Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

A technology of activated carbon and desulfurizer, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of high application conditions, reduced hydrogen sulfide removal rate, short service life of desulfurizer, etc., and achieves simple operation. Convenience, easy access to raw materials, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

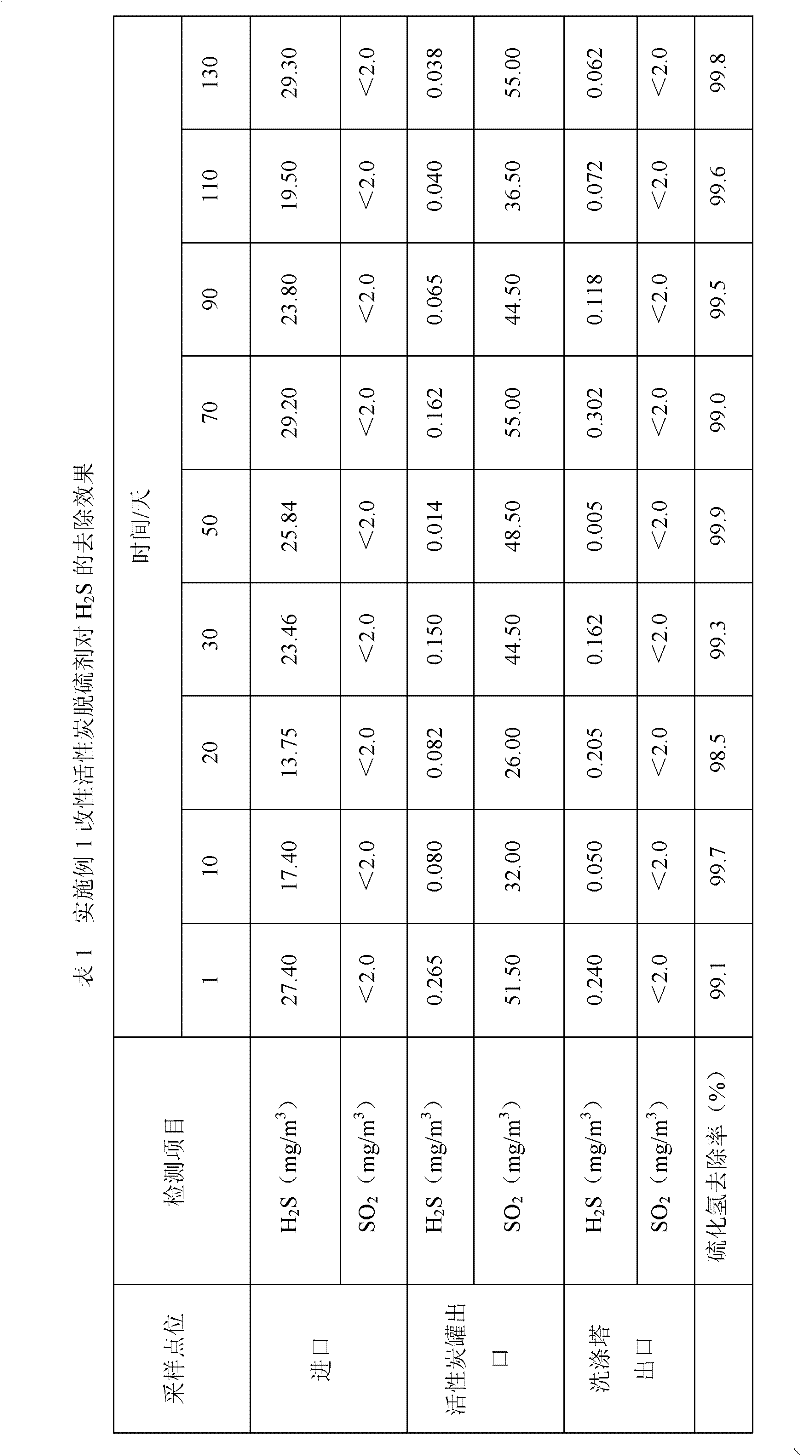

Embodiment 1

[0043] Weigh 50g of activated carbon, boil it in water at 60°C for 8 hours, and dry it in vacuum at 105°C for 9 hours. 200g of active material mixture, including: 10g of sodium carbonate, 4g of ferric nitrate, 4g of acetone, 0.6g of phenol, and 181.4g of ethanol. The mixed solution of the above-mentioned active agent and the pretreated activated carbon are immersed in the pretreated activated carbon at 25° C., and left to stand for 12 hours. The active agent mixed solution is twice the volume of the activated carbon. Then discard the upper layer solution and dry at 100°C for 4 hours. It is activated for 3 hours under inert gas protection at 300°C. Prepared modified activated carbon desulfurizer. The modified activated carbon desulfurizer has a bulk density of 725kg / m 3 ;The specific surface area is 1250m 2 / g; The specific pore volume is 0.60mL / g.

[0044] The sulfur capacity test of the obtained modified activated carbon desulfurizer was carried out in a fixed bed reactor: t...

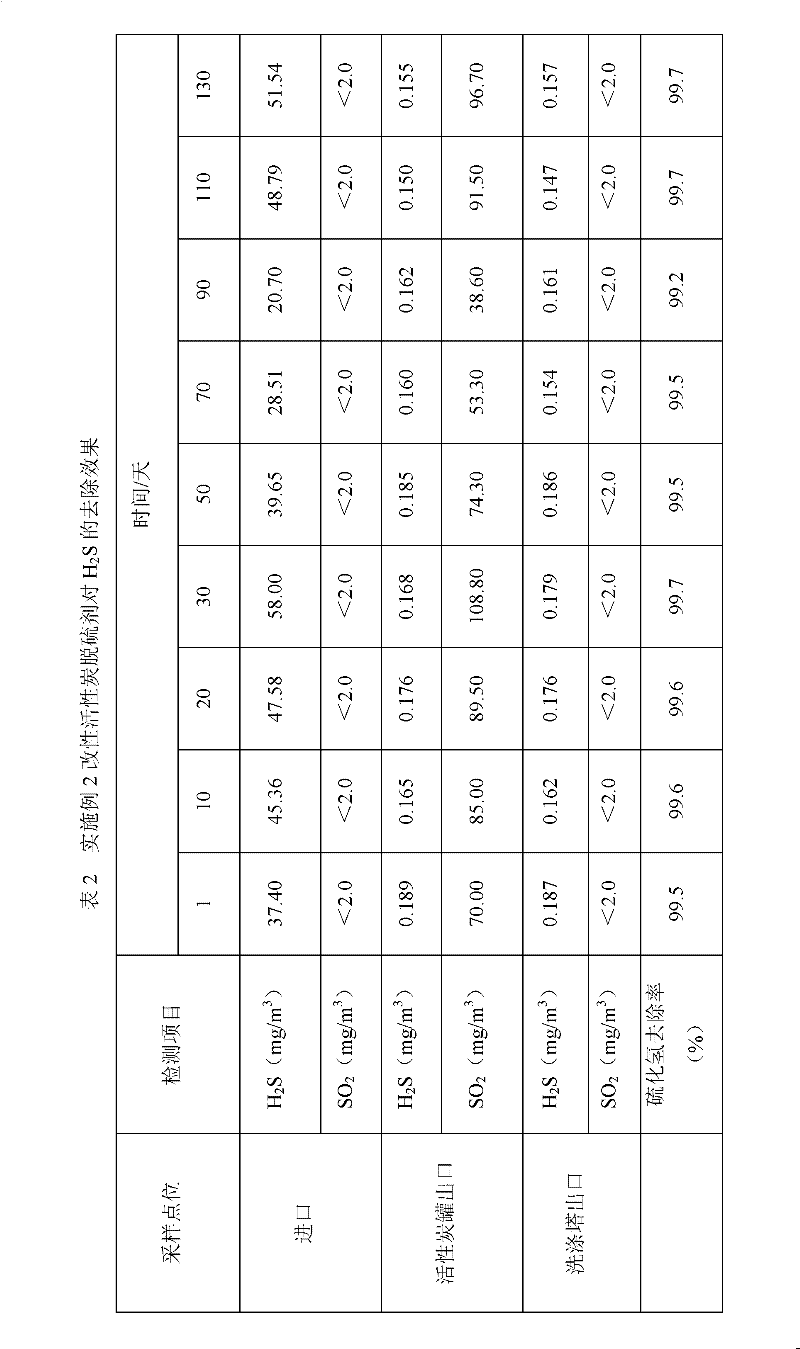

Embodiment 2

[0049] Weigh 50g of activated carbon, boil it at 90°C for 8h, and dry it in vacuum at 105°C for 9h. 300g of active material mixture, including 21g of sodium carbonate, 7.1g of ferric nitrate, 6g of acetone, 0.9g of phenol, and 265g of ethanol. The mixed solution of the above-mentioned active agent and the pretreated activated carbon were immersed at 50° C., and left to stand for 20 hours. The active agent mixed solution is 3 times the volume of activated carbon. Then discard the upper layer solution and dry at 120°C for 5h. It is activated by inert gas roasting at 400℃ for 5h. Prepared modified activated carbon desulfurizer. Its bulk density is 700kg / m 3 ;The specific surface area is 1200m 2 / g; The specific pore volume is 0.50mL / g.

[0050] The sulfur capacity test of the obtained modified activated carbon desulfurizer was carried out in a fixed bed reactor: the inner diameter of the reactor was 14mm, the bed reaction temperature was 85°C, and the space velocity was 800~1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com