Organic-inorganic composite gel material for bone repair and preparation method thereof

A composite gel and organic material technology, applied in medical science, prosthesis, etc., can solve the problems of limited material performance improvement, inability to repair with load-bearing bone, inability to uniformly blend, etc., to achieve good processing performance and good cell compatibility Good effect of sex and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

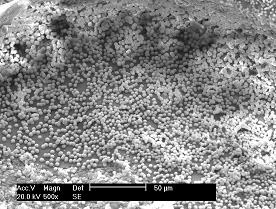

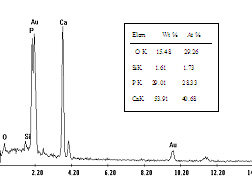

Image

Examples

preparation example Construction

[0031] The concrete steps of described preparation method are:

[0032] 1) SiO 2 The precursor of tetraethyl orthosilicate, the precursor of CaO calcium chloride and P 2 o 5 The precursor triethyl phosphate is mixed according to the molar fraction of 50-80%, 10-40%, 1-10%, wherein the solvent of ethyl orthosilicate is water, the co-solvent is ethanol, and the hydrolysis catalyst has a mass concentration of 5-10% strong acid solution, the amount of catalyst added is to adjust the pH of the solution to 1-3, and stir evenly;

[0033]2) During the hydrolysis process, add an organic polymer aqueous solution with a mass concentration of 1-20%, so that the mass ratio of the organic component to the inorganic component is 0.1-1:1, and add 0.15-0.25mL catalyst to promote the SiO 2 The formation of a network structure, thus forming an organic-inorganic composite system;

[0034] 3) React the organic-inorganic composite system after adding the catalyst in step 2) for 5-6 minutes, pou...

Embodiment 1

[0037] Stir 12.3ml tetraethyl orthosilicate, 4ml distilled water and 6ml ethanol at room temperature, add hydrochloric acid with a mass concentration of 5% to adjust the pH of the system to about 2. Stir evenly, add 1.2 g of calcium chloride and 0.5 ml of triethyl phosphate into the system, and dissolve completely. Add 5 ml of an aqueous solution of polyglutamic acid with a mass concentration of 10% to the system, so that the mass ratio of polyglutamic acid to ternary inorganic components is 0.12:1, after stirring and mixing, add 0.15 mL of hydrofluoric acid dropwise To promote the polycondensation process, pour the composite system into the mold when it is close to the gel point. After aging at room temperature for about 1 week, freeze in a freeze dryer at -50 °C for 24–48 h, and then vacuum-dry for 4–6 h to remove residual solvents and obtain the desired porous gel material.

Embodiment 2

[0039] Stir 12.3 ml of tetraethyl orthosilicate, 4 ml of distilled water and 6 ml of ethanol at room temperature, and add 10% hydrochloric acid to adjust the pH of the system to about 2. After stirring for a period of time, add 3.6 g of calcium chloride and 1.25 ml of triethyl phosphate into the system and dissolve them completely. Add 7 ml of an aqueous solution of polycapropropionamide and polylactide with a mass concentration of 20% to the system so that the mass ratio of the organic component to the ternary inorganic component is 0.25:1. After stirring and mixing, add 0.25 mL of hydrogen dropwise Fluoric acid promotes the polycondensation process, and when it is close to the gel point, the composite system is poured into a mold for molding. After aging and drying at room temperature for about 30 days, the desired porous gel material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com