Method for increasing content of tetramethylpyrazine in edible vinegar

A technology of tetramethylpyrazine and vinegar, which is applied in the field of food processing, can solve the problems of limited production due to storage time and low content of tetramethylpyrazine, and achieve the effects of shortening aging time, short processing time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

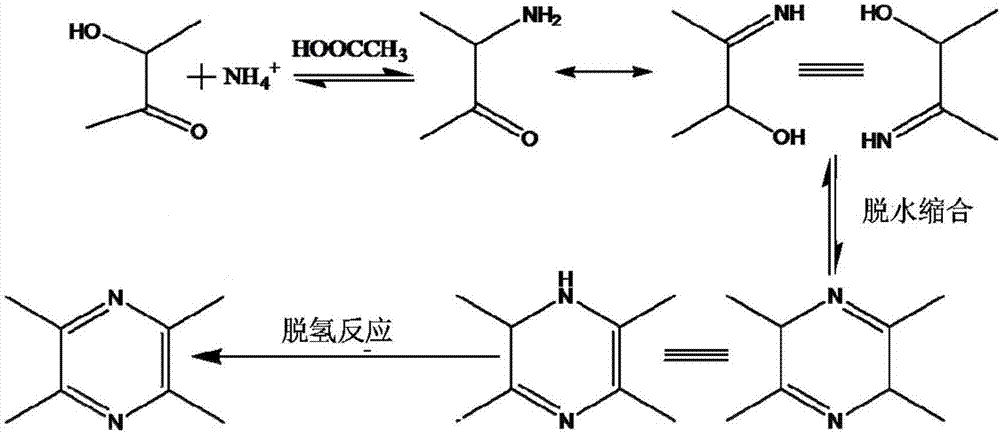

[0029] Embodiment 1 of the present invention is: a method for increasing the content of tetramethylpyrazine in vinegar, which can greatly increase the content of tetraalkylpyrazine in vinegar within a short aging time.

[0030] First, high-quality sorghum and glutinous rice and other starchy raw materials are selected through liquefaction, saccharification, alcoholic fermentation, and acetic acid fermentation to obtain freshly fermented smoked vinegar, and then a mixture of acetoin and ammonium salt is added to the vinegar. The salt is at least one of ammonium acetate, ammonium chloride, ammonium sulfate, ammonium nitrate, ammonium phosphate and ammonium citrate. In this embodiment, ammonium acetate is preferred. The molar ratio of acetoin and ammonium acetate is 1:2-1:4, and the content of the mixture of acetoin and ammonium acetate is 0.5-1.5% by weight of vinegar. Then add acetoin and ammonium salt to the vinegar to carry out high-voltage pulse electric field treatment, the...

Embodiment 2

[0033] Embodiment 2 of the present invention differs from Embodiment 1 in that:

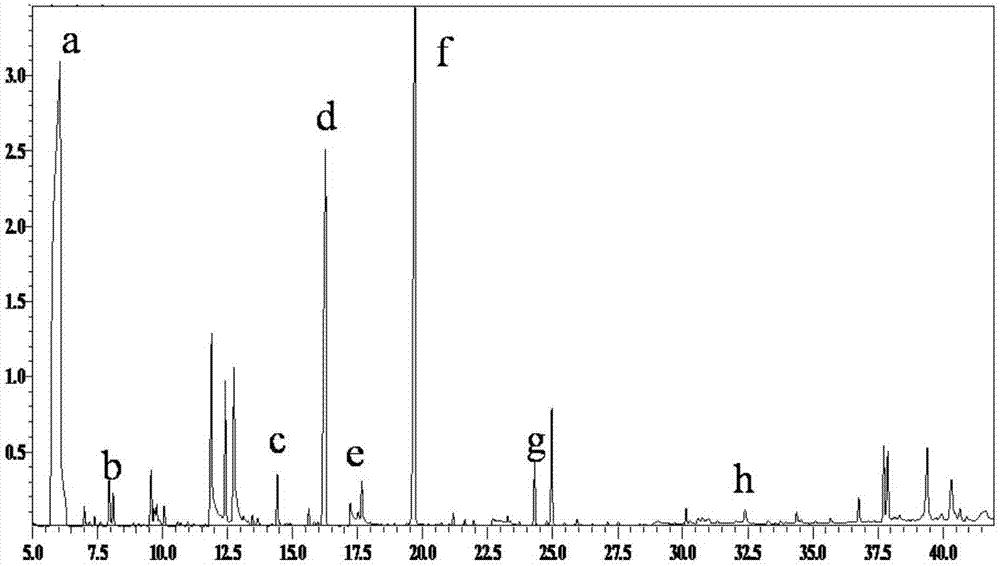

[0034] The content of the mixture of the acetoin and ammonium acetate is 0.5% of the vinegar weight, the mol ratio of the acetoin and ammonium acetate is 1:2, the voltage is 5kV, and the electric field strength is 20kV / cm, the pulse frequency is 100 Hz, and the pulse width is 2 μs. The vinegar treated by the high-voltage pulse electric field is kept at 35° C. for 3 hours, and the cooled vinegar is aged for 3 months.

[0035] In this example, the content of tetramethylpyrazine in the vinegar treated with the high-voltage pulse electric field is 5 times that in the vinegar without the high-voltage pulse electric field treatment.

Embodiment 3

[0037] Embodiment 3 of the present invention differs from the foregoing embodiments in that:

[0038] Select high-quality sorghum, barley, pea and other starchy raw materials to obtain freshly fermented mature vinegar through liquefaction, saccharification, alcohol fermentation, acetic acid fermentation and other processes.

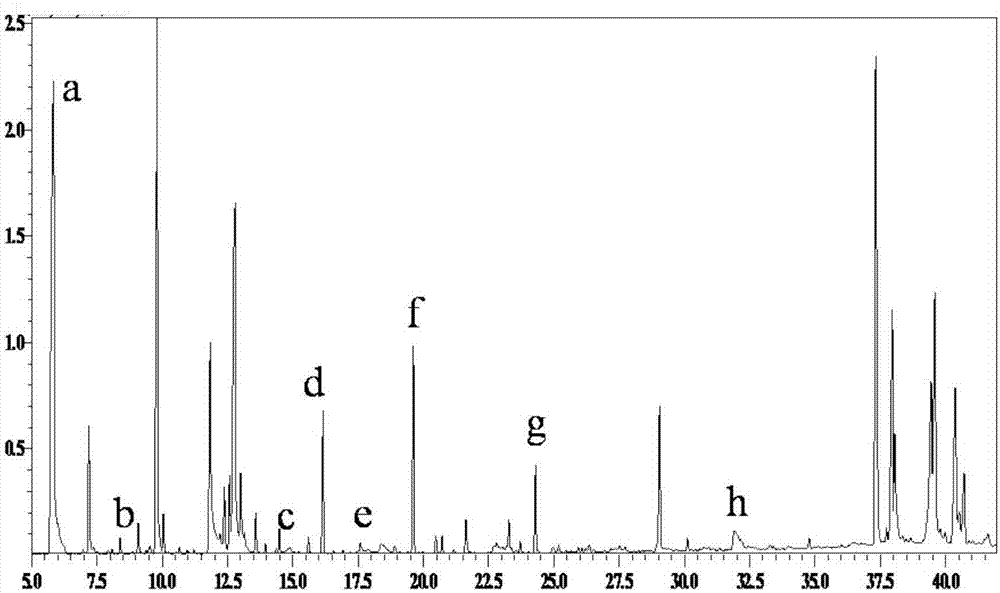

[0039] The content of the mixture of the acetoin and ammonium acetate is 1.5% of the vinegar weight, the mol ratio of the acetoin and ammonium acetate is 1:3, the voltage is 10kV, and the electric field strength is 40kV / cm, the pulse frequency is 250 Hz, and the pulse width is 20 μs. The vinegar treated by the high-voltage pulse electric field is kept at 45° C. for 15 hours, and the cooled vinegar is aged for 6 months.

[0040] In this example, the content of tetramethylpyrazine in the vinegar treated with the high-voltage pulse electric field was 13.5 times that of the vinegar without the high-voltage pulse electric field treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com