Tetramethylpyrazine-producing bacillus licheniformis and application thereof

A technology of Bacillus licheniformis and tetramethylpyrazine, applied in the field of fermentation engineering, can solve problems such as not being able to meet industrial production functions, and achieve far-reaching effects in favor of cell growth, improvement of healthy active substances in liquor, transformation and upgrading, and ecological manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

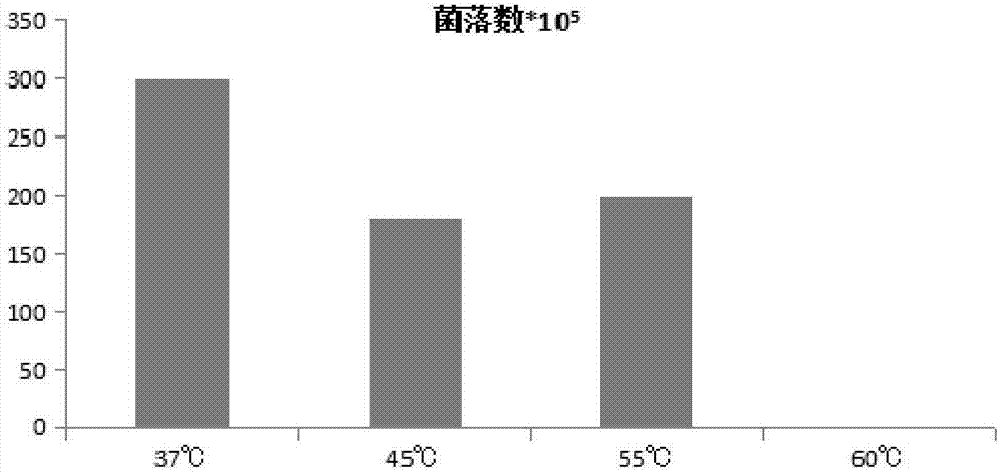

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of Bacillus licheniformis functional bacteria culture fluid

[0033] Use an inoculation loop to pick 1-2 rings of Bacillus licheniformis GJBL055 strains stored on a slant and place them in 300-400mL liquid medium, culture them on a shaker at 120rpm at 37°C for 24 hours to obtain a first-grade seed liquid; Inoculate the inoculum of 10% of the inoculum into the fermenter, cultivate at 80rpm at 37°C for 24 hours, and obtain the second-grade seed solution; then inoculate the second-grade seed solution at 10% of the inoculation amount in the fermenter, and cultivate at 80rpm at 37°C for 24 hours to obtain the third-grade seed solution. The seed solution is the functional bacteria culture solution;

[0034] The 10% inoculation amount refers to the ratio of the volume of the primary or secondary seed solution to the volume of the fermenter.

[0035] Described liquid culture medium constitutes as follows by mass concentration:

[0036] Glucose 1w...

Embodiment 2

[0037] Embodiment 2: the optimization of the addition amount of Bacillus licheniformis functional bacteria culture solution

[0038] Add the functional bacteria culture solution obtained in Example 1 to the water storage tank at the rate of 0.1%, 0.5%, and 1% of the koji mass per room, and after mixing, add the koji-making material whole wheat flour, mix evenly, and press the shelf-style Daqu cultivation method.

[0039] When the different addition amount of table 1, tetramethylpyrazine output

[0040] Addition amount of functional bacteria solution

[0041] It can be seen from Table 1 that when the addition ratio of Bacillus licheniformis functional bacteria culture solution is 0.5%, the content of tetramethylpyrazine in Atrial Quercus is relatively high.

Embodiment 3

[0042] Example 3: Arrangement of functional frame Daqu

[0043] Add the functional bacteria culture solution obtained in Example 1 to the water storage tank at a rate of 0.5% of the koji mass per room, add the koji-making material whole wheat flour after mixing, fully mix the material by stepping on it, and control the moisture content to 36- 37%, to obtain bent billets, the thickness of each bent billet is controlled at 6.9-7.1cm; put the bent billets in a straight line on the curved frame, and place 32-34 curved billets on each shelf, and the distance between each curved frame 5-8 cm, there are three placement schemes in total, namely "five-layer shelf with six-layer curved", "five-layer shelf with five-layer curved (the bottom floor is not placed)", "four-layer shelf with five-layer curved", a total of Place 3 rows and 10 columns of curved racks.

[0044] Table 2 The content of tetramethylpyrazine in the atrial song when different arrangements of Daqu are arranged in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com