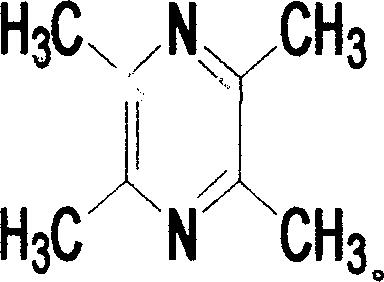

Method for preparing tetramethyl pyrazine

A technology of ligustrazine and oxidant, applied in the direction of organic chemistry, can solve the problems of easy volatilization, high production cost, and large consumption of organic solvents, and achieve the effects of small organic residues, low production cost, high yield and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

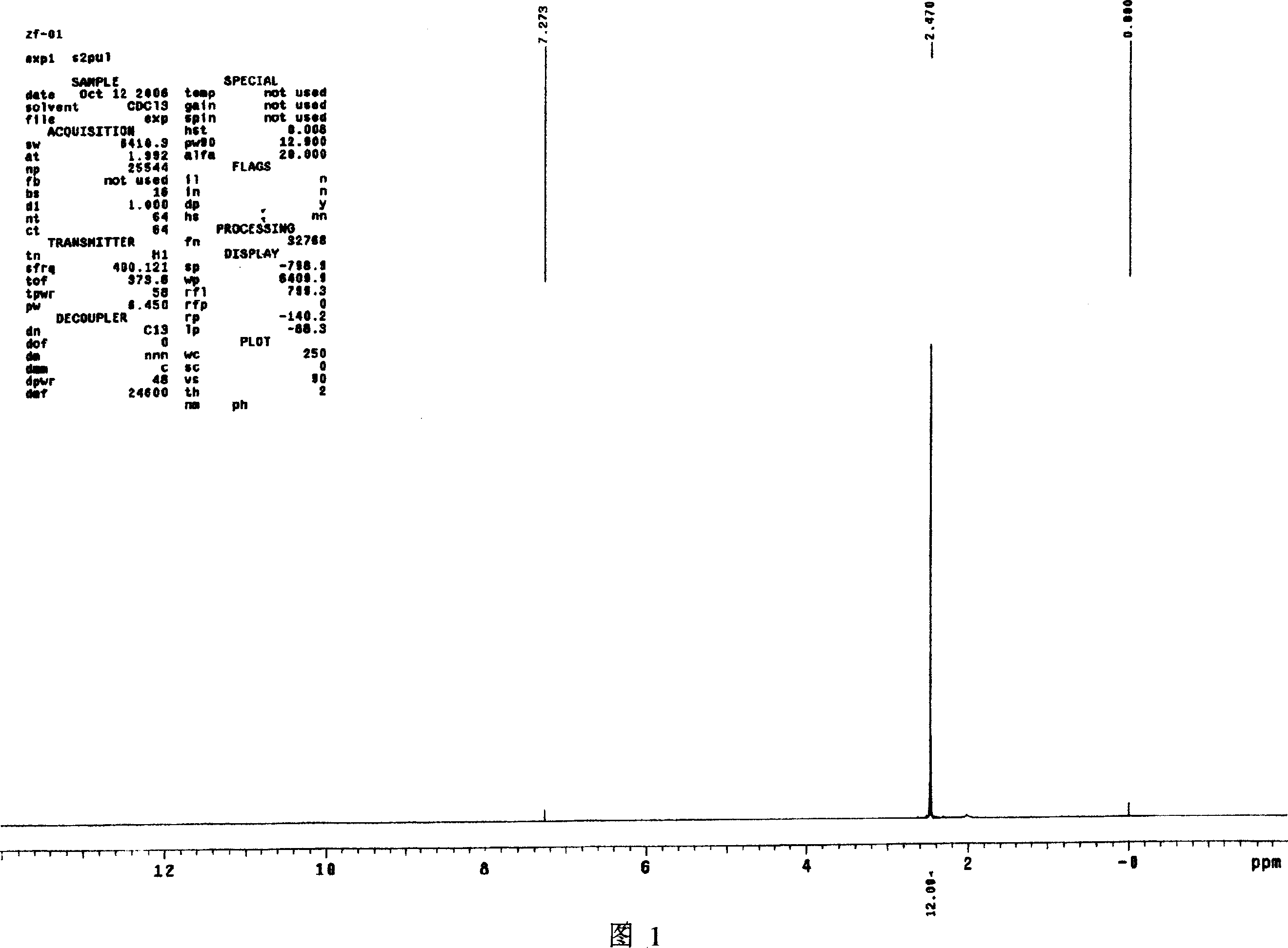

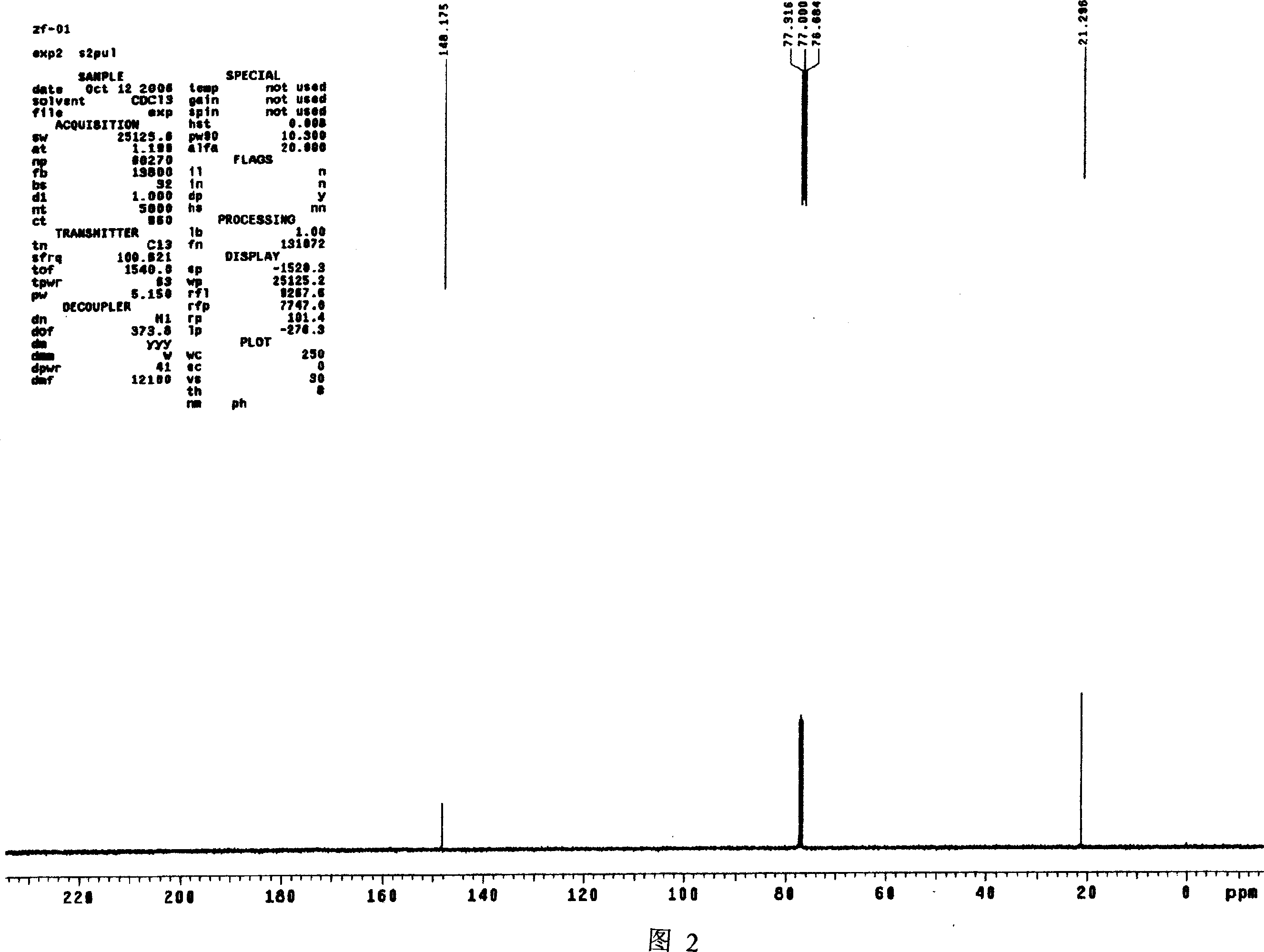

Image

Examples

Embodiment 1

[0025] Add 50g of 0.57mol of 3-hydroxy-2-butanone, 150ml of ethanol and 35.78g of 0.54mol of ammonium acetate into a 500ml round-bottomed flask, feed nitrogen, heat the oil bath at 79-89°C, and stir for 5-8 hours with magnetic force . After the stirring was completed, it was left open or magnetically stirred under oxygen condition for 12 hours. Add 31.45g of 0.36mol manganese dioxide, and stir magnetically for 1 to 2 hours. After the reaction is complete, use a Buchner funnel to filter the remaining manganese dioxide under reduced pressure. Under reduced pressure distillation, 29.12 g of ligustrazine needle crystals were collected by vacuum distillation. Use 50ml of ethyl acetate and 6 grams of activated carbon to re-distill under reduced pressure. The conditions of the reduced-pressure distillation are the same as those mentioned above. After drying, 28.32 g of 0.21 mol of Ligustrazine was received, with a yield of 72.50%.

[0026] Using 3-hydroxy-2-butanone and ammonium ac...

Embodiment 2

[0032] In the present invention, ketones such as butanone can be halogenated under acidic conditions to obtain acetoin, and then the method of Example 1 can be used to prepare ligustrazine. The specific method is: take 50g of butanone in a 250ml three-necked flask (equipped with a stirrer and a thermometer), add 80ml of hydrochloric acid and 120g of liquid bromine, stir, and heat to 50°C to 60°C with nitrogen gas for 2 to 3 minutes. hour, then alkalized with sodium hydroxide to obtain the acetoin mixture, passed through n-hexane for extraction, and dehydrated with anhydrous sodium sulfate to obtain acetoin, which was transferred to a flask, and Ligustrazine was prepared by the method of Example 1.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com