Method for producing acetoin by vinasse fermentation and producing tetramethylpyrazine by acetoin transformation

A technology of tetramethylpyrazine and acetoin, which is applied in the field of bioengineering, can solve complex and liquid fermentation wastewater pollution problems, and achieve the effects of increasing added value, reducing wastewater pollution, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

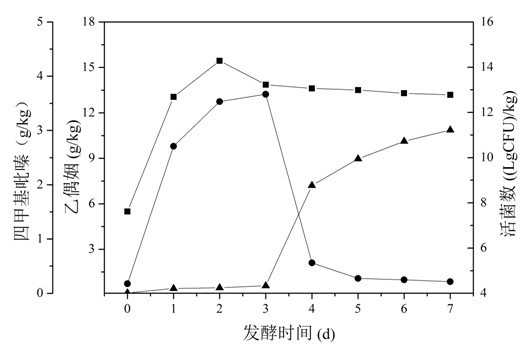

[0035] Embodiment 1. Fermentation of rice distiller's grains to produce acetoin

[0036] Preparation of culture medium: fresh distiller's grains are added with NaOH solution to adjust the acidity to 0-5, and supplemented with glucose 0-100g / kg.

[0037] Strain seed culture: any one of Bacillus subtilis (CCTCC NO: M208157) and Bacillus licheniformis (CGMCC 3961, 3962, 3963), in liquid or solid bran medium, pick a ring of strains to inoculate, and culture at 37°C 16~48h.

[0038] Liquid seed medium: take the raw materials used for liquor brewing as the medium components, select sorghum, barley, wheat, peas and their mixed formulas in various proportions to prepare the raw liquid medium. The production method is: after the raw material samples are crushed , after mixing with water at a ratio of 1:1-4 (w / v), cooking for 1-5h, adding saccharification enzyme 10-50 units / g raw material after cooling, keeping at 40-80°C for 2-10h, filtering, centrifuging The obtained filtrate is adj...

Embodiment 2

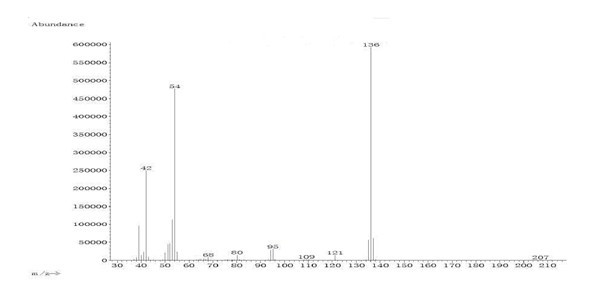

[0041] Example 2 Fermentation and transformation of white distiller's grains to produce tetramethylpyrazine

[0042] Preparation of culture medium: add NaOH to adjust the acidity of fresh distiller's grains to 0-5, and supplement glucose 0-100g / kg.

[0043] Strain seed culture: any one of Bacillus subtilis (CCTCC NO: M208157) and Bacillus licheniformis (CGMCC3961, 3962, 3963), in liquid or solid bran medium, pick a ring of strains for inoculation, and culture at 37 ° C for 16 ~48h.

[0044] Liquid seed medium: take the raw materials used for liquor brewing as the medium components, select sorghum, barley, wheat, peas and their mixed formulas in various proportions to prepare the raw liquid medium. The production method is: after the raw material samples are crushed , after mixing with water at a ratio of 1:1-4 (w / v), cooking for 1-5h, adding saccharification enzyme 10-50 units / g raw material after cooling, keeping at 40-80°C for 2-10h, filtering, centrifuging The obtained fi...

Embodiment 3

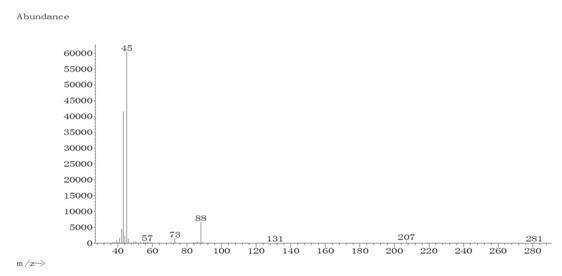

[0047] Example 3 Extraction of acetoin produced by fermentation of white distiller's grains

[0048] 1kg of solid-state fermentation culture was added with distilled water at 1:1-2 (w / v), placed in a 60°C water bath for 1 hour, and the leaching solution was centrifuged at 8000 rpm for 10 minutes, and the obtained supernatant was distilled at 70°C under reduced pressure to remove non-volatile impurities; The collected fractions were distilled at 80°C under reduced pressure for a second time to remove water to obtain 9.6 mL of liquid acetoin product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com