Method and strain for producing tetramethylpyrazine

A technology of tetramethylpyrazine and bacterial strains, which is applied in the field of bioengineering, can solve problems such as failure to develop corresponding technologies, and achieve the effects of low production costs, mild conditions, and abundant sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the verification that acetoin and ammonia react to generate TTMP

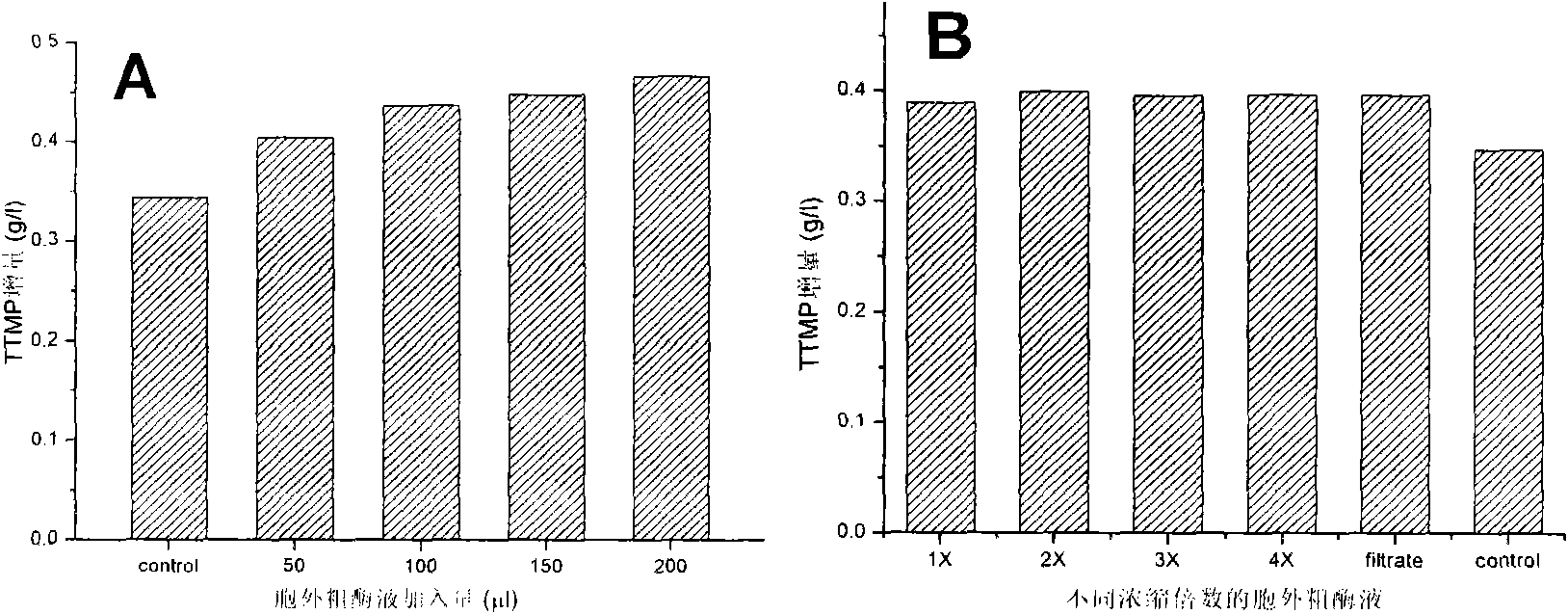

[0036] (1) Verification of extracellular enzymatic catalytic reaction: In order to verify whether there is an extracellular enzymatic catalytic reaction in the process of the reaction of precursor acetoin and ammonia to generate TTMP in the fermentation system, a model system is designed, which contains a certain concentration of Acetoin and 30g / L DAP adjusted the pH of the model system to 7.0.

[0037] Bacillus subtilis XZ1124 was inoculated in YG medium for shake flask culture. The fermented liquid cultured for 48 hours was taken, centrifuged at 8000 rpm for 15 minutes, the supernatant was passed through a 0.22 μm water membrane, and the obtained clarified liquid was used as the extracellular crude enzyme liquid. Add a certain volume of crude enzyme solution to the above-mentioned model system, and start the reaction after vigorous shaking, and take the reaction of adding the same volume...

Embodiment 2

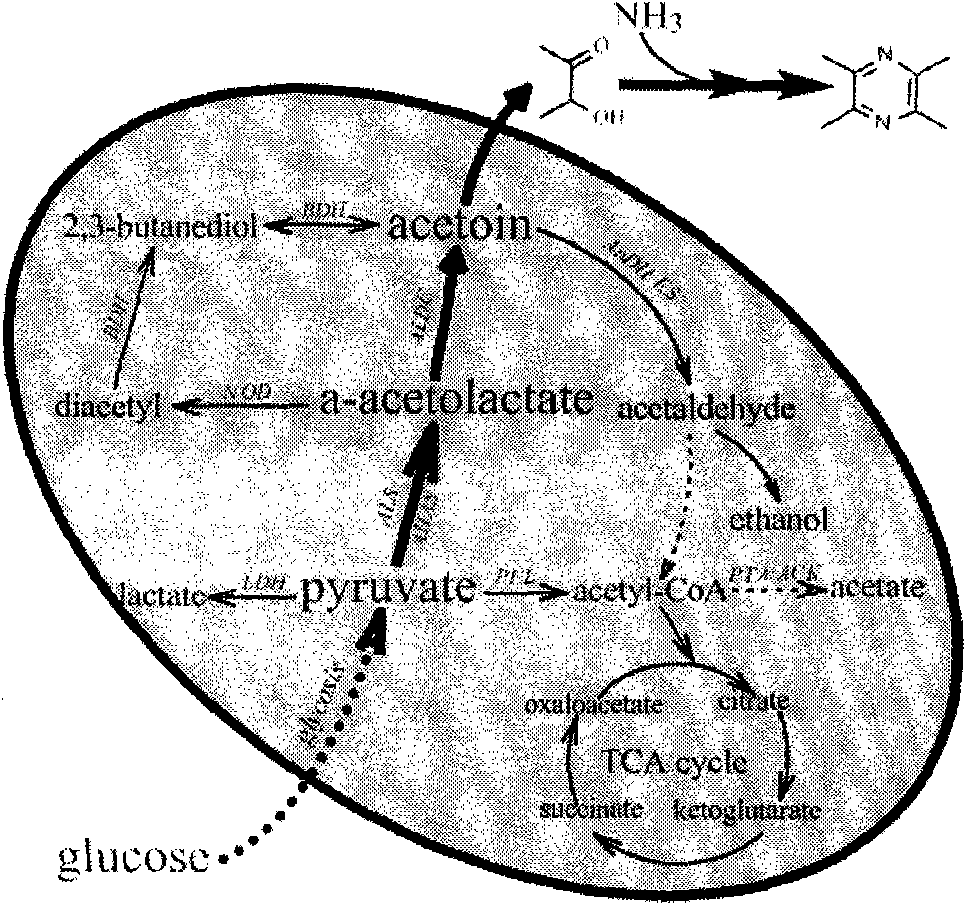

[0047] Embodiment 2: Determination of TTMP synthesis pathway in microbial fermentation system

[0048] The process of Bacillus sp. to metabolize acetoin is generally believed to be the condensation of two molecules of pyruvate to form a molecule of α-acetolactate, and the decarboxylation of α-acetolactate under the action of α-acetolactate decarboxylase to form acetoin. Acetoin is reduced to 2,3-butanediol under the action of butanediol dehydrogenase, and the two can be transformed into each other.

[0049] Bacillus subtilis XZ1124 was inoculated on YG medium, cultured on a shaker at 37°C and 200r / min for 72 hours, the fermentation broth was extracted with ether, the extraction phase was qualitatively analyzed by GC-MS, and the spectra of each chromatographic peak were compared with NIST05a. The standard spectra in L Database (Agilent Technologies Inc.) were compared, and compared with the retention time of the standard, the following main metabolites were identified: acetoin,...

Embodiment 3

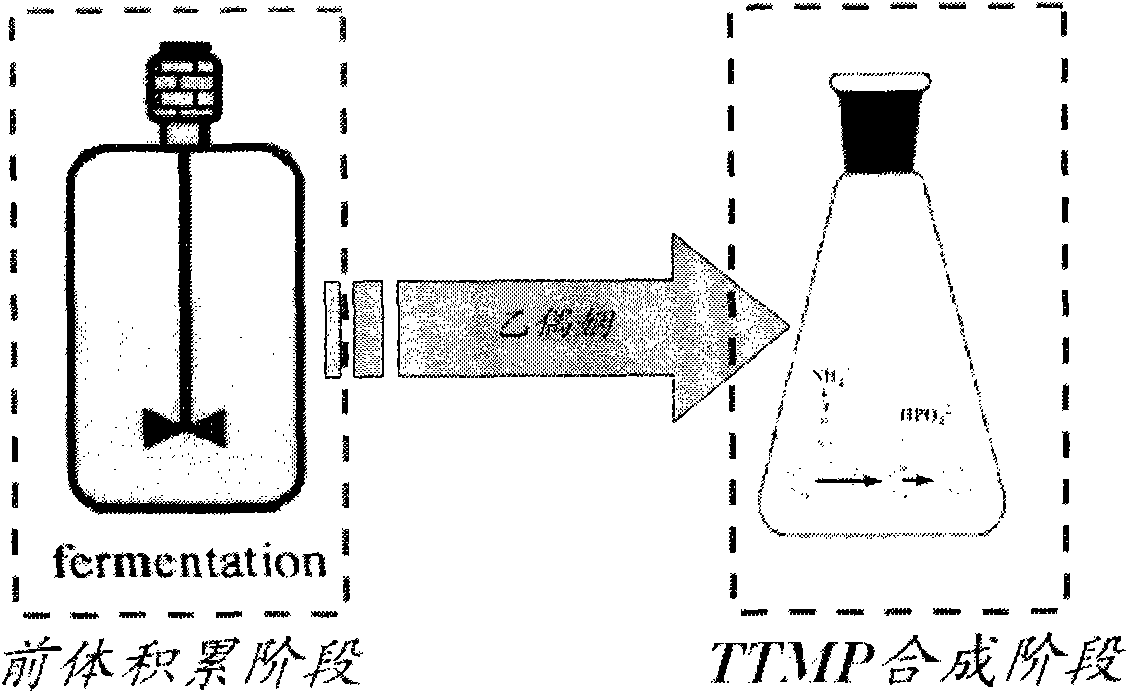

[0050] Example 3: Application of pH-controlled fermentation to improve the ability of microbial fermentation to accumulate precursor acetoin

[0051] Step 1: Activation of slant culture: Inoculate the B.licheniformis BL-L1 strain on broth agar medium, and culture it statically for 24-48 hours at 37°C, and set aside;

[0052] Step 2: Preparation of liquid seed culture: the bacterial strain cultivated in step 1, under aseptic conditions, pick 1-2 rings with an inoculation loop in a 250mL shaker flask equipped with 50mL liquid seed medium, and put it on a shaker at a rotating speed Cultivate at 200r / min and 37°C for 18-20h to obtain a liquid seed culture.

[0053] Step 3: Inoculate the liquid seed culture into a 7L fermenter with 5L of YG medium at an inoculum volume of 24%, set the stirring speed of the fermenter to 500rpm, the temperature to 35-40°C, and the ventilation rate to 1vvm , the fermentation time is 48h, the acid-base control fermented liquid pH value is 5.5-6.0 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com