Fermented blank bean beef powder essence and preparation method thereof

A technology of tempeh essence and beef powder, which is applied in the field of food processing, can solve problems such as poor taste, achieve long aftertaste, pure flavor, and solve the effect of not having a natural and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

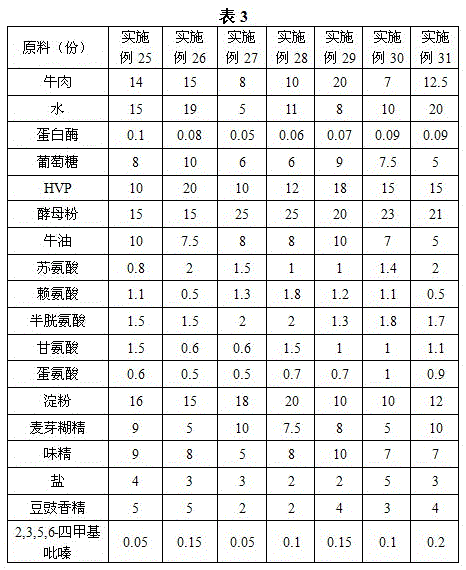

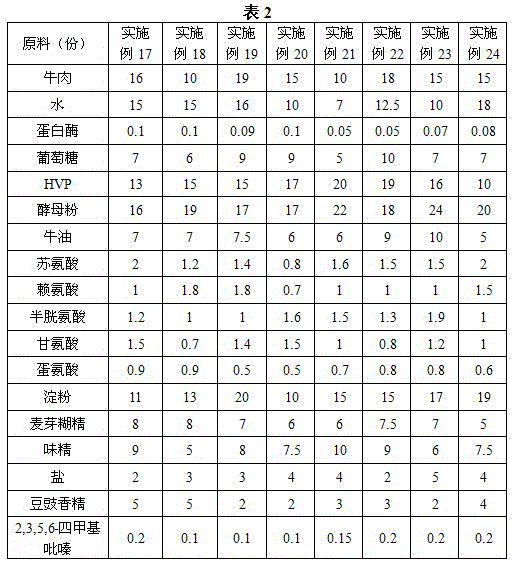

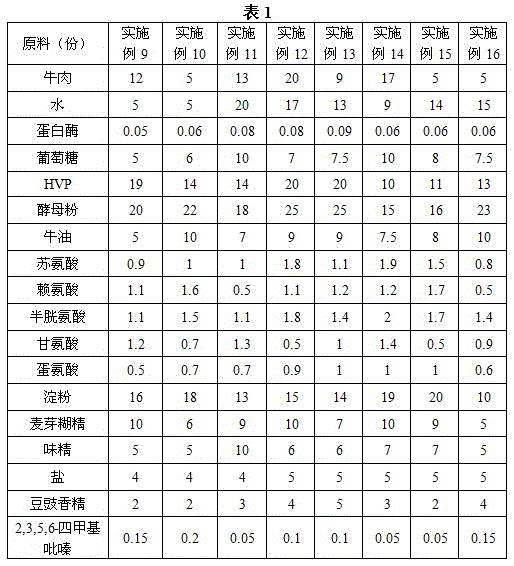

Examples

Embodiment 1

[0022] A fermented soya bean beef powder essence is prepared from the following raw materials in parts by weight: beef 5-20, water 5-20, protease 0.05-0.1, glucose 5-10, HVP10-20, yeast powder 15-25, butter 5 -10, threonine 0.8-2, lysine 0.5-1.8, cysteine 1-2, glycine 0.5-1.5, methionine 0.5-1, starch 10-20, maltodextrin 5-10, monosodium glutamate 5- 10. Salt 2-5, tempeh essence 2-5, 2,3,5,6-tetramethylpyrazine 0.05-0.2.

[0023] Glucose and amino acids in the formula are used as raw materials for the Maillard reaction, which makes the flavor of the fermented soybean beef flavor realistic. Threonine and lysine are not only used as raw materials for the Maillard reaction, but also can increase the roasted flavor of the product. The added fermented soybean flavor The product has a fermented soy flavor, and 2,3,5,6-tetramethylpyrazine is added to the product to have a pure fermented soybean flavor. It is used together with the fermented soy flavor to make the product have a pur...

Embodiment 2

[0031] A fermented soya bean beef powder essence is prepared from the following raw materials in parts by weight: beef 10, water 20, protease 0.05, glucose 8, HVP 12, yeast powder 21, butter 9, threonine 1.4, lysine 1.8, semi Cystine 1.2, glycine 0.8, methionine 1, starch 15, maltodextrin 6, monosodium glutamate 9, salt 2, tempeh essence 3, 2,3,5,6-tetramethylpyrazine 0.2.

[0032] The preparation method of the above-mentioned tempeh beef powder essence comprises the following steps:

[0033] (1) Grind the beef in a meat grinder with an orifice plate of 11mm, put it into the reaction kettle, add water and protease, and carry out enzymatic hydrolysis at 55°C for 2 hours;

[0034] (2) Add glucose, HVP, yeast powder, cysteine, tallow, lysine, threonine, glycine, methionine, heat up to 100°C for Maillard reaction, and react for 2 hours;

[0035] (3) When the temperature drops to 60°C, add starch, maltodextrin, monosodium glutamate, salt, tempeh essence, 2,3,5,6-tetramethylpyrazin...

Embodiment 3

[0039] A fermented soybean beef powder flavor prepared from the following raw materials in parts by weight: beef 6, water 5, protease 0.09, glucose 8, HVP11, yeast powder 19, butter 5, threonine 1.4, lysine 0.8, semi Cystine 1.6, glycine 1.3, methionine 0.6, starch 17, maltodextrin 7.5, monosodium glutamate 8, salt 2, tempeh essence 5, 2,3,5,6-tetramethylpyrazine 0.05.

[0040] The preparation method of the above-mentioned tempeh beef powder essence comprises the following steps:

[0041] (1) Grind the beef in a meat grinder with an orifice plate of 11mm, put it into the reaction kettle, add water and protease, and carry out enzymatic hydrolysis at 50°C for 2 hours;

[0042] (2) Add glucose, HVP, yeast powder, cysteine, tallow, lysine, threonine, glycine, methionine, heat up to 110°C for Maillard reaction, and react for 1.5 hours;

[0043] (3) When the temperature drops to 60°C, add starch, maltodextrin, monosodium glutamate, salt, tempeh essence, 2,3,5,6-tetramethylpyrazine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com