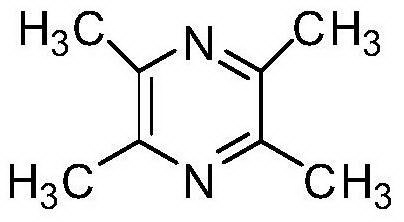

Preparation method of tetramethyl-pyrazine

A technology of tetramethylpyrazine and ammonium formate, which is applied in the direction of organic chemistry, can solve problems such as safety risks, and achieve the effects of complete reaction, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

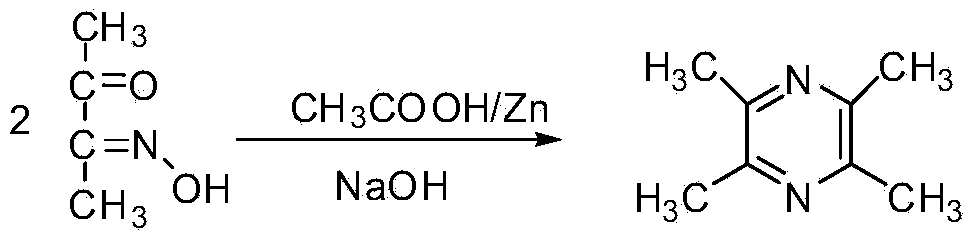

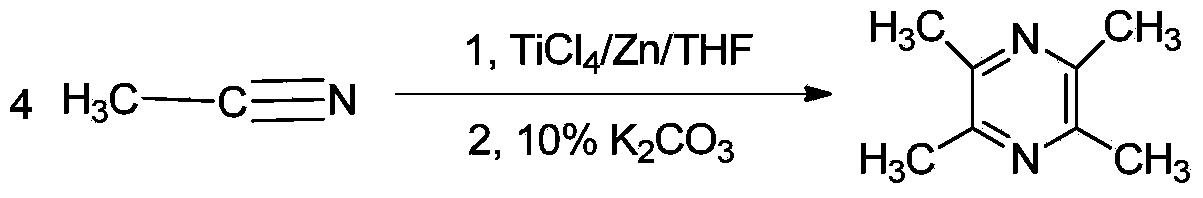

Image

Examples

Embodiment 1

[0028] Add 10.0 g of dimethylglyoxime and 10.0 g of palladium carbon into 120 ml of methanol, then stir and heat up to 60°C. Add 67.4g of ammonium formate in batches, and after the addition of ammonium formate is completed, reflux and stir at 60-65°C for 2 hours. After the reaction, remove the palladium carbon by cloth filtration (recovery), add hydrochloric acid, remove the solvent methanol under reduced pressure, add 120mL water, NaOH to adjust the pH to 8-9, extract three times with 60ml ethyl acetate, combine the organic phases, and add anhydrous sulfuric acid Dry over sodium, filter, and concentrate under reduced pressure to obtain 5.3 g of tetramethylpyrazine, with a yield of 79.2%.

Embodiment 2

[0030] Add 10.0 g of diacetyl monoxime and 5.0 g of palladium carbon into 120 ml of water, then stir and heat up to 90°C. Add 50.5 g of ammonium formate in batches, and after the addition of ammonium formate is completed, reflux and stir at 95-100°C for 2 hours. After the reaction finishes, remove the palladium carbon, and the filtrate is washed with dichloromethane (CH 2 Cl 2 ) was extracted three times, the organic phases were combined, dried by adding anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain 5.6 g of tetramethylpyrazine with a yield of 83.7%.

Embodiment 3

[0032] Add 10.0 g of dimethylglyoxime and 1.0 g of palladium carbon to 134 ml of water, then stir and raise the temperature to 80-90°C. Add 67.4g of ammonium formate (HCOONH4) in batches, after the ammonium formate is added, continue to reflux and stir for 4 hours. After the reaction was complete, use a Buchner funnel to filter under reduced pressure to remove palladium carbon, and the filtrate was extracted three times with dichloromethane (CH2Cl2), the organic phases were combined, dried by adding anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain tetramethylpyrazine 5.7 g, the yield is 84.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com