Method for preparing tetramethyl pyrazine

A kind of technology of tetramethylpyrazine and tetramethyldihydropyrazine, which is applied in the field of chemical synthesis of tetramethylpyrazine and achieves the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

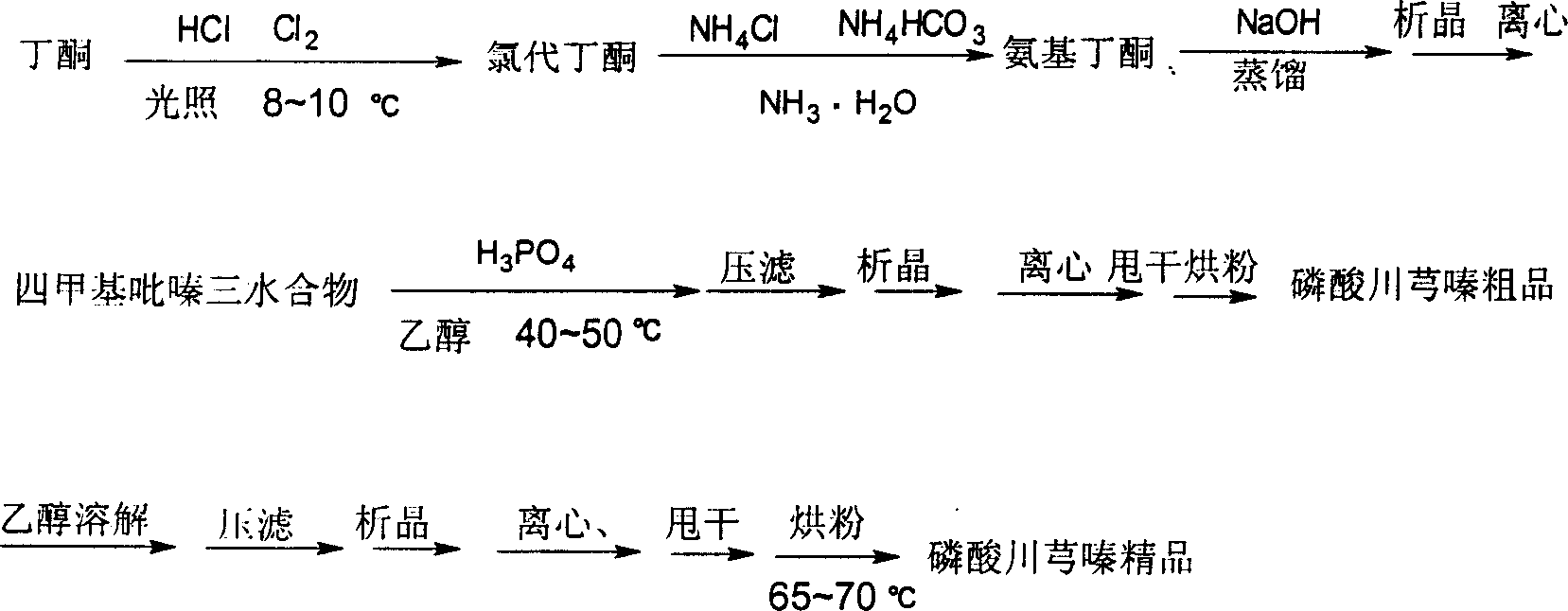

[0034] The present invention adopts methyl ethyl ketone chlorination method to prepare ligustrazine, and this production technology gets rid of the drawback of general methyl ethyl ketone oximation method. In the methyl ethyl ketone oximation method, it is required to prepare highly toxic gas nitrosoethyl ester. Among them, nitrosoethyl ester is generated by reacting concentrated sulfuric acid with sodium nitrite to generate nitrous acid gas, which is then generated by reacting with ethanol.

[0035] In the present invention, especially apply following reaction or course of action:

[0036]

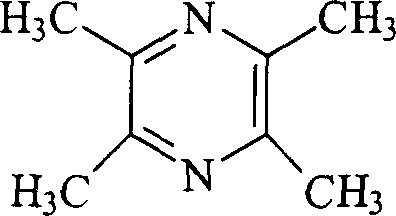

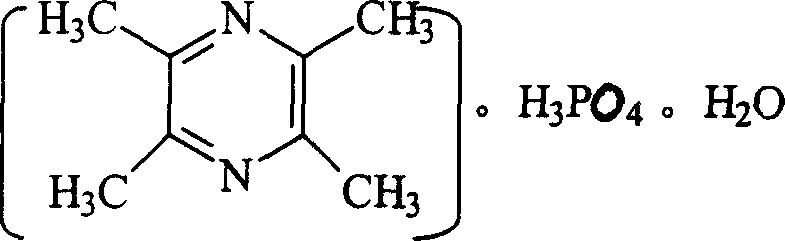

[0037] The invention relates first to the preparation of tetramethylpyrazine by condensation reaction using aminobutanone. Specifically, aminobutanone is 3-aminobutanone. A compound with a ring structure is formed by the condensation reaction between molecules of 3-aminobutanone, and steam is introduced into it to produce tetramethylpyrazine. Because atomic oxygen, ie [O], is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com