Treatment and recycling of kitchen wastes

A food waste and pretreatment technology, which is applied to the removal of solid waste, methods based on microorganisms, microorganisms, etc., can solve problems such as human health hazards, cross-infection of human and animal diseases, and high requirements for operational safety, and achieve the realization of solid waste. Recycling, high requirements for equipment and equipment, complicated operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 kitchen waste pretreatment material

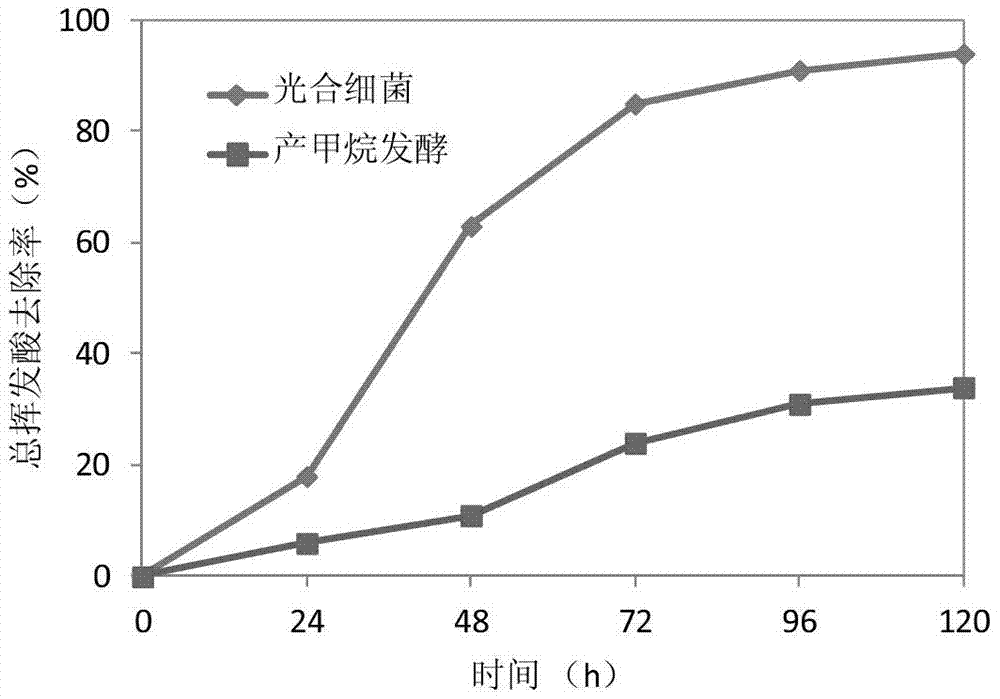

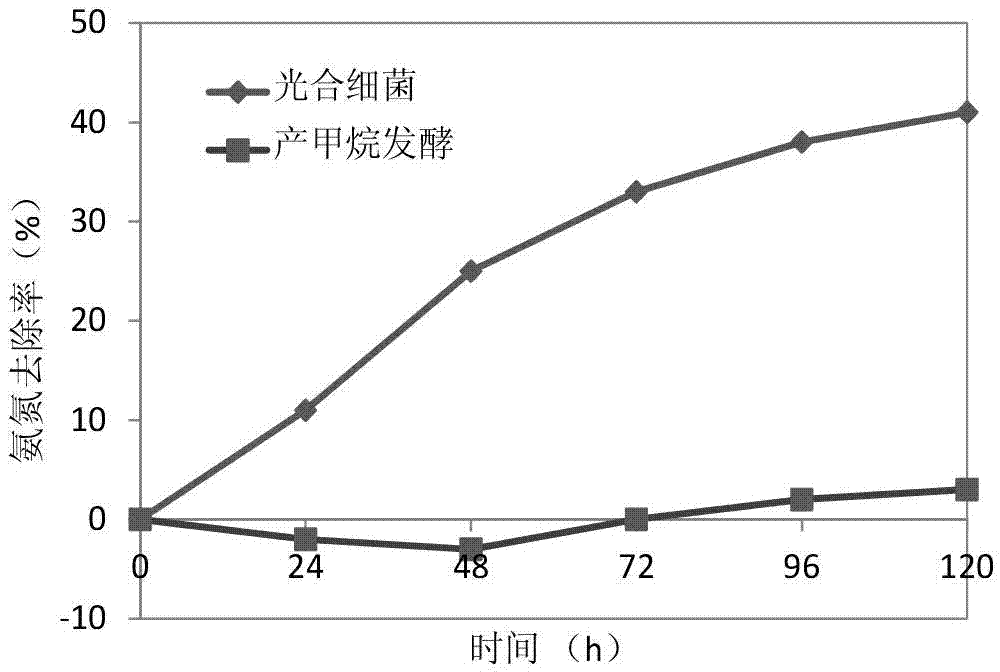

[0048] The food waste comes from a mixture of food processing leftovers and edible residues in a university cafeteria, with a moisture content of 83%, a carbon-to-nitrogen ratio of 26.3%, and an ash content of 1.1%. Firstly, the kitchen waste is crushed, and after crushing, 2g / L anaerobic sludge is added for hydrolysis and acidification treatment to obtain a hydrolysis and acidification solution. The method of acidification hydrolysis treatment is the prior art, or refer to the Chinese patent application with application number 200910117333. The broken food waste is in the form of granules, and the organic matter in it is released and dissolved to produce small molecular fatty acids under the action of hydrolysis and acidification microorganisms. When the total VFA concentration reaches 8000 mg / L, solid-liquid separation is carried out; the solid part continues to undergo hydrolysis and acidification ...

Embodiment 2

[0049] The preparation of embodiment 2 kitchen waste pretreatment material

[0050] The food waste comes from a mixture of food processing scraps and edible residues from a restaurant in Yubei District, Chongqing City, with a moisture content of 75%, crude fat of 2.67%, and ash content of 1.8%. Firstly, the kitchen waste is crushed, and then acidified and hydrolyzed to obtain a hydrolyzed and acidified liquid. The method of acidification and hydrolysis treatment is the prior art, which can be referred to the Chinese patent application with application number 200910117333; or the hydrolysis and acidification is carried out by adding anaerobic sludge with a concentration of 10g / L. The broken food waste is in the form of granules, and the organic matter in it is released and dissolved to generate small molecular fatty acids under the action of hydrolytic acidification microorganisms. When the total VFA concentration reaches 6000mg / L, solid-liquid separation is carried out; the so...

Embodiment 3

[0051] The preparation of embodiment 3 kitchen waste pretreatment material

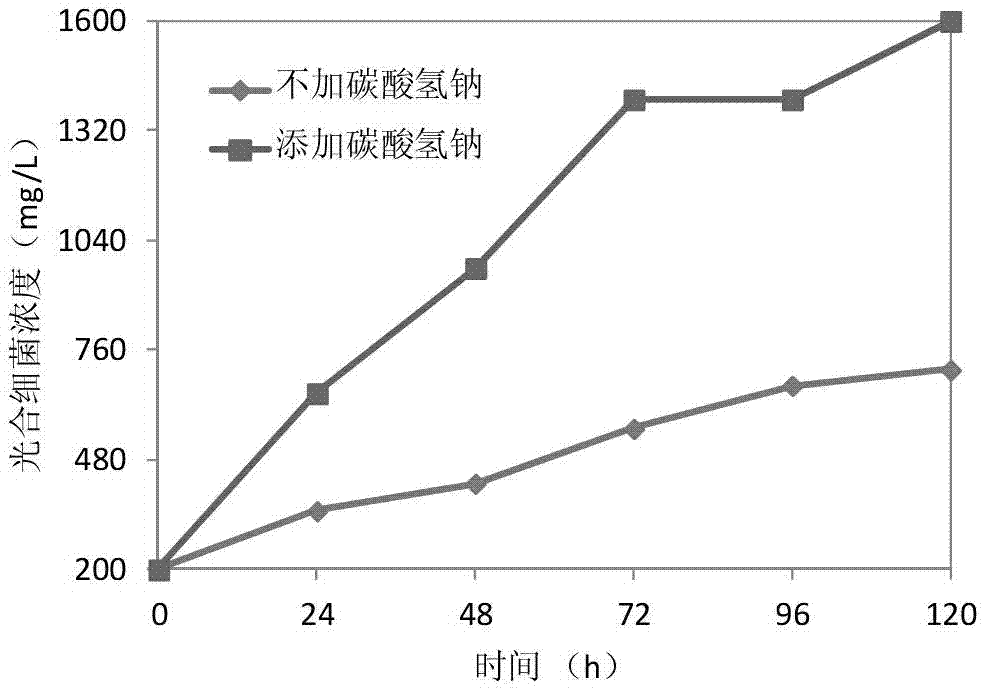

[0052] Food waste comes from a mixture of food processing scraps and food residues from a household in Chongqing, with a moisture content of 80%, crude fat of 3.14%, and ash content of 1.5%. liquid. The method of acidification and hydrolysis treatment is a prior art, for which reference may be made to Chinese patent application No. 200910117333. The broken food waste is in the form of granules, and the organic matter in it is released and dissolved to produce small molecular fatty acids under the action of hydrolysis and acidification microorganisms. When the total VFA concentration reaches 12000mg / L, solid-liquid separation is carried out; the solid part continues to undergo hydrolysis and acidification treatment ;Add 10mol / L sodium hydroxide to the liquid part to adjust the pH value until the pH is stable at about 6.0, then add 0.6g / L sodium bicarbonate to obtain the pretreatment material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com