Patents

Literature

41results about How to "Complete oxidation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

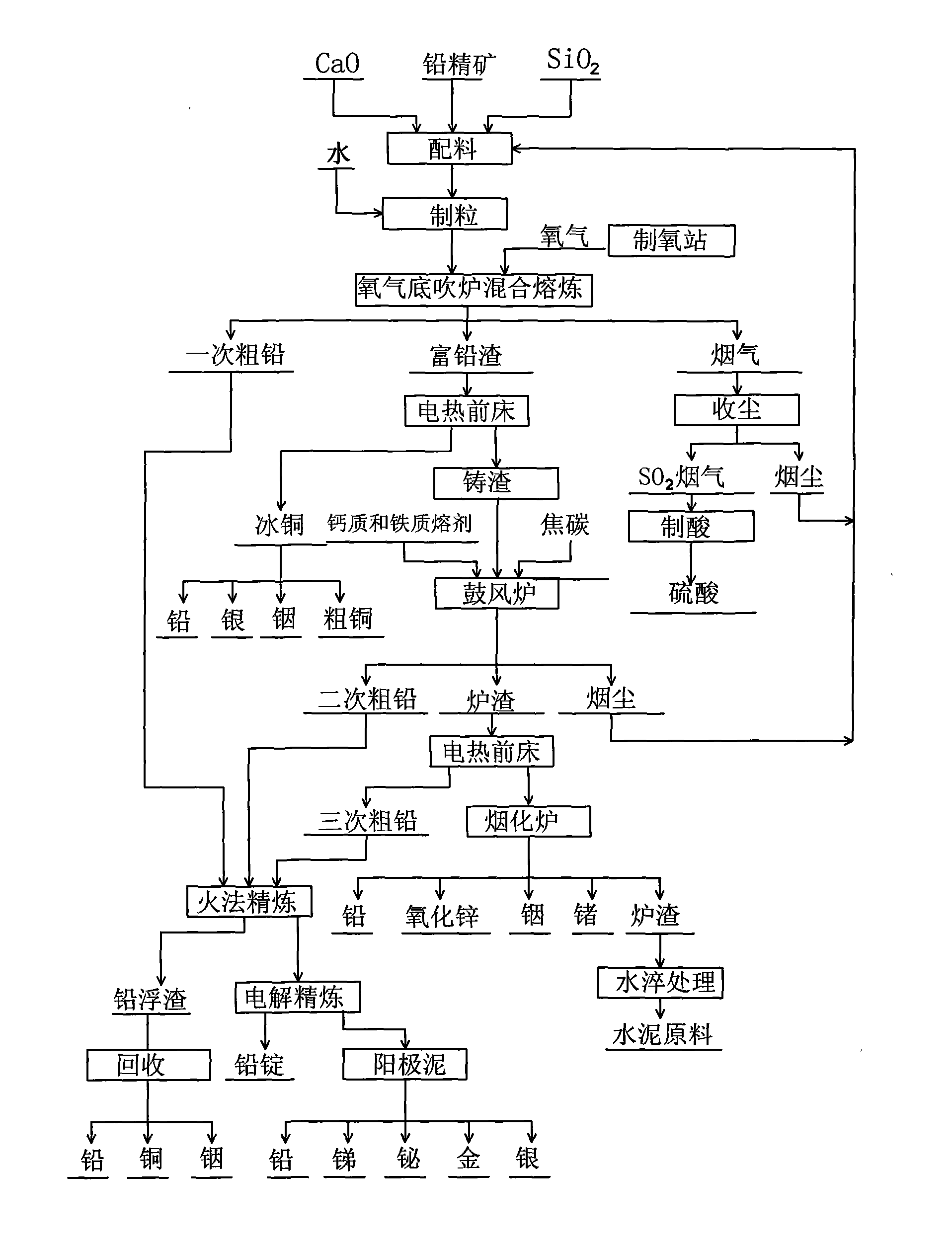

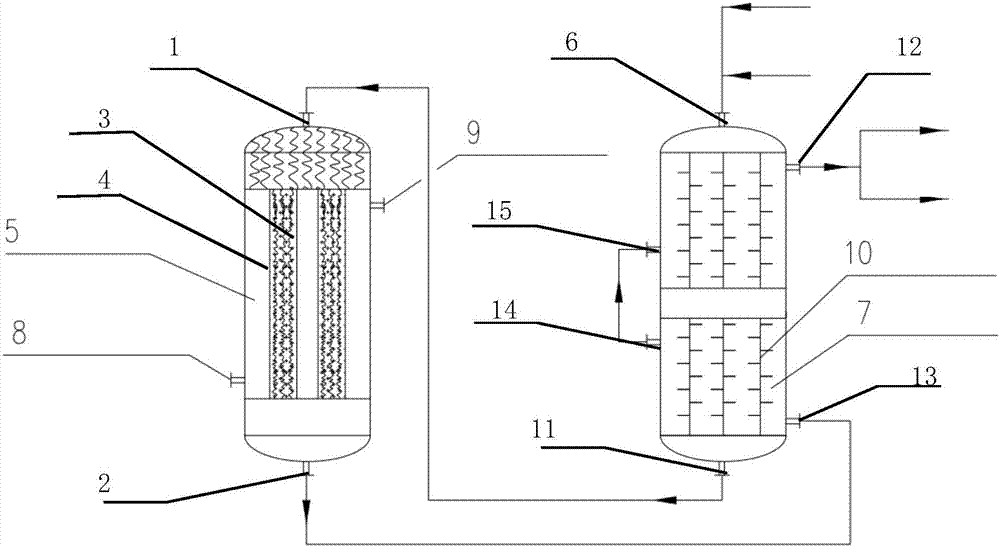

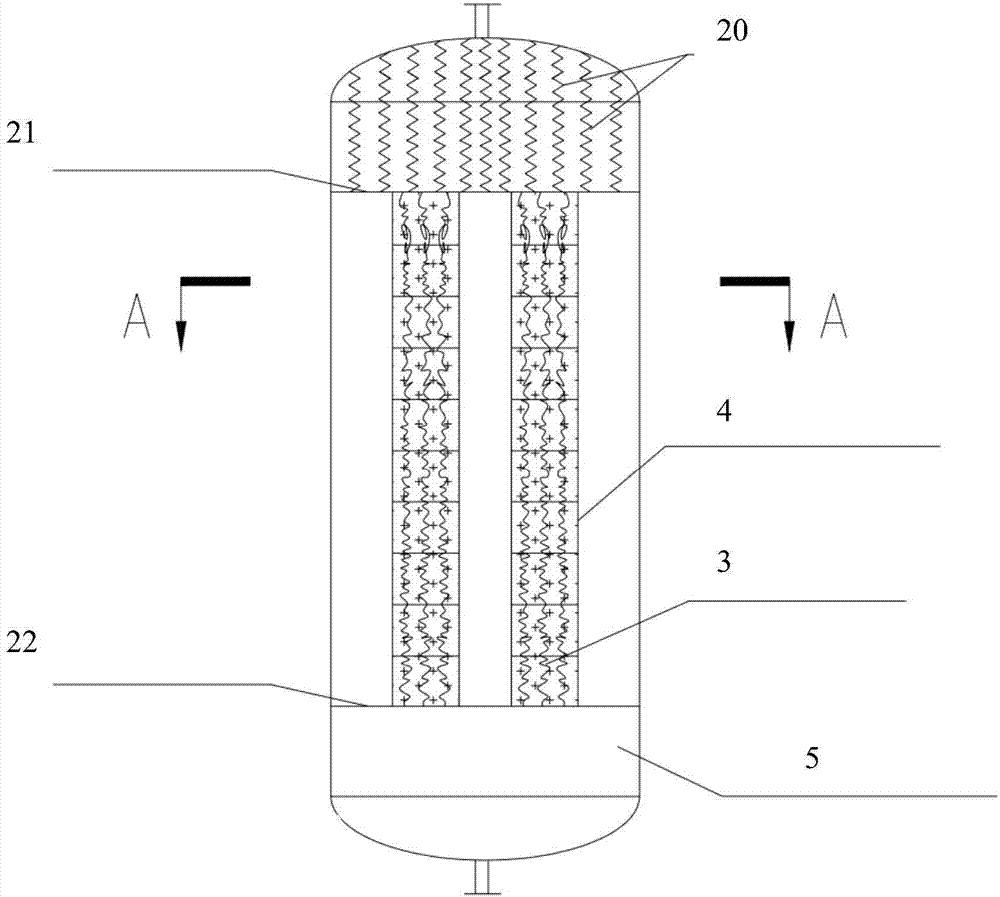

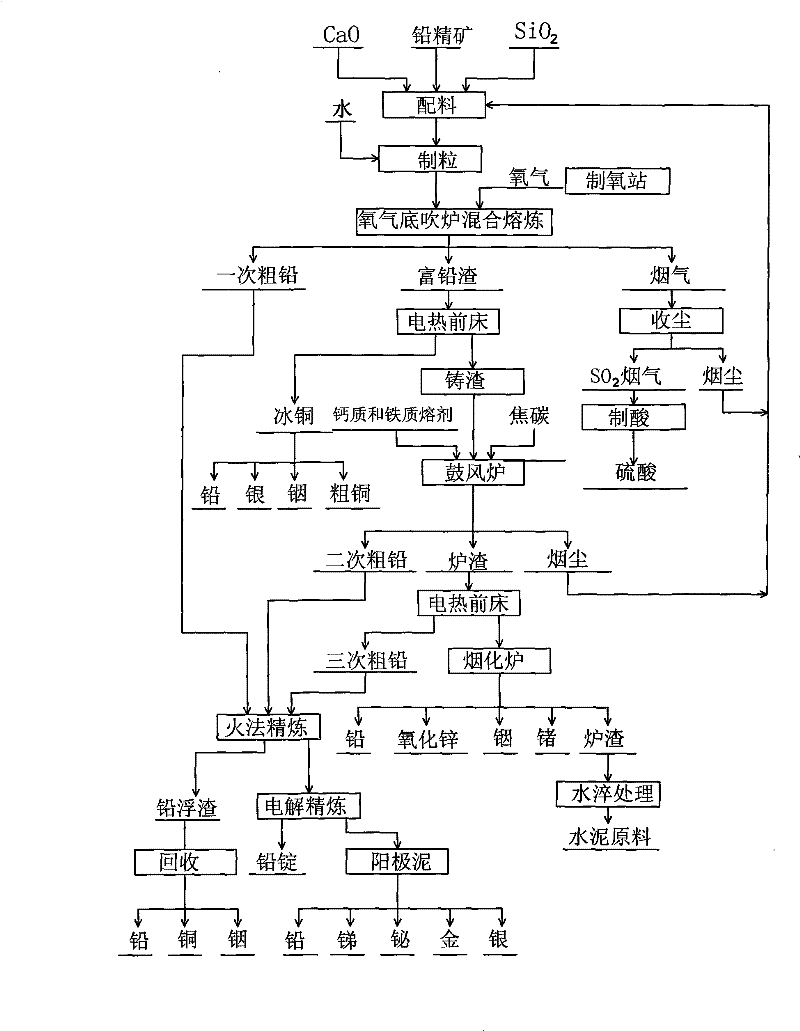

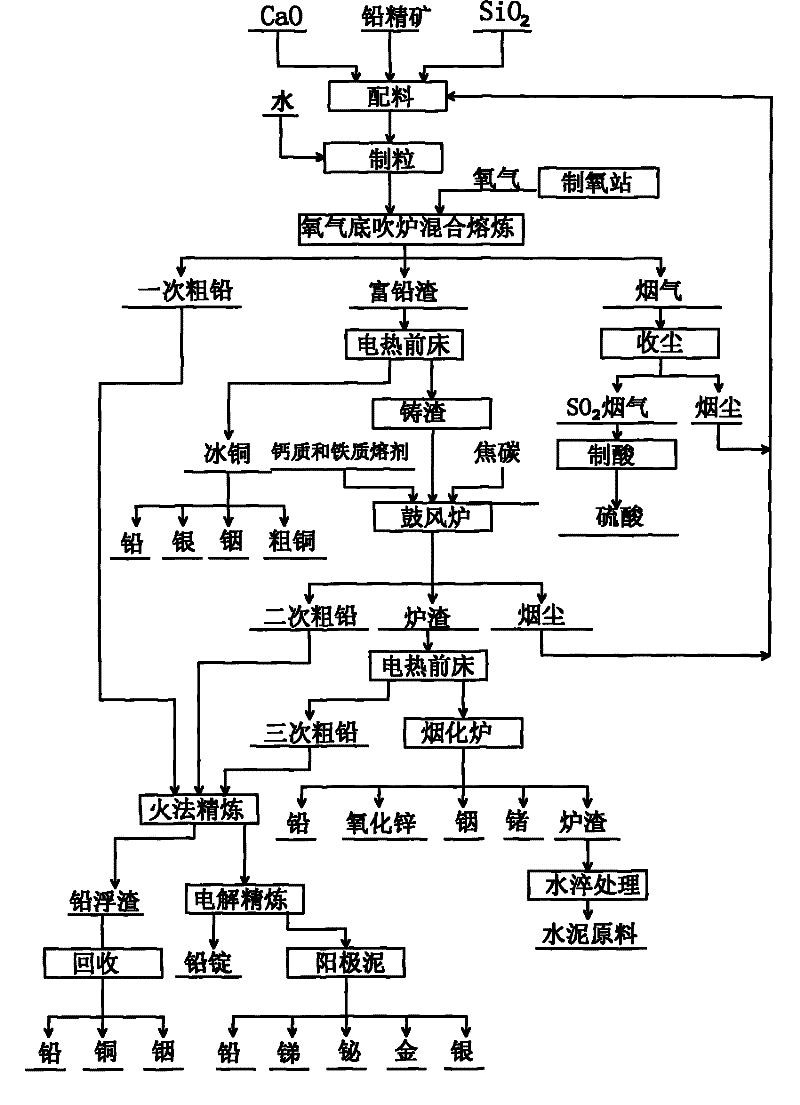

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

Preparation method of spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide

InactiveCN102142547AImprove liquidityFully dispersedAlkaline accumulator electrodesLithium hydroxidePhysical chemistry

The invention relates to a preparation method of a spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide, comprising the following steps: heating cobalt hydroxide coated spherical nickel hydroxide which is utilized as a precursor, and spraying an alkali metal hydroxide aqueous solution; evenly mixing the precursor with the alkali metal hydroxide aqueous solution; introducing oxygen to oxidize the cobalt hydroxide to convert the cobalt hydroxide into high-valency gamma-hydroxy cobalt oxide; and during oxidation, combining mechanical agitation and ultrasonic agitation to prevent the spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide from gathering and cause alkali metal ions to be embedded into a crystal lattice with the laminated structure of the gamma-hydroxy cobalt oxide. After oxidation reaction is over, a lithium hydroxide alkaline solution at certain temperature is added into an oxidation reaction pot to carry out heat preservation on the spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide; when heat preservation is carried out, mechanical agitation and ultrasonic agitation are adopted to cause the lithium ions to be embedded into the laminated structure of the gamma-hydroxy cobalt oxide; and the obtained spherical nickel hydroxide anode material coated with gamma-hydroxy cobalt oxide is screened by an ultrasonic sieve shaker after being washed and dried.

Owner:JIANGMEN CHANCSUN UMICORE IND

Method for preparing chromium salt

The invention discloses a method for preparing chromium salt. The method is characterized by comprising the following steps: sufficiently and uniformly mixing a raw material containing chromium oxide (chrome ore or chromium slag) with sodium carbonate, carrying out oxidizing roasting at the roasting temperature of 900-1100 DEG C for 0.5-2.5 hours in an atmosphere with the oxygen content of higher than 20% by using microwaves as a heat source, leaching the roasted product with water, and preparing chromium salt from the leach solution. The chemical analysis on the clinker and leaching slag indicates that the insoluble waste slag contains less than 5% of chromium (on the basis of chromic oxide). The method reduces the chromium content in the discharged chromium slag, enhances the chromium utilization ratio in the chromium salt production process, effectively saves the chrome ore resources, and has obvious advantages of resource saving and environmental protection by using the microwaves as the heat source instead of the traditional coal and natural gas heating.

Owner:LIAONING SING HORN GROUP CO LTD

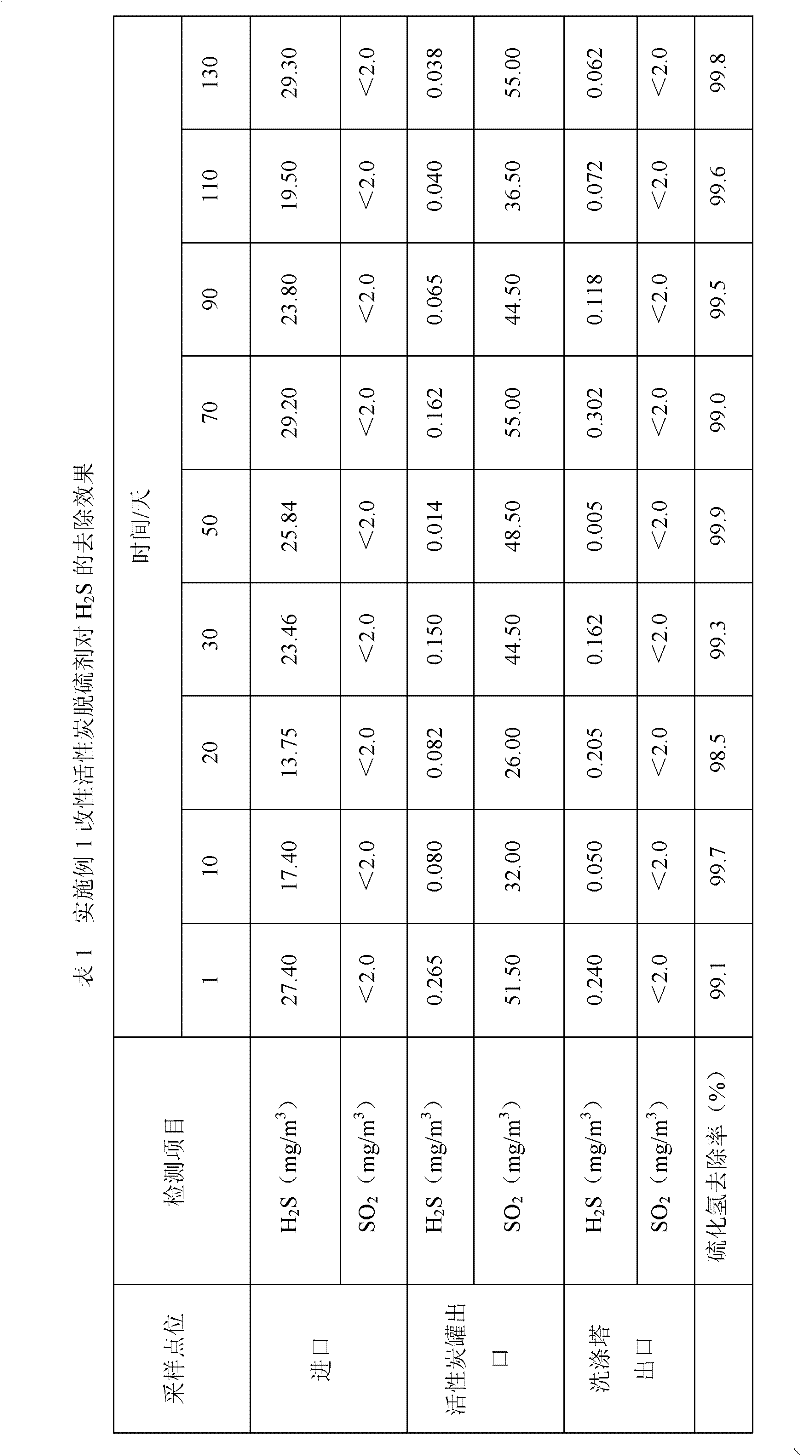

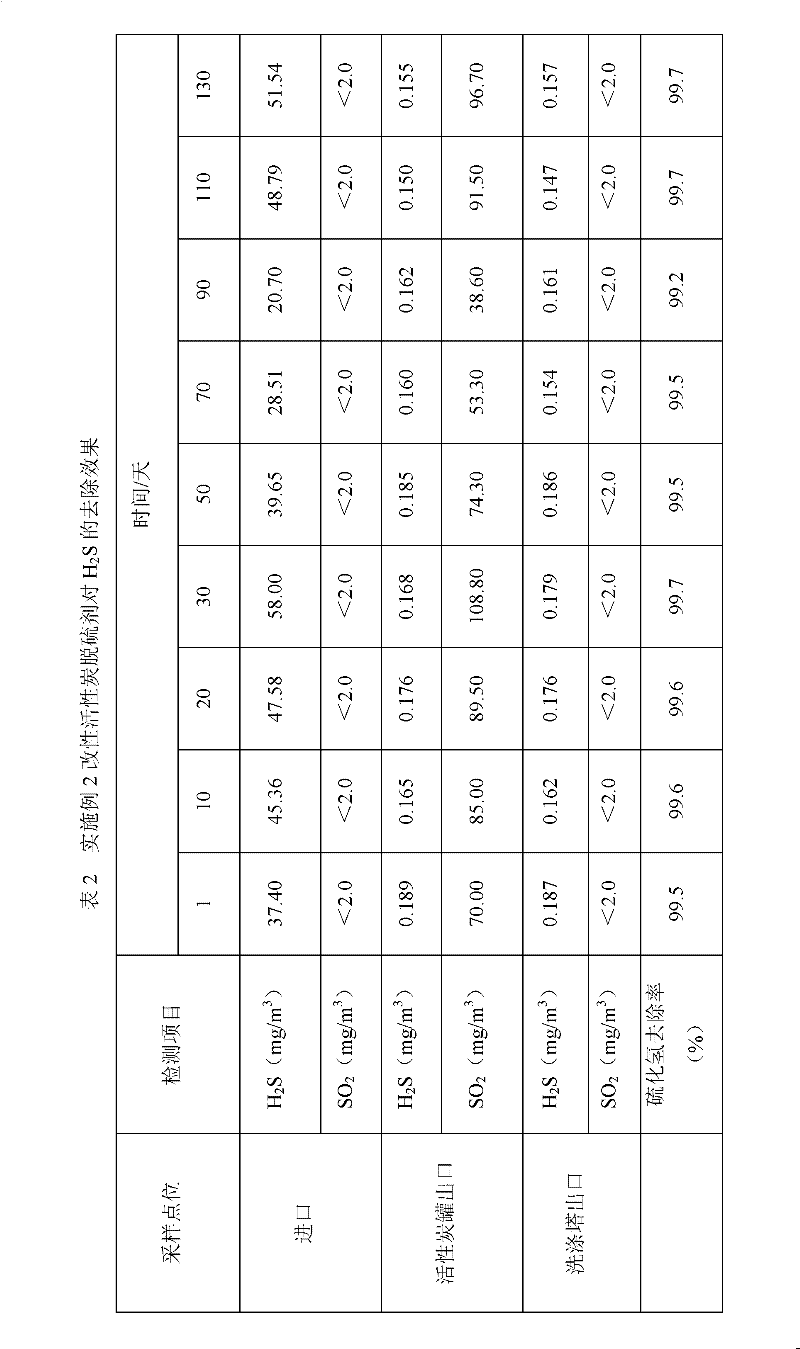

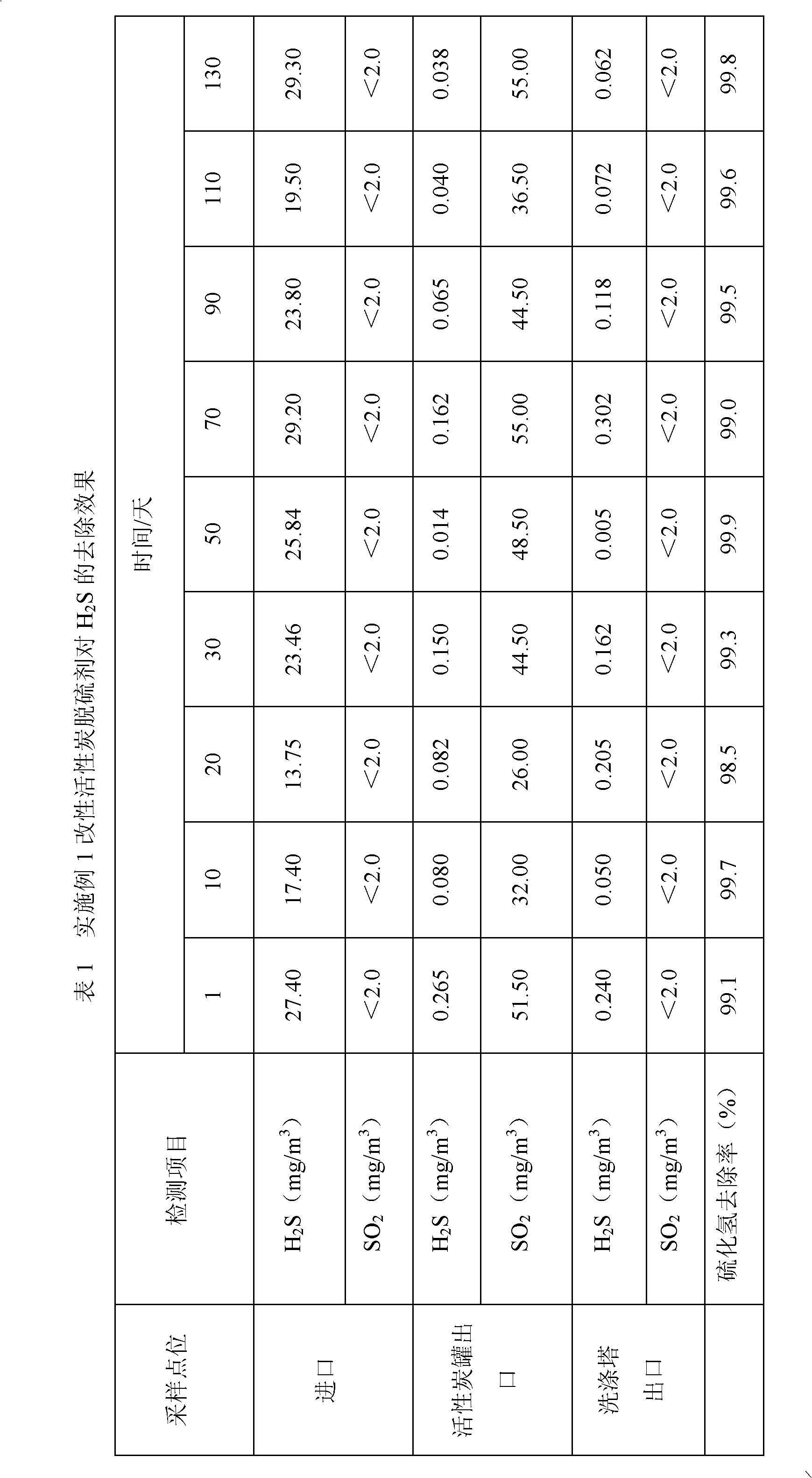

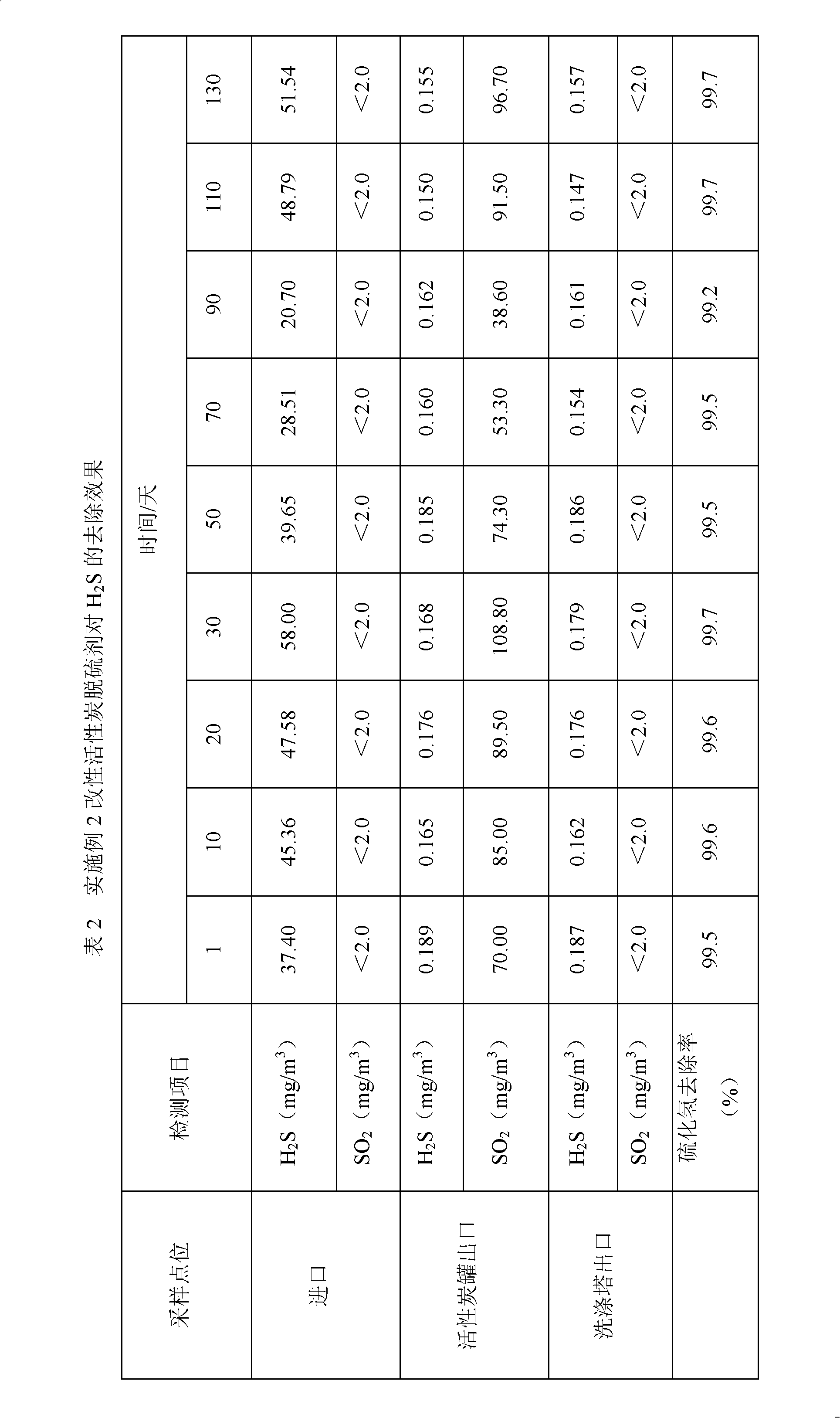

Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

InactiveCN102500323AEasy accessLow costPhysical/chemical process catalystsOther chemical processesActive agentCatalytic oxidation

The invention belongs to the technical field of waste gas desulfurization and purification, particularly provides a modified active carbon desulfurizer and a preparation method thereof, and a hydrogen sulfide waste gas treatment method using the desulfurizer. The modified active carbon desulfurizer is prepared from impregnating activated carbon with active agent mixed solution comprising phenol, acetone, sodium carbonate, ferric nitrate and organic solvent, and drying and roasting the mixture. The modified active carbon desulfurizer converts the hydrogen sulfide in the waste gas into sulfur dioxide at atmospheric temperature and pressure under the absorption and catalytic oxidation action, and the sulfur dioxide is converted into SO42- in water phase by washing and removed. The waste gas treatment method uses the modified active carbon desulfurizer, and prevents the defects that the desulfurizer needs to be regularly desorbed and regenerated due to blockage caused by adsorption saturation and generated elemental sulfur. Compared with an ordinary activated carbon desulfurization process, the process has the advantages of high hydrogen sulfide removal rate, long service life of the desulfurizer, low operation cost, simplicity in operation and management and the like.

Owner:北京天灏柯润环境科技有限公司

Mixed desalination method and device for wastewater

ActiveCN103193309AEasy dischargeReduce solubilityWater/sewage treatment by oxidationWater treatment systemPretreatment method

The invention provides a desalination pretreatment method and device for raw wastewater before entering a reactor. The device and the method are as below: raw wastewater is mixed with a small amount of an oxidizer; the temperature is adjusted to a supercritical state; and the salt components are separated. Most salts dissolved in the raw wastewater can be removed through the device and the method provided by the invention to prevent clogging of a subsequent supercritical water treatment system for raw wastewater. Besides, a corrosion resistant / abrasion resistant lining can be arranged to realize corrosion / abrasion resistant effect, so as to prolong the service life of the device.

Owner:ENN ENVIROTECH CO LTD

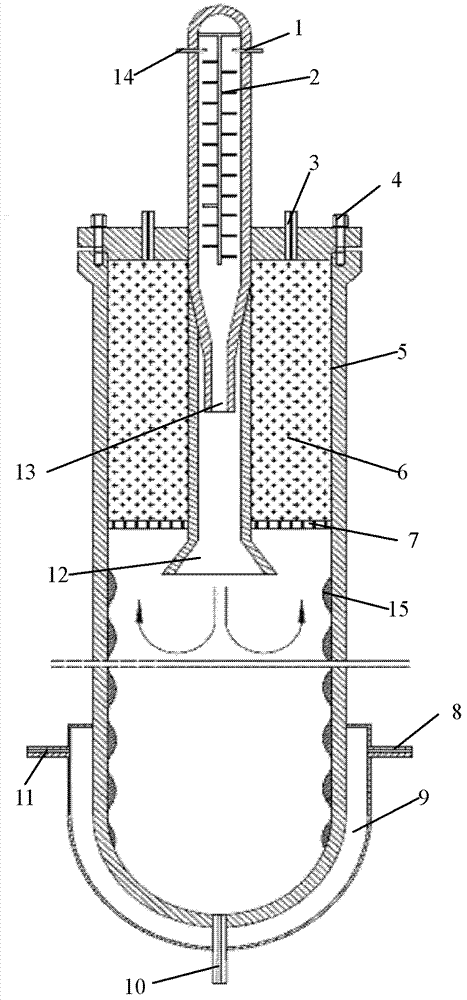

Treatment process for arsenic sulfide containing material

InactiveCN108315571AShort processHigh recovery rateProcess efficiency improvementChemistrySulfur dioxide

The invention discloses a treatment process for an arsenic sulfide containing material. The treatment process for the arsenic sulfide containing material comprises three main steps: pulpifying of theraw material, oxygen pressure acid leaching, and reducing and separating. The liquid-solid mass ratio is 3:1 to 10:1 in the pulpifying of the raw material, the pulpifying lasts for 2-4 hours at the temperature of 80-100 DEG C; the oxygen pressure acid leaching lasts for 2-4 hours at the temperature of 90-180 DEG C at the pressure of 0.1-3 MPa at the speed of 100-3000 r / min; an arsenic containing leaching agent is reduced and separated through sulfur dioxide, sodium thiosulfate or sulfite, and is then secondarily pulpified and separated to obtain a sulfite product. The arsenic content in a leaching residue is less than 5%, the recovery rate of arsenic is more than 80%; a surfactant is added in the pulpifying process, so that the oxidation reaction is more thorough; a vacuum pulpifying tankprovided with an exhaust system is used to prevent the waste gas from overflowing, and is beneficial for improving the operation environment. The technological process is short, and the treatment process has the advantages of environmental protection, economical efficiency, energy saving, and efficient utilization of resources, etc.

Owner:CHINA NERIN ENG

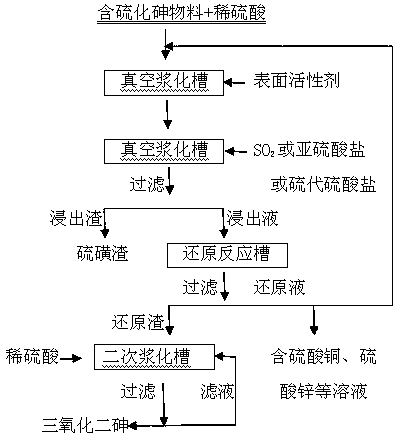

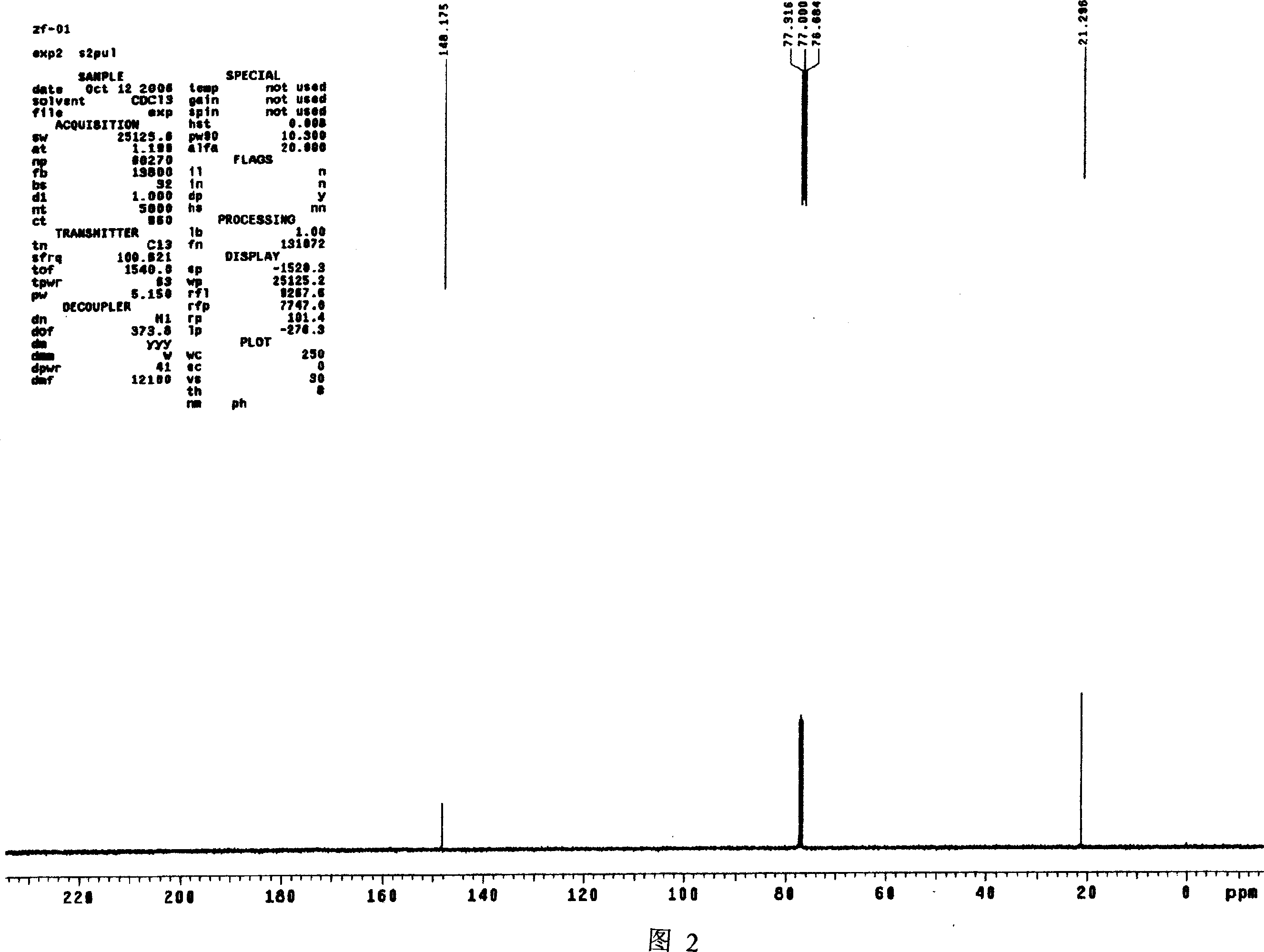

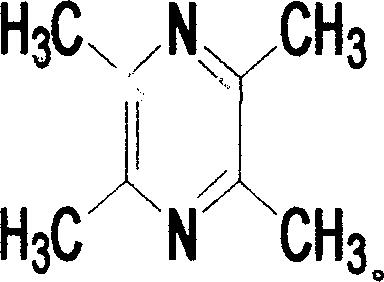

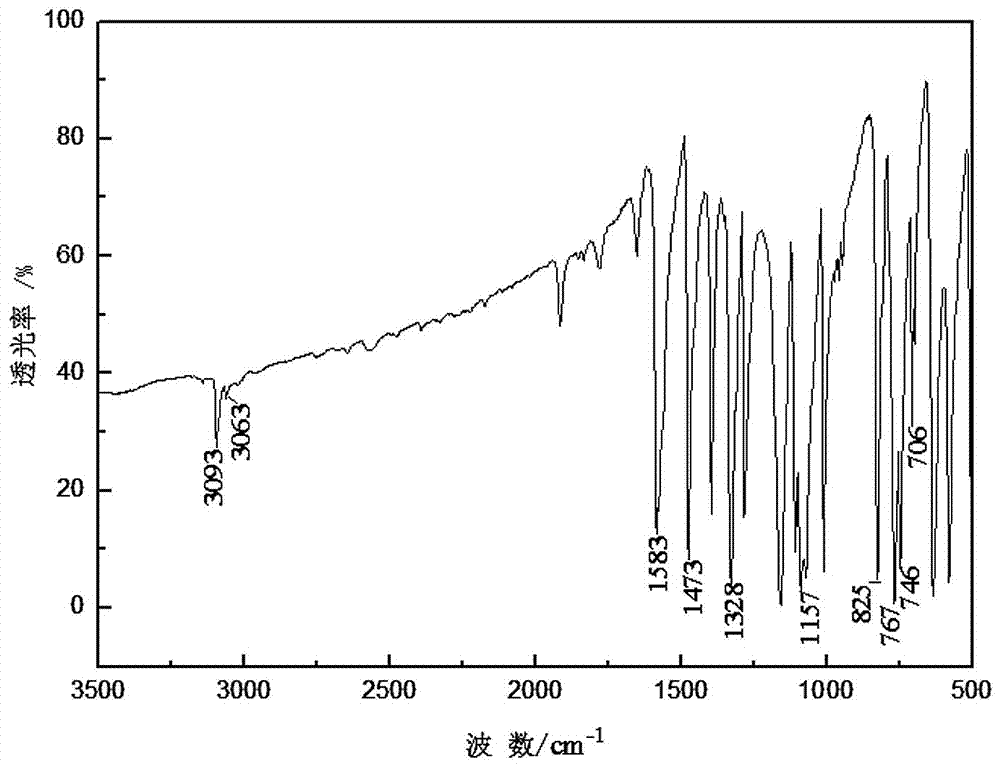

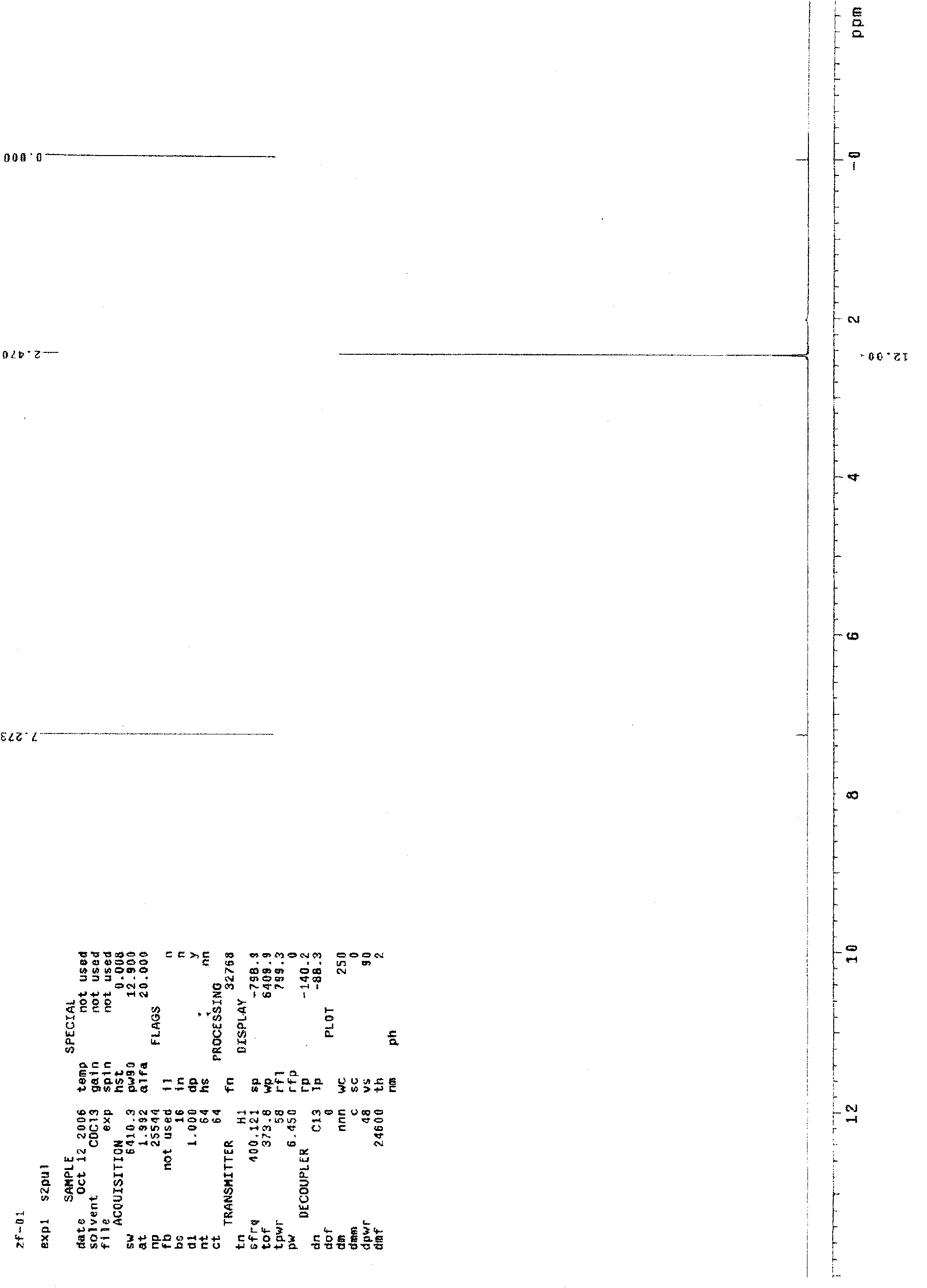

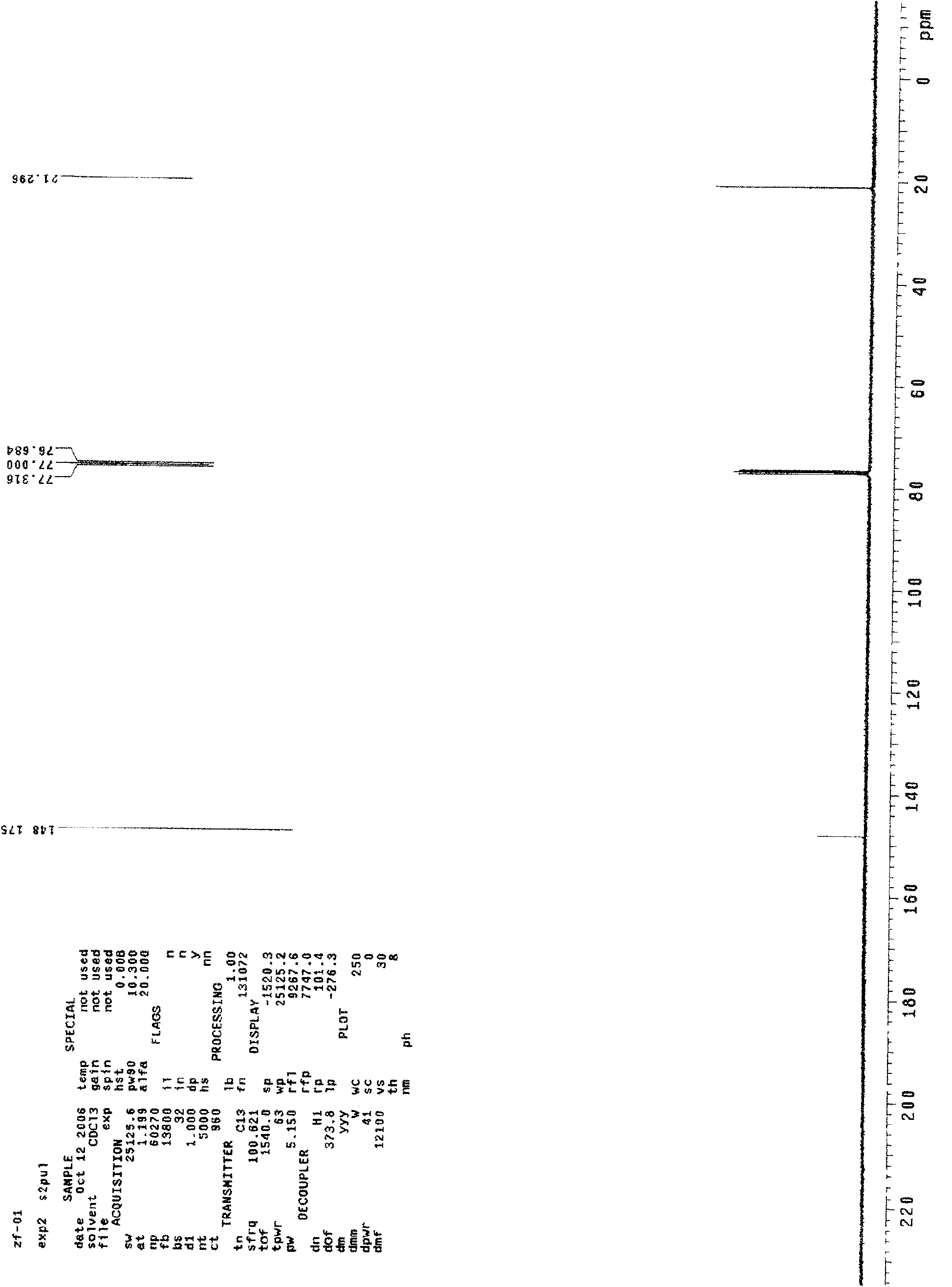

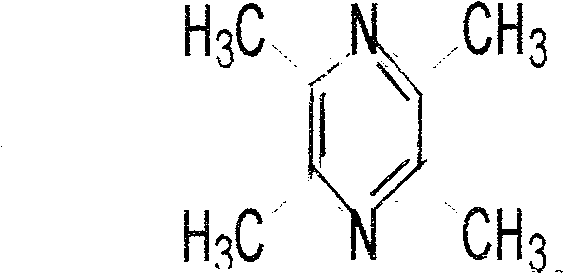

Method for preparing tetramethyl pyrazine

InactiveCN1935794AThorough responseResidue reductionOrganic chemistryTetramethyl pyrazineNitrogen gas

The invention relates to a Chuanxiongzine preparing method, comprising the steps of: using 3-hydrox-2-butanone and ammonium acetate as raw materials, adding in alcohol, charging nitrogen gas, and blending in hot bath for 5-8 h; on air or oxygen condition, blending for 12 h; adding in oxidant, and blending for 1-2 h, where the weight ratio of oxidant to 3-hydrox-2-butanone = (0.5-1):1; and filtering out the remaining oxidant; vacuum-distilling to make it. And the method has high yield. And the organic solvent utilization in the preparing course is less, beneficial to environmental protection. And the invention has advantages of low cost and simple operation.

Owner:张锋

Treatment method of cyanogen-containing waste residue

The invention discloses a treatment method of cyanogen-containing waste residue. The method comprises the steps of (1) adjusting alkali, wherein the pH value of the leachate of the waste residue after alkali is adjusted is 10-13; (2) breaking cyanogen, feeding a chlorine-containing cyanogen-breaking reagent into a stirring reaction kettle in a stirring state; (3) pelleting, feeding slaked lime powder and calcined gypsum powder into the material obtained after the cyanogen-breaking reaction in the step (2) in a stirring state, and mixing to enable the material in the stirring reaction kettle to form uniform spherical particles; and (4) drying and curing, naturally drying the particles in the stirring reaction kettle for 1-2 days after pelleting in the step (3), and curing. According to the method, cyanogen is broken by a chlorination process under the alkaline condition, so that the cyanide removal effect is good; after the oxidation reaction of the cyanide is finished, the salinity is cured in the particles instead of entering a waste water system; during stirring, two-section frequency is applied, so that the formed particles are even in sizes; during pelleting, gypsum is fed, so that the strength of the particles is greatly improved, and the construction in a landfill is more easily carried out.

Owner:扬州杰嘉工业固废处置有限公司

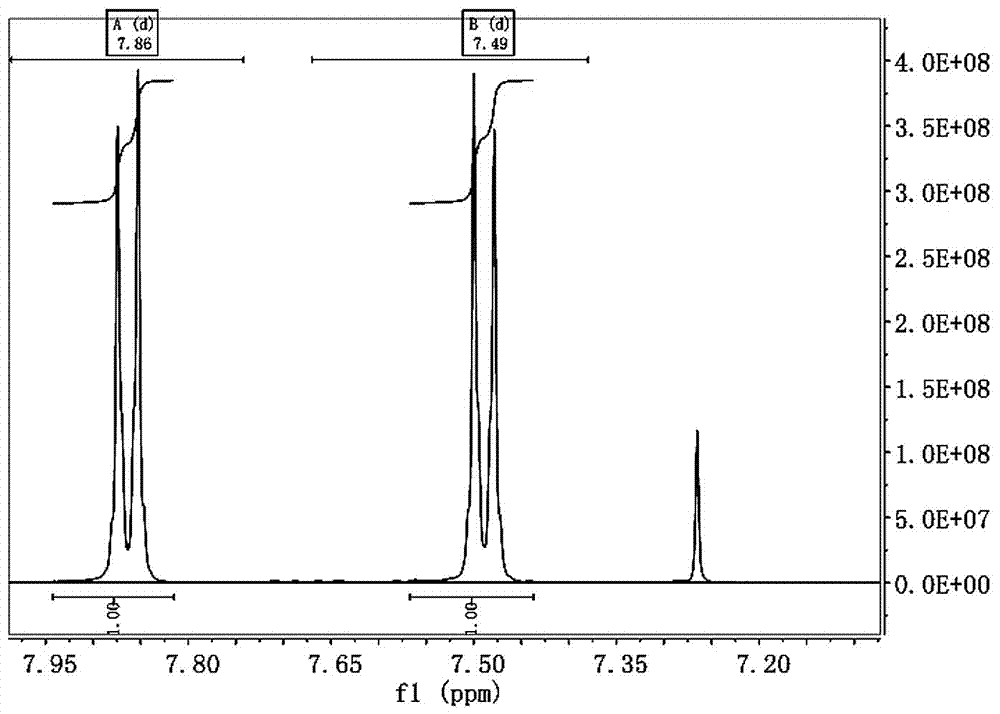

Preparation method for 4,4'-dichlorodiphenyl sulfone

InactiveCN107540581AQuality improvementComplete oxidation reactionOrganic chemistryOrganic compound preparationMedicinal chemistrySulfone

The invention provides a preparation method for 4,4'-dichlorodiphenyl sulfone. According to the invention, 4,4'-dichlorodiphenyl sulfoxide is used as a raw material; formic acid or glacial acetic acidis used as a reaction medium; and an acid peroxide oxidizing agent corresponding to the composition of the reaction medium is used for an oxidation reaction so as to prepare 4,4'-dichlorodiphenyl sulfone. The preparation method has better effect than traditional methods using hydrogen peroxide as an oxidizing agent, and is simple and easily practicable.

Owner:CHENGDU HUIEN FINE CHEM

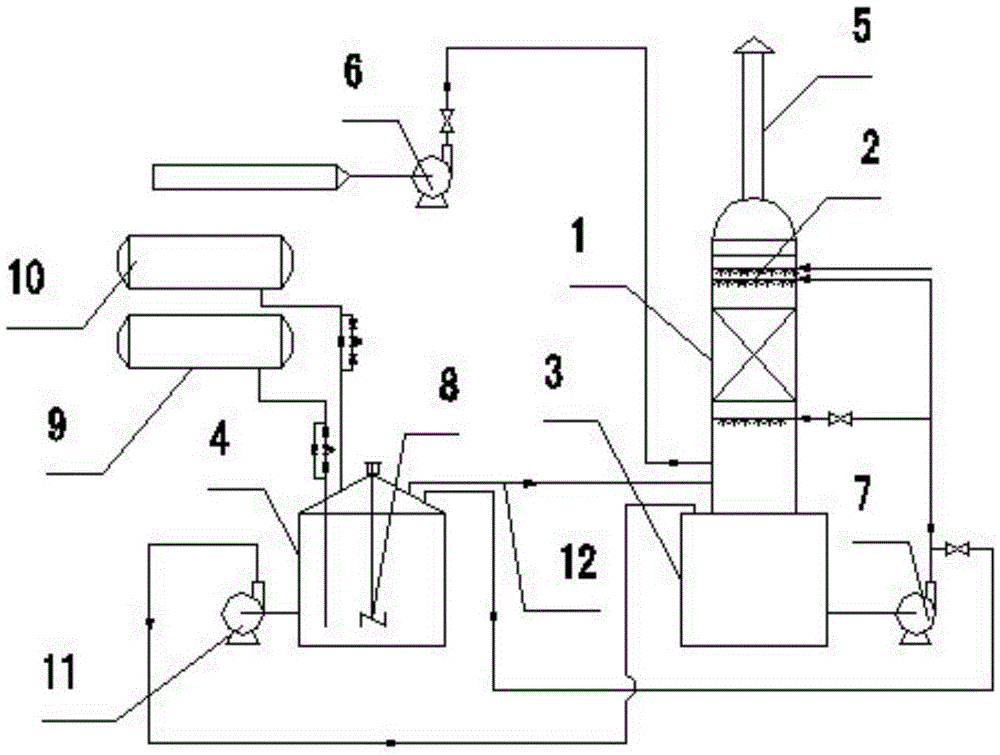

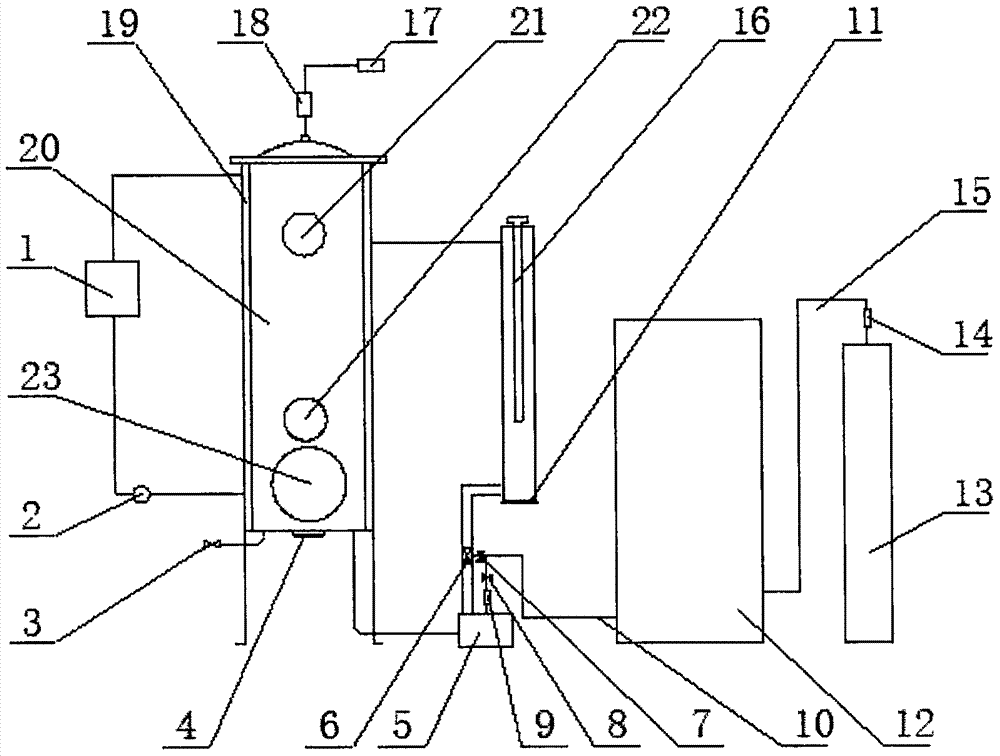

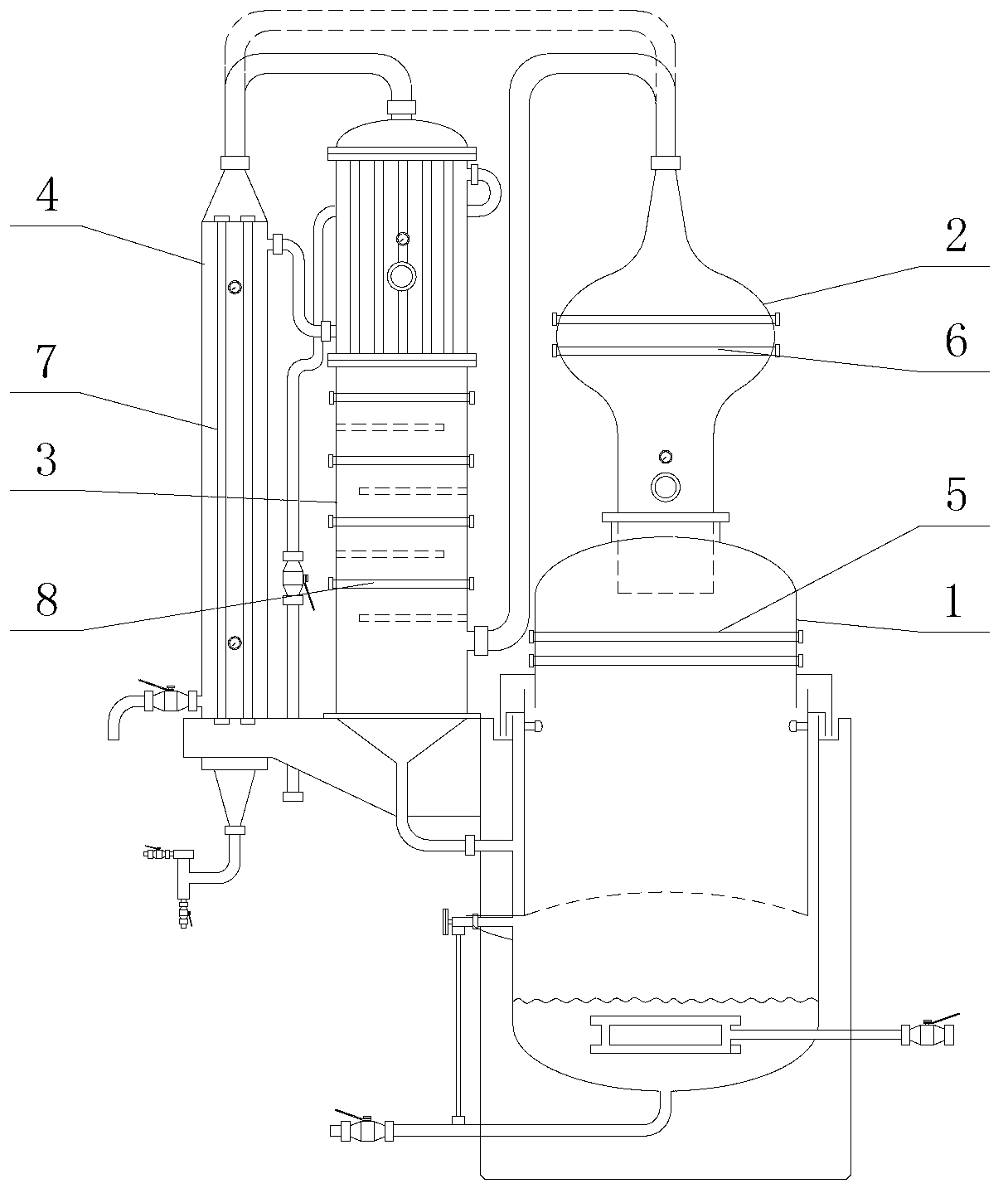

Low concentration formaldehyde waste gas oxidation treatment process and special equipment

InactiveCN105617846AComplete oxidation reactionImprove absorption rateCombination devicesIndustrial gasEnvironmental engineering

The invention relates to a low concentration formaldehyde waste gas oxidation treatment process and special equipment. A collection tower, a spray pipe component, a formaldehyde liquid circulation tank and a formaldehyde solution oxidation tank are arranged, wherein a chimney is arranged on the collection tower, the formaldehyde liquid circulation tank is arranged at the bottom of the collection tower, the spray pipe component is arranged at the upper part of the inside of the collection tower, an organic waste gas inlet pipe is arranged at the lower part of the collection part which is connected with an organic waste gas pipeline through a pipeline and a fan, and a liquid outlet is formed in the side wall of the formaldehyde liquid circulation tank. According to the low concentration formaldehyde waste gas oxidation treatment process and special equipment, by the aid of the characteristic that formaldehyde is very soluble in water, formaldehyde is absorbed by water, so that the formaldehyde waste gas concentration is reduced, waste gas standard emission is can be realized, at the same time, a formaldehyde concentration solution can be obtained after absorption, formaldehyde is decomposed into harmless carbon dioxide and water through oxidation of hydrogen peroxide, and the absorptivity of formaldehyde in industrial waste gas can be as high as 95% or above.

Owner:BEIJING HANQING ENERGY SAVING TECH CO LTD

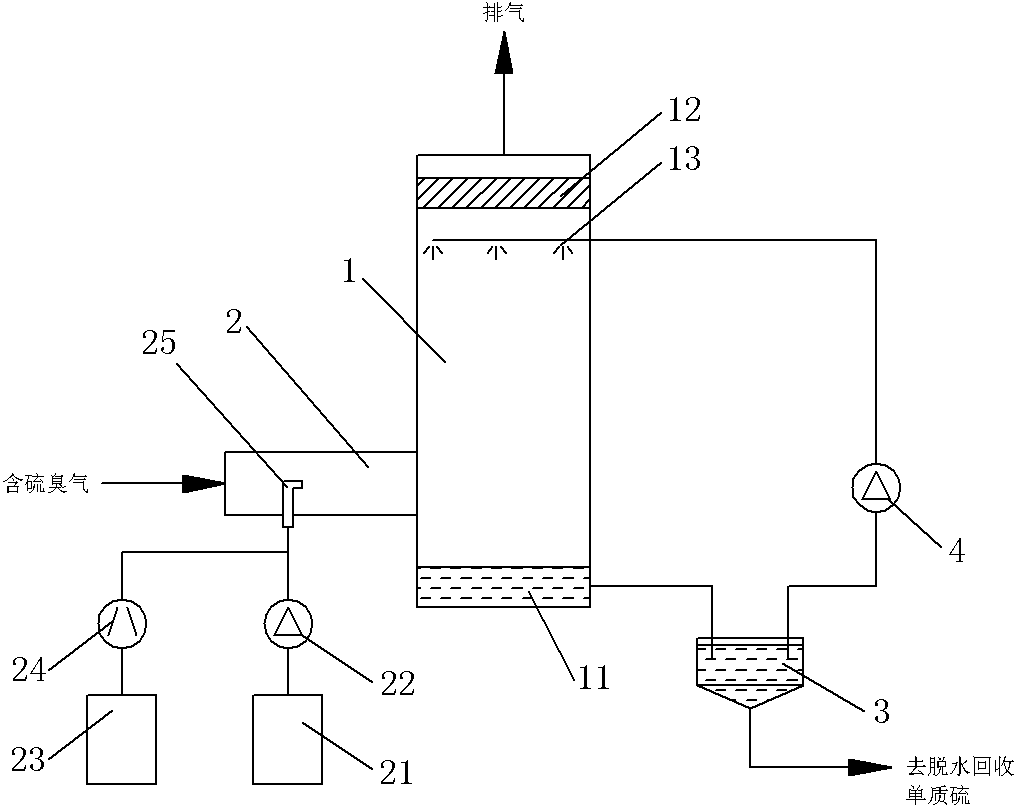

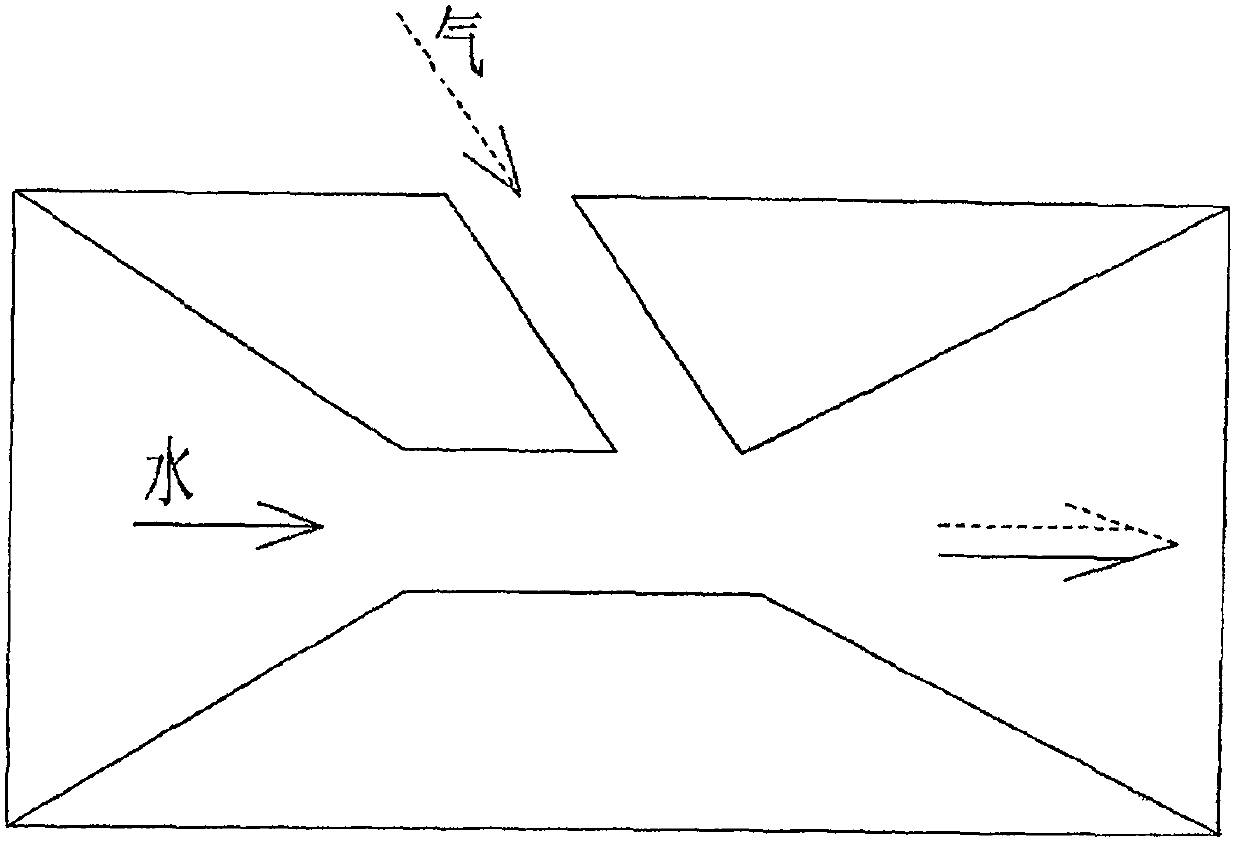

Wet oxidation desulfurization method and device

InactiveCN104275086AAchieve recyclingSolve technical problems with increased loadDispersed particle separationPollutionHydrogen peroxide

The invention discloses wet oxidation desulfurization method and device capable of removing hydrogen sulfide pollutants generated by a biochemical pool and the like. The wet oxidation desulfurization method disclosed by the invention comprises the following steps: (1) supercharging an ozone gas through a compressor, and supercharging a hydrogen peroxide solution through a booster pump; (2) mixing the supercharged ozone gas with hydrogen peroxide and then atomizing through an ejector; (3) spraying an odor gas containing hydrogen sulfide into a mixing pipe, simultaneously, spraying the atomized ozone gas and hydrogen peroxide mixture into the mixing pipe and mixing the mixture with the odor gas containing hydrogen sulfide; and (4) introducing a mixture of the odor gas containing hydrogen sulfide, the ozone gas and hydrogen peroxide into a spray tower for spraying through the mixing pipe. According to the wet oxidation desulfurization method, green and pollution-free ozone and hydrogen peroxide free of alkali are adopted as oxidants, and hydrogen sulfide can be oxidized into elemental sulfur by the oxidants, so that cyclic utilization of a sulfur element can be achieved, a by-product polluting the environment is not generated in the overall desulfurization process, and no brine waste is generated after the spray tower is washed.

Owner:NANJING UNIV

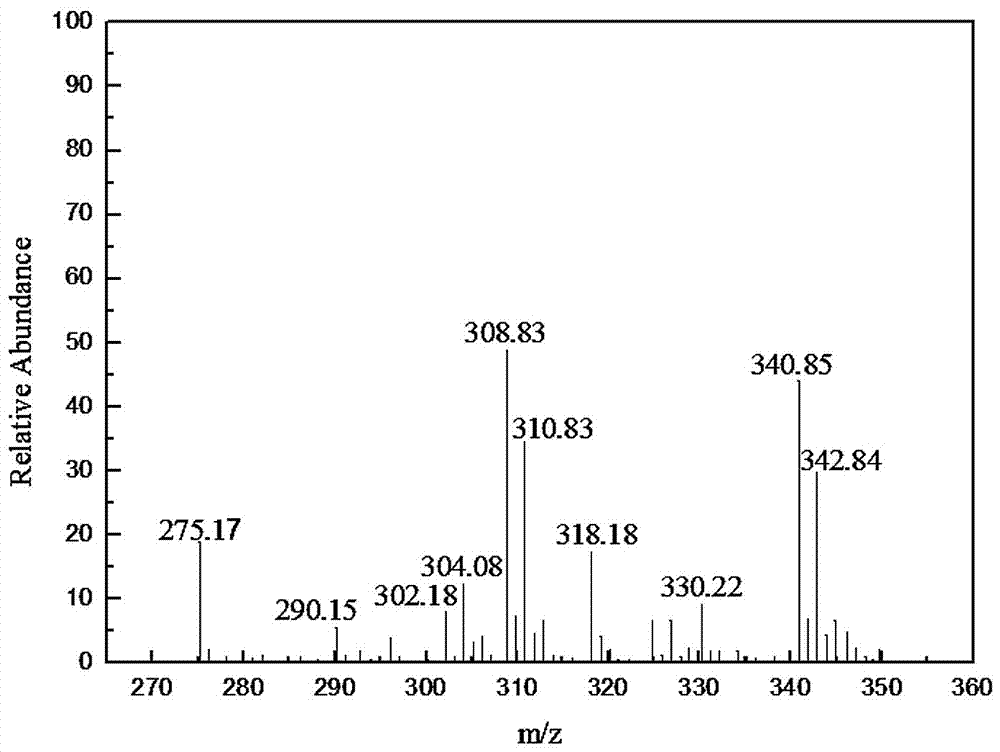

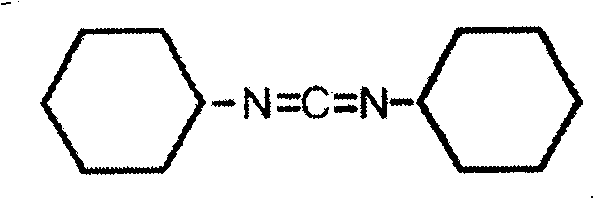

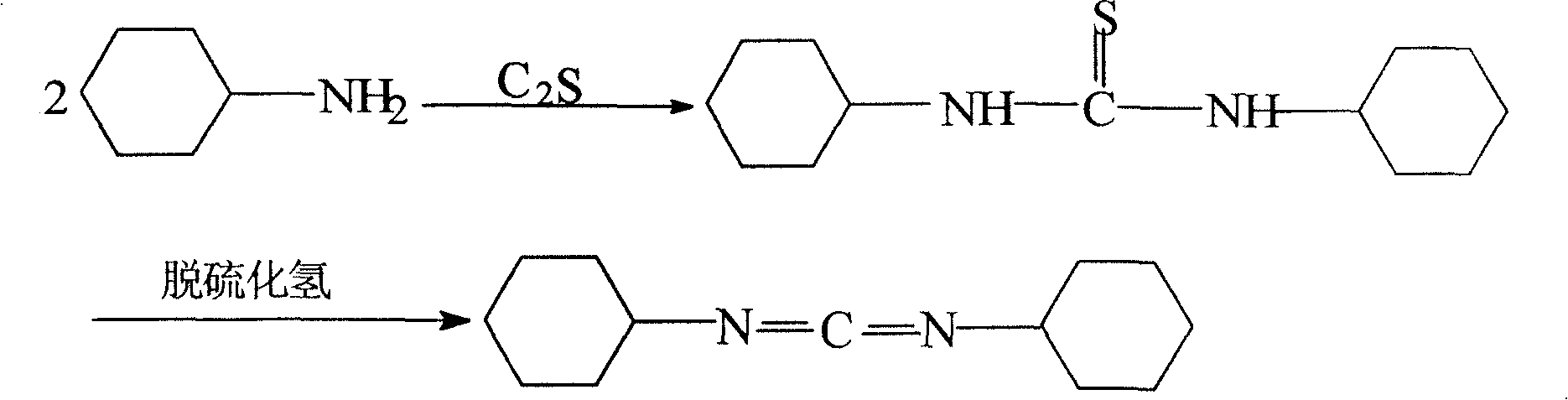

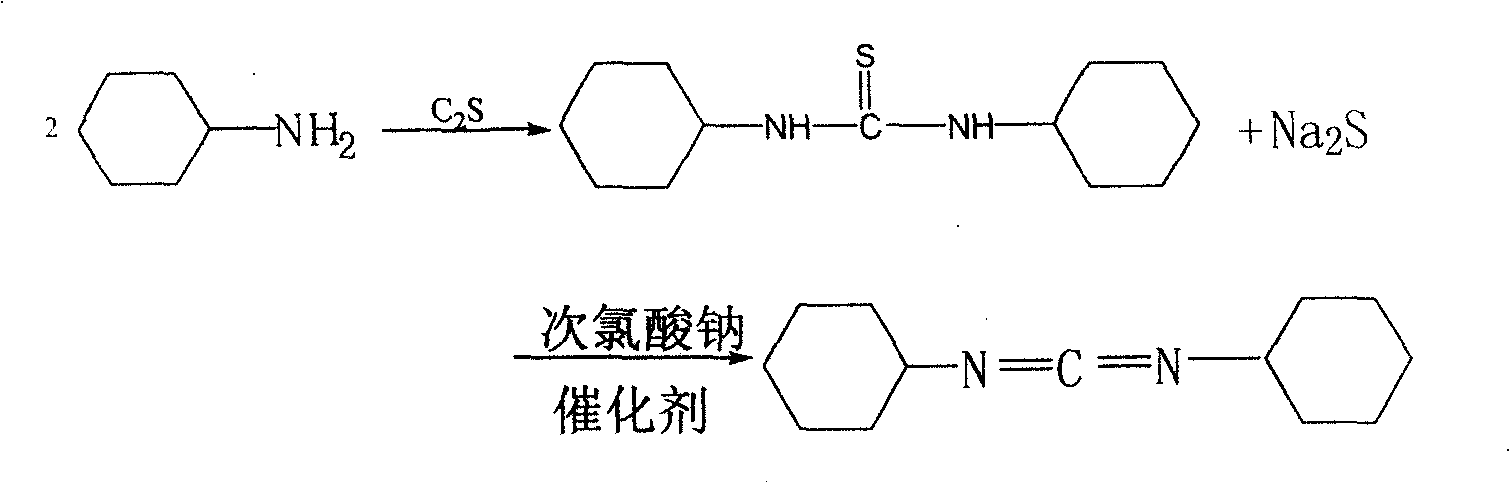

Production technique of N,N'-dicyclo hexylcar bodiimide

ActiveCN100434416CComplete oxidation reactionReduce manufacturing costImino compound preparationPolyethylene glycolCyclohexylamine

The invention discloses a production technology of N, N'-dicyclo hexylcar bodiimide, which comprises the following steps: generating dicyclohexyl sulfourea and sodium sulfide with cyclohexylamine and carbon bisulphide; generating N, N'-dicyclo hexylcar bodiimide by oxygenizing dicyclohexyl sulfourea twice with sodium hypochlorite and removing hydrogen sulfide. The invention is characterized by the following: adding the accelerant when dicyclohexyl sulfourea is oxygenized by sodium hypochlorite; applying triethyl benzyl ammonium chloride(TEBA)or carbowax as the accelerant; adding sodium sulfide which is generated in the first step reaction in order to removing sulfur by reacting with sulfur in the organic phase after oxygenizing twice. The invention guarantees the sufficient oxidation reaction, which reduces the production cost, and improves the product quality.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

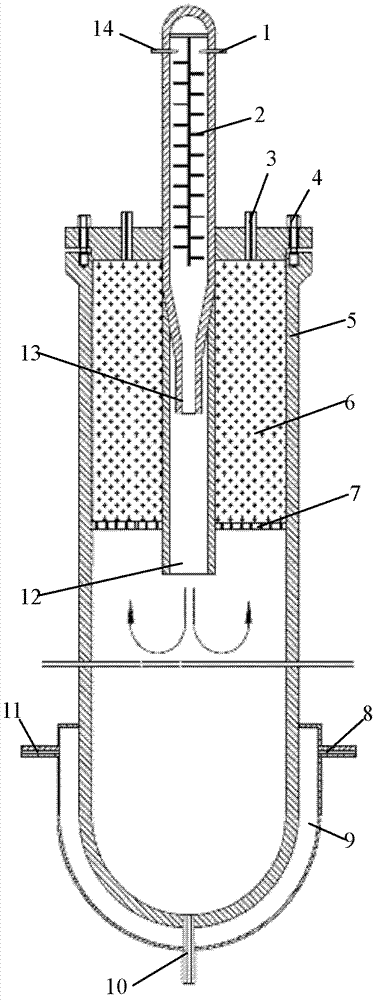

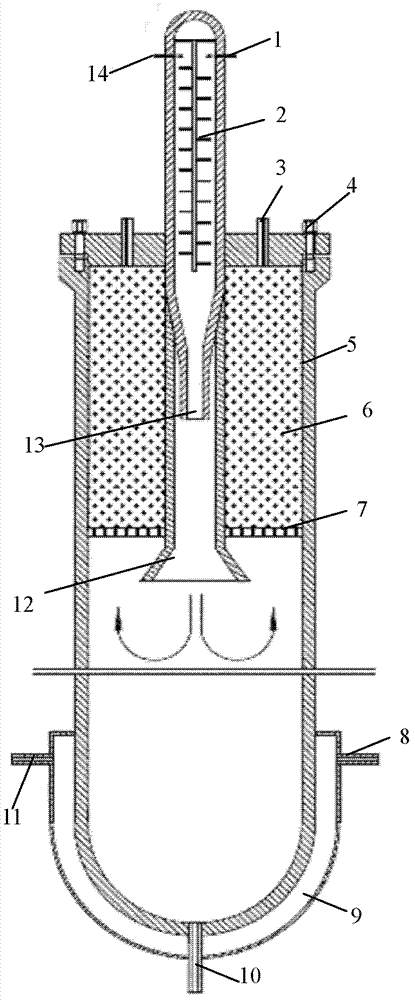

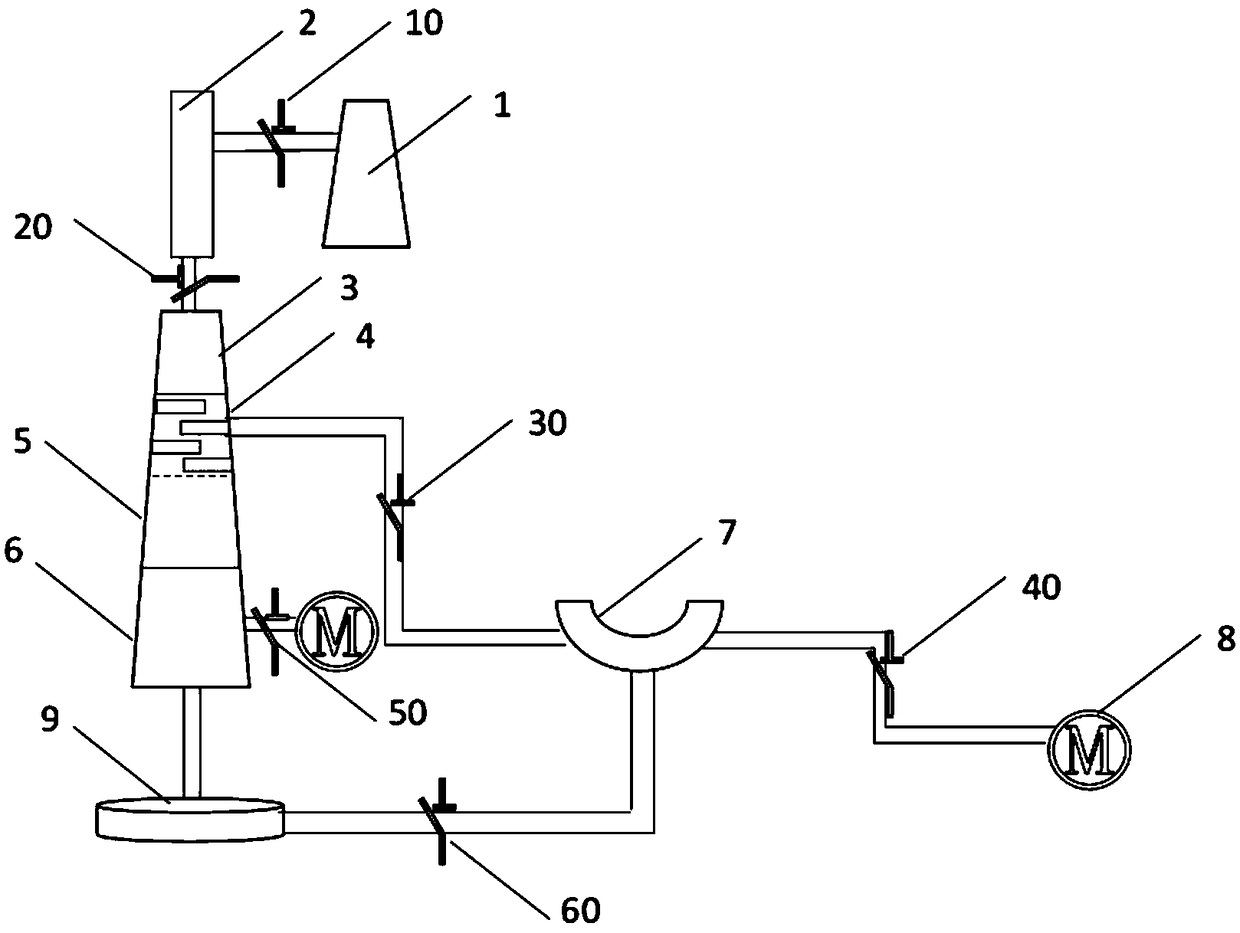

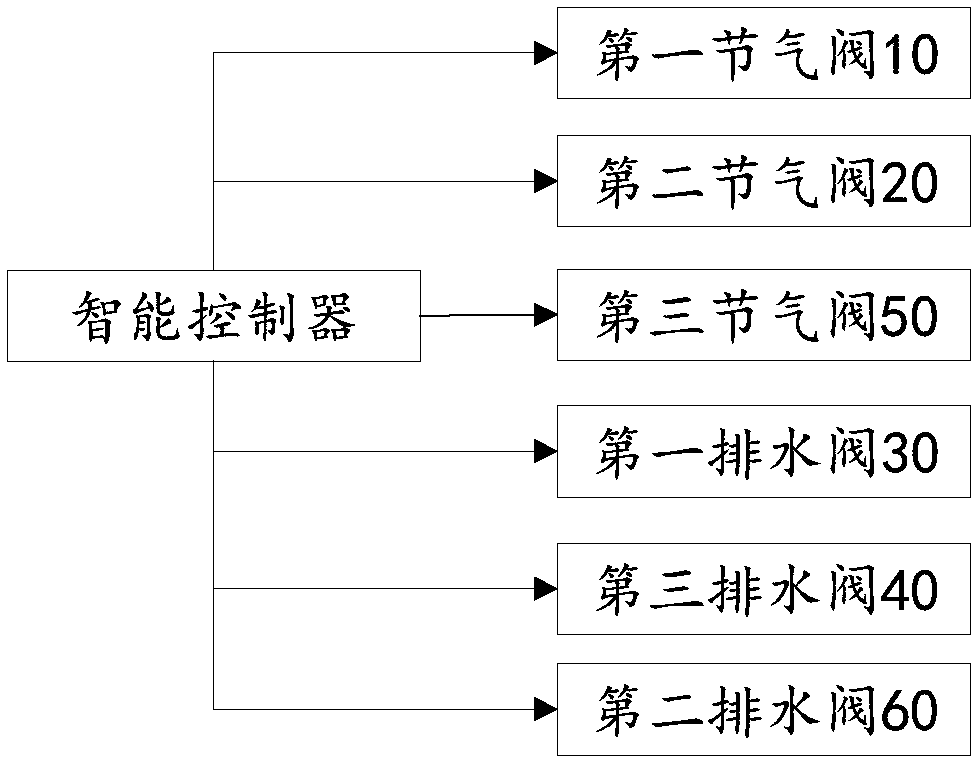

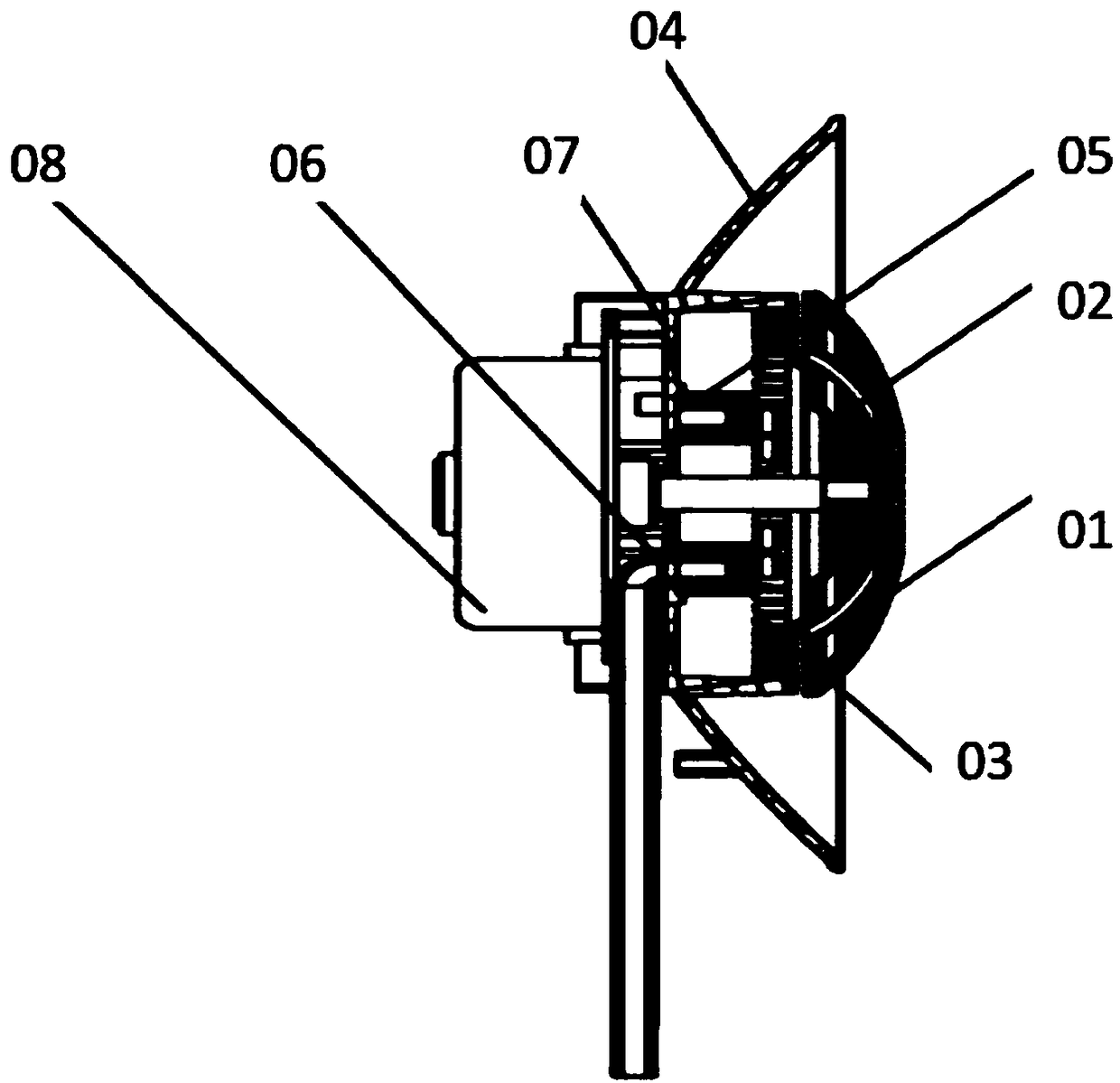

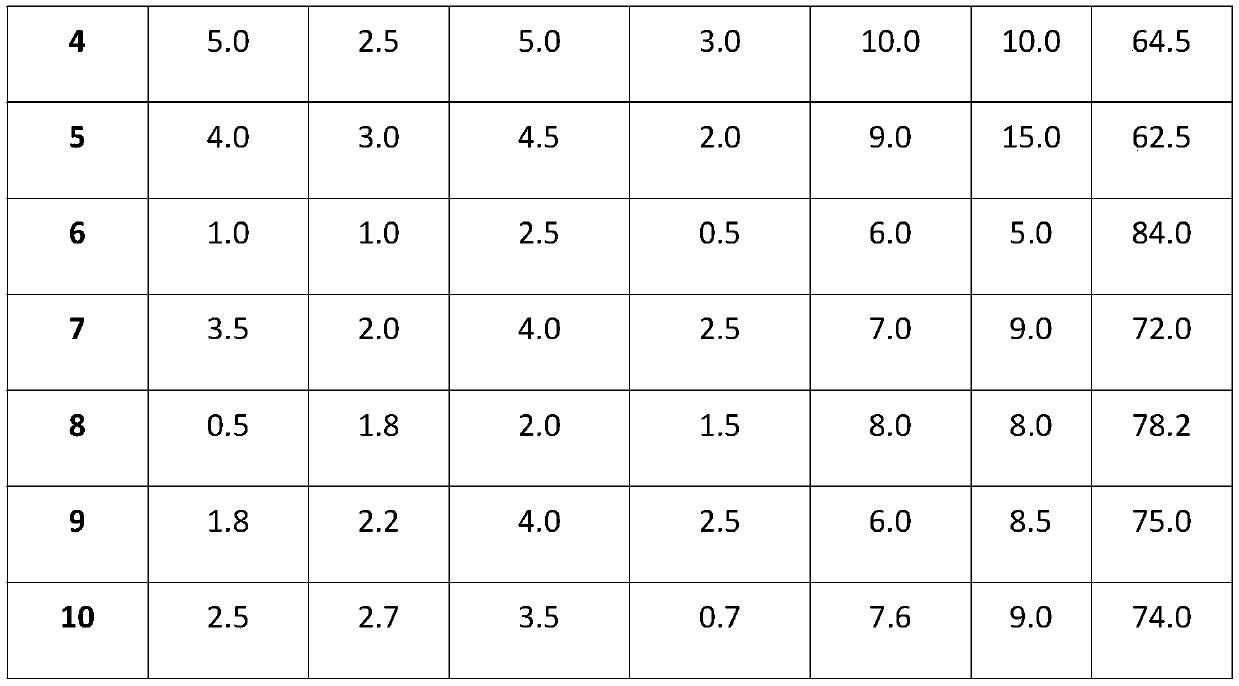

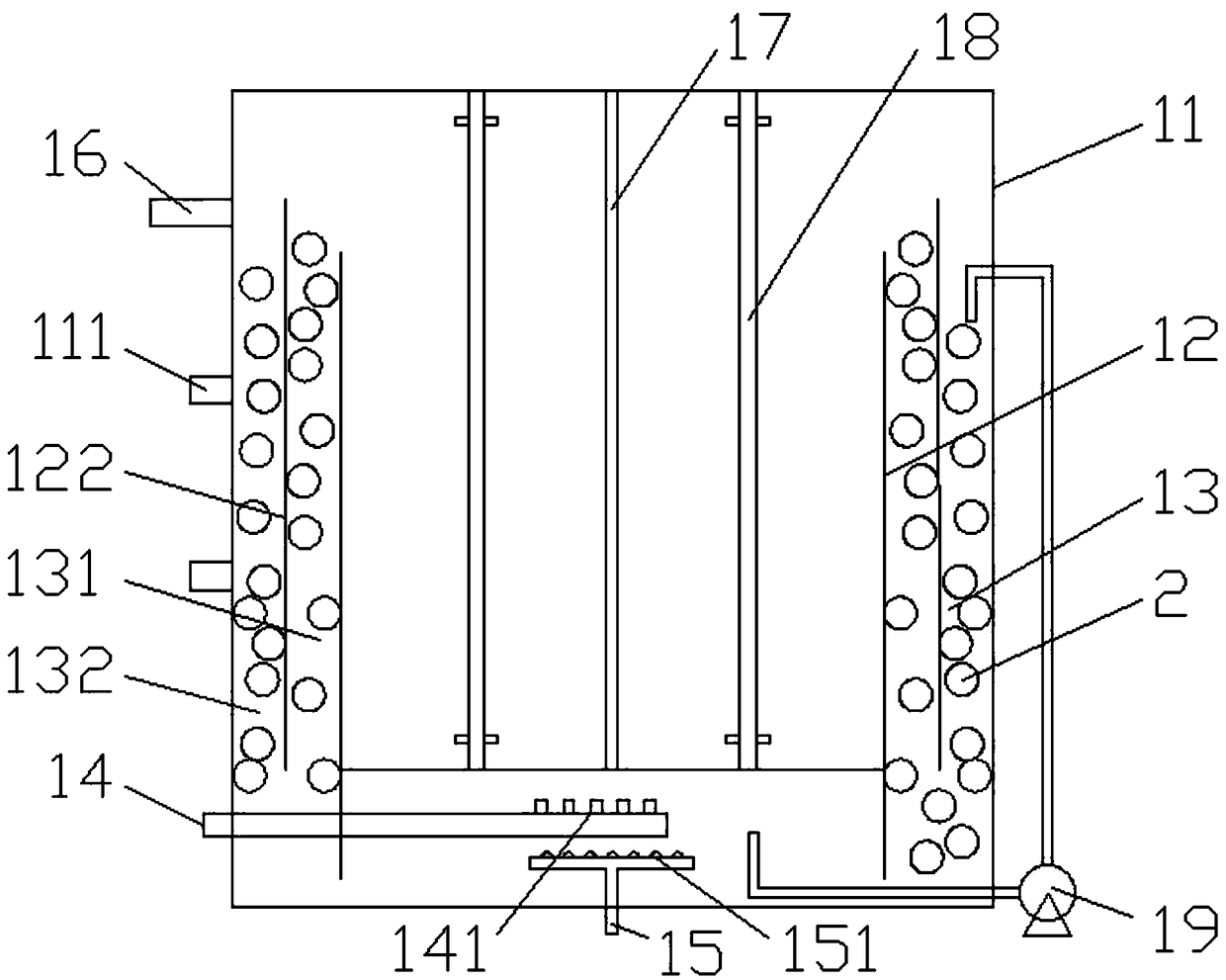

Production device and method for efficiently preparing ozonized oil

InactiveCN107057859AIncrease contactImprove dissolved oxygen efficiencyFatty acid chemical modificationEnergy based chemical/physical/physico-chemical processesExhaust valveVegetable oil

The invention relates to a production device for efficiently preparing trioxidized oil. The production device comprises an ozonized oil reaction tank, wherein the upper part of the ozonized oil reaction tank is provided with a feed port; the lower part of the ozonized oil reaction tank is provided with a view port and a material receiving port; the left side of the ozonized oil reaction tank is connected with a temperature controller and a cooling water pump; the cooling water pump is connected with a cooling water tank; the upper end of the ozonized oil reaction tank is connected with an automatic exhaust valve; and the automatic exhaust valve is connected with an ozonized tail gas destructor. The invention also relates to a method for efficiently preparing trioxidized oil. The method uses vegetable oil, and is characterized in that the vegetable oil is vegetable oil with high alpha-linolenic acid content and is composed of one or both of perilla oil and flaxseed oil. The method has the advantages of controllable ozone oxidization process and more thorough oxidization, implements large-scale industrial production, enhances the ozone utilization efficiency, and enhances the stability of the ozone oxidization product.

Owner:郑州中仁臭氧技术服务有限公司

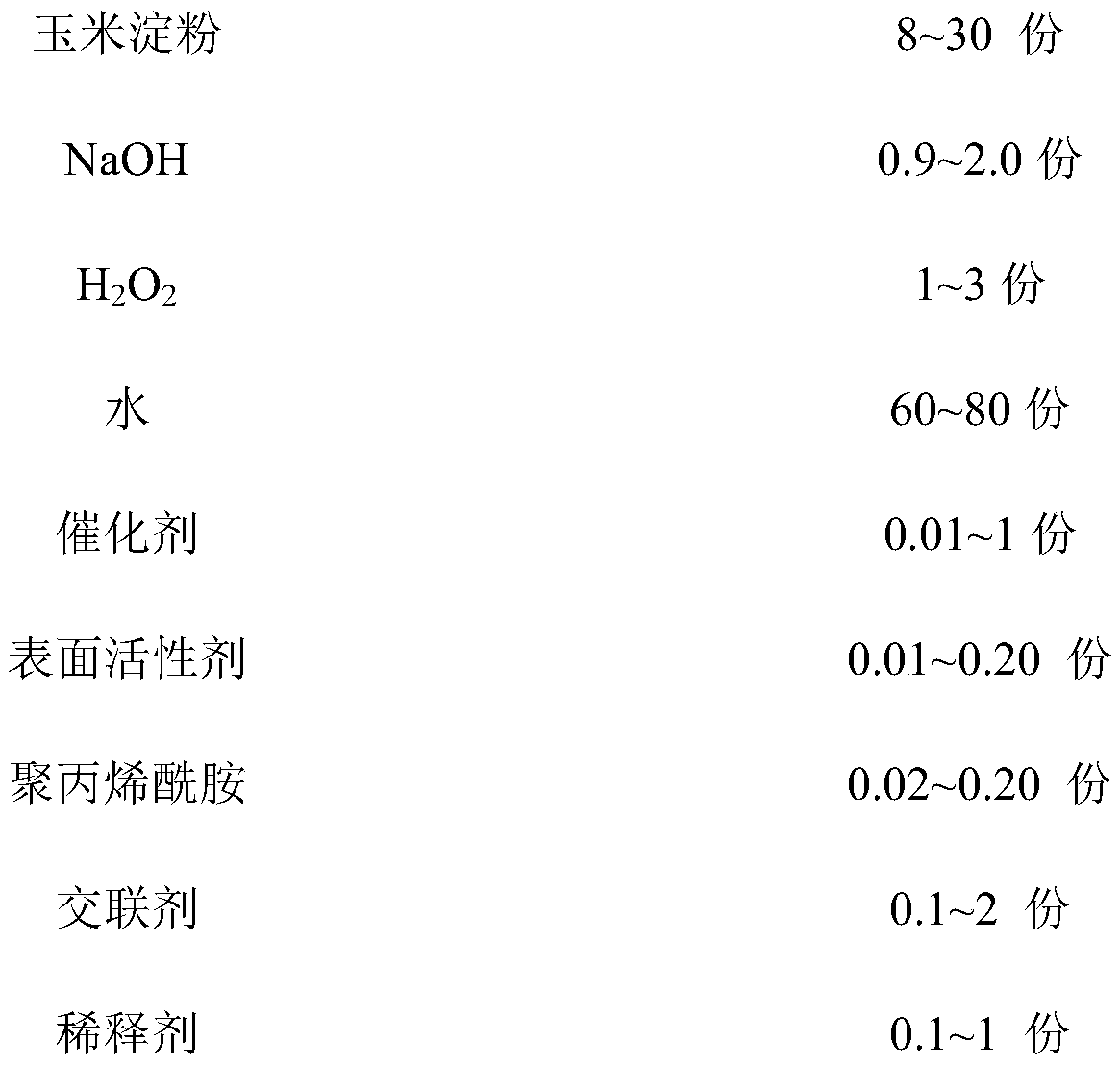

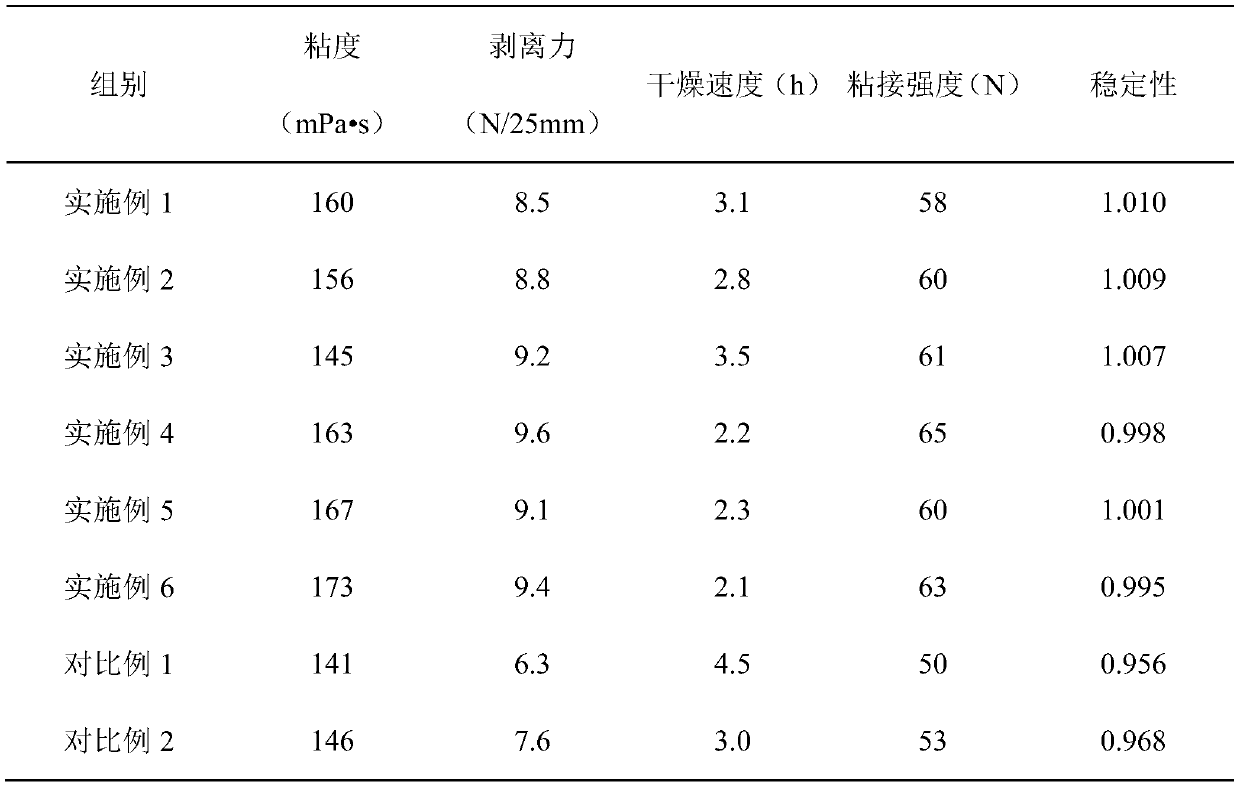

Oxidized corn starch adhesive and preparation method thereof

InactiveCN110804405AImprove initial tackExcellent adhesionNon-macromolecular adhesive additivesStarch derivtive adhesivesPtru catalystAdhesive

The invention discloses an oxidized corn starch adhesive and a preparation method thereof. The oxidized corn starch adhesive is prepared from the following raw materials in parts by weight: 8-30 partsof corn starch, 0.9-2.0 parts of NaOH, 1-3 parts of H2O2, 60-80 parts of water, 0.01-0.12 part of a catalyst, 0.01-0.20 part of a surfactant, 0.02-0.20 part of polyacrylamide, 0.1-2 parts of a cross-linking agent, 0.1-1 part of a diluent, 0.01-0.1 part of a defoaming agent, 0.1-5 parts of a drier and 0.01-0.5 part of a preservative. The preparation method comprises the following steps: pre-gelatinizing, oxidizing, gelatinizing, crosslinking and modifying the corn starch to obtain the oxidized corn starch adhesive; and the prepared oxidized corn starch adhesive is good in mechanical property,large in initial adhesion, high in adhesive force, high in drying speed and good in film-forming property and stability.

Owner:SHAANXI YUTENG IND

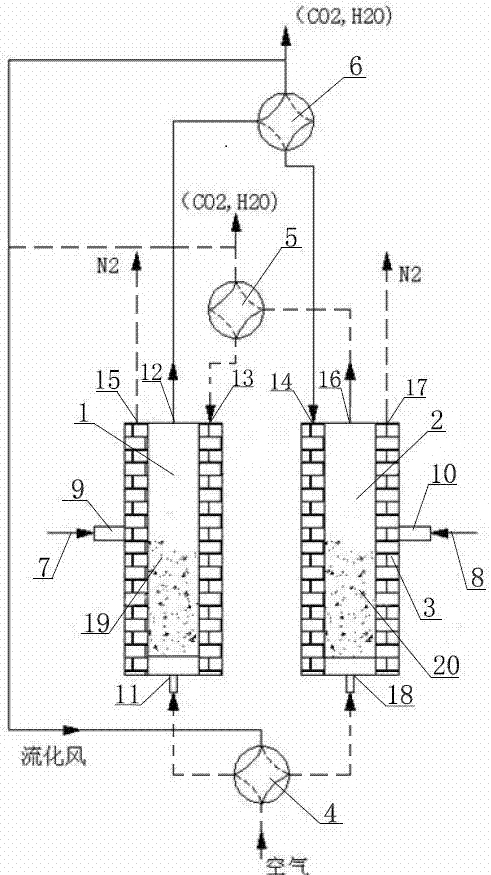

Device for treating sludge based on heat storage type chemical-looping combustion and method of device

PendingCN106996569AEliminate generationEmission reductionIndirect carbon-dioxide mitigationIncinerator apparatusPeriodic alternatingProcess engineering

The invention discloses a device for treating sludge based on heat storage type chemical-looping combustion and a method of the device, and belongs to the technical field of sludge treatment. The device comprises a reactor, a reversing valve, sludge conveying channels and a tail gas treatment device; the reactor comprises an oxidation reactor and a reduction reactor, a heat storage body is arranged on the periphery of the reactor, the reversing valve is arranged between the oxidation reactor and the reduction reactor, the sludge conveying channels are both formed in the oxidation reactor and the reduction reactor, and the reversing valve is connected with the tail gas treatment device. Through the oxidizing reaction, the reduction reaction and the tail gas treatment, generation of dioxin in the sludge incineration process can be removed, meanwhile, emissions of NOX and the like in the sludge incineration process can be reduced, smoke gas waste heat is used for greatly improving the energy utilization efficiency of the sludge incineration process, meanwhile, through reversing valve switching and intermittent sludge feeding, the reactor periodically and alternatively works, the work efficiency of the process is improved, and the cost is saved.

Owner:中国东方电气集团有限公司

Waste gas desulfurization system

InactiveCN108525501AComplete oxidation reactionEfficient removalCombination devicesElectrostatic separationParticulatesDraining tube

The invention discloses a desulfurization device. A dust removal chamber, an atomizing and spraying chamber, a sulfide absorbing chamber and a wastewater collecting chamber are arranged in the desulfurization tower from top to bottom separately; the dust removal chamber, the atomizing and spraying chamber, the sulfide absorbing chamber and the wastewater collecting chamber are sequentially in communication; the wastewater collecting chamber is communicated with a circulating water device; the device is further equipped with a circulating water device; the circulating water device comprises a circulating water extracting device; the circulating water extracting device is communicated with a circulating water condensing device; a water pump is communicated with the atomizing and spraying chamber through a plurality of water draining tubes; a first water draining valve is arranged on each water draining tube; an electrostatic dust remover is arranged in the dust removal chamber; and theair filter and the electrostatic dust remover are mounted inside the dust removal chamber. The dust removal chamber is arranged, so that particles such as dust contained in smoke gas can be efficiently removed.

Owner:丁武轩

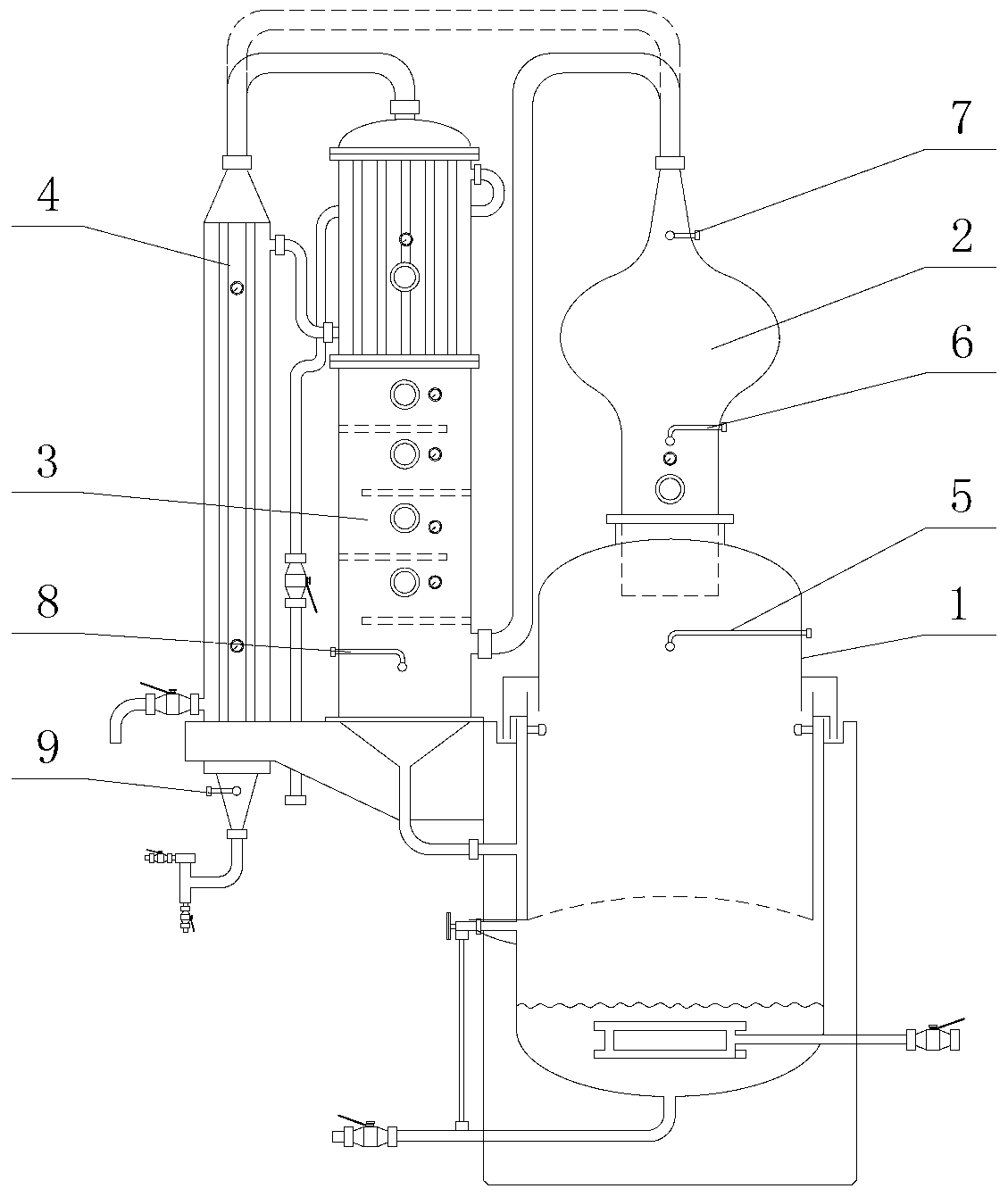

Method and device for deeply purifying distilled liquor by utilizing ozone

InactiveCN103232934AThoroughly oxidizedIncrease contact areaAlcoholic beverage preparationDistillationEnvironmental engineering

The invention discloses a method for deeply purifying distilled liquor by utilizing zone. The method comprises ventilating ozone to liquor steam. The invention further discloses a device for deeply purifying distilled liquor by utilizing ozone. The device comprises a distillation kettle and a condensing tower which are connected with each other, wherein an ozone adding tube I is connected to the kettle head of the distillation kettle; and a gas outlet of the ozone adding tube I is formed in the middle part of the kettle head o the distillation kettle. According to the method and the device for deeply purifying distilled liquor by utilizing ozone, the gaseous ozone and liquor steam are sufficiently mixed, so that the gas-steam mixing contact area is extremely large, and the ozone utilization rate is greatly improved; and the gas-steam mixing does not have ozone dissolving limit, so that the adding amount of the ozone can be adjusted according to the practical needs, and therefore, the purpose of deeply distilling liquor is achieved.

Owner:李建东

Treatment method of waste residue containing cyanide

ActiveCN104070052BAchieve solidificationAchieve entrySolid waste disposalPregnant leach solutionCyanide

The invention discloses a treatment method for cyanide-containing waste residue, which comprises the following steps: ① alkali adjustment, the pH value of the leaching solution of the waste residue after alkali adjustment is 10-13; Chlorine cyanogen breaking agent; ③ Granulation, adding slaked lime powder and plaster powder to the material after the cyanogen breaking reaction in step ② under stirring, and stirring the material in the reactor to form uniform spherical particles after stirring. ④Dry and solidify. After the granulation in step ③ is completed, stir the granules in the reactor for 1 to 2 days to dry and solidify naturally. The present invention chooses to use the chlorination method to break cyanide under alkaline conditions, and the cyanide removal effect is good; after the oxidation reaction of cyanide is completed, the salt is solidified in the particles and does not enter the waste water system; when stirring, two stages of frequency are used to make the formed particles The size is uniform; the gypsum added during granulation greatly improves the strength of the granules, which is beneficial to the construction of the landfill site.

Owner:扬州杰嘉工业固废处置有限公司

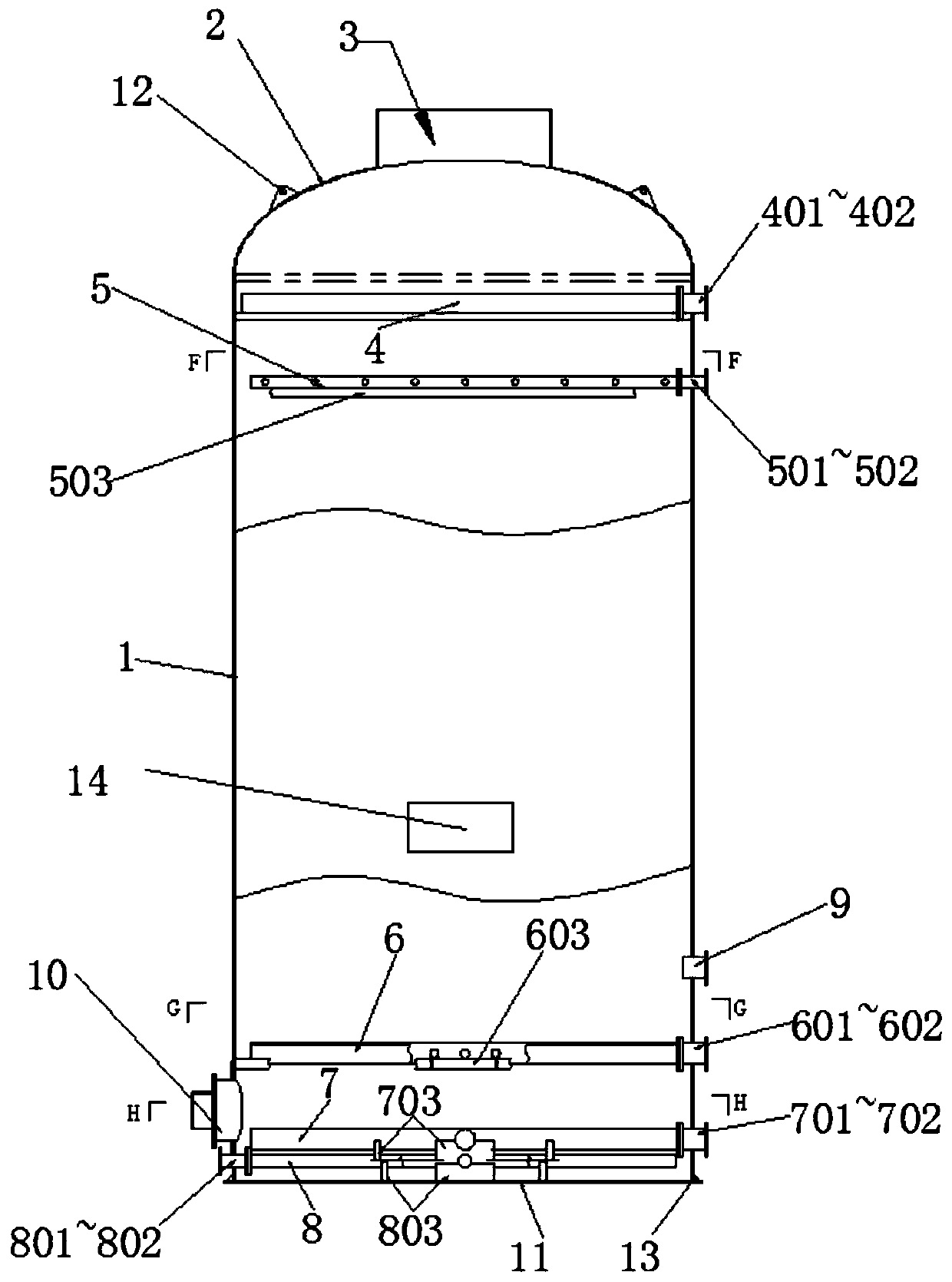

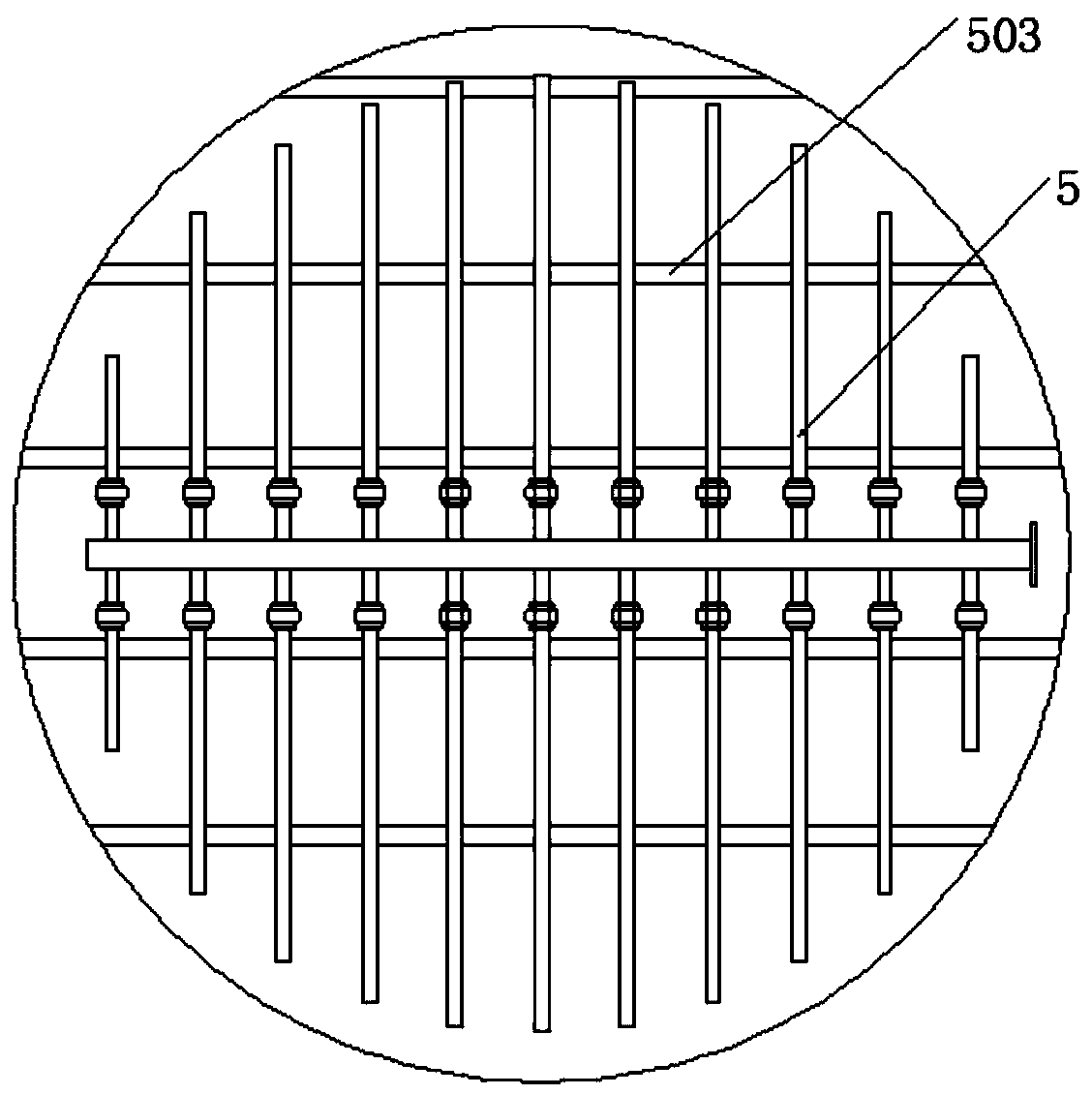

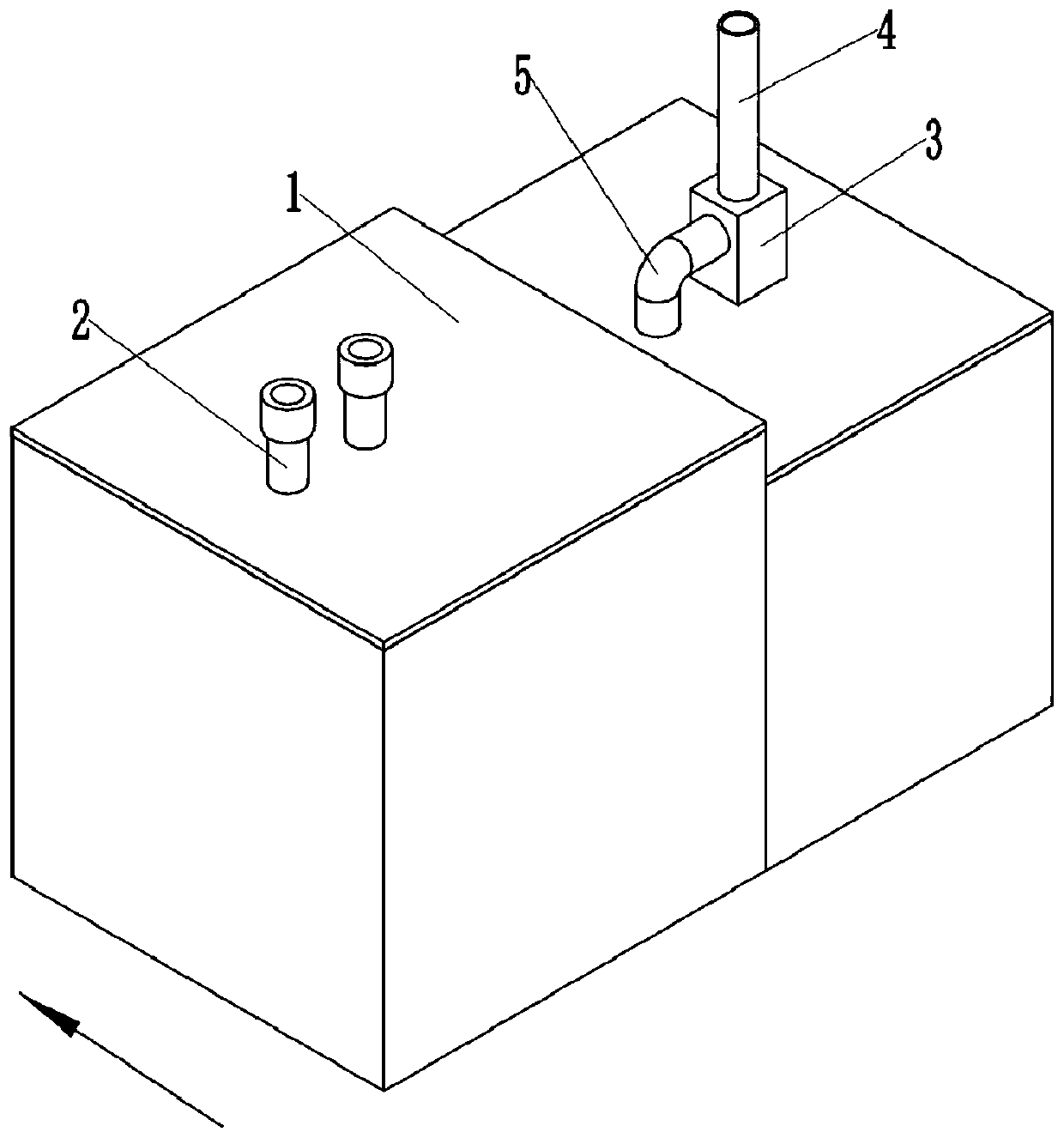

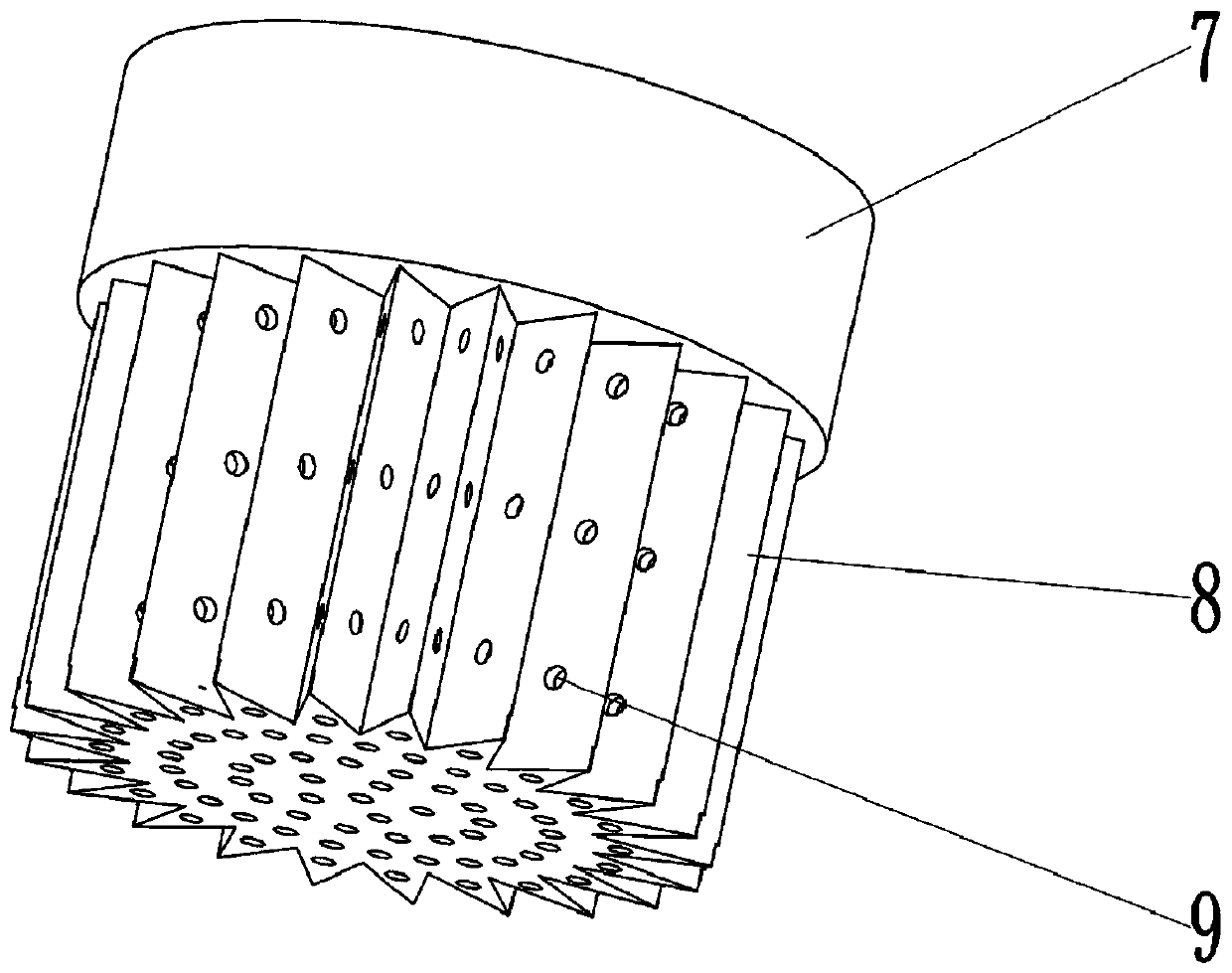

Oxidation tower for waste salt refining

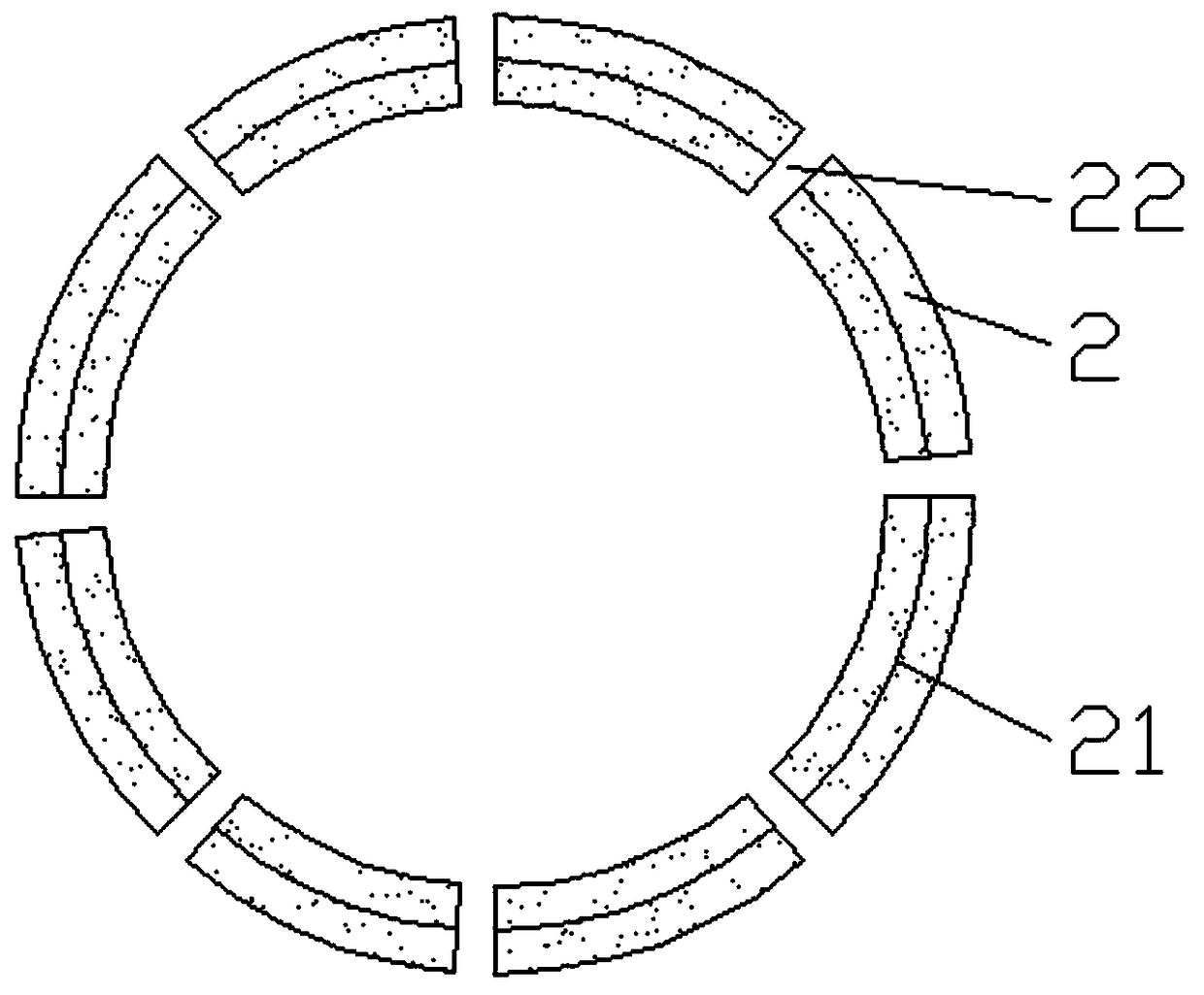

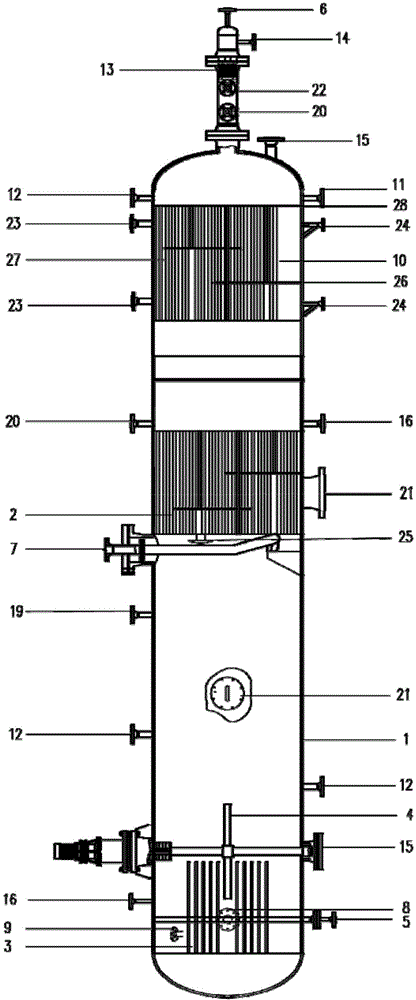

PendingCN109701472AImprove processing efficiencyPracticalTransportation and packagingHollow article cleaningSaline waterSalt water

The invention discloses an oxidation tower for waste salt refining. The oxidation tower includes a cylinder and a seal head, an air outlet is arranged on that seal head, a backwash water drain pipe and a water distribution pipe are sequentially arranged on the upper end of the inner part of that cylinder from top to bottom, the right end of the backwash water drain pipe is connected with a backwash water drain pipe adapter pipe which penetrates through the side wall of the cylinder by a backwash water drain pipe flange, the right end of the distribution pipe is connected with a water inlet pipe adapter pipe passing through the side wall of the cylinder by a water inlet pipe flange, a water distribution pipe support is arranged on the inner wall of the cylinder under the water distributionpipe, and an aeration pipe, a water drain pipe and a backwash pipe are arranged at the lower end of the inner part of the cylinder from top to bottom in sequence, and the right end of the aeration pipe is connected with an aeration pipe connecting pipe passing through the side wall of the cylinder through an aeration pipe flange. The invention not only realizes the continuity of feeding and discharging and has high automation degree, but also realizes the nanometer aeration of the reaction solution through the aeration device, improves the treatment efficiency of the waste brine, and has higher practicability.

Owner:ANHUI HUAXING CHEM IND CO LTD

A kind of synthetic method of flame retardant intermediate methylphosphonphthalein dichloride

ActiveCN108640947BLow purityHigh security riskGroup 5/15 element organic compoundsSulfonyl chlorideReaction temperature

The invention discloses a method for synthesizing flame retardant intermediate methylphosphinephthalein dichloride. Slowly add methyl phosphine dichloride dropwise, keep the reaction temperature at 15-20°C, and the dropwise addition time is 1-3h; C, after the addition is complete, continue to stir and react at a temperature of 0-30°C for 0.5-1h; D, After the reaction is complete, the by-product thionyl chloride is distilled out by vacuum distillation, and the 40-50°C fraction is collected; E, continue to increase the distillation temperature, and the methylphosphinephthalein dichloride product is obtained by vacuum distillation, and the 70-80°C fraction is collected. The invention has mild reaction conditions, simple operation, low cost, no addition and generation of gas, high safety, and easy realization of industrial production, and the purity of the methylphosphinephthalein dichloride product and the by-product thionyl chloride can reach 98%. Above, the reaction yield is above 95%.

Owner:四川省乐山市华莱利科技有限公司

Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

InactiveCN102500323BEasy accessLow costPhysical/chemical process catalystsOther chemical processesActive agentCatalytic oxidation

The invention belongs to the technical field of waste gas desulfurization and purification, particularly provides a modified active carbon desulfurizer and a preparation method thereof, and a hydrogen sulfide waste gas treatment method using the desulfurizer. The modified active carbon desulfurizer is prepared from impregnating activated carbon with active agent mixed solution comprising phenol, acetone, sodium carbonate, ferric nitrate and organic solvent, and drying and roasting the mixture. The modified active carbon desulfurizer converts the hydrogen sulfide in the waste gas into sulfur dioxide at atmospheric temperature and pressure under the absorption and catalytic oxidation action, and the sulfur dioxide is converted into SO42- in water phase by washing and removed. The waste gas treatment method uses the modified active carbon desulfurizer, and prevents the defects that the desulfurizer needs to be regularly desorbed and regenerated due to blockage caused by adsorption saturation and generated elemental sulfur. Compared with an ordinary activated carbon desulfurization process, the process has the advantages of high hydrogen sulfide removal rate, long service life of the desulfurizer, low operation cost, simplicity in operation and management and the like.

Owner:北京天灏柯润环境科技有限公司

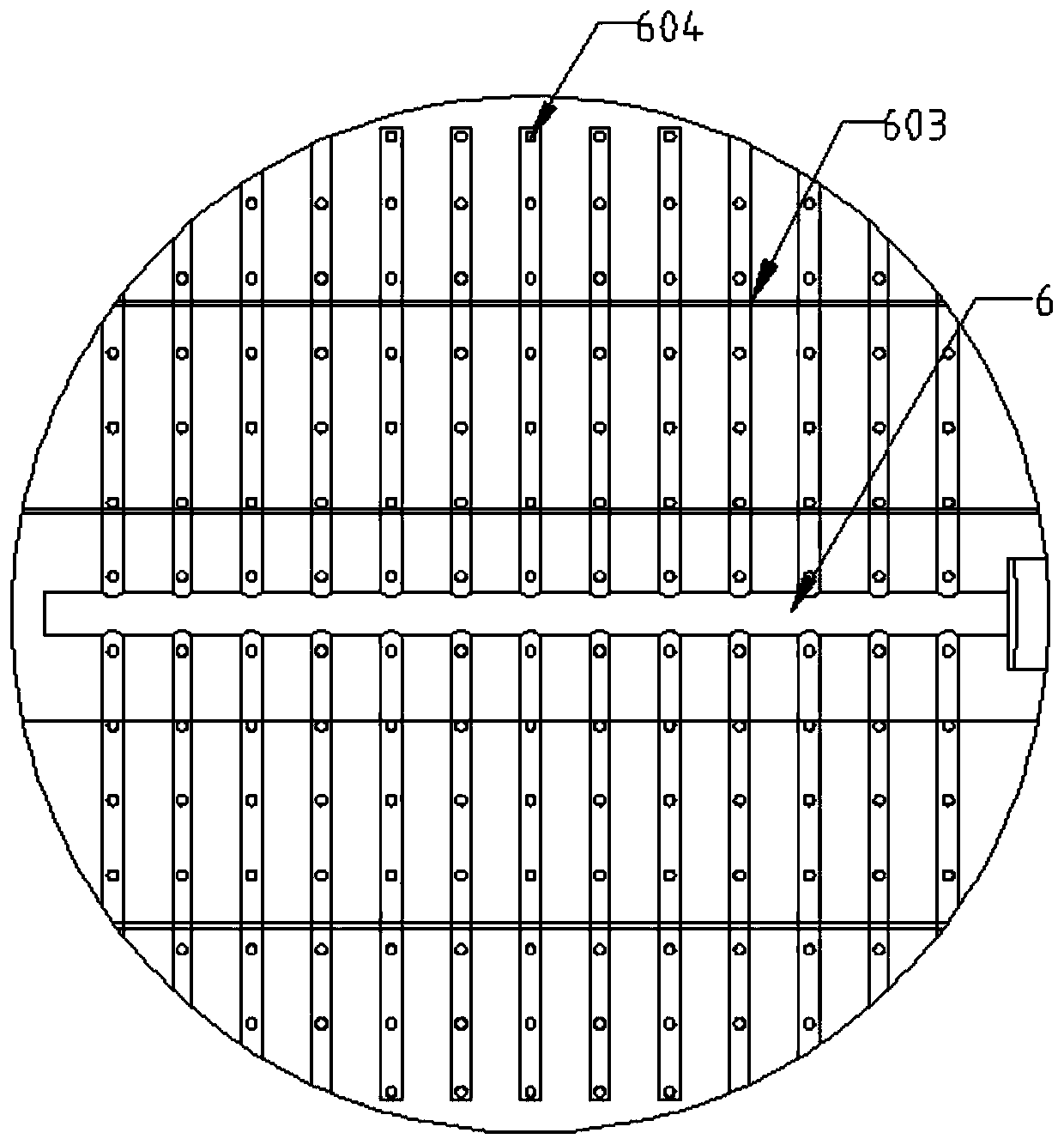

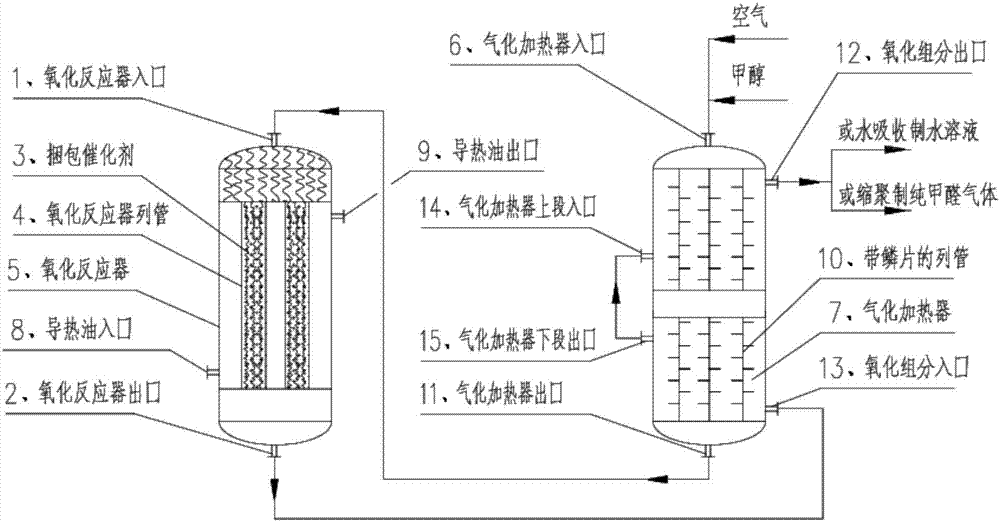

Methanol oxidation reaction device and method

InactiveCN106925187AImprove distributionSimple wayOrganic compound preparationCarbonyl compound preparationHeat conductingAqueous solution

The invention discloses a methanol oxidation reaction device and method. The device comprises an oxidation reactor and a gasification heater. The top of the oxidation reactor is provided with an inlet A, the bottom is equipped with an outlet A, the lower part of one side wall is provided with a heat conducting oil inlet, the upper part of another side wall is equipped with a heat conducting oil outlet, tubes are disposed inside, and a pack catalyst loaded in the tubes; the top of the gasification heater is provided with an inlet B, the bottom is equipped with an outlet B, the upper of one side wall is provided with an oxidation component outlet, the lower part is provided with an oxidation component inlet, and another side wall is equipped with an upper inlet and a lower segment outlet, the inside is provided with scale equipped tubes; the inlet A is connected to the outlet B, the outlet A is connected to the oxidation component inlet, the inlet B is connected an external fan and methanol pump, the oxidation component outlet is connected to an external aqueous solution device for formaldehyde preparation by water absorption and a gas device for formaldehyde preparation by polycondensation, the upper segment inlet is in connection with the lower segment outlet, the heat conducting oil inlet is connected to an external heat conducting oil pump, and the heat conducting oil outlet is connected to an external "waste pan".

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399BPromote environmental protectionHigh melting temperaturePhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

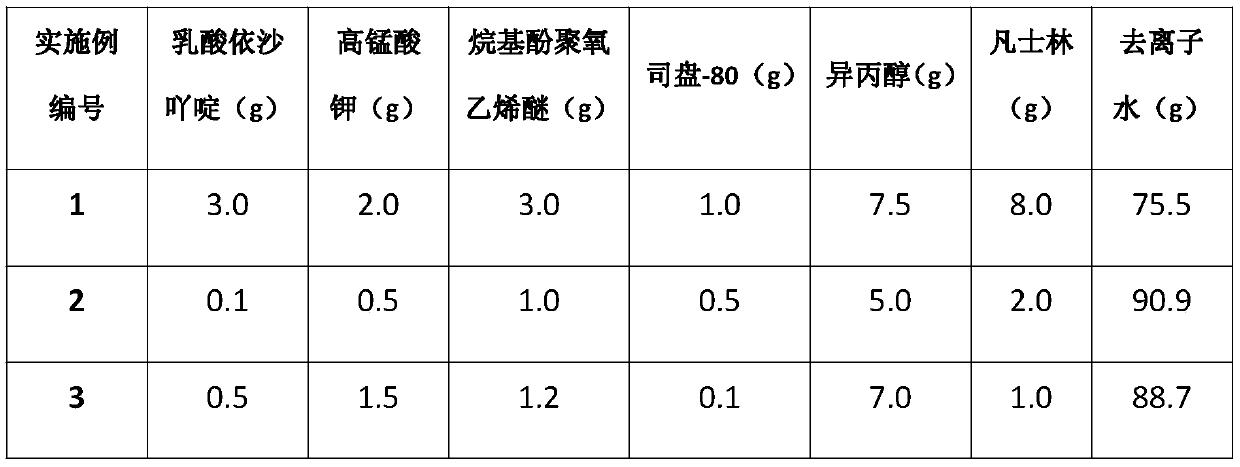

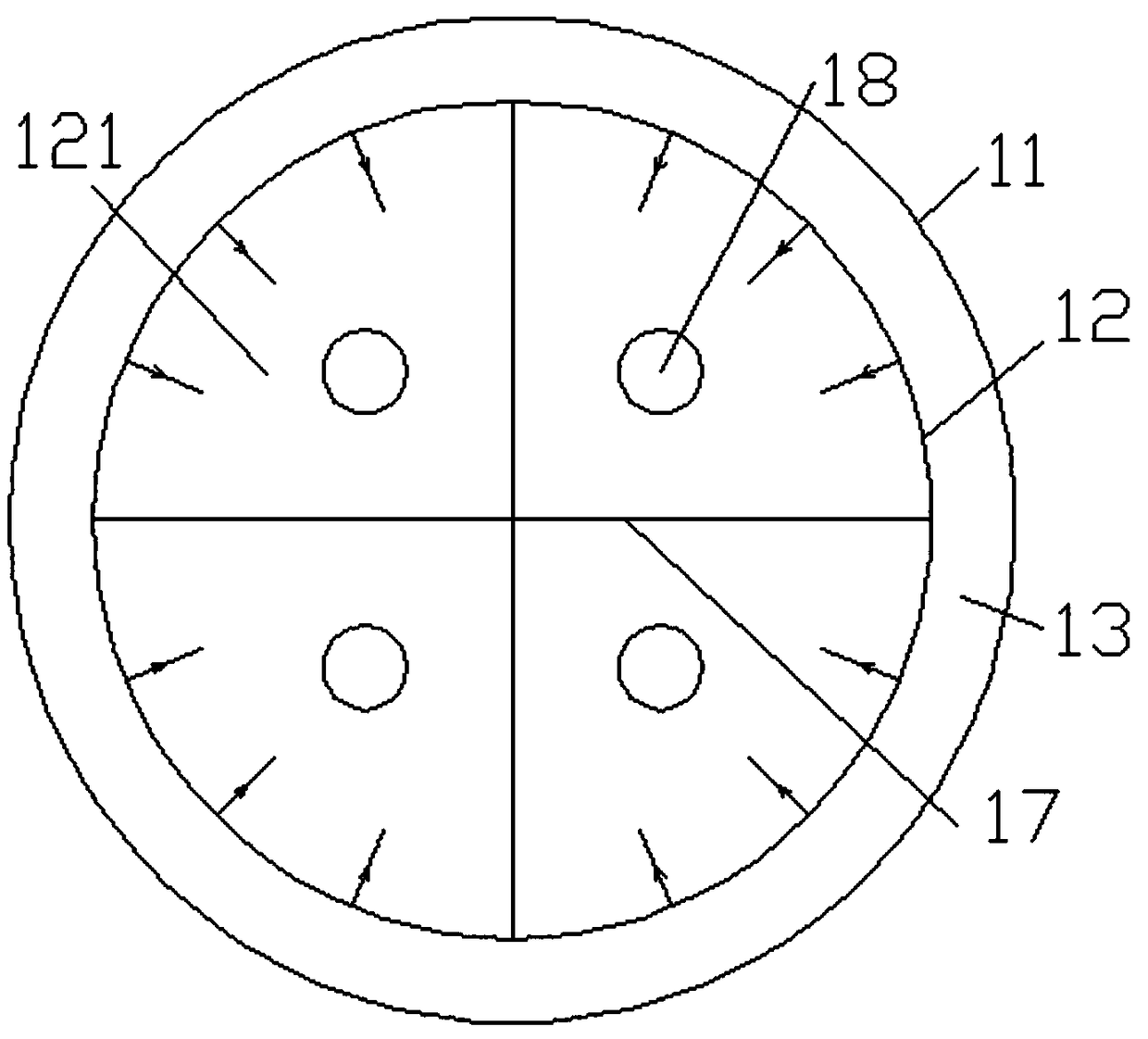

Ink for animal body surface marking pen and preparation method of ink

InactiveCN110054932APlay a local anti-infective effectTopical anti-infection does not causeInksAnimal husbandryEthacridine lactateAlkylphenol

The invention relates to ink for an animal body surface marking pen and a preparation method of the ink. Each 100g of the ink comprises, by weight, 0.1-5.0g of ethacridine lactate, 0.5-3.0g of potassium permanganate, 1.0-5.0g of alkylphenol ethoxylates, 0.1-3.0g of Span-80, 5.0-10.0g of isopropanol, 1.0-15.0g of Vaseline and the balance deionized water. The ink is nonirritant to the skin, high inhair adhering performance and capable of generating marks which do not fade for a long time and has a local anti-infection effect. The preparation method is high in process operability, low in production cost, beneficial to production transformation and promising in market prospect.

Owner:李会芳

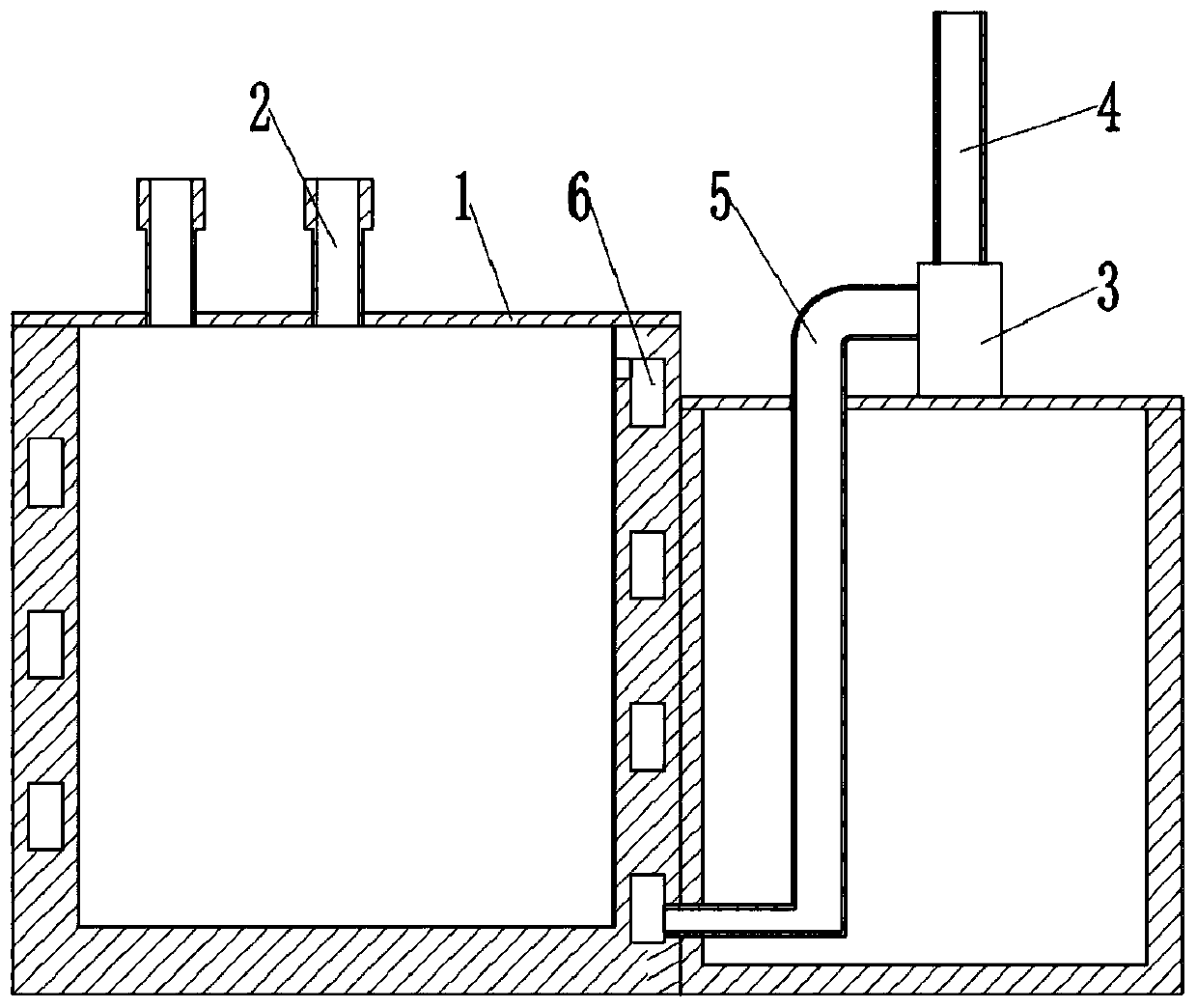

Low-pressure catalytic oxidation reactor

PendingCN108689478AFully contactedImprove reaction efficiencyWater/sewage treatment by irradiationWater treatment compoundsDraining tubeCatalytic oxidation

The invention discloses a low-pressure catalytic oxidation reactor which comprises a reactor barrel. A light reflection flow guide barrel is arranged in the reactor barrel, a filler zone is arranged between the light reflection flow guide barrel and the reactor barrel, a water inlet pipe and a gas inlet pipe penetrate the portion, which is positioned on the lower portion of the reactor barrel, ofthe filler zone and are provided with water distributors and aerators, and the water distributors and the aerators are arranged at an opening in the bottom of the light reflection flow guide barrel. The low-pressure catalytic oxidation reactor has the advantages that wastewater and ozone can be directly fed into the light reflection flow guide barrel, the low-pressure wastewater can be fed into the light reflection flow guide barrel in a jet flow manner to be circulated in the light reflection flow guide barrel in a rotational flow manner, and can be sufficiently fused with the ozone, a drainpipe is arranged on the upper portion of the reactor barrel, the wastewater can flow out from the light reflection flow guide barrel, then sufficient reaction can be carried out on the wastewater andthe filler zone, and the wastewater can be ultimately drained from the drain pipe; the light reflection flow guide barrel is divided into a plurality of longitudinal oxidation zones by titanium dioxide catalysis plates, an ultraviolet lamp pole is arranged in the center of each oxidation zone, the catalysis plates are completely positioned in irradiation distances of ultraviolet light, the ultraviolet light can be reflected by the light reflection flow guide barrel, accordingly, illumination can be intensified, and the photocatalytic efficiency can be improved.

Owner:SUZHOU FANGZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

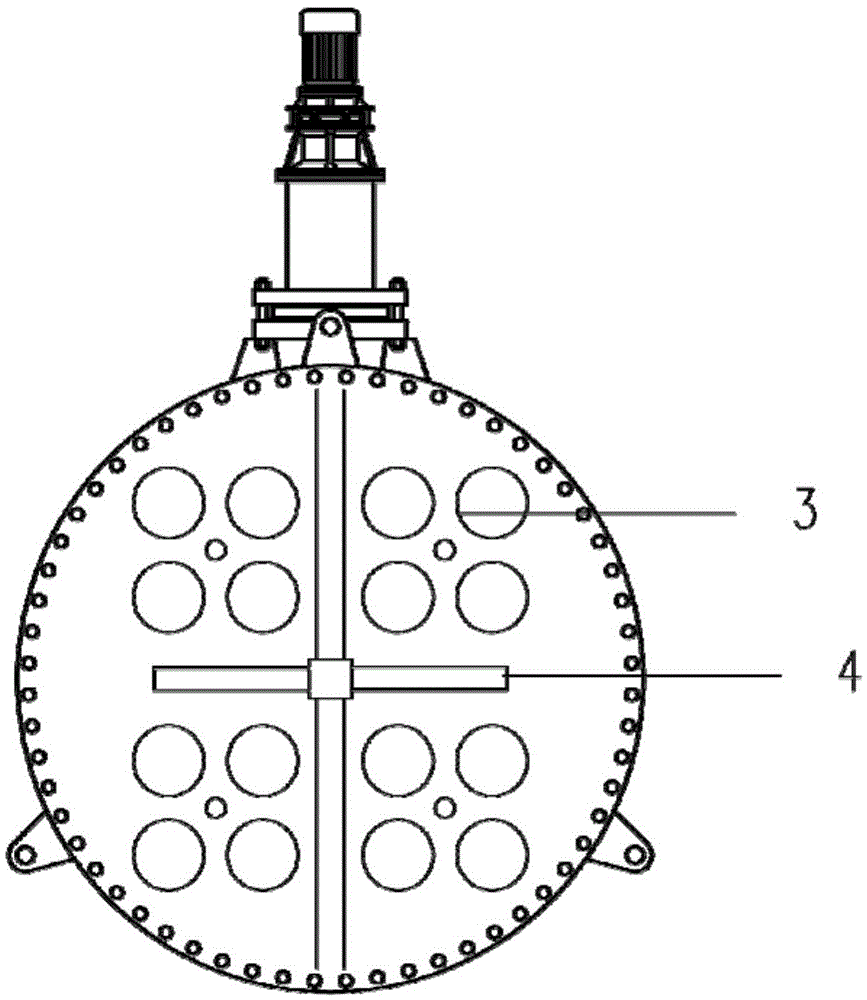

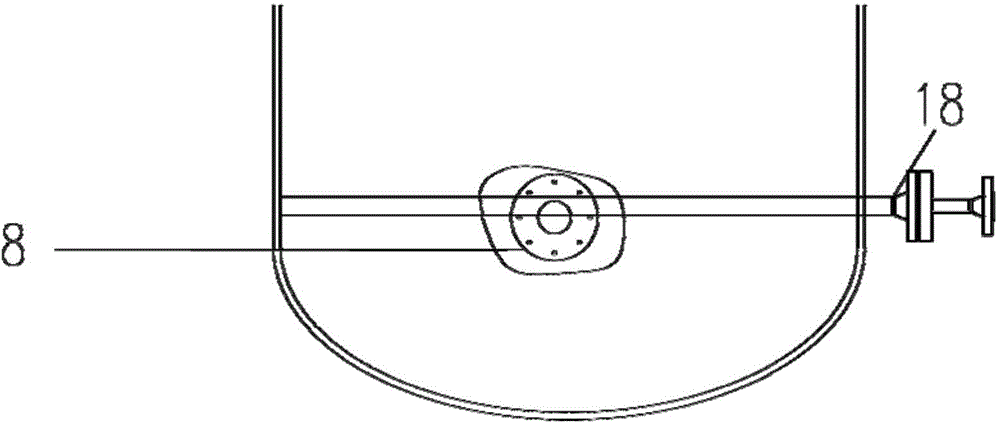

Sludge treatment reactor

ActiveCN105800898AEasy to handleIncrease temperatureSludge treatment by oxidationPlate heat exchangerSludge

The invention relates to a sludge treatment reactor which comprises a kettle body which is vertically arranged and an insulating layer covering the outer side of the kettle body; a heat exchanger for preheating an oxidizing medium is arranged on the upper part inside the kettle body; a heat exchange structure for preheating sludge slurry is arranged in the middle inside the kettle body; the heat exchange structure is connected to a material inlet on the outer side of the middle of the kettle body; at least one longitudinally-arranged electric heating bar and at least one transversely-arranged stirrer are arranged on the lower part inside the kettle body; a gas inlet and an exhaust port are respectively formed in the bottom and the top of the kettle body; a material outlet and a drain outlet are also formed in the bottom of the kettle body. The sludge treatment reactor disclosed by the invention can respectively preheat the oxidizing medium and sludge material by virtue of the heat exchanger and the heat exchange structure, so that the oxidizing medium and the sludge material just entering the reactor have relatively high temperature, and thus a faster and more complete oxidizing reaction is implemented.

Owner:北京首创大气环境科技股份有限公司 +1

Method for preparing tetramethyl pyrazine

InactiveCN100556895CPrevent oxidationAdequate responseOrganic chemistryDistillationTetramethyl pyrazine

The invention relates to a preparation method of ligustrazine. It comprises the following steps: taking 3-hydroxy-2-butanone and ammonium acetate as raw materials, adding ethanol, feeding nitrogen, stirring for 5-8 hours in a hot bath; stirring for another 12 hours under air or oxygen conditions; adding an oxidizing agent , the weight ratio is oxidant: 3-hydroxyl-2-butanone=0.5~1:1, stirred for 1~2 hours; filtered to remove remaining oxidant; depressurized distillation to obtain Ligustrazine. The production rate of ligustrazine produced by the method of the invention is high. The amount of organic solvent used in the preparation process is small, which is beneficial to environmental protection, and has the advantages of low cost and simple operation.

Owner:张锋

Method and device for carrying out deep purification on distilled liquor by utilizing ultraviolet light

InactiveCN103266048AThoroughly oxidizedIncrease contact areaAlcoholic beverage preparationDistillationUltraviolet lights

The invention discloses a method for carrying out deep purification on distilled liquor by utilizing ultraviolet light. The ultraviolet light is used for irradiating liquor steam. The invention further discloses a device for carrying out the deep purification on the distilled liquor by adopting the method; the device comprises a distillation kettle and a condensation tower; the distillation kettle and the condensation tower are connected with each other; and a kettle head of the distillation kettle is provided with a plurality of uniformly-distributed ultraviolet lamp tubes I. According to the method and the device disclosed by the invention, the ultraviolet light is used for irradiating the liquor steam and the contact area is large, so that the utilization rate of the ultraviolet light can be improved; and the irradiation amount of the ultraviolet light can be adjusted according to the actual requisite amount so that the aim of deeply purifying the distilled liquor is realized. The distilled liquor produced by adopting the method and the device disclosed by the invention is soft in mouth feel; and a user does not feel thirsty and headache after drinking the distilled liquor.

Owner:李建东

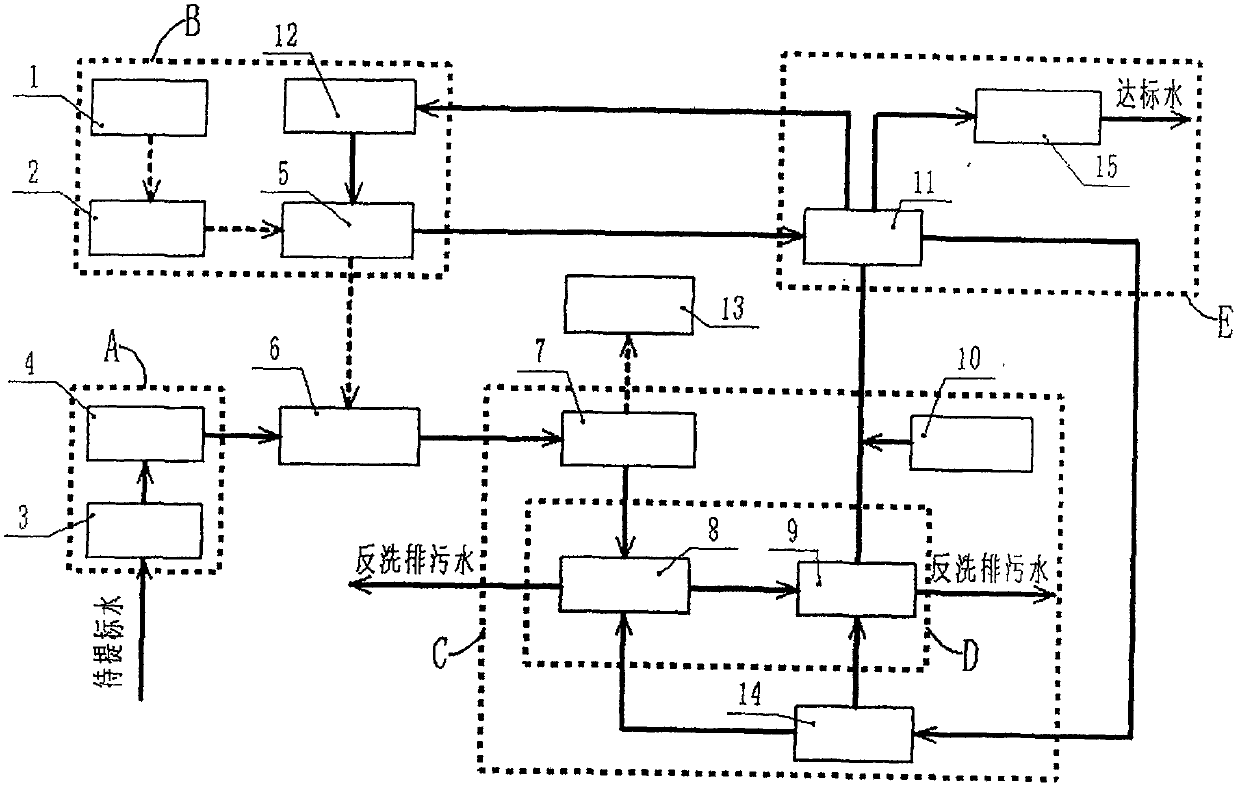

Water quality standard improving treatment and reusing device based on oxidation technology

PendingCN107619128ASatisfy the needs of upgrading and recyclingSmooth water intakeDispersed particle filtrationMultistage water/sewage treatmentOzone generatorWater quality

The invention discloses a water quality improving treatment and reusing device based on a oxidation technology, and relates to the technical field of sewage treatment. The oxidation treatment is takenas a key technology. Water inlet ends on the left sides of a water tank, a pump and a gas-water mixer are fixed by pipelines; air inlet ends on the upper sides of an air compressor, an oxygenerator,an ozone generator and the gas-water mixer are fixed by air pipes; the ozone generator, a water replenishing tank and a circulating pump are fixed by circulating water pipes; an outlet end on the right side of the gas-water mixer, an oxidation reaction tower, a filter A, a filter B, the water replenishing tank and a water outlet pump are fixed by water pipes; a tee joint on the water pipe betweenthe filter B and the water replenishing tank is fixedly provided with a doser; the water replenishing tank, a backwashing pump, the filter A and the filter B are fixed by backwashing pipes; the oxidation reaction tower and an exhaust purifier are fixed by exhaust pipes. The water quality improving treatment and reusing device is used for sewage treatment, and has the advantages of reasonable design, ingenious structure, easy manufacturing, high efficiency and good effect.

Owner:YUHUI WATER TREATMENT TECH BEIJING

Bottle pattern baking furnace

ActiveCN111023823AAvoid situations where quality compromisesNot easy to scratchMaintainance of heating chambersCharge treatment typeThermodynamicsProcess engineering

The invention relates to the technical field of bottle patterns, and discloses a bottle pattern baking furnace. The bottle pattern baking furnace comprises a high-temperature furnace body, wherein thehigh-temperature furnace body is provided with an air inlet port and an air exhaust port, the air exhaust port communicates with a draught fan, and the draught fan is fixed to the high-temperature furnace body. The side wall of the high-temperature furnace body is provided with a circulation channel, wherein the air inlet end of the circulation channel communicates with the high-temperature furnace body, and the air outlet end of the circulation channel communicates with the air exhaust port. According to the technical scheme, the technical problem in the prior art that volatile substances are retained in the furnace for a long term, and the processing quality of bottles is affected can be solved.

Owner:重庆德立玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com