Method for harmlessly preparing fertilizer through carcasses and special equipment

A technology for animal carcass and fertilizer preparation, which is applied to animal carcass fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of destruction, incomplete treatment, and low practical value, and achieves the effects of simple process, improved crop quality, and strong functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

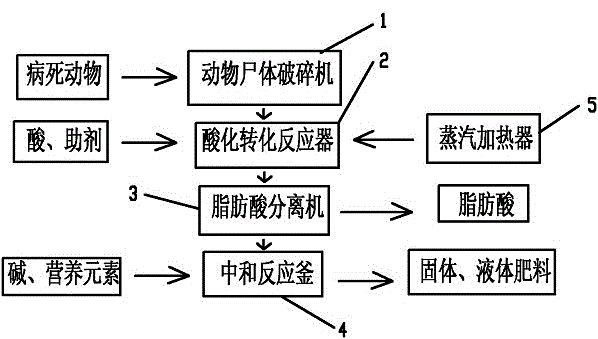

[0044] See attached figure 1 , special equipment for preparing fertilizers from animal carcasses harmlessly, the equipment includes an animal carcass crusher 1, the discharge port of the animal carcass crusher 1 is connected to an acidification transformation reaction kettle 2 with a steam heater 5, and the acidification transformation reaction kettle 2 is provided with a fatty acid separator 3 at the outlet of the fatty acid separator 3. The fatty acid outlet and the amino acid mixed solution outlet are arranged on the fatty acid separator 3. The amino acid mixed solution outlet is connected to the neutralization reactor 4, and the neutralization reactor 4 is provided with a liquid fertilizer outlet.

Embodiment 2

[0046] Refer to attached figure 1 , make use of animal corpses to prepare fertilizers. First, put the sick and dead cows into the corpse crusher for crushing. 15% of the weight of the dead cow, the amount of manganese dioxide is 1.6% of the weight of the dead cow, heat the conversion reactor through a steam generator, make the temperature in the reactor reach 120 ° C and maintain the temperature, start stirring, and the reaction time is 60 minutes After the conversion is completed, it is discharged into the separator for separation. The fatty acid in the upper layer of the liquid is used to produce chemical raw materials such as surfactants. Add a certain proportion of calcium oxide, magnesium oxide, manganese oxide, zinc oxide, adjust the PH value to 6-7.5, cool, static precipitation, a small amount of insoluble matter is solid fertilizer, and the liquid is mixed liquid fertilizer of amino acid and humic acid.

Embodiment 3

[0048] Refer to attached figure 1, make use of animal corpses to prepare fertilizers. First, put the dead pigs into the corpse crusher to crush them. 25% of the weight of the dead cow, and the amount of manganese dioxide is 1.8% of the weight of the dead cow. The steam generator is used to heat the conversion reactor, so that the temperature in the conversion reactor reaches 120 ° C and maintains the temperature, and the stirring is started. The reaction time After 60 minutes, the conversion is completed, and it is discharged into the separator for separation. The fatty acid in the upper layer of the liquid is used to produce chemical raw materials such as surfactants, and the liquids such as amino acids and humic acid in the lower part enter the neutralization reactor, and start stirring to neutralize the reaction. Potassium oxide is added to the kettle to adjust the PH value to be neutral, cooled, and a certain proportion of ferrous sulfate, manganese sulfate, zinc sulfate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com