Production device and method for efficiently preparing ozonized oil

A production device and ozone oil technology, applied in chemical instruments and methods, fatty acid production, fatty acid chemical modification, etc., can solve the problems of low mass transfer efficiency, uneven reaction, small contact area of oil and gas, etc. Controlling, improving production efficiency, and rapid oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

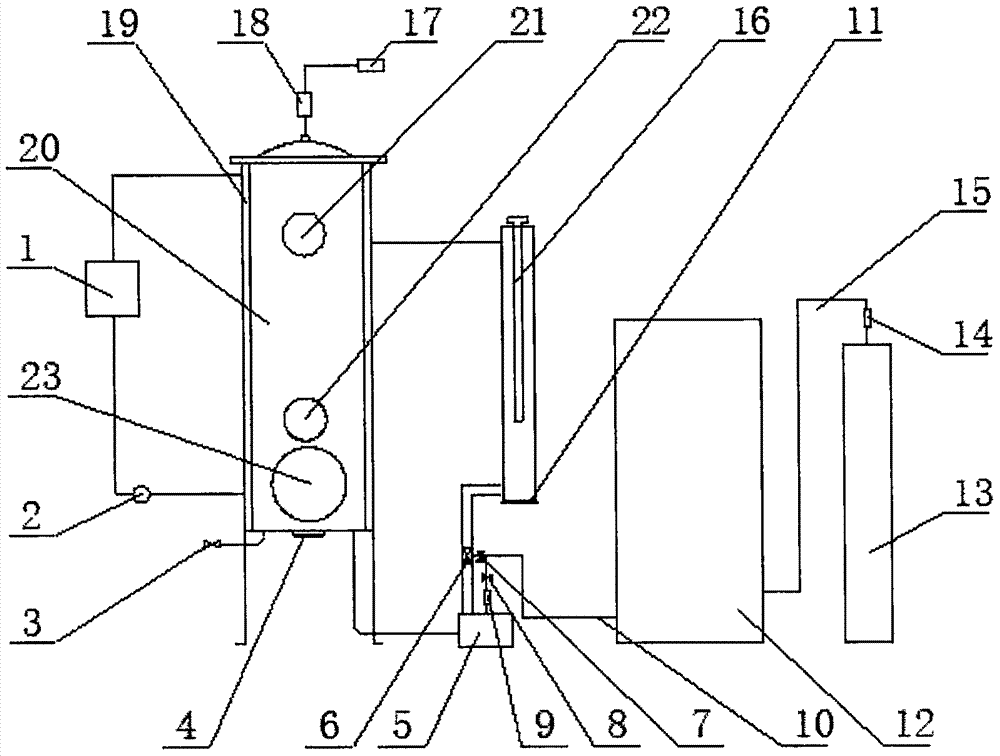

[0018] Such as figure 1 Shown, a kind of production device of producing trioxidized oil efficiently, it comprises ozone oil reaction tank 20, and the top of described ozone oil reaction tank 20 is provided with feeding port 21, and the bottom of described ozone oil reaction tank 20 is provided with Observation port 22 and material receiving port 23 are arranged, and the left side of described ozone oil reaction tank 20 is connected with temperature controller 19 and cooling water pump 2, and described cooling water pump 2 is connected with cooling water tank 1, and described ozone oil reaction The upper end of tank 20 is connected with automatic exhaust valve 18, and described automatic exhaust valve 18 is connected with ozone tail gas destroyer 17, and the lower end of described ozone oil reaction tank 20 is provided with ultrasonic device A4 and discharge opening 3, so The lower end of the ozone oil reaction tank 20 is connected with a gas-liquid mixing pump 5, and the upper...

Embodiment 2

[0021] Such as figure 1 Shown, a kind of production device of producing trioxidized oil efficiently, it comprises ozone oil reaction tank 20, and the top of described ozone oil reaction tank 20 is provided with feeding port 21, and the bottom of described ozone oil reaction tank 20 is provided with Observation port 22 and material receiving port 23 are arranged, and the left side of described ozone oil reaction tank 20 is connected with temperature controller 19 and cooling water pump 2, and described cooling water pump 2 is connected with cooling water tank 1, and described ozone oil reaction The upper end of tank 20 is connected with automatic exhaust valve 18, and described automatic exhaust valve 18 is connected with ozone tail gas destroyer 17, and the lower end of described ozone oil reaction tank 20 is provided with ultrasonic device A4 and discharge opening 3, so The lower end of the ozone oil reaction tank 20 is connected with a gas-liquid mixing pump 5, and the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com