for 4h. After stopping vacuuming, slowly add potassium dihydrogen phosphate aqueous solution of saturated concentration to it, adjust the pH value to about 9, filter after aging for 12 hours, and dry at 120°C.

[0070] This catalyst was packed in a fixed bed reactor. The temperature of the fixed bed catalytic reactor is set at 200°C; the space velocity is set at 5000h -1 , the water vapor content in the reaction gas is 25%. Total phosphorus before purification of yellow phosphorus tail gas 830mg / m 3 , total sulfur 2000mg / m 3 . After passing through the fixed bed reactor for purification, the total phosphorus in the yellow phospho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com