Bacillus subtilis highly producing tetramethylpyrazine and method thereof for fermentation producing tetramethylpyrazine

A technology of Bacillus subtilis and tetramethylpyrazine, which is applied in the field of bioengineering, can solve problems such as adverse effects of bioprocess industrial applications, low utilization rate of precursor substances, and disordered microbial metabolic balance, achieving low production costs and green products Natural, Biopromoting Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Screening of Bacillus subtilis CCTCC NO: M208157 strain with high yield of tetramethylpyrazine

[0039] The strain involved in the present invention is derived from the high-temperature Daqu that produces sauce-flavor liquors such as'Kouzijiao Wine','Langjiu','Jinshiyuan' and'Moutai Wine'. Take a certain amount of the above Daqu, crush it and add it to an appropriate amount of sterile physiological saline filled with glass beads, shake on a shaker at 37°C and 150rpm for 24 hours; place the prepared bacterial suspension in a water bath at 80°C for 20 minutes, and cool in running water; take an appropriate amount The above-mentioned bacterial suspension was aseptically connected to the broth medium, cultured at 37°C and 150rpm for 18 hours, and the plate was coated with gradient dilution, and cultured at 37°C for 48 hours; Picked colonies with better growth and different traits were inoculated on the broth agar slope, As a strain for screening.

[0040] Inoculate t...

Embodiment 2

[0043] Example 2: Preparation of liquid seed culture of CCTCC NO: M 208157 strain

[0044] Step 1: Slant culture activation: inoculate the CCTCC NO: M 208157 strain on broth agar medium, and stand it for 24-48 hours at 37°C for use;

[0045] Step 2: Preparation of liquid seed culture: The strains cultured in step 1 are used aseptically to pick 1-2 loops with an inoculating loop into a 250ml shake flask containing 30-50ml liquid seed culture medium, and place it on a shaker. The rotation speed is 150-200 rpm and 35-40°C for 16-20 hours to obtain a liquid seed culture.

Embodiment 3

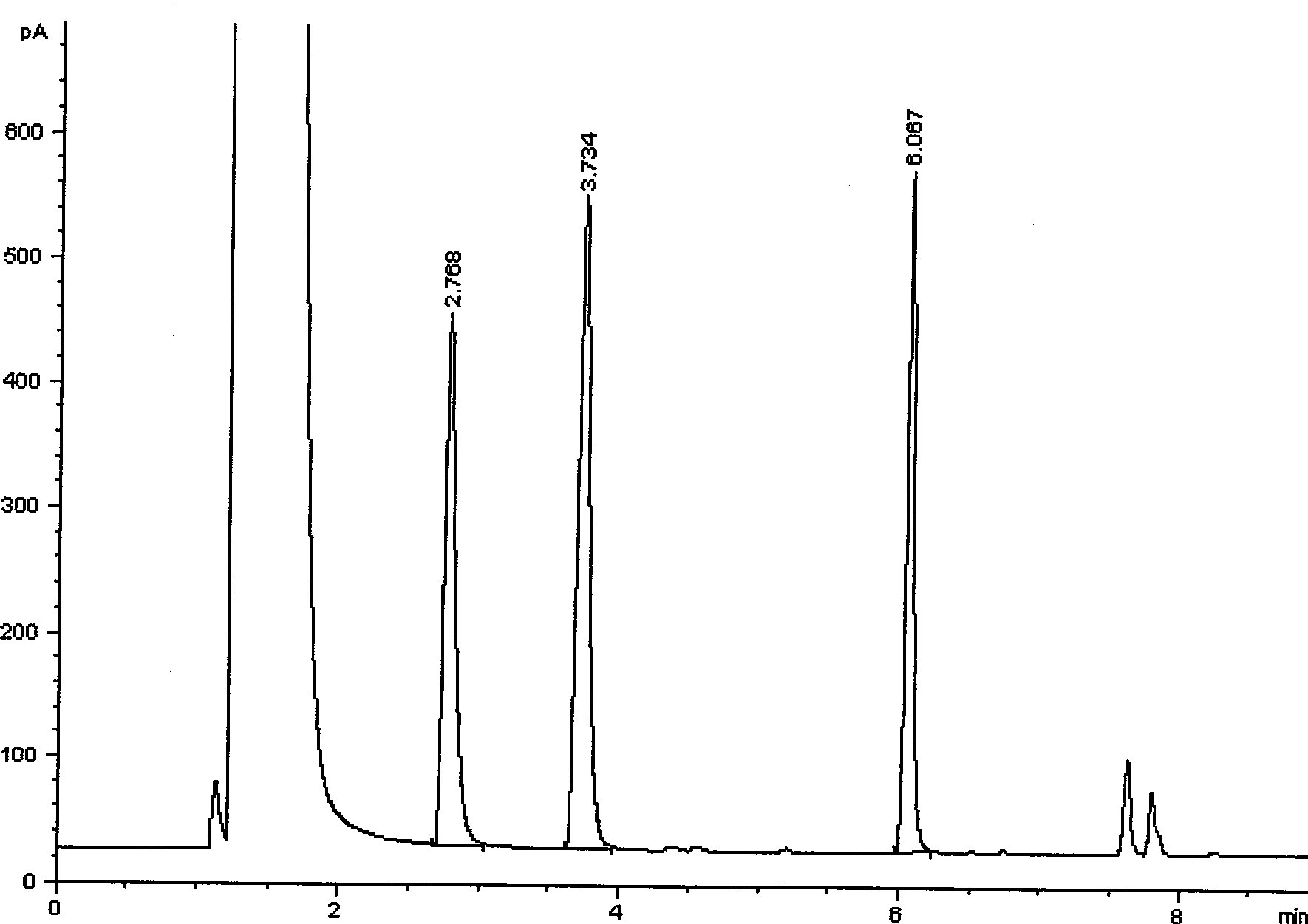

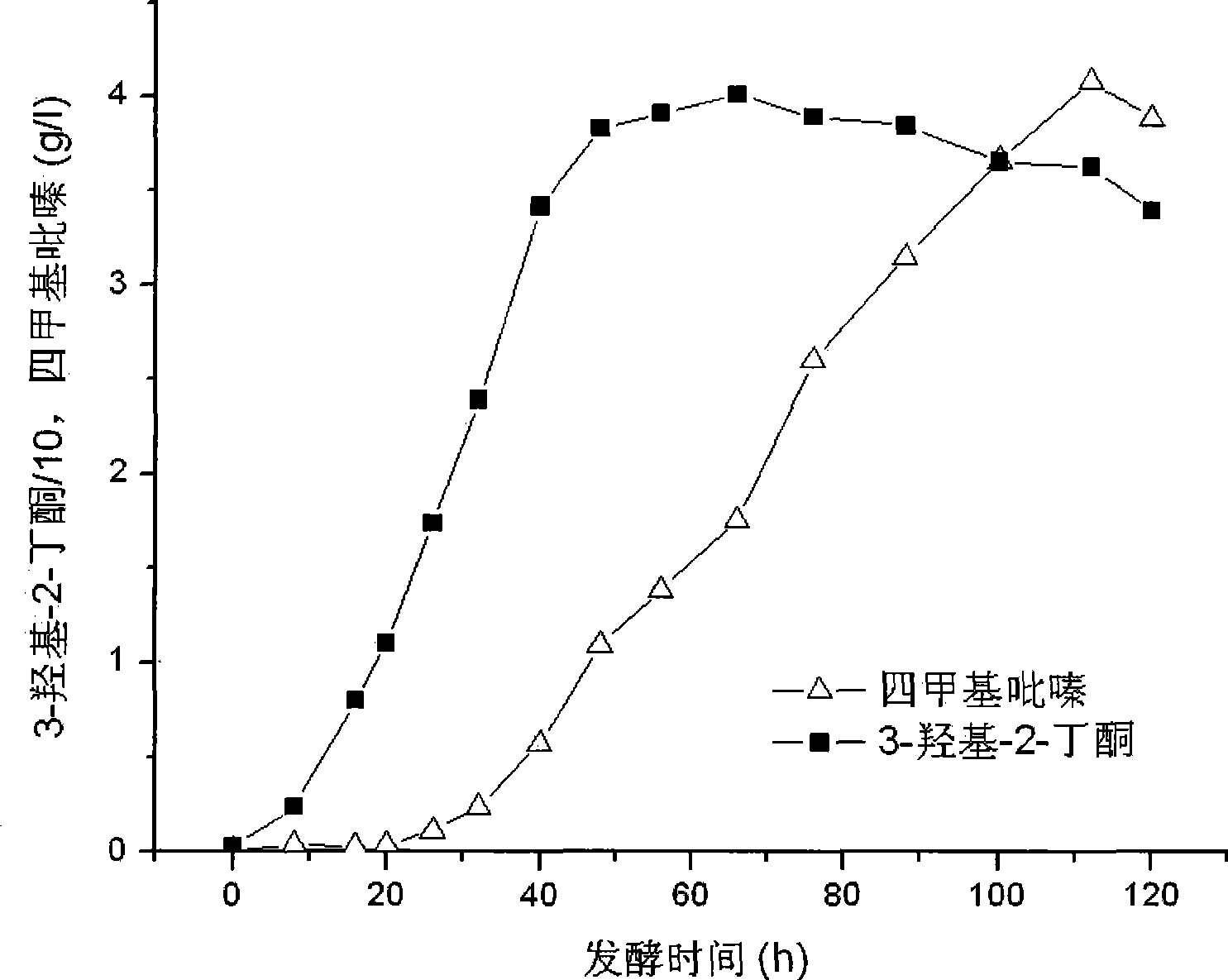

[0046] Example 3: Using the above CCTCC NO:M 208157 strain to produce tetramethylpyrazine by fermentation in a sucrose medium.

[0047] The liquid seed culture of the CCTCC NO:M 208157 strain of Example 2 was inoculated into a 250 mL shake flask containing a sterilized 50 mL sucrose medium at an inoculum volume of 5% by volume at a rotation speed of 200 rpm. Incubate at 37°C for 96-120 hours on the bed. The accumulation of the precursor substance 3-hydroxy-2-butanone in the fermentation broth is 31.0 grams per liter, and the concentration of tetramethylpyrazine can reach 3.68 grams per liter.

[0048] The composition of the above sucrose medium is (g, per liter of distilled water): sucrose 100, peptone 30, yeast extract 10, diammonium phosphate 30, and adjust the initial pH of the medium to 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com