High yield tetramethylpyrazine saccharomyces cerevisiae and construction method thereof

A technology of tetramethylpyrazine and Saccharomyces cerevisiae, which is applied in the field of bioengineering, can solve problems such as application limitations, and achieve the effects of not being easy to reverse mutations, increasing production, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Construction of Knockout BDH1 Gene and Overexpression BDH2 Gene Saccharomyces cerevisiae Strain

[0038]The starting strain used in this example is Saccharomyces cerevisiae CICC32315, the Escherichia coli DH5a is purchased from Takara Company, and the YEPD medium is a universal complete medium.

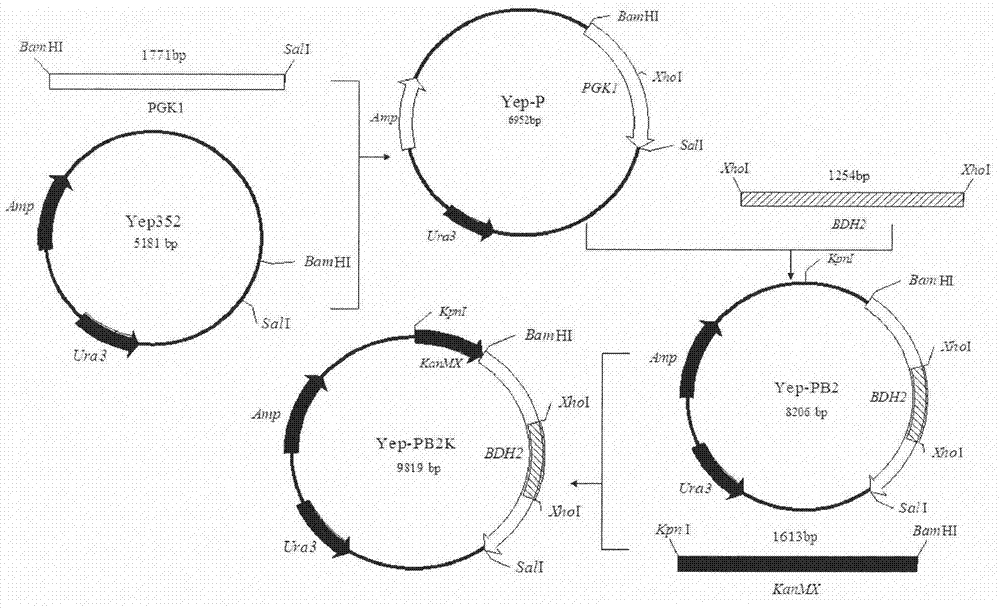

[0039] The construction process of the recombinant plasmid Yep-PB2K is as follows: figure 1 shown. The PGK1 promoter and terminator gene on the pPGK1 plasmid were excised and then connected to the Yep352 plasmid to obtain Yep-PGK1; the gene encoding diacetyl reductase BDH2 derived from Saccharomyces cerevisiae obtained by PCR was inserted into the PGK1 promoter and Between the terminators, Yep-PGK1-BDH2 was obtained; the KanMX resistance gene derived from pUG6 was connected to obtain the plasmid Yep-PGK1-BDH2-Kan, which was named as plasmid Yep-PB2K.

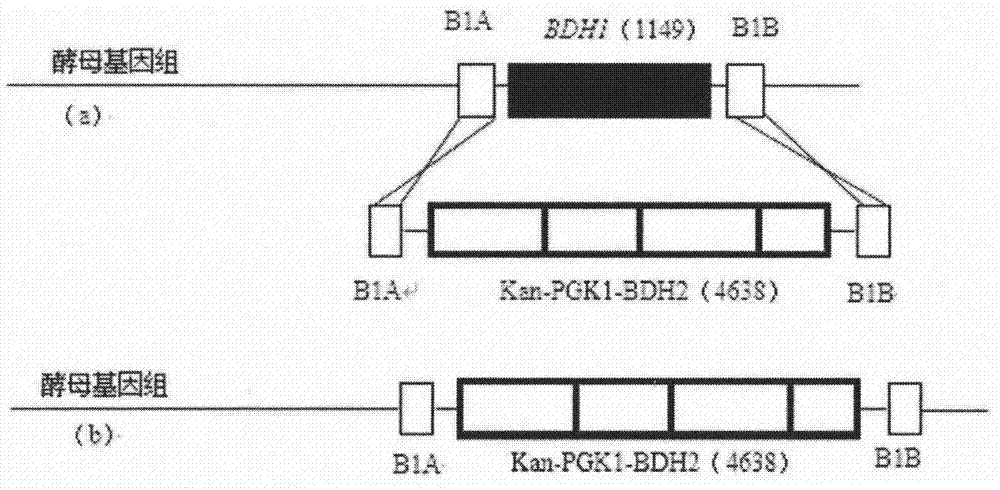

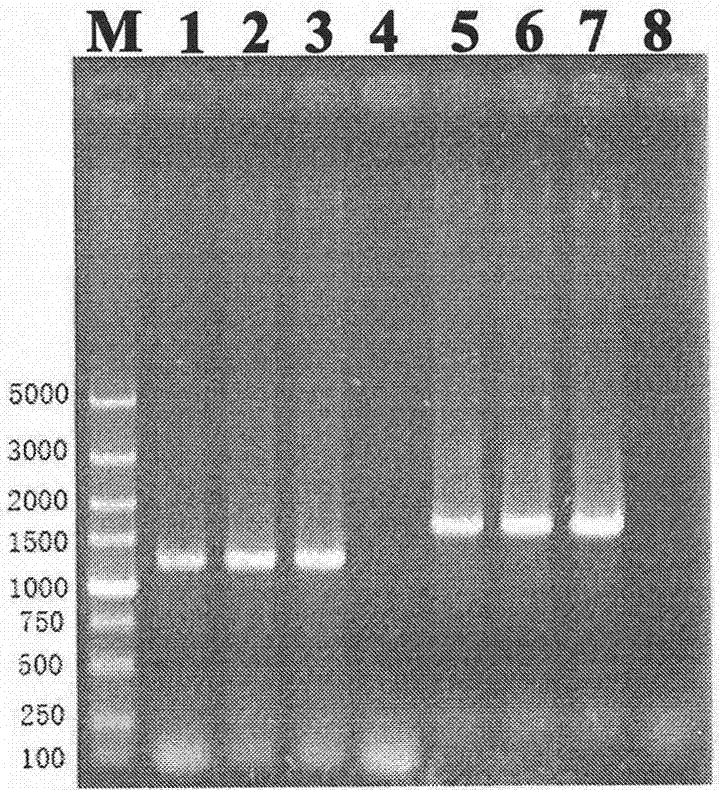

[0040] BDH1 recombination process such as figure 2 shown. Using the constructed vector plasmid Yep-PB2K as a te...

Embodiment 2

[0046] Example 2: Construction of Saccharomyces cerevisiae strain with complete deletion of BDH1 gene

[0047] According to the method in Example 1, the following scheme was designed to obtain a recombinant strain of Saccharomyces cerevisiae that knocked out the BDH1 gene. The starting strain used in this example was also Saccharomyces cerevisiae CICC32315, and the YEPD medium was a universal complete medium.

[0048] Using the KanMX resistance gene on the pUG6 plasmid as a template, the nucleotide sequence is shown in SEQ NO: 13 in the nucleotide sequence list. Using long primers B1K-U (SEQ NO: 14) and B1K-D (SEQ NO: 15) for PCR amplification to obtain homologous fragments B1KA and B1KB at both ends of the 2,3-butanediol dehydrogenase BDH1 gene The recombinant gene fragment, the long primer sequence for sequence fragment amplification is:

[0049] B1K-U: 5'-GGAACTAAAAAAGTTTTTAATTAATTATGAGAGCTTTGGCATATTTCAACAGCTGAAGCTTCGTACGC-3'

[0050] B1K-D: 5'-CGCGAGGGGCCCCAAATATTATTTTTG...

Embodiment 3

[0058] Example 3: Knockout of BDH1 gene and overexpression of BDH2 gene Saccharomyces cerevisiae strain fermentation experiment

[0059] (1) Corn thick mash fermentation experiments of recombinant strains and starting strains

[0060] The recombinant strain and the original strain were subjected to corn thick mash fermentation experiments at the same time, and the fermentation process route was: corn flour→soaking→liquefaction→saccharification→cooling→inoculation→fermentation→steaming wine→measurement indicators;

[0061] Process conditions:

[0062] Soaking conditions: 60-70°C, soaking for 20 minutes; liquefaction conditions: 85-90°C, adding high-temperature resistant α-amylase, liquefying for 90 minutes; saccharification conditions: 55-60°C, adding glucoamylase, saccharifying for 20 minutes.

[0063] Determination of strain CO after fermentation 2 Fermentation performance indicators such as cumulative discharge, alcohol content and residual reducing sugar, the results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com