Patents

Literature

93 results about "Tetramethyl pyrazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

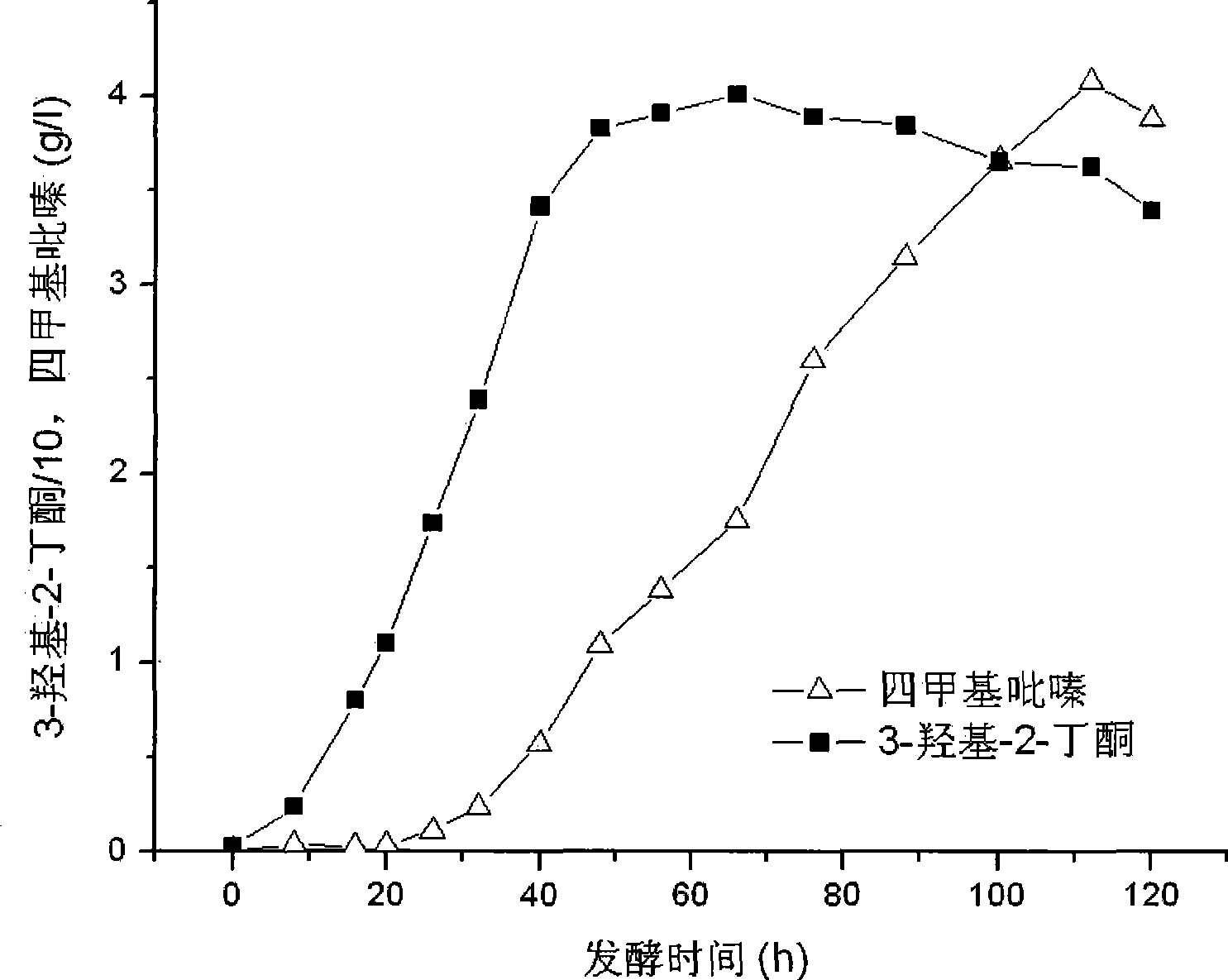

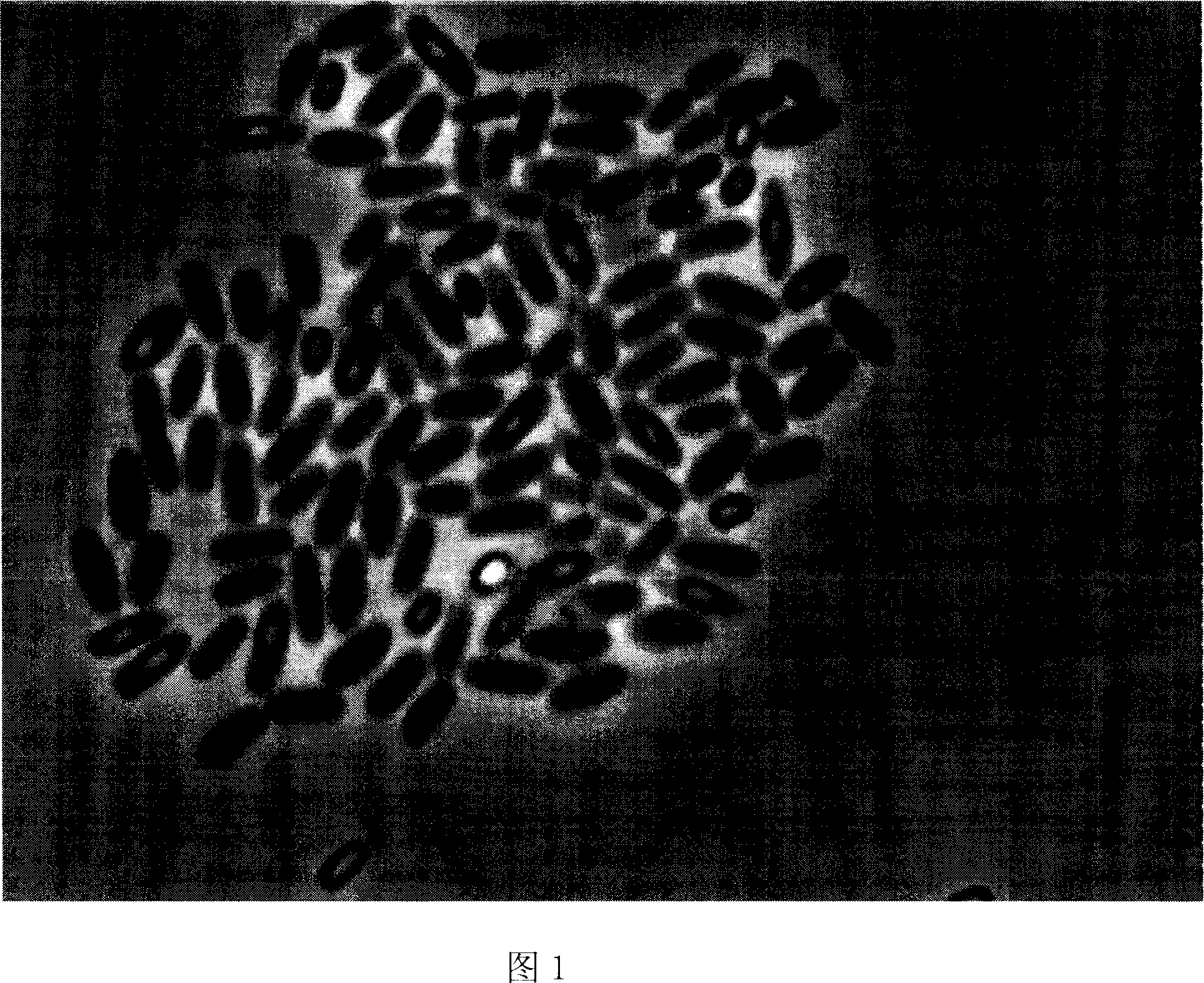

Bacillus subtilis highly producing tetramethylpyrazine and method thereof for fermentation producing tetramethylpyrazine

InactiveCN101445786AIncrease productionRich sourcesBacteriaMicroorganism based processesSaccharumSucrose

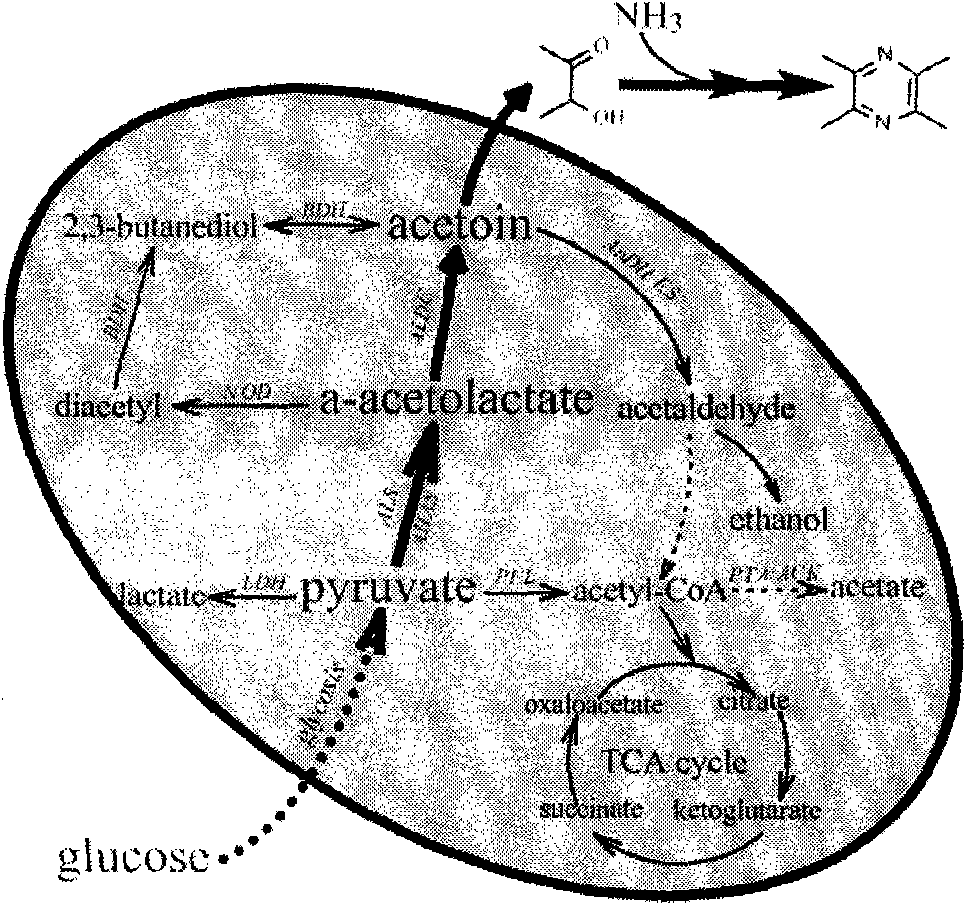

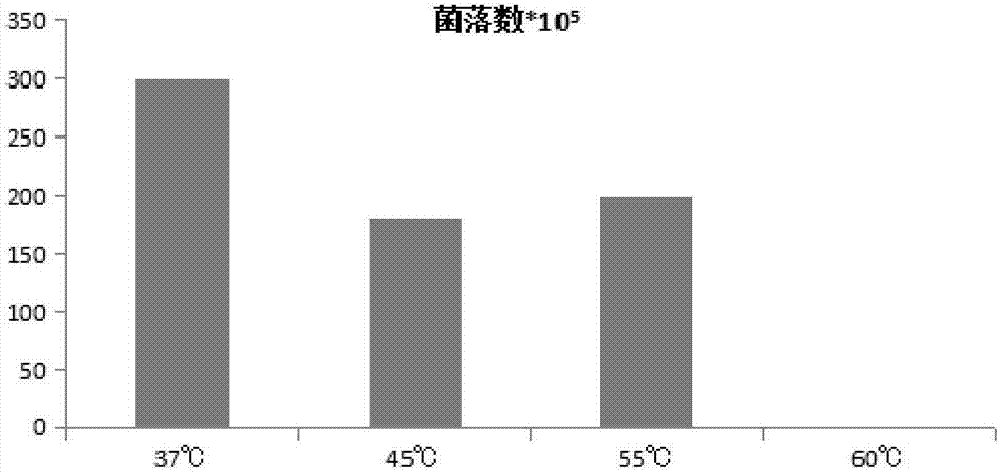

The invention relates to a bacillus subtilis highly producing tetramethylpyrazine and a method thereof for fermentation producing tetramethylpyrazine, and belongs to the technical field of bio-engineering. The invention discloses a Bacillus subtilis XZ1124 which can highly produce tetramethylpyrazine, and is preserved in CCTCC, and the preservation number is CCTCC NO: M 208157. The strain is made of Maotai-flavor liquor and high temperature Daqu; the strain is identified as Bacillus subtilis based on colony, cell form, physiological and biochemical characteristics and 16S rRNA gene sequence comparative result thereof. The strain can utilizes glucose, sucrose, molasses and soybean cake powder as substrate, and increases the output of tetramethylpyrazine through accumulating a great deal of endogenous precursors, so as to solve the problems of low product density, exogenous adding precursor requirement, and low precursor utilization rate in tetramethylpyrazine production through microbe fermentation. When sucrose and soybean cake powder are used as substrate, 4.08 g / L of tetramethylpyrazine can obtained through shaking culture of the raw material for 120 h at the temperature of 37 DEG C.

Owner:JIANGNAN UNIV

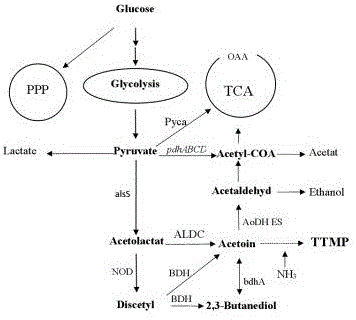

Method and strain for producing tetramethylpyrazine

InactiveCN101955980APromote rapid proliferationRich sourcesBacteriaMicroorganism based processesBacillus licheniformisHigh concentration

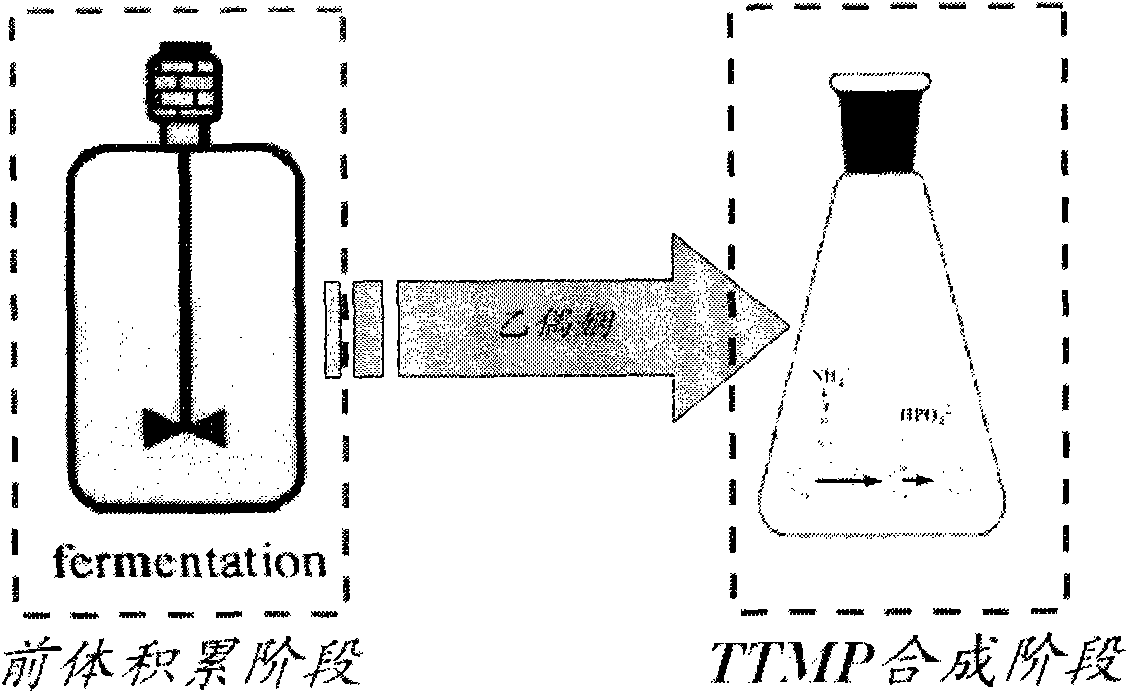

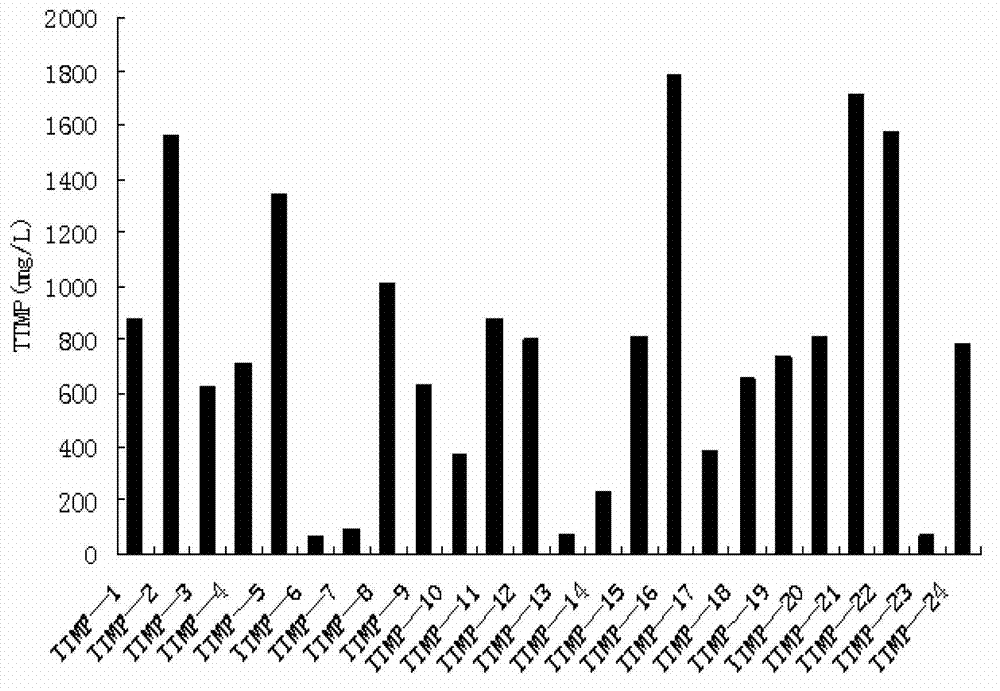

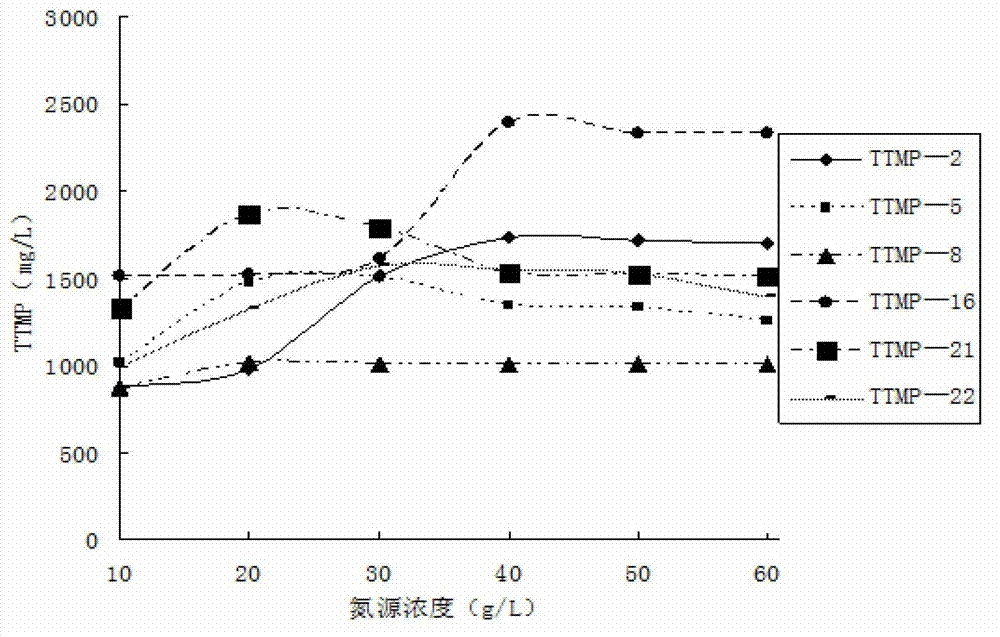

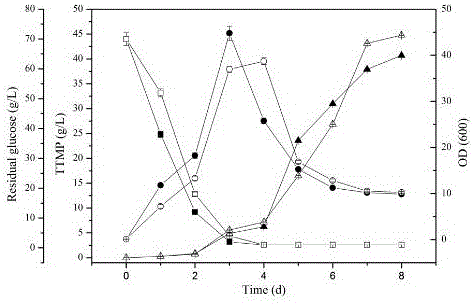

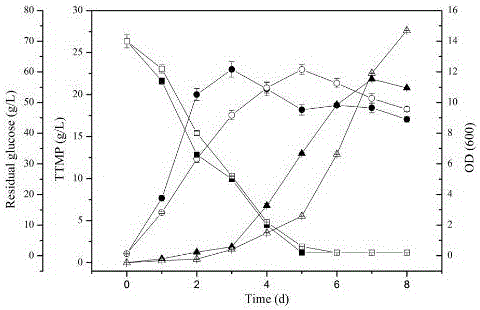

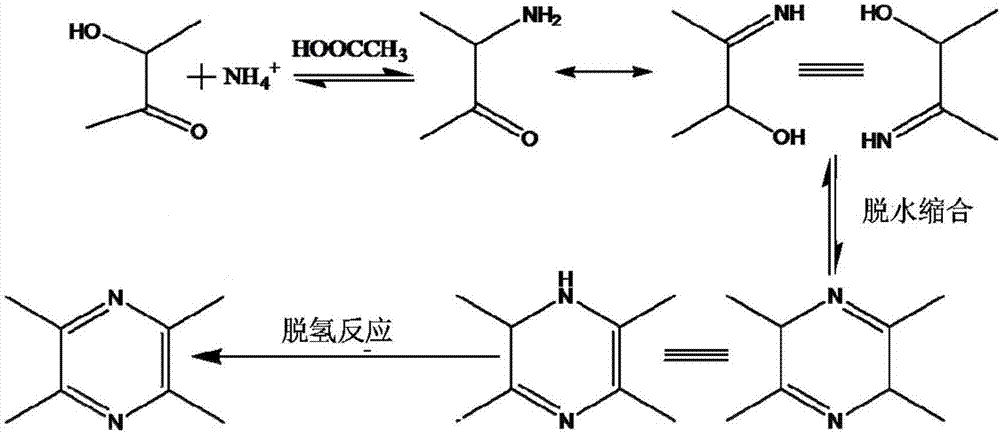

The invention discloses a method and a strain for producing tetramethylpyrazine (TTMP), in particular a two-step production process that a microorganism accumulates precursor acetoin by using the fermentation of reducing sugar and the acetoin and ammonia undergo a non-enzymatic reaction to synthesize the TTMP, and belongs to the technical field of bioengineering. The microorganism is any one of bacillus subtilis (CCTCC NO:M 208157), bacillus licheniformis (CGMCC NO:3961), bacillus licheniformis (CGMCC NO:3962) and bacillus licheniformis (CGMCC NO:3963). The strain obtains biomass and accumulates endogenous precursor acetoin by using the fermentation of the reducing sugar, and the acetoin and the ammonia in a fermentation system undergo the non-enzymatic reaction to synthesize the TTMP. The method has the advantages that: the obtained bacteria quantity is higher, the accumulation amount of the acetoin is effectively improved (38 to 44g / L); the high-concentration endogenous precursor acetoin and the ammonia can quickly react under proper conditions to form the TTMP (16 to 20g / L); and the use ratio (40.3 percent) of precursors is obviously improved due to the accumulation of endogenous acetoin and an in-situ fermentation environment.

Owner:JIANGNAN UNIV

Production method of strong aromatic Chinese spirits

ActiveCN102994317AIncrease contentDoes not affect styleAlcoholic beverage preparationMicroorganism based processesTetramethyl pyrazineHusk

The invention discloses a production method of strong aromatic Chinese spirits. The production method comprises the following steps of: preparing fermented grains by using 1000-1200 parts of unprocessed food grains, 100-200 parts of steamed rice husk steamed, and 4000-5000 parts of middle-level fermented grains fermented at the upper row; filling the fermented grains in a steaming bucket for cooking, mixing cooking wine of the fermented grains, fermented at the upper row while cooking the raw materials so as to obtain the cooked fermented grains and large dreg wine after ending cooking; taking out the cooked grain wine and placing for aeration cooling, adding 200-250 parts of middle-temperature Daqu, 30-50 parts of bacterial mouldy bran, firstly placing 1000-1200 parts of upper fermented grains fermented at the upper row in a pit, then placing 5500-6500 parts of the grain wine obtained in the previous step in a pit, and fermenting for 60-70 days; filling 1000-1200 parts of lower fermented grains fermented at the lower row in the steaming bucket for cooking, thereby obtaining double-turn wine; and after operating once according to the steps, mixing the large dreg wine and the double-turn wine obtained in the next turns to obtain the strong aromatic Chinese spirits. The production method has the advantages that the content of tetramethylpyrazine in the strong aromatic Chinese spirits is increased, and the style of the strong aromatic Chinese spirits is not affected.

Owner:山东景芝白酒有限公司

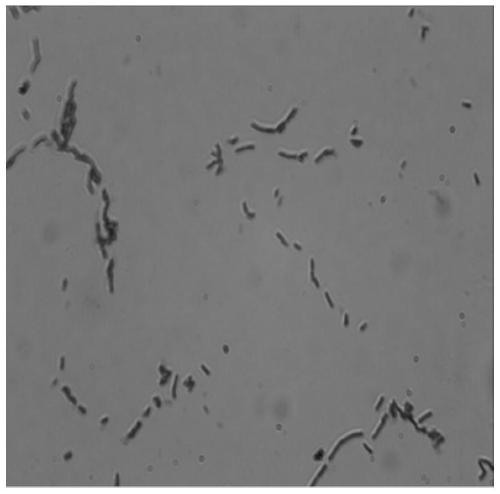

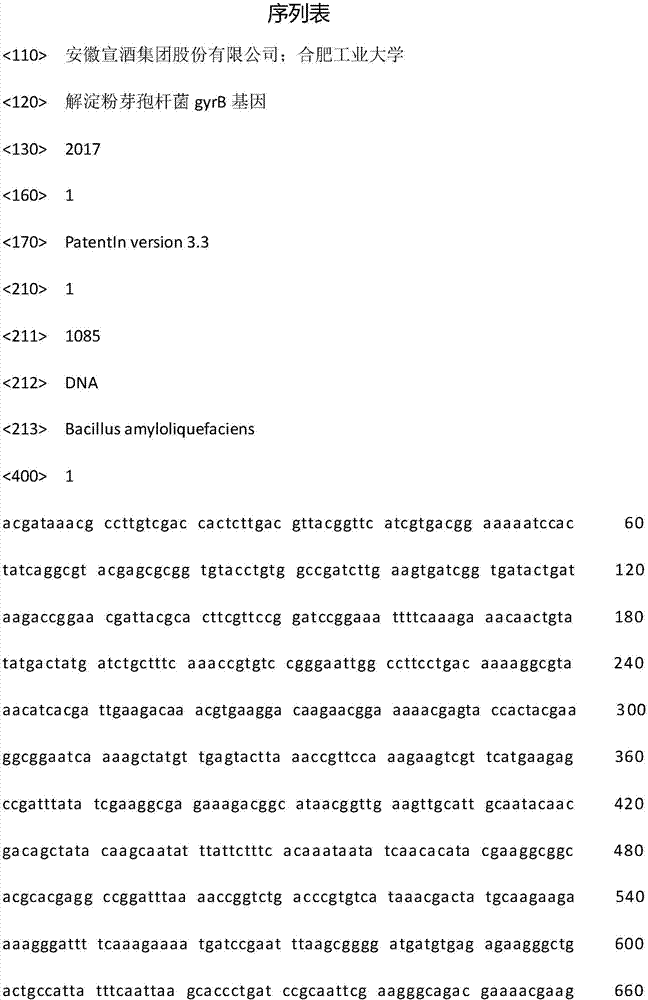

Bacillus amyloliquefaciens and application thereof

The invention relates to a strain of bacillus amyloliquefaciens and an application thereof and belongs to the field of microorganisms. According to the bacillus amyloliquefaciens JNC-002 and the application thereof, the conservation number of the strain is China general microbiological culture collection center (CGMCC) No.5740, and the strain is separated and obtained from distiller's yeast of Sichuan jiannanchun liquor (enterprise group) limited liability company. The capacity of producing tetramethylpyrazine by the bacillus amyloliquefaciens can reach to 2.4g / L, and the bacillus amyloliquefaciens can be applied to producing the tetramethylpyrazine.

Owner:四川绵竹剑南春酒厂有限公司

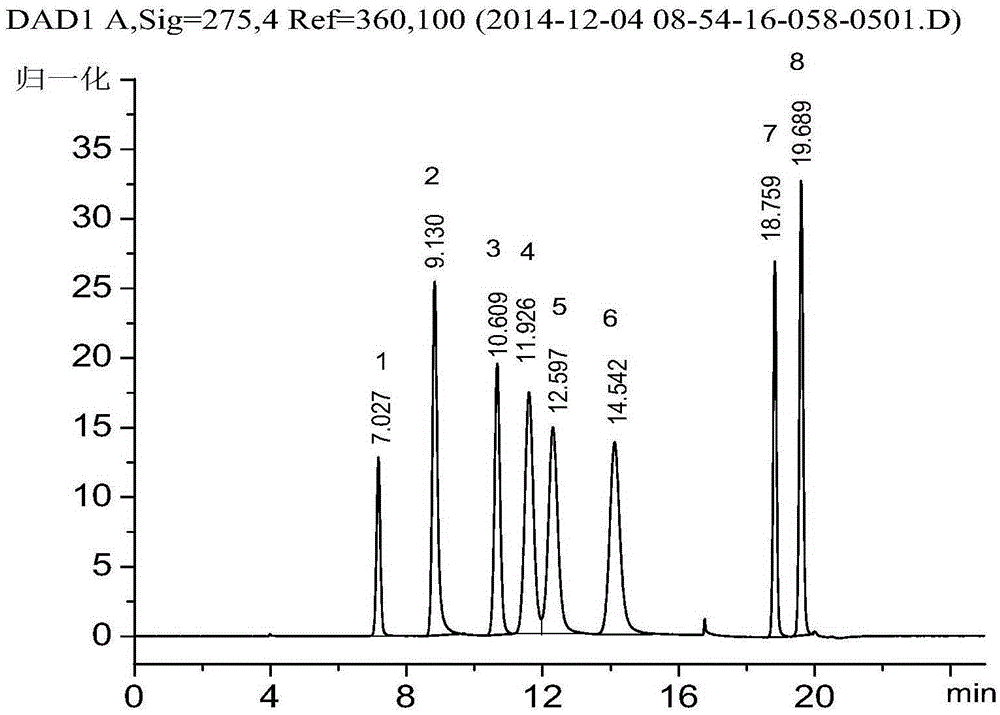

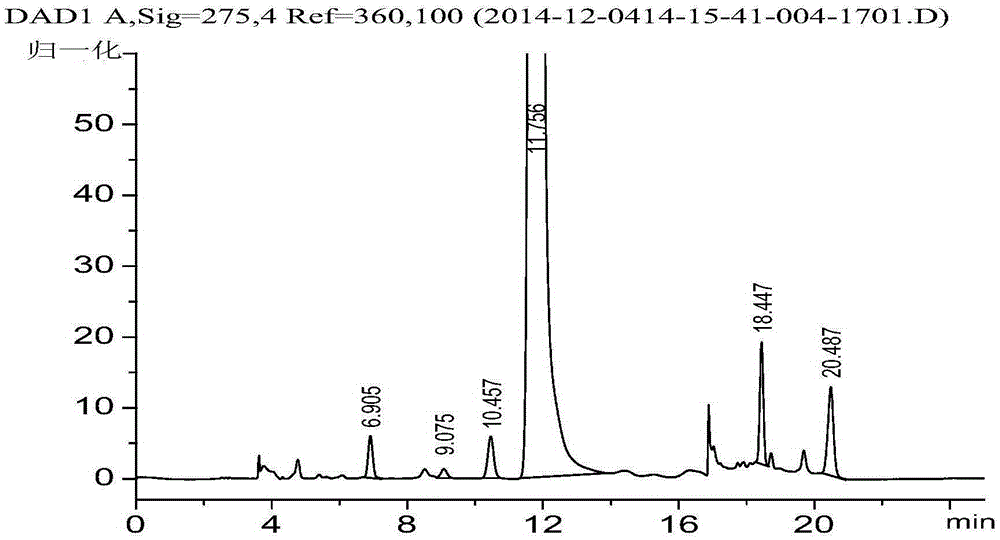

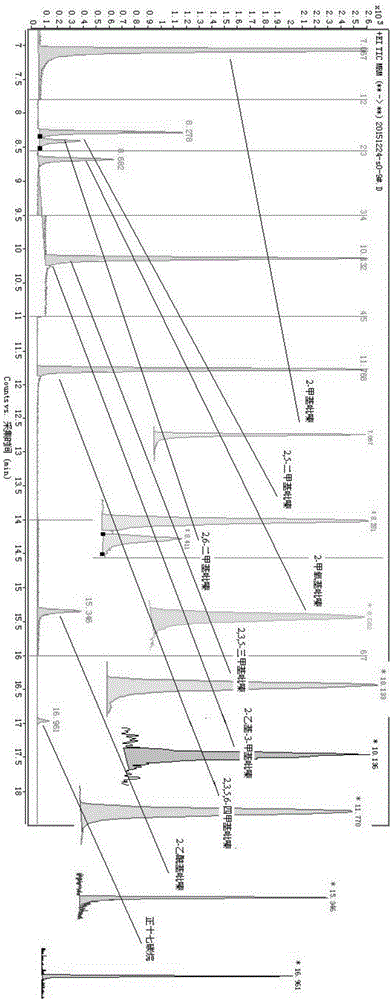

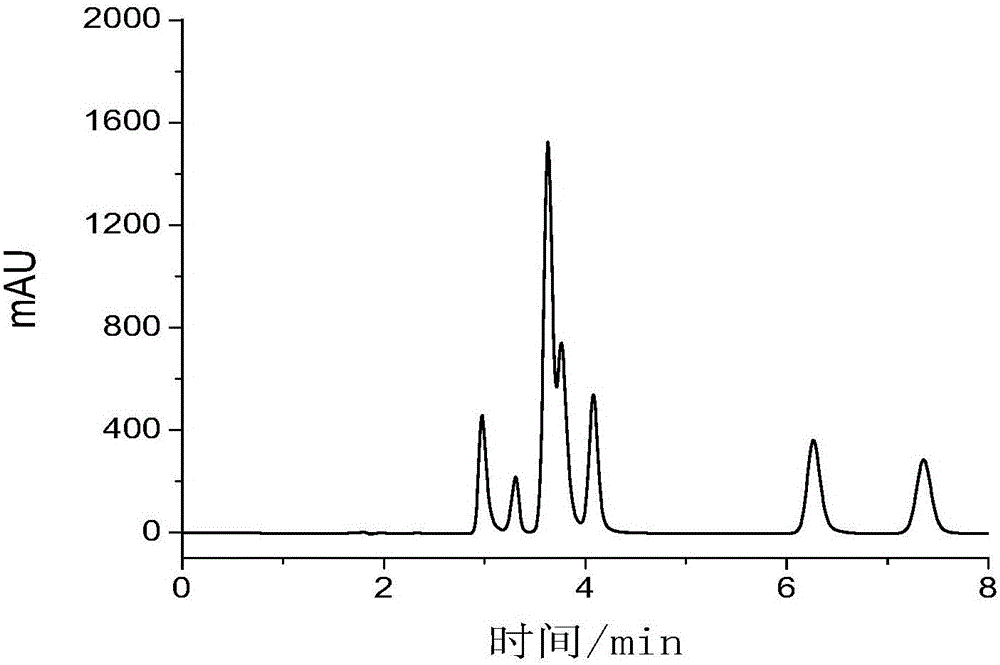

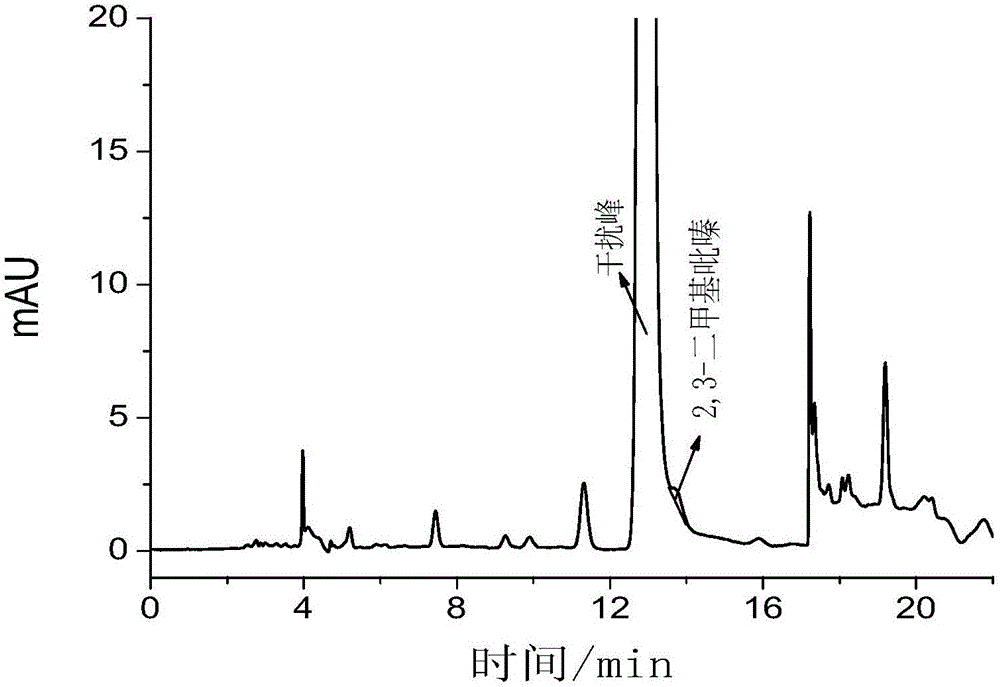

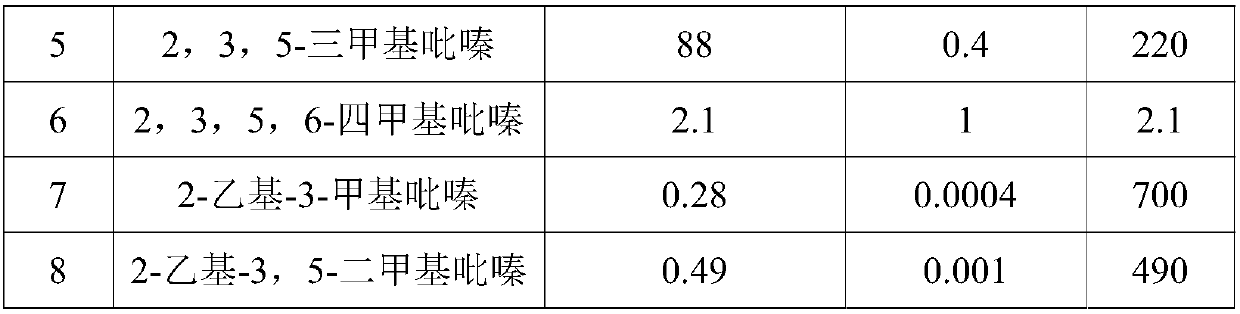

Detection method of pyrazine compounds in Jiang-flavour Chinese spirit

The present invention discloses a detection method of pyrazine compounds in Jiang-flavour Chinese spirit, according to the method, qualitative and quantitative analysis of the pyrazine compounds in the Jiang-flavour Chinese spirit can be performed by high performance liquid chromatography-tandem mass spectrometry, and eight pyrazine compounds of 2-methyl pyrazine, 2,3-dimethyl pyrazine, 2,5-dimethyl pyrazine, 2,6-dimethyl pyrazine, 2,3, 5-trimethyl pyrazine, 2-ethyl-6-methyl pyrazine, 2,3,5,6-tetramethyl pyrazine, 2,3-dimethyl-5-ethyl-pyrazine in the Jiang-flavour Chinese spirit can be simultaneously detected by the method. A sample directly passes through into a membrane for sample injection, no chiral column or chiral additive is used for isomeride resolution in the chromatography, sample derivatization is not needed, and the method has the advantage of high sensitivity, good accuracy and repeatability, and simple operation.

Owner:GUIZHOU PROVINCIAL PRODUCT QUALITY SUPERVISION AND INSPECTION INSTITUTE +1

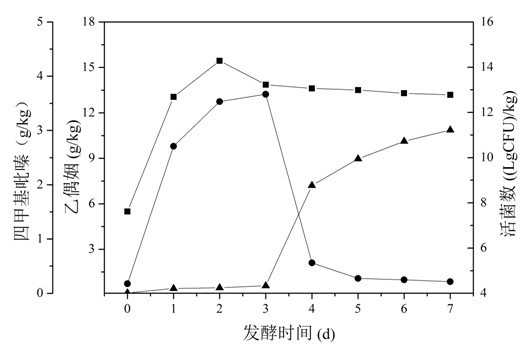

Bacillus licheniformis, yeast prepared through same and preparation method of yeast

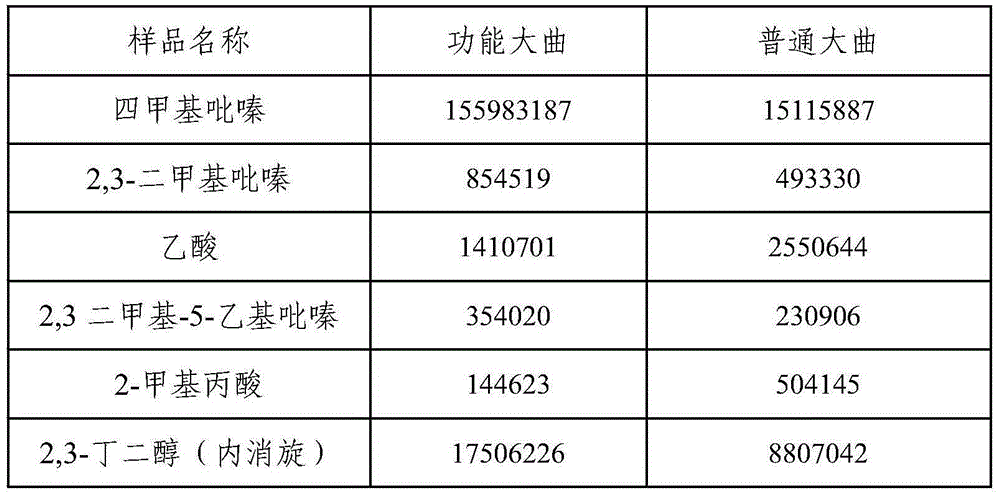

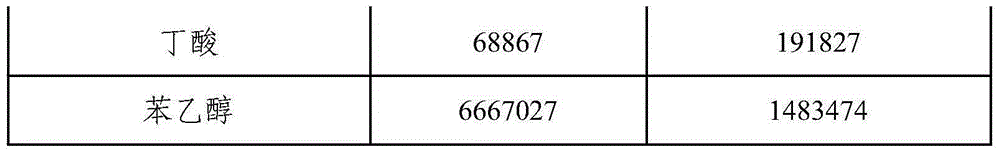

The invention relates to the technical field of yeast for making hard liquor, in particular to bacillus licheniformis, yeast prepared through the same and a preparation method of the yeast. The bacterial strain is named as the bacillus licheniformis according to classification and collected in the China center for type culture collection, and the collection number is CCTCC NO. M2015224; after the bacterial strain is made into a fermentation bacterium solution, the fermentation bacterium solution serving as the functional bacterium solution is inoculated onto raw materials for making the yeast to be subjected to fermentation treatment, and the yeast product is obtained. The technological process is short and easy to operate; compared with traditional yeast, the content of tetramethylpyrazine in the obtained yeast is increased by over nine times.

Owner:KWEICHOW MOUTAI COMPANY

Method for producing acetoin by vinasse fermentation and producing tetramethylpyrazine by acetoin transformation

ActiveCN102618587AIncrease added valueEfficient use ofMicroorganism based processesFermentationBiotechnologyBacillus licheniformis

The invention discloses a method for producing biological aromatics: acetoin and tetramethylpyrazine by taking vinasse as a raw material by utilizing microbial fermentation and belongs to the technical field of biological engineering. The method disclosed by the invention comprises the following steps of: supplementing a proper amount of glucose (0-100g / kg) into fresh vinasse of which the acidity is regulated; adding a seed culture cultured by any one of bacillus subtilis (CCTCCNO: M208157) or bacillus licheniformis (CGMCC3961, 3962, 3963); then, fermenting for 1-3 days at the temperature of 37 DEG C to produce a great amount of one of the biological aromatics: the acetoin; and on the basis, adding ammonium salt to the fermentation product to produce the other biological aromatic: the tetramethylpyrazine by acetoin transformation. The method for selectively producing the biological aromatics: the acetoin and the tetramethylpyrazine under control by taking the vinasse as the raw material through whether the ammonium salt is added or not has the outstanding advantages that not only can the biological aromatics with different high additional values be selectively obtained but also the vinasse is prevented from polluting the environment and the utilization value of the vinasse is promoted.

Owner:JIANGNAN UNIV

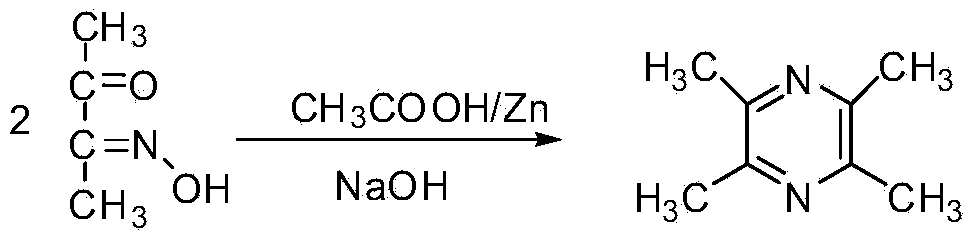

Method for preparing tetramethyl pyrazine

InactiveCN1935794AThorough responseResidue reductionOrganic chemistryTetramethyl pyrazineNitrogen gas

The invention relates to a Chuanxiongzine preparing method, comprising the steps of: using 3-hydrox-2-butanone and ammonium acetate as raw materials, adding in alcohol, charging nitrogen gas, and blending in hot bath for 5-8 h; on air or oxygen condition, blending for 12 h; adding in oxidant, and blending for 1-2 h, where the weight ratio of oxidant to 3-hydrox-2-butanone = (0.5-1):1; and filtering out the remaining oxidant; vacuum-distilling to make it. And the method has high yield. And the organic solvent utilization in the preparing course is less, beneficial to environmental protection. And the invention has advantages of low cost and simple operation.

Owner:张锋

Method for producing sesame flavored white spirit high in tetramethylpyrazine content

ActiveCN102978073AIncrease softnessImprove comfortAlcoholic beverage preparationMicroorganism based processesTetramethyl pyrazineBran

The invention discloses a method for producing sesame flavored white spirit high in tetramethylpyrazine content, comprising the following steps of: crushing 800-900 parts of broomcorn and 100-200 parts of wheat, blending 50-100 parts of bran and 200-300 parts of stillage obtained through the previous round of steaming with starch solution evenly, and steaming the mixture in a rice steamer, thereby obtaining fermented grains; blending the obtained fermented grains with the stillage obtained through the previous round of steaming in the ratio of 1: (5-5.5) and performing aeration cooling; adding 150-200 parts of sesame flavored yeast and 200-250 parts of bran to the mixture and supplementing the starch solution, and then gathering and stacking for 2-3 days, thereby obtaining fermented residues; performing aeration cooling on the fermented residues so that the temperature thereof reaches 28-32 DEG C; sealing and fermenting in a pit for 50-60 days; and mixing 1000-1200 parts of fermented grains with 150-180 parts of steamed rice husk in the rice steamer for steaming, thereby obtaining the sesame flavored white spirit. The sesame flavored white spirit through the production process provided by the invention is obviously improved in quiet and tasteful degree, softness and comfort in contrast with the wine produced through the existing process; and the premium grade rate of the sesame flavored white spirit is improved by more than 20% in contrast with the existing process, while the content tetramethylpyrazine thereof beneficial for human body health is increased to 3000-4000 ug / L from 300-800 ug / L.

Owner:山东景芝白酒有限公司

Novel fried wheat essence

InactiveCN101602983ACover up moldy smellGreat tasteEssential-oils/perfumesFood scienceTetramethyl pyrazine2-acetylthiophene

The invention discloses a novel fried wheat essence, comprising 2-acetylthiophene, furanone, 2,3-pentanedione, 3-methyl-2-cyclohexenyl-1-one, 2,3,5,6-tetramethylpyrazine, 5-methyl-6,7-dihydrocyclopentylpyrazine, 2-acetylpyrazine, tricin, furfuryl thioacetate, biradical disulfide and propylene glycol. The invention not only has fried wheat fragrance and but also can be used in the coarse grain beverage after baking, in particular to wheat smell milk beverage. Meanwhile, the invention can better enhance the mouthfeel and cover the bilgy odour and musty taste of legume coarse grain in base materials.

Owner:广州市凯虹香精香料有限公司

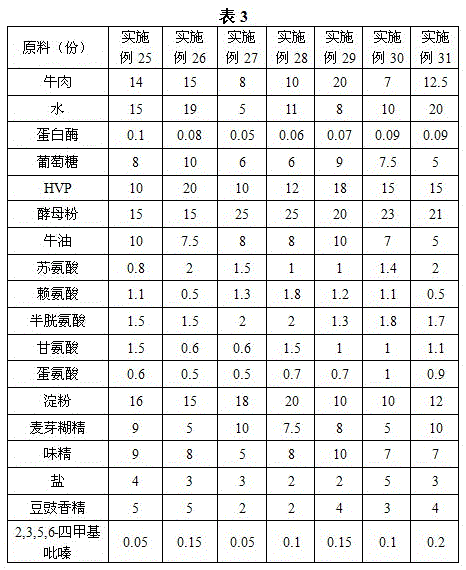

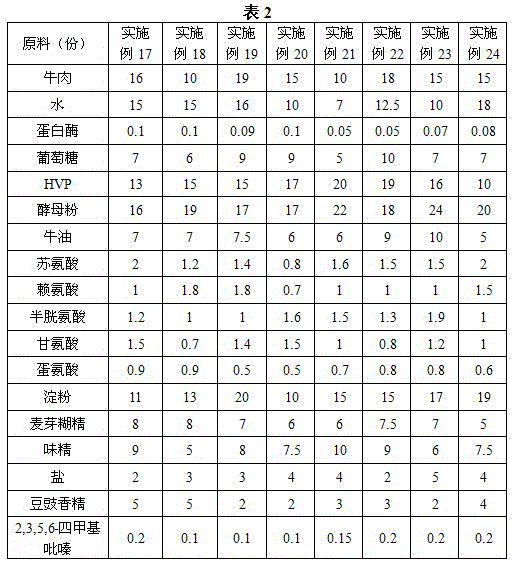

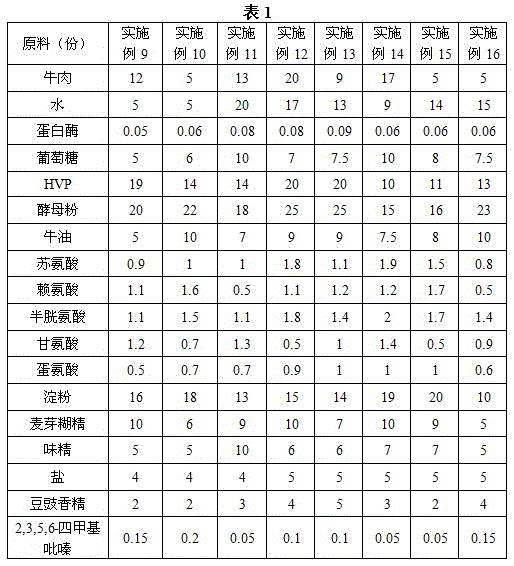

Fermented blank bean beef powder essence and preparation method thereof

The invention discloses fermented blank bean beef powder essence. The fermented blank bean beef powder essence is prepared from the following raw materials in parts by weight: 5 to 20 parts of beef, 5 to 20 parts of water, 0.05 to 0.1 parts of protease, 5 to 10 parts of glucose, 10 to 20 parts of HVP, 15 to 25 parts of yeast powder, 5 to 10 parts of beef tallow, 0.8 to 2 parts of threonine, 0.5 to 1.8 parts of lysine, 1 to 2 parts of cysteine, 0.5 to 1.5 parts of glycine, 0.5 to 1 part of methionine, 10 to 20 parts of starch, 5 to 10 parts of maltodextrin, 5 to 10 parts of monosodium glutamate, 2 to 5 parts of salt, 2 to 5 parts of fermented blank bean essence, and 0.05 to 0.2 parts of 2,3,5,6-tetramethylpyrazine. The fermented blank bean beef powder essence provided by the invention is sandy beige powdery essence; fermented blank bean beef is pure in flavor, tastes delicious, is long in aftertaste, pure in taste and long in fragrance, does not taste bitter, and is true and natural in fragrance; the bitterness generated by drying original fermented blank bean beef powder is eliminated, and the defect that the taste is not natural and mellow enough due to adoption of fermented blank bean essence is overcome.

Owner:LUOHE LEJIA FOOD TECH CO LTD

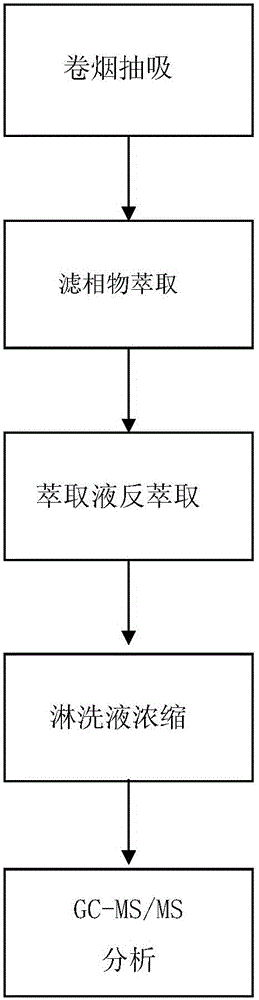

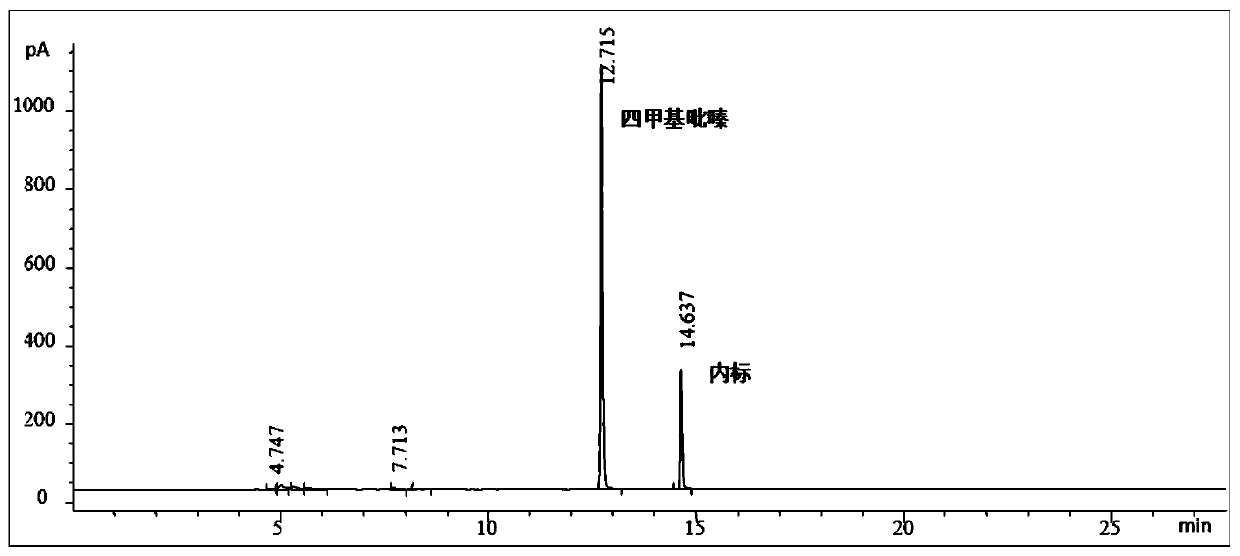

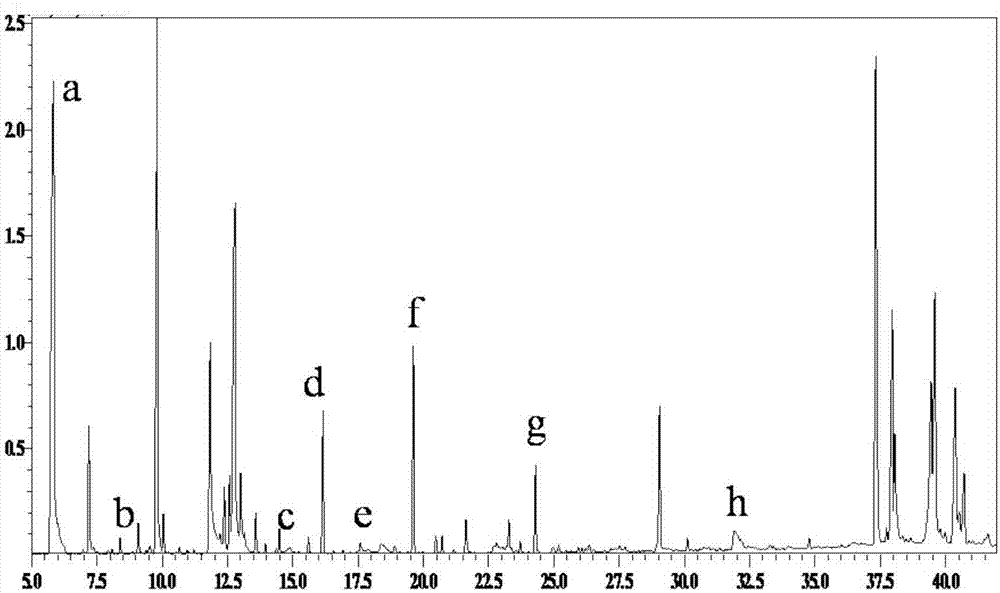

Method for quantitative analysis of main pyrazine flavor substances in cigarette mainstream smoke

ActiveCN105842374AGood effectSolve the impact of factors such as serious interference analysisComponent separationResponse sensitivityTetramethyl pyrazine

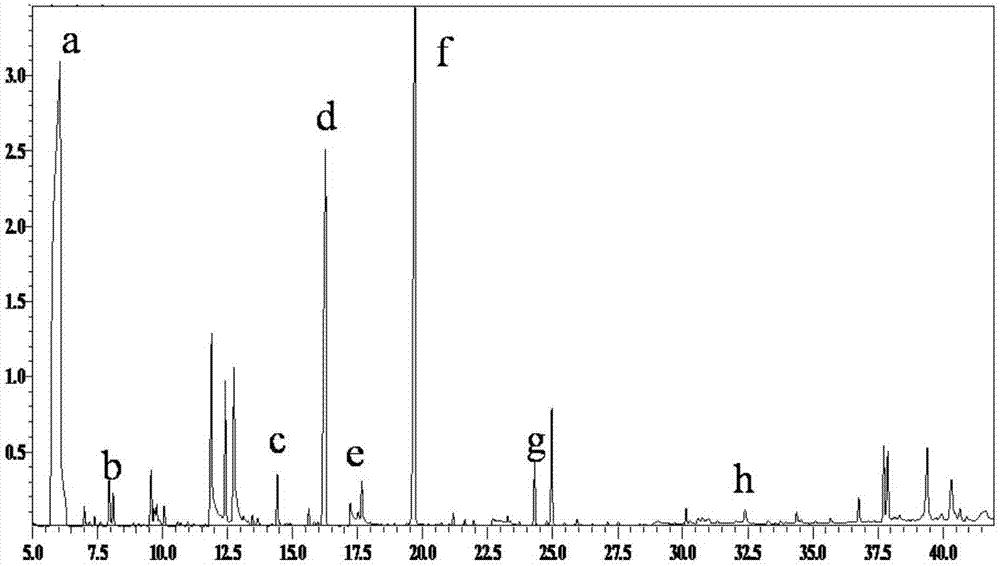

The invention discloses a method for quantitative analysis of main pyrazine flavor substances in cigarette mainstream smoke and relates to a method for gas chromatography-tandem mass spectrometer-based determination of eight main pyrazine flavor substances such as 2-methylpyrazine, 2, 5-dimethylpyrazine, 2, 6-dimethylpyrazine, 2-methoxypyrazine, 2, 3, 5-trimethylpyrazine, 2-ethyl-3-methylpyrazine, 2, 3, 5, 6-tetramethylpyrazine and 2-acetylpyrazine in cigarette mainstream smoke. The method comprises internal standard solution, standard work solution and sample solution preparation, gas chromatography-tandem mass spectrometry analysis and determination result calculation. The improved detection method can be operated simply, has response sensitivity and quantitative analysis accuracy, effectively reduces complex sample matrix-caused interference and is suitable for quantitative analysis of a trace quantity of a target object in a complex flue gas matrix.

Owner:CHINA TOBACCO JIANGSU INDAL

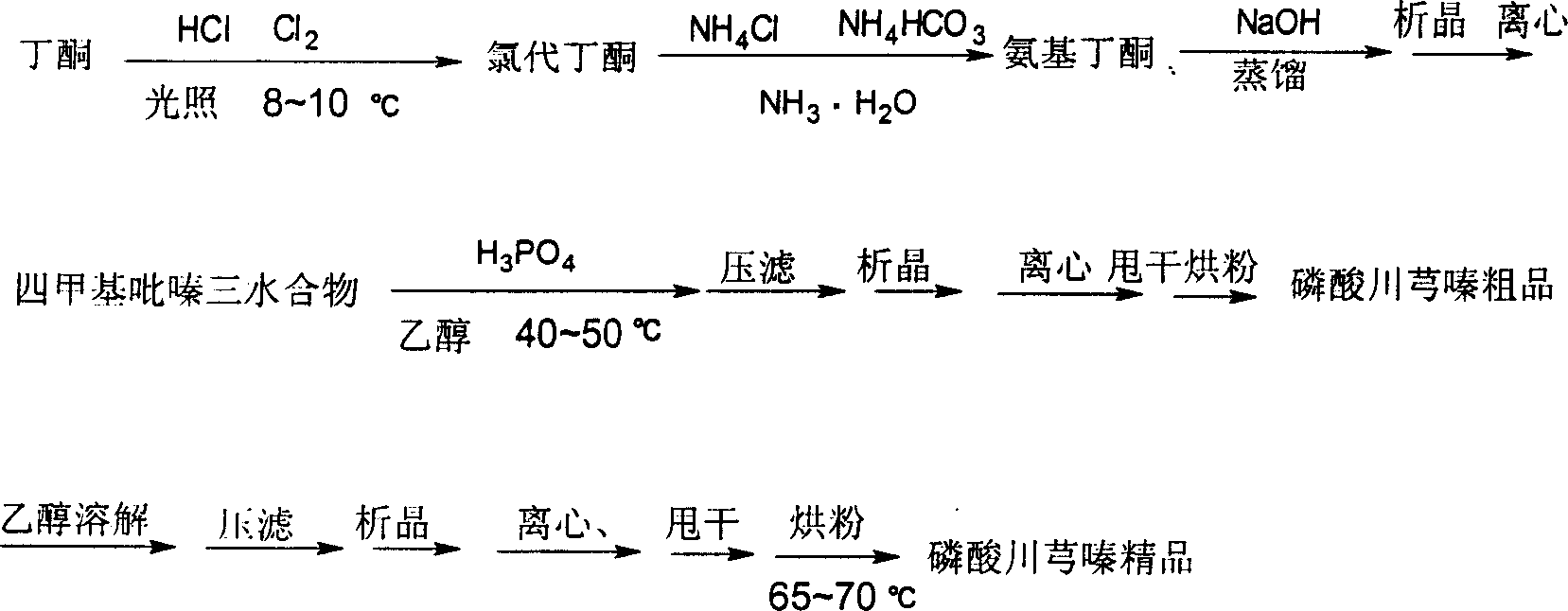

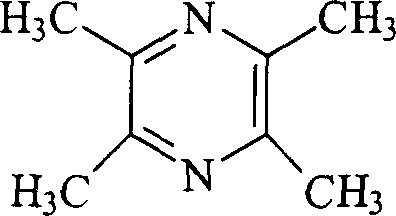

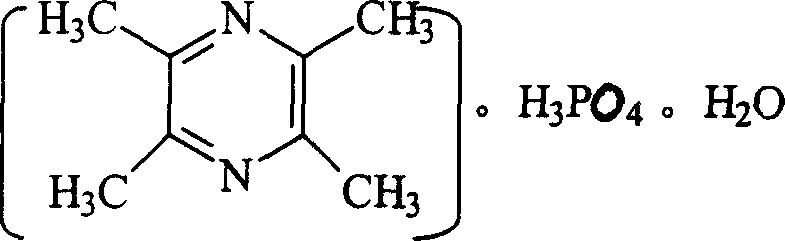

Method for preparing tetramethyl pyrazine

The invention provides a process for chemically synthesizing tetramethylpyrazine by using amino butanone as raw material and letting in steam at the presence of alkalinity, wherein the obtained tetramethylpyrazine is in the form of trihydrate. The synthesis process can be applied to the field of pharmacy. The invention also provides the process for preparing phosphoric ligustrazine and phosphoric ligustrazine by using tetramethylpyrazine.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP

Bacillus pumilus capable of highly producing tetramethylpyrazine

ActiveCN101078006ARaw materials are cheap and easy to getMild reaction conditionsBacteriaEnzymologyMicroorganismTetramethyl pyrazine

The invention discloses tetramethylpyrazine bacillus pumilis with high yield, called Bacillus pumilus RX3-17 and preserved in China Center for Type Culture Collection on 19th, April, 2006, whose serial number is CCTCC M 206043. This bacterial stripe is separated from soil, which have shape of stick, length of 1.5-3.0 micron, and diameter of 0.6-0.7micron with white colony. The striple has typical characteristic of bacillus pumilis, whose sequence of 16S rDNA has 99% similarity as that of other bacillus pumilis. The invention exists in field of biology and technology. Tetramethylpyrazine can be produced by Bacillus pumilus RX3-17 using glucose as substrate, solving problems of low concentration of tetramethylpyrazine by microbic fermentation method.

Owner:SHANGHAI KAIXIN BIOTECH +2

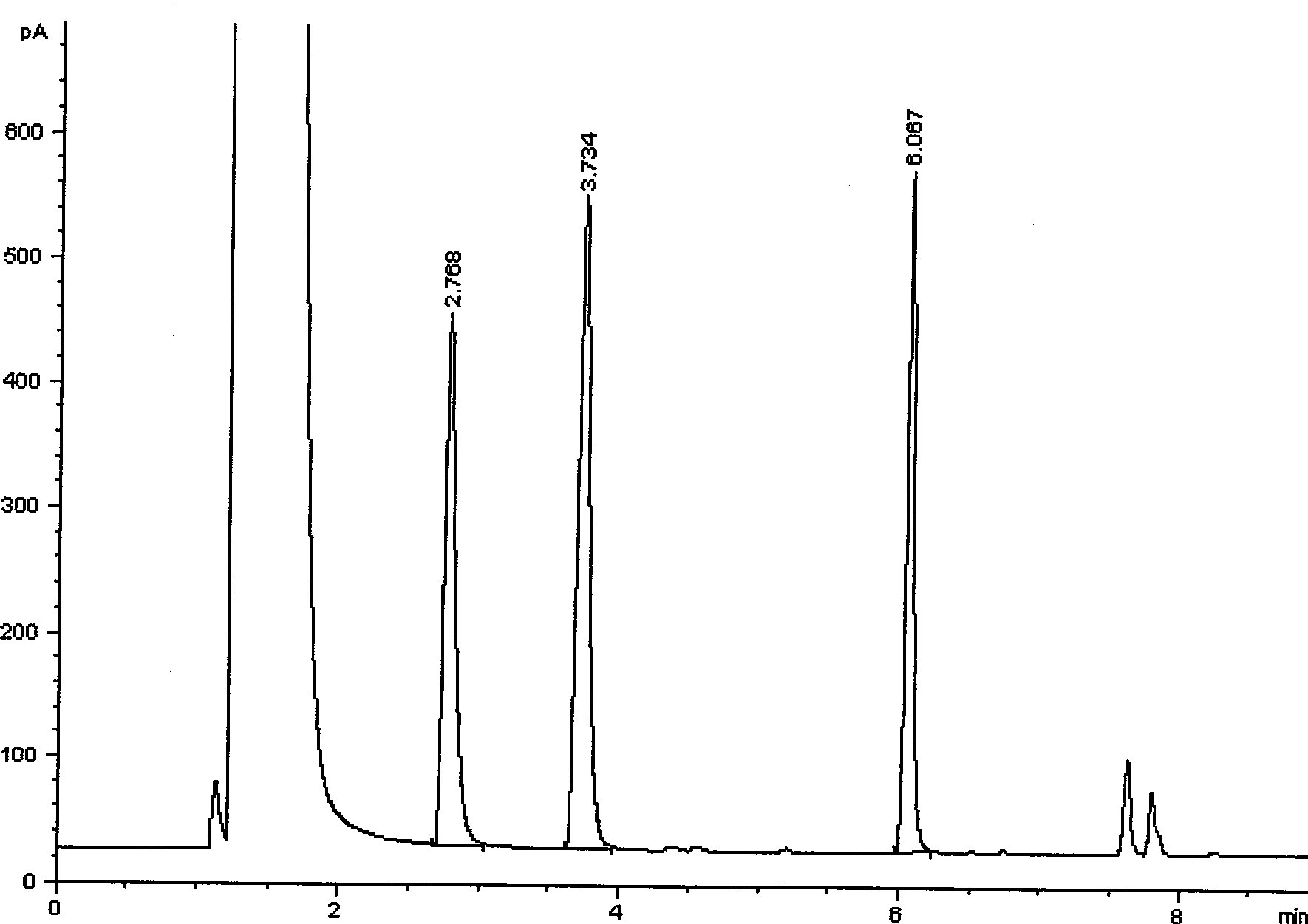

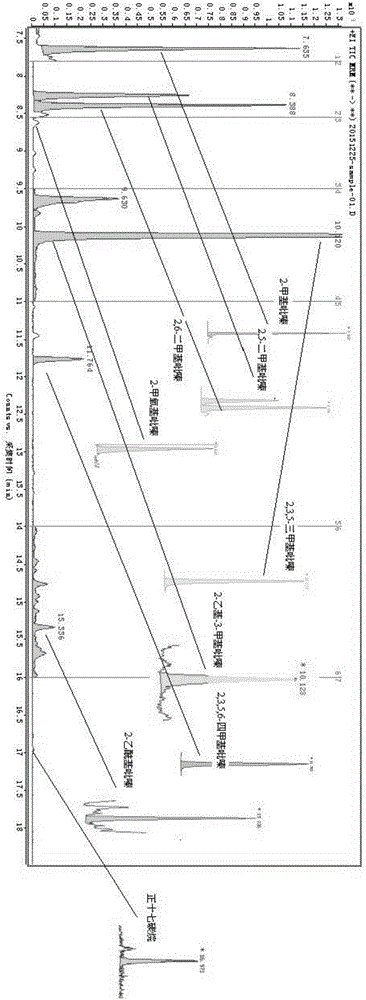

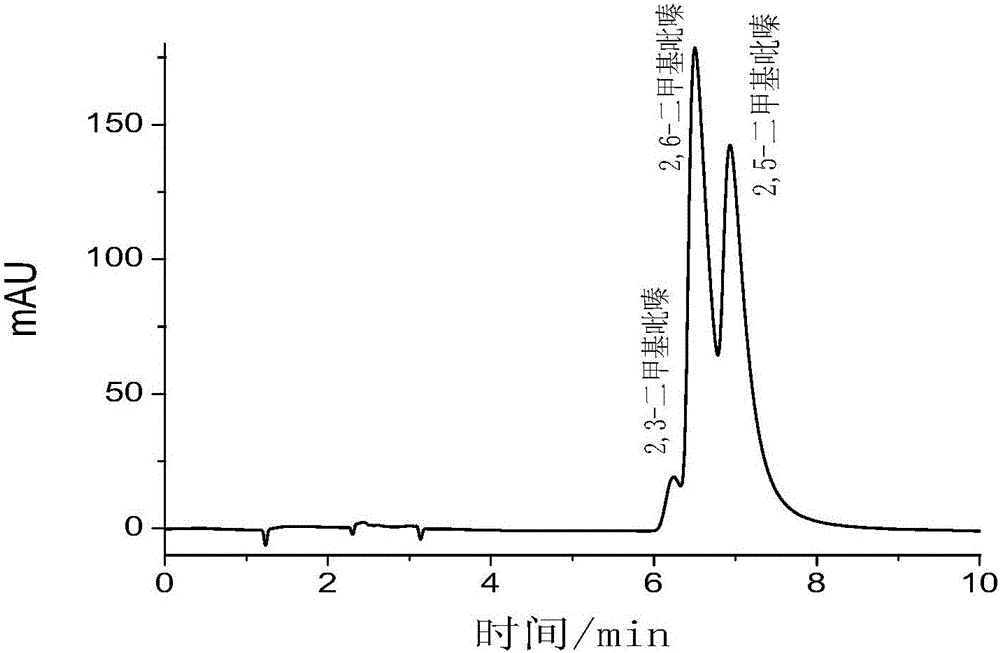

High performance liquid chromatography detection method for pyrazine compounds in Baijiu

InactiveCN105842377AHigh sensitivityImprove accuracyComponent separationTetramethyl pyrazineFluorescence

The invention discloses a high performance liquid chromatography detection method for pyrazine compounds in Baijiu. According to the method, a high performance liquid chromatography-fluorescence detector (HPLC-FLD) method is adopted to perform qualitative and quantitative analysis on the pyrazine compounds in Baijiu, and 2-methylpyrazine, 2, 3-dimethylpyrazine, 2, 5-dimethylpyrazine, 2, 6-dimethylpyrazine, 2, 3, 5-trimethyl pyrazine, 2-ethyl-6-methylpyrazine, 2, 3, 5, 6-tetramethylpyrazine and 2, 3-dimethyl-5-ethylpyrazine can be measured at the same time. With the adoption of the method, 3 types of isomeride can be separated without chemical derivation, chiral columns or adding chiral reagents, is high in sensitivity, good in accuracy and repeatability, simple to operate, and low in cost.

Owner:GUIZHOU PROVINCIAL PRODUCT QUALITY SUPERVISION AND INSPECTION INSTITUTE

Bacillus licheniformis for producing 2,3,5,6-tetramethylpyrazine in high yield as well as separation culture method and application of bacillus licheniformis

ActiveCN111218415AHealth enhancing activesIncrease productivityBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

The invention relates to bacillus licheniformis for producing 2,3,5,6-tetramethylpyrazine in a high yield as well as a separation culture method and application of the bacillus licheniformis. The bacillus licheniformis for producing the 2,3,5,6-tetramethylpyrazine in the high yield is named a bacillus licheniformis S1001 strain, the preservation unit is China General Microbiological Culture Collection Center, the preservation time is February 25, 2019, the preservation number is CGMCC No.17255, and the address is No.3, Yard NO.1 Beichen West Road, Chaoyang District, Beijing. The strain has thecharacteristics of producing the 2,3,5,6-tetramethylpyrazine in the high yield by using a raw material under the condition of facultative anaerobic solid fermentation, and when the strain is appliedto a raw material solid culture process, starter rich in the 2,3,5,6-tetramethylpyrazine can be produced, so that the strain has an important effect on further improving healthy active substances in awine body.

Owner:JIANGSU KINGS LUCK BREWERY

Tetramethylpyrazine bacillus amyloliquefaciens, and applications of sesame-flavor baijiu special-purpose mouldy bran

InactiveCN106987546AIncrease contentHigh production controllabilityBacteriaAlcoholic beverage preparationTetramethyl pyrazineBacillus amyloliquefaciens

The invention discloses a tetramethylpyrazine bacillus amyloliquefaciens, and applications of a sesame-flavor baijiu special-purpose mouldy bran. The tetramethylpyrazine sesame-flavor baijiu special-purpose mouldy bran is obtained using tetramethylpyrazine bacillus amyloliquefaciens XJB-104 strain via following steps: preparation of a primary seed solution, preparation of a secondary seed solution, bran solid state culture medium fermentation, and aeration-drying of an obtained matured mouldy bran material. The obtained tetramethylpyrazine sesame-flavor baijiu special-purpose mouldy bran is bright in color, is dark brown, possesses typical smell, and slight ammonia smell, and is beneficial for improvement of the quality of sesame-flavor baijiu; and the tetramethylpyrazine content is higher than 380mg / kg.

Owner:ANHUI XUANJIU GRP +1

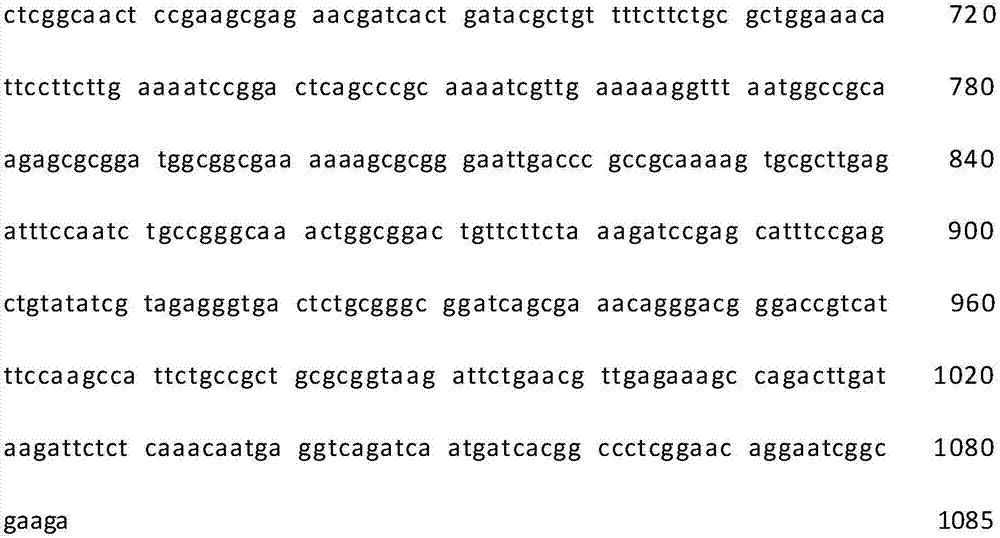

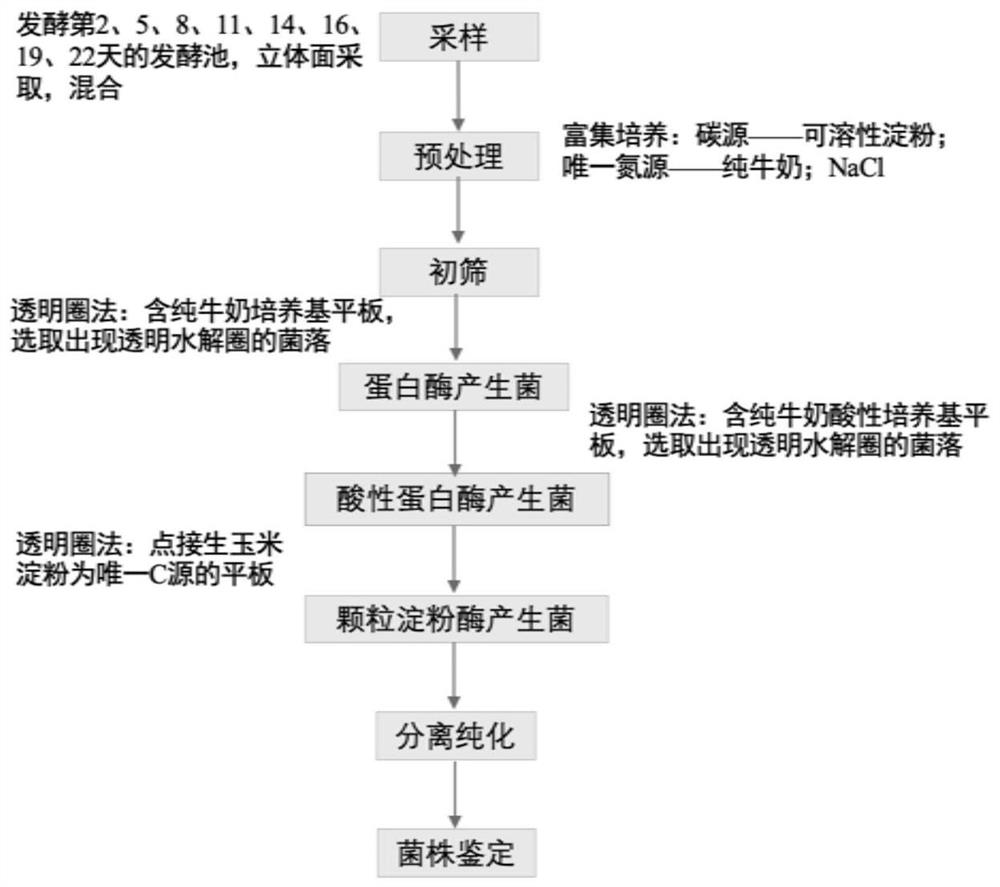

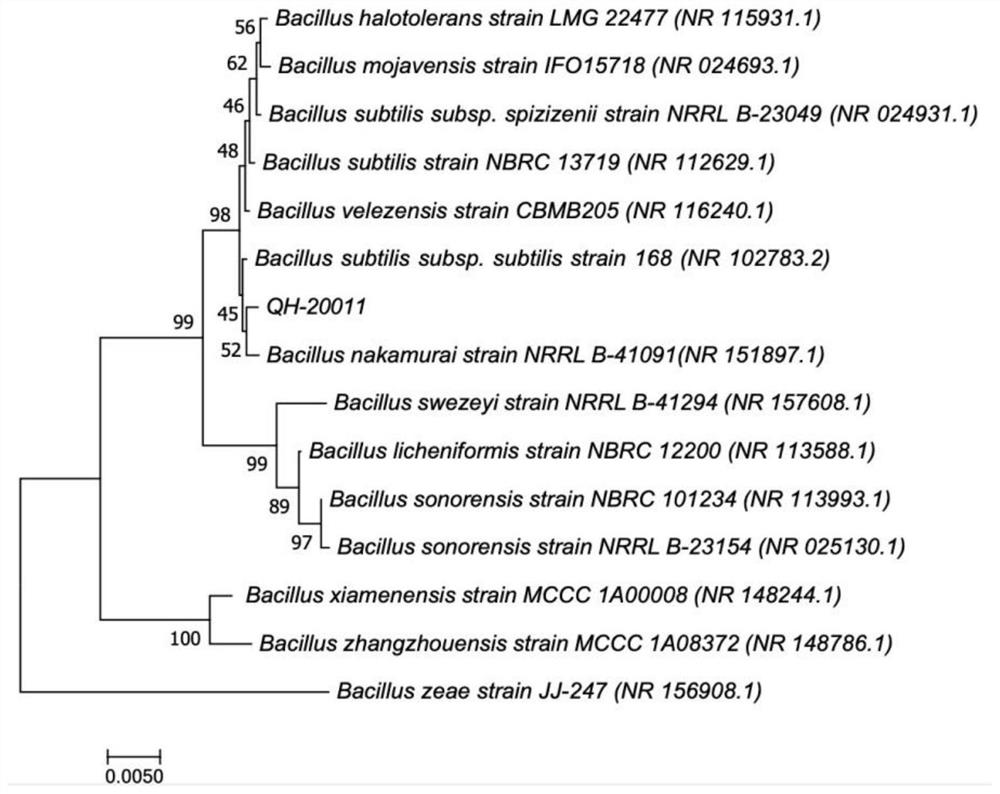

ZHONGCUN bacillus QH-20011 with low pH tolerance and application of ZHONGCUN bacillus QH-20011

ActiveCN113430147AImprove protein utilizationIncreased acetoin contentBacteriaBiofuelsBiotechnologyNutritive values

The invention discloses ZHONGCUN bacillus QH-20011 with low pH tolerance and application of the ZHONGCUN bacillus QH-20011, the ZHONGCUN bacillus QH-20011 is preserved in the China General Microbiological Culture Collection Center, the preservation name is QH-20011, and the preservation number is CGMCC No: 22253. The ZHONGCUN bacillus QH-20011 can grow, metabolize and produce enzymes under the condition of acidity (pH 3.0), has the capacity of producing high-activity protease and granular amylase, and is applied to vinegar brewing, so that the protein utilization rate and starch utilization rate of vinegar brewing raw materials can be remarkably increased, the content of free amino acids in vinegar is increased, particularly the content of sweet amino acids such as glycine and threonine, and the content of the sour amino acid cysteine can be increased, the content of acetoin and tetramethylpyrazine in the brewed vinegar can be increased, the flavor and the nutritional value of the brewed vinegar can be improved, and the quality of the vinegar product can be improved.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Liquid lubricant

InactiveCN103013630AImprove corrosion resistanceEasy to useLubricant compositionGLYCERYL PALMITATEHeptadecanoic acid

The invention discloses a liquid lubricant which comprises the following raw materials in parts by mass: 1-2 parts of leaf-contained fenchone, 3-6 parts of dilinoleoyl-palmitoyl-rac-glycerol, 2-5 parts of nitrogen-containing compound tetramethylpyrazine, 2-7 parts of methyl silicone resin, 2-3 parts of spathulenol, 1-2 parts of methoxy-methylfurfural, 2-4 parts of cycloalkyl arene, 2-4 parts of isoctadecanoic acid ethyl esters and 2-6 parts of iso-heptadecanoic acid ethyl esters. The liquid lubricant disclosed by the invention is not only strong in corrosion resistance, stable in application effect, and capable of effectively lubricating each part of machines, but also can significantly prolong the service life of machines, produce no bubble and facilitate the washing of machines, and is safe and nontoxic to human bodies.

Owner:南通市华东润滑设备有限公司

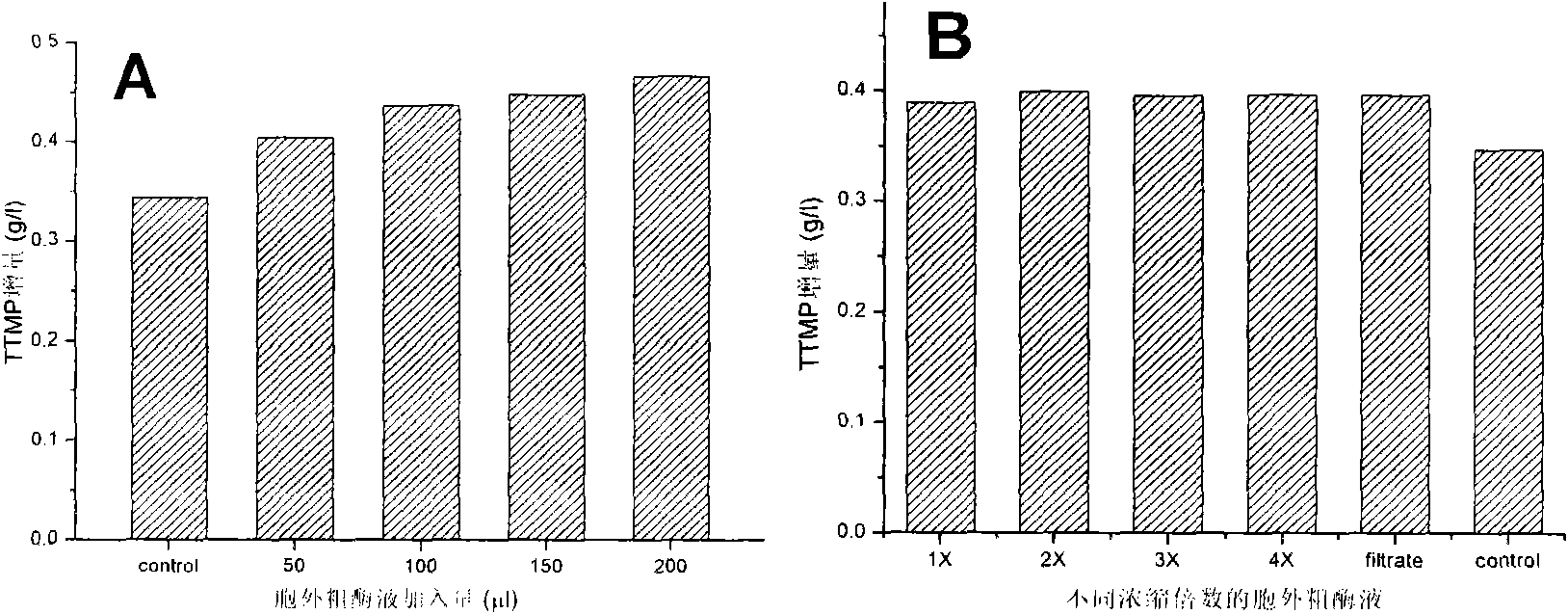

Method for improving output of tetramethylpyrazine produced through fermentation by Bacillus

InactiveCN105838751AIncrease productionNo pollution in the processMicroorganism based processesFermentationBiotechnologyTetramethyl pyrazine

The invention specifically relates to a method for improving output of tetramethylpyrazine produced through fermentation by Bacillus, belonging to the field of bioengineering. The method is characterized in that a certain amount of acetaldehyde is added into a fermentation medium in an early stage of fermentation and NaOH is added to allow the pH value of fermentation broth to be slightly greater than 7.0, thereby improving the output of tetramethylpyrazine by Bacillus. The method has the advantages that the output of tetramethylpyrazine is increased by adding acetaldehyde in the early stage of fermentation; the output of tetramethylpyrazine is substantially increased through controlling of a weakly alkaline condition; and the method is economic, environment-friendly and low in cost.

Owner:QILU UNIV OF TECH +1

Method for increasing content of tetramethylpyrazine in edible vinegar

InactiveCN107384728AIncrease contentDoes not destroy nutrientsVinegar preparationTetramethyl pyrazineReaction rate

The invention relates to a method for increasing content of tetramethylpyrazine in edible vinegar. The method comprises the following steps: adding a mixture of acetoin and ammonium salt in the edible vinegar, performing high-voltage pulse electric field treatment on the edible vinegar added with acetoin and ammonium salt, insulating the edible vinegar processed with high-voltage pulse electric field treatment for 3-15 h at the temperature of 35-55 DEG C, cooling the edible vinegar; and ageing the cooled edible vinegar for 3-12 months at the temperature of 20-30 DEG C. By adding a certain amount of acetoin and ammonium salt, acetoin and ammonium salt content in the edible vinegar can be increased, the intermolecular collision probability is increased; the energy consumption during a high-voltage pulse electric field treatment process is little, the high-voltage pulse electric field treatment can be carried out under normal temperature, the reaction rate is increased, the nutrition component of the edible vinegar cannot be destroyed, the processing efficiency is high, the processing time is short which is generally short than 3 min, and the method is suitable for large-scale production usage by enterprises. The method can greatly shortens the ageing time of the edible vinegar and increases the content of tetramethylpyrazine in the edible vinegar in short time.

Owner:FUJIAN AGRI & FORESTRY UNIV

Production method for increasing 3-methylthio propanol and tetramethylpyrazine in Luzhou- and sesame-flavor Baijiu

InactiveCN105695225ASesame flavor is prominentElegant and delicateAlcoholic beverage preparationMicroorganismFlavor

The invention relates to a production method for increasing 3-methylthio propanol and tetramethylpyrazine in Luzhou- and sesame-flavor Baijiu.To be more specific, on the basis of traditional methods, the method produces the Luzhou- and sesame-flavor Baijiu by using microorganisms containing 3042 soybean sauce strains to perform fermentation.The contents of the 3-methylthio propanol and the tetramethylpyrazine of the Baijiu produced by the method can reach a high level.The sensory evaluation of the Baijiu produced by the method shows that the Baijiu has the features of Luzhou-flavor Baijiu and is full in Baijiu body, prominent in scorch aroma and fragrant in first taste.

Owner:晋江尚京富本环保科技有限公司

Tetramethylpyrazine extraction and purification method

ActiveCN105859642AHigh purityImprove purification efficiencyOrganic chemistryPurification methodsTetramethyl pyrazine

The invention relates to a tetramethylpyrazine extraction and purification method. The method includes the following steps that firstly, a fermentation solution is heated, thalluses are centrifugally separated to obtain supernatant, and the supernatant is subjected to active carbon decoloration; secondly, the decolorized supernatant is filtered to obtain tetramethylpyrazine dialysate; thirdly, the tetramethylpyrazine dialysate is filtered and then concentrated through a reverse osmosis filter membrane to obtain an infiltration solution; fourthly, the infiltration solution is cooled and crystallized, the temperature is reduced, tetramethylpyrazine crystals are centrifugally separated, then the tetramethylpyrazine crystals are cooled and re-crystallized after redissolving, centrifugal separation is conducted, and high-purity tetramethylpyrazine is obtained. By means of the separation and extraction method, the purity of tetramethylpyrazine is high and is up to 99% or above, and purification efficiency is high and is up to 88% or above.

Owner:QILU UNIV OF TECH +1

Diet therapy milk powser candy for diabetes and its preparing method

InactiveCN1498545ASimple recipeClear ingredientsUnknown materialsCheese manufactureInsulin-like growth factorTetramethyl pyrazine

A milk tablet for the dietotherapy of diabetes is prepared through extracting the insulin-like growth factor, protein and polypeptide from formilk of cow, extracting tetramethyl pyrazine from chuan-xiong rhizome, extracting cinnamaldehyde from cinnamon bark, proportionally mixing them with said foremilk and dextrin, and tabletting. Its advnatages are high curative effect and no by-effect.

Owner:于连发

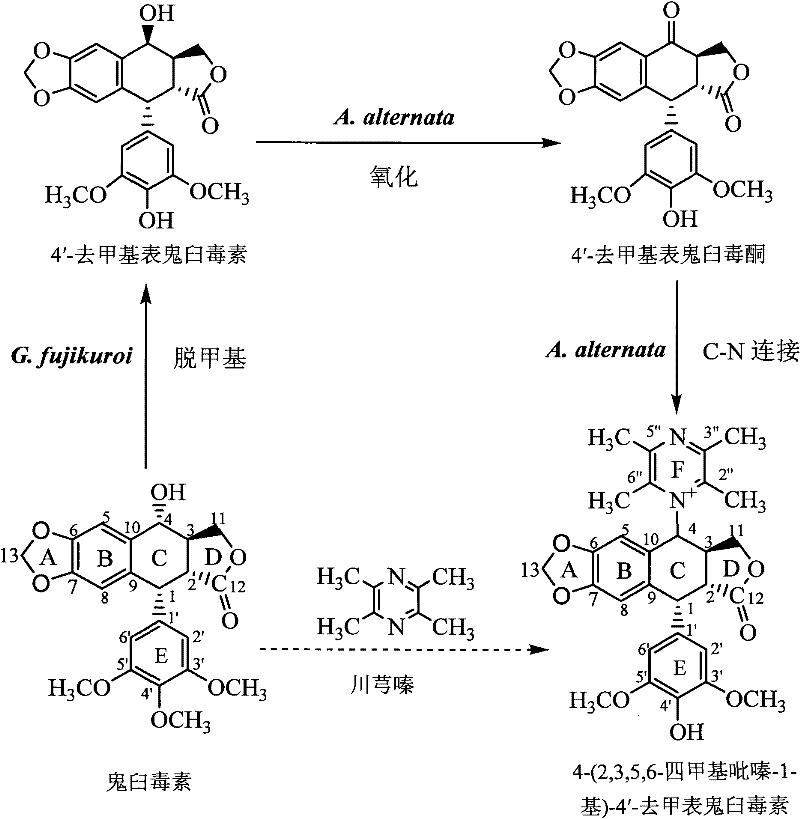

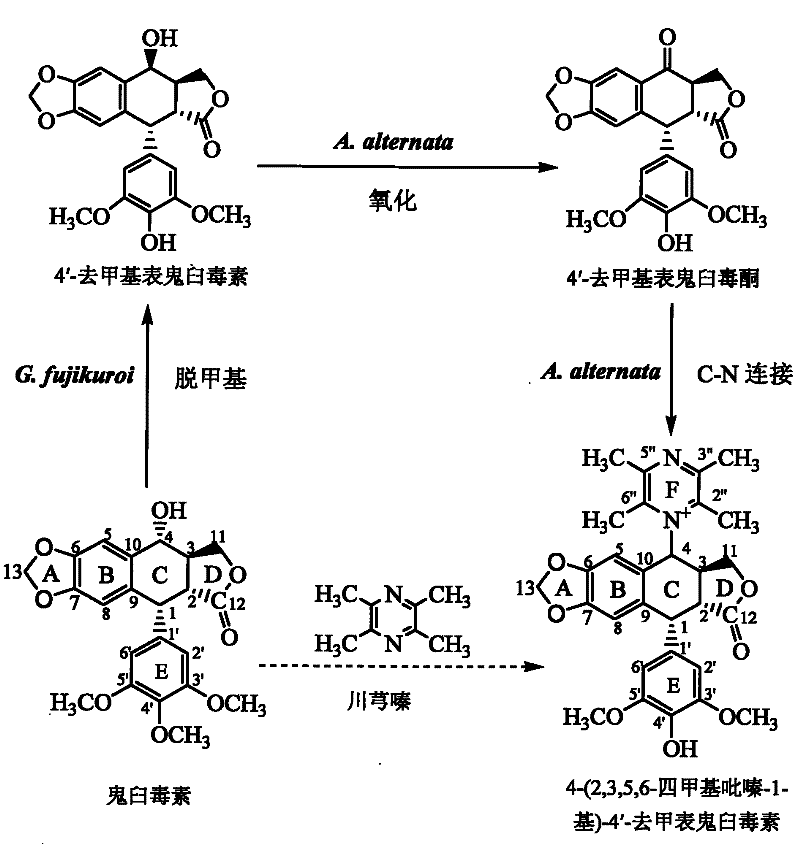

Biotransformation and purification method of 4-(2,3,5,6-tetramethylpyrazine-1-group)-4'-demethylepipodophyllotoxin

InactiveCN102234669ACultivableHas supplyOrganic chemistryComponent separationPurification methodsTetramethyl pyrazine

The invention discloses a method for transforming podophyllotoxin into 4-(2,3,5,6-tetramethylpyrazine-1-group)-4'-demethylepipodophyllotoxin, comprising the following steps of: (1) adding podophyllotoxin into a liquid fermentation medium, and carrying out biotransformation by inoculating second-class liquid seeds of humic soil fungi; (2) separating and purifying the product from the Step (1), followed by adding into the liquid fermentation medium, carrying out biotransformation by inoculating second-class liquid seeds of podophyllum taxa endophytes; then continuously carrying out biotransformation by adding ligustrazine, and collecting the transformation product. The invention also discloses a method for purifying 4-(2,3,5,6-tetramethylpyrazine-1-group)-4'-demethylepipodophyllotoxin from the above product and a method for detecting the content of 4-(2,3,5,6-tetramethylpyrazine-1-group)-4'-demethylepipodophyllotoxin. According to the invention, the molecular structure of podophyllotoxin is modified by the biotransformation method, which has advantages of mild reaction condition, low E-factor, quality controllability and simple separation process.

Owner:HUBEI UNIV OF TECH

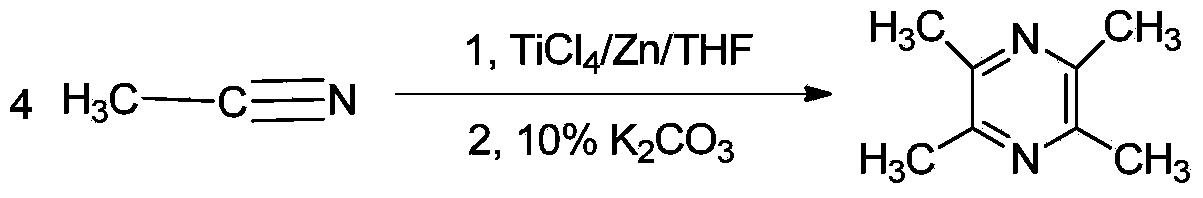

Preparation method of tetramethyl-pyrazine

ActiveCN104341359AThorough responseResidue reductionOrganic chemistryTetramethyl pyrazineSynthesis methods

The invention relates to a synthesis method of medical intermediate tetramethyl-pyrazine. The method takes butanedione monoxime as raw material, water as a solvent and palladium carbon as a catalyst, and comprises the steps of feeding ammonium formate in a reflux state, continuously carrying out reflux mixing for 4 hours after the ammonium formate is fed, filtering to remove the catalyst, cooling, extracting dichloromethane, and concentrating under the reduced pressure to obtain the tetramethyl-pyrazine. The method for preparing the tetramethyl-pyrazine is mild in reaction conditions and simple and convenient in aftertreatment, has the conversion rate of more than 95% and the yield of more than 80%, and is lower in cost and beneficial to industrial production.

Owner:WUHAN WUYAO PHARMA

Pork oily essence and preparation method thereof

InactiveCN107890068AEnhance aroma fragranceImprove meat textureFood ingredient as taste affecting agentLipidic food ingredientsFuranTetramethyl pyrazine

The invention relates to pork oily essence and a preparation method thereof. The pork oily essence is prepared from 2-mercapto-3-butanol, 2-acetyl-furan, bis(2-methyl-3-furyl)disulfide, 3-methylthiopropionaldehyde, methyl furfuryldisulfide, 2-acetylthiazole, cinnamon oil, thyme oil, clove oil, 4-methyl-5-hydroxyethylthiazole, 2, 3, 5, 6-tetramethylpyrazine, MCP, triacetin and salad oil. The pork oily essence is suitable for meat product flavoring, can improve the pork aroma and texture of a flavored product, has a long aftertaste and the harmonious and natural whole fragrance and has a high degree of truth.

Owner:TIANJIN CHUNYU FOOD INGREDIENTS

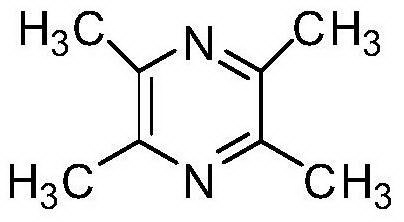

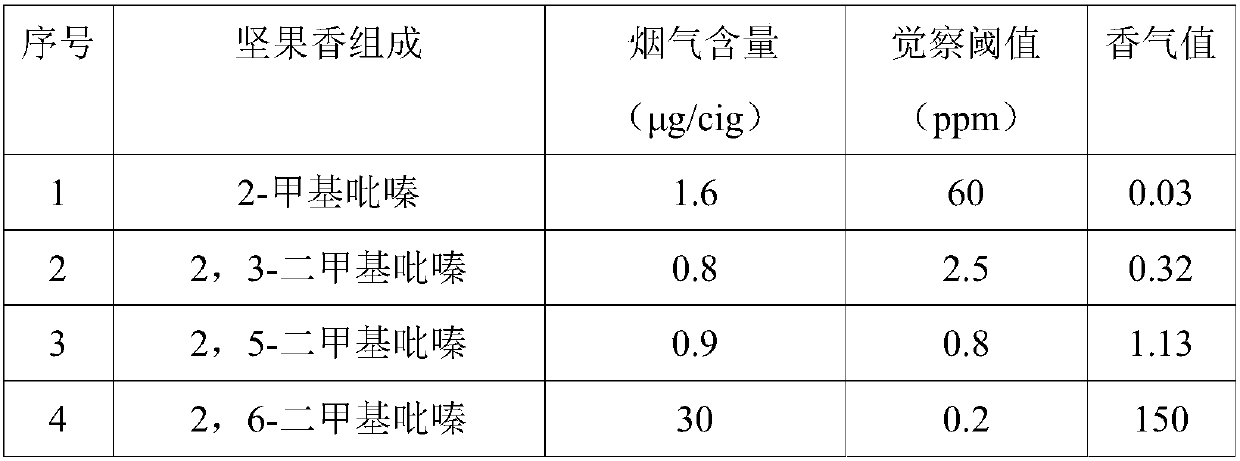

Nutty essence for cigarette

ActiveCN109576053AImprove fragrance experienceFlavor raw materials are simpleTobacco preparationTobacco treatmentTetramethyl pyrazineTobacco product

The invention relates to nutty essence for a cigarette, and belongs to the technical field of the scent blending of tobacco products. The nutty essence for the cigarette, which is provided by the invention, is prepared from a methylpyrazine compound, a dimethylpyrazine compound, a trimethylpyrazine compound and a tetramethylpyrazine compound. The essence provided by the invention is simple in rawmaterial, is easy to obtain, and is low in cost; and the scent feeling of the smoke of a tobacco product can be obviously improved by adding the essence.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

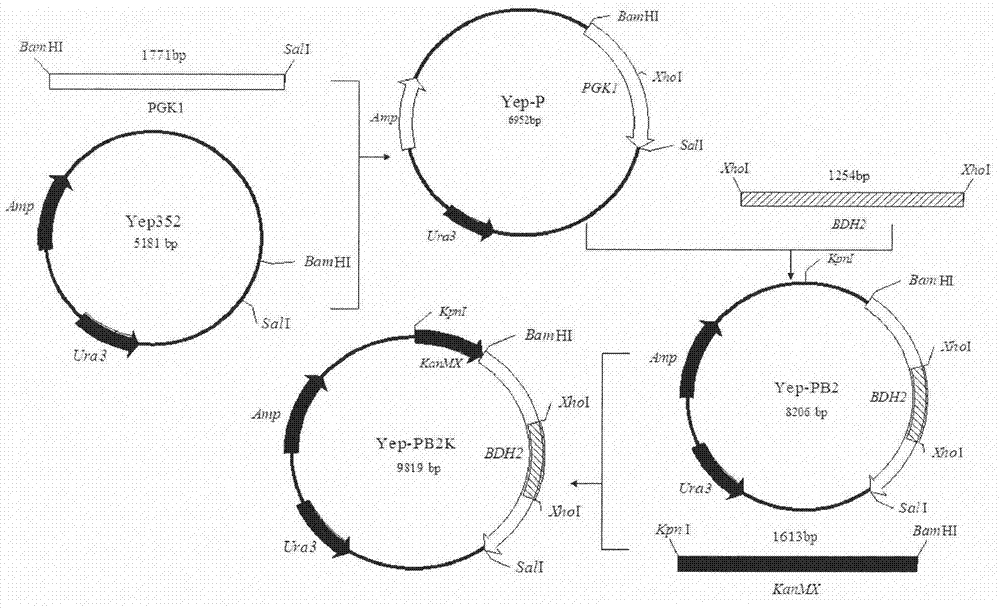

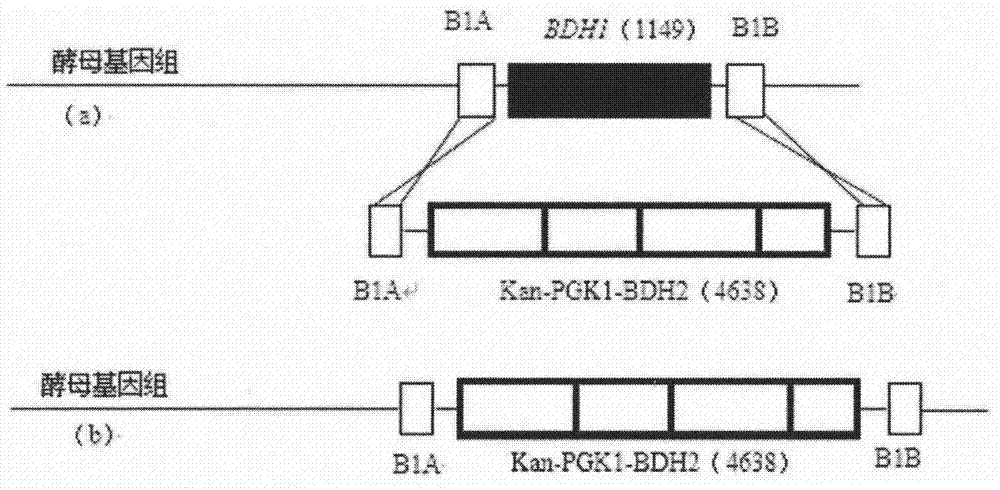

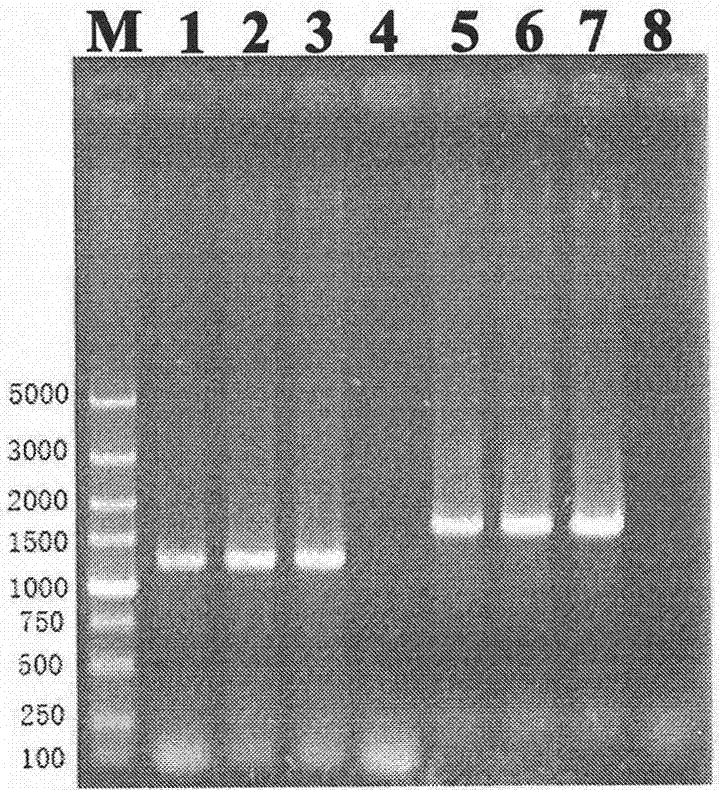

High yield tetramethylpyrazine saccharomyces cerevisiae and construction method thereof

InactiveCN106929438AEnsure safetyHigh yieldFungiMicrobiological testing/measurementWhite liquorTetramethyl pyrazine

The invention discloses a high yield tetramethylpyrazine saccharomyces cerevisiae strain and belongs to the technical field of bioengineering technology. The saccharomyces cerevisiae strain having similar fermenting property of a parent strain but being high in yield of tetramethylpyrazine is bred. Compared with the parent strain, the other fermenting properties of the obtained saccharomyces cerevisiae strain are not affected in the liquor fermentation test, the content of the tetramethylpyrazine is remarkably improved by increasing the content of a precusor substance acetoin, the content of the acetoin is 880.82 mg / L and is ten times that of the original strain, and the content of tetramethylpyrazine is 55.53 mg / L and is 4 times that of the original strain. The saccharomyces cerevisiae strain remarkably improves the yield of the tetramethylpyrazine, meets the higher requirements on yeasts in the related fields of white liquors, and has a broad application prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tetramethylpyrazine-producing bacillus licheniformis and application thereof

ActiveCN107446860APromote growthEasy to synthesizeBacteriaAlcoholic beverage preparationMicroorganismBacillus licheniformis

The invention discloses tetramethylpyrazine-producing bacillus licheniformis and application thereof. The bacillus licheniformis is classified and named bacillus licheniformis GJBL055; the bacillus licheniformis is preserved in CCTCC (China Center for Type Culture Collection) on April 24th, 2017; the preservation code is CCTCC NO:M2017204; the preservation address is Wuhan University, China. The medium-temperature shelf culture mode is used; the bacillus licheniformis is inoculated into flat Daqu; through the pre-culture on functional microbes, the building of a shelf starter space model and the four-stage regulation and control on secret room temperatures, a Daqu manufacturing process for producing tetramethylpyrazine under the medium temperature condition is formed, so that the content of the tetramethylpyrazine in the Daqu is improved to 400mg / kg.

Owner:ANHUI RUISIWEIER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com