Patents

Literature

172results about How to "High security risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

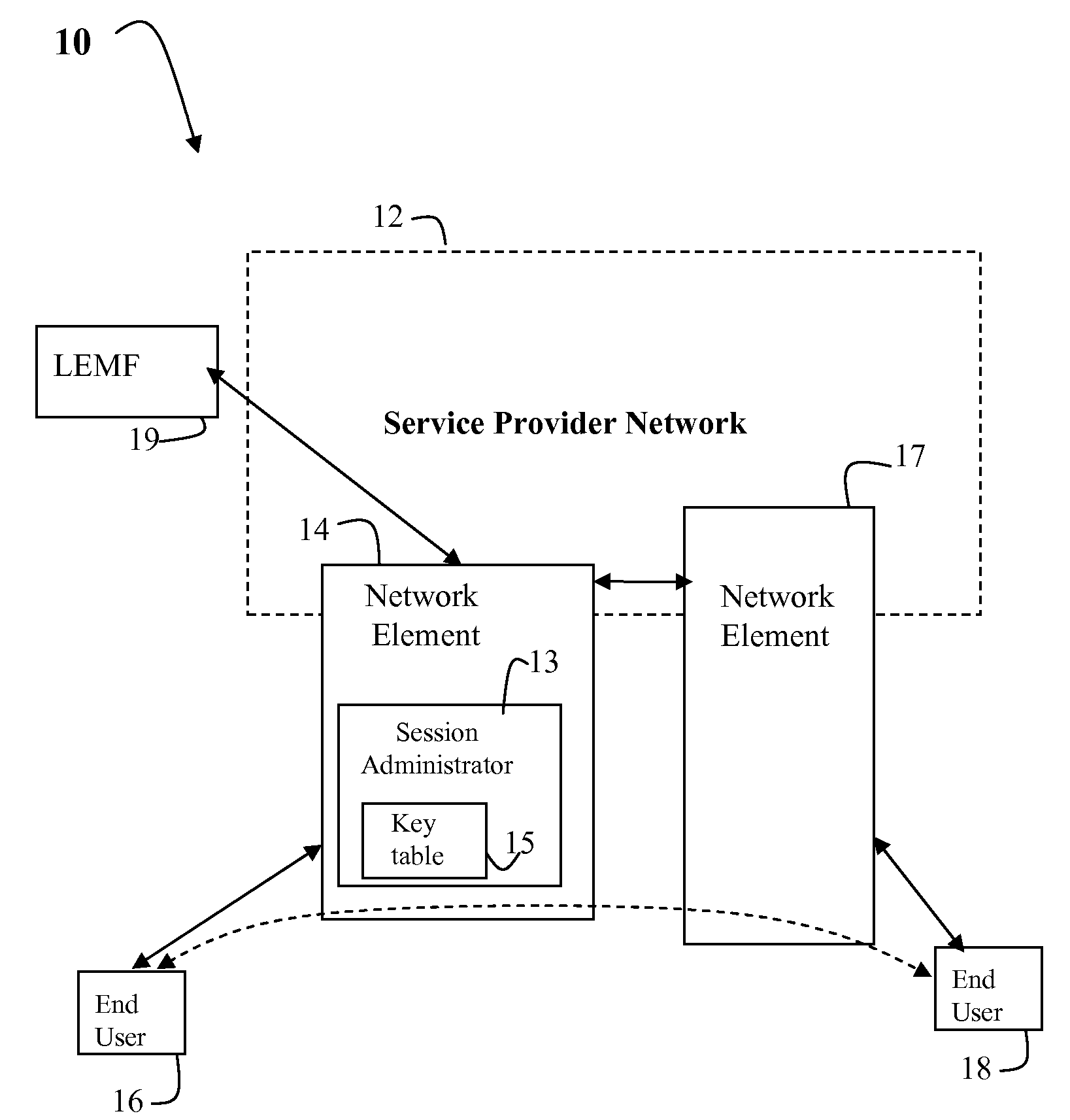

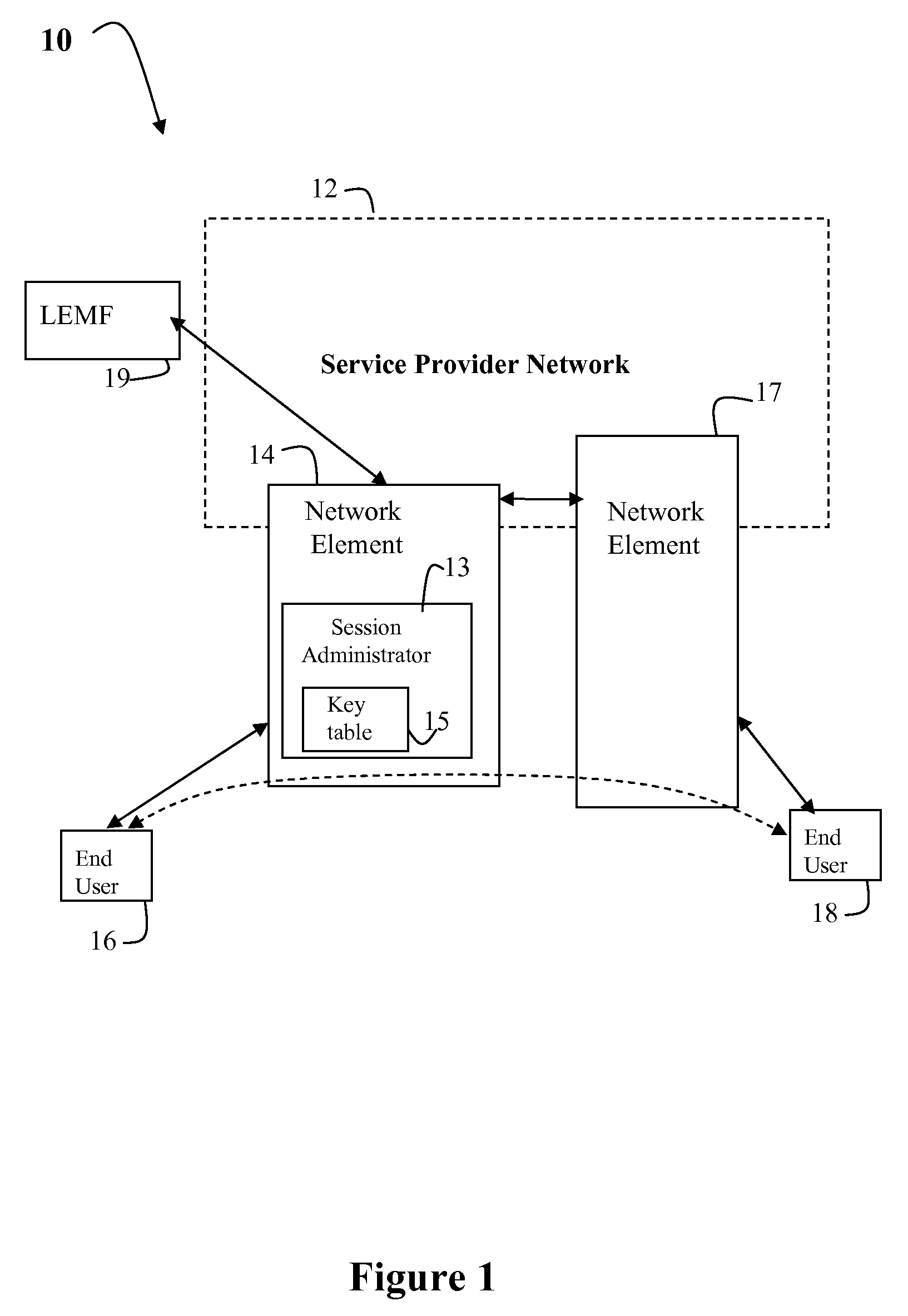

Method and Apparatus for Identifying and Monitoring VOIP Media Plane Security Keys for Service Provider Lawful Intercept Use

ActiveUS20070297418A1Easy to identifyHigh security riskTime-division multiplexData switching by path configurationService providerNetwork element

A mechanism is described that enables encrypted end-point communications in a VoIP network to be accessed by a service provider. The mechanism includes a session information retrieval component which gathers session information such as encryption keys for each session that traverses a network element. The encryption keys may be used to decrypt data to make it available for lawful interception. A media stream monitoring component monitors media streams and verifies that the identified keys for each session are valid, to ensure continuity in compliance with LI regulations. Advantageously a security alert component may be used to controls further session operation for those sessions identified as potential security risks. With such an arrangement, the service provider can satisfy the legal requirement to provide interception, verify that the accuracy of the legal interception support and take appropriate steps to handle security risks.

Owner:GENBAND US LLC

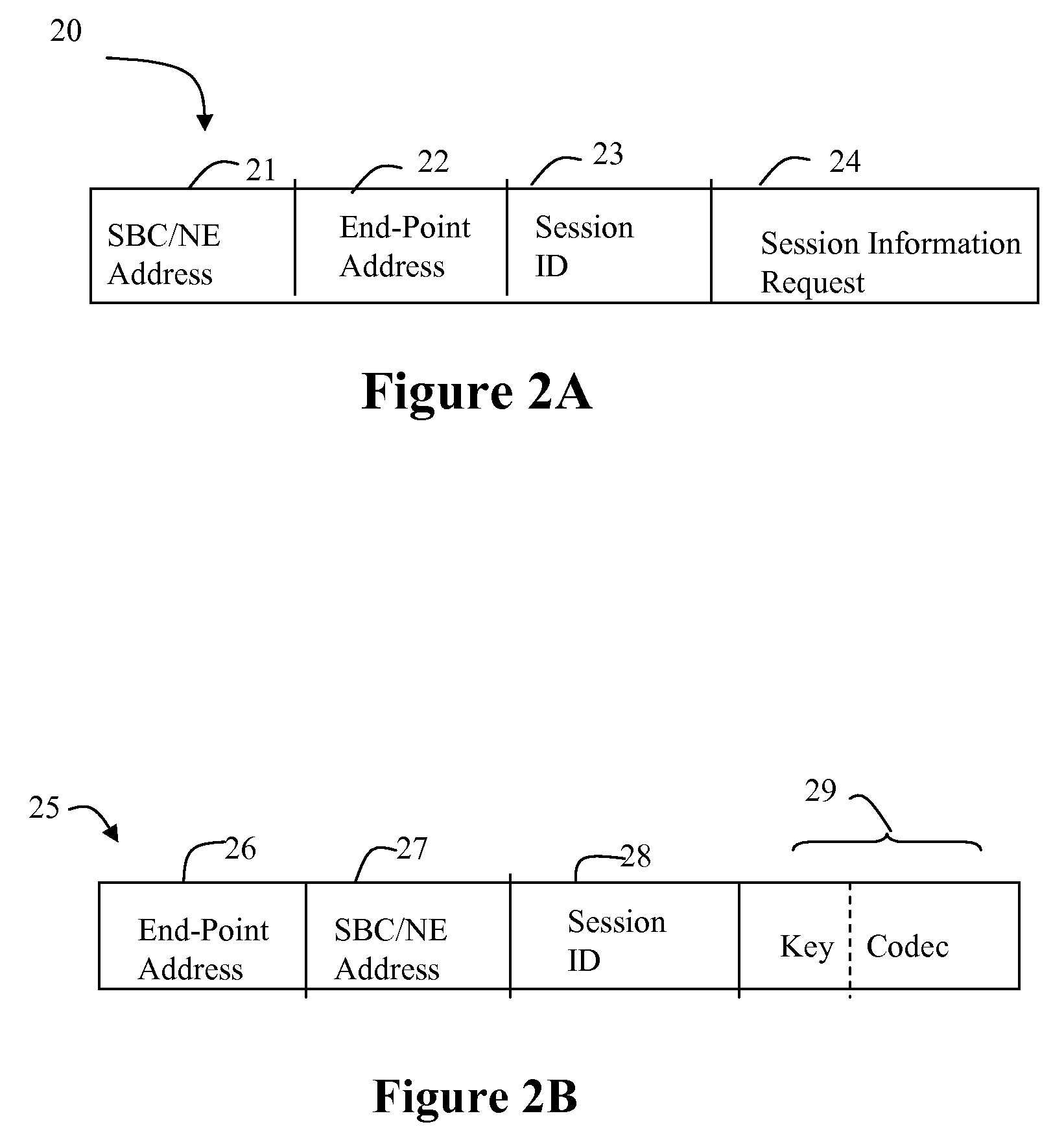

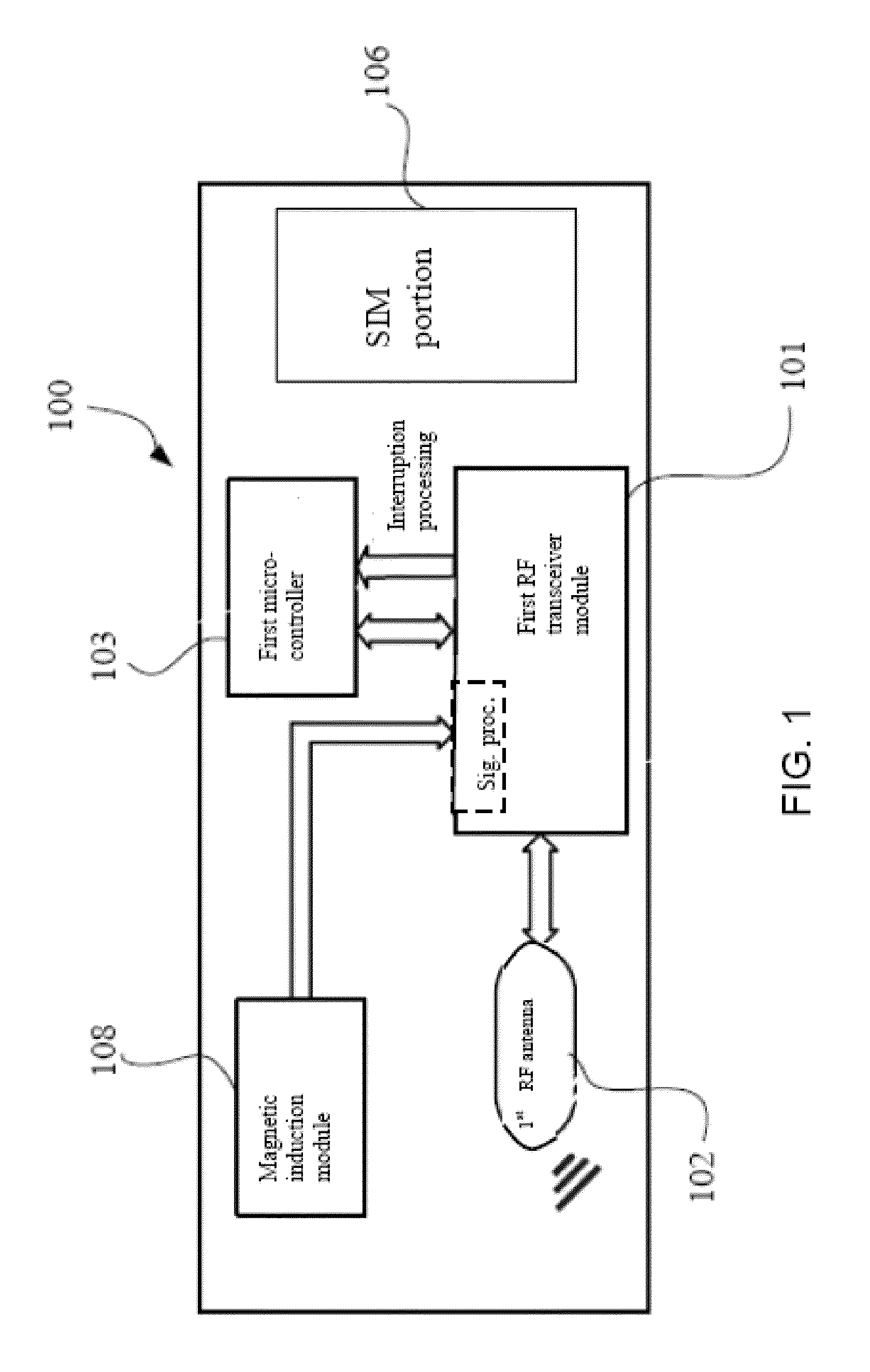

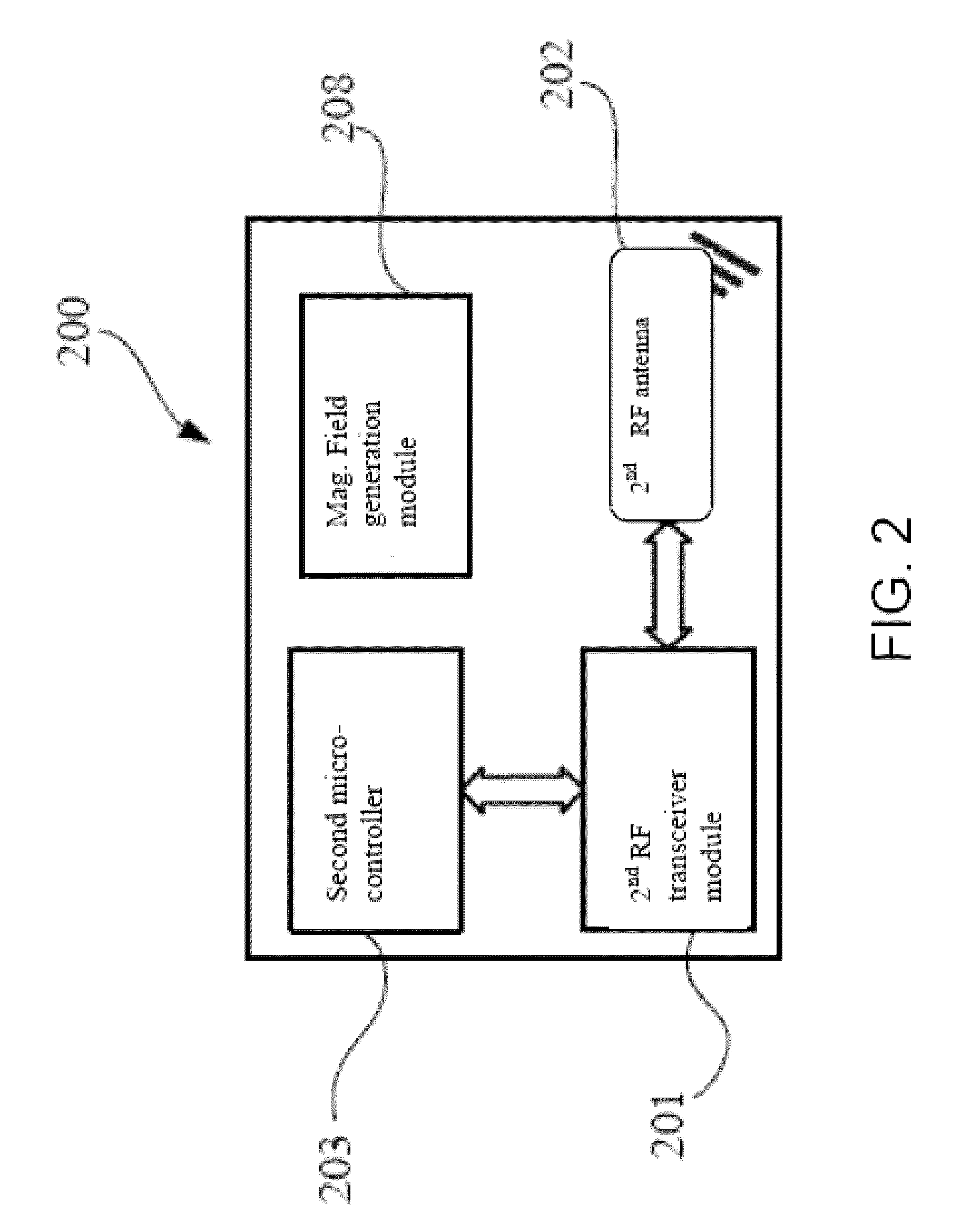

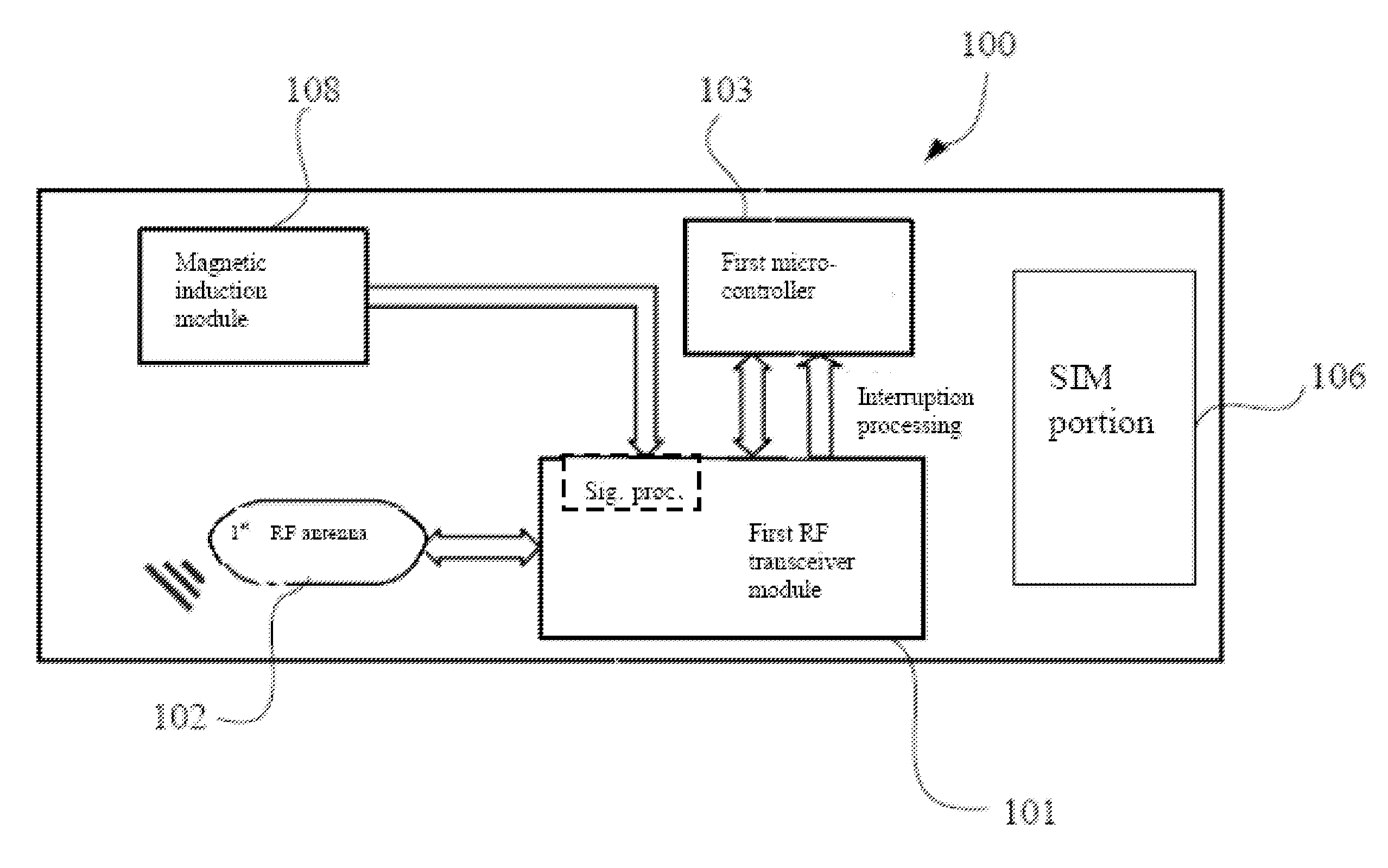

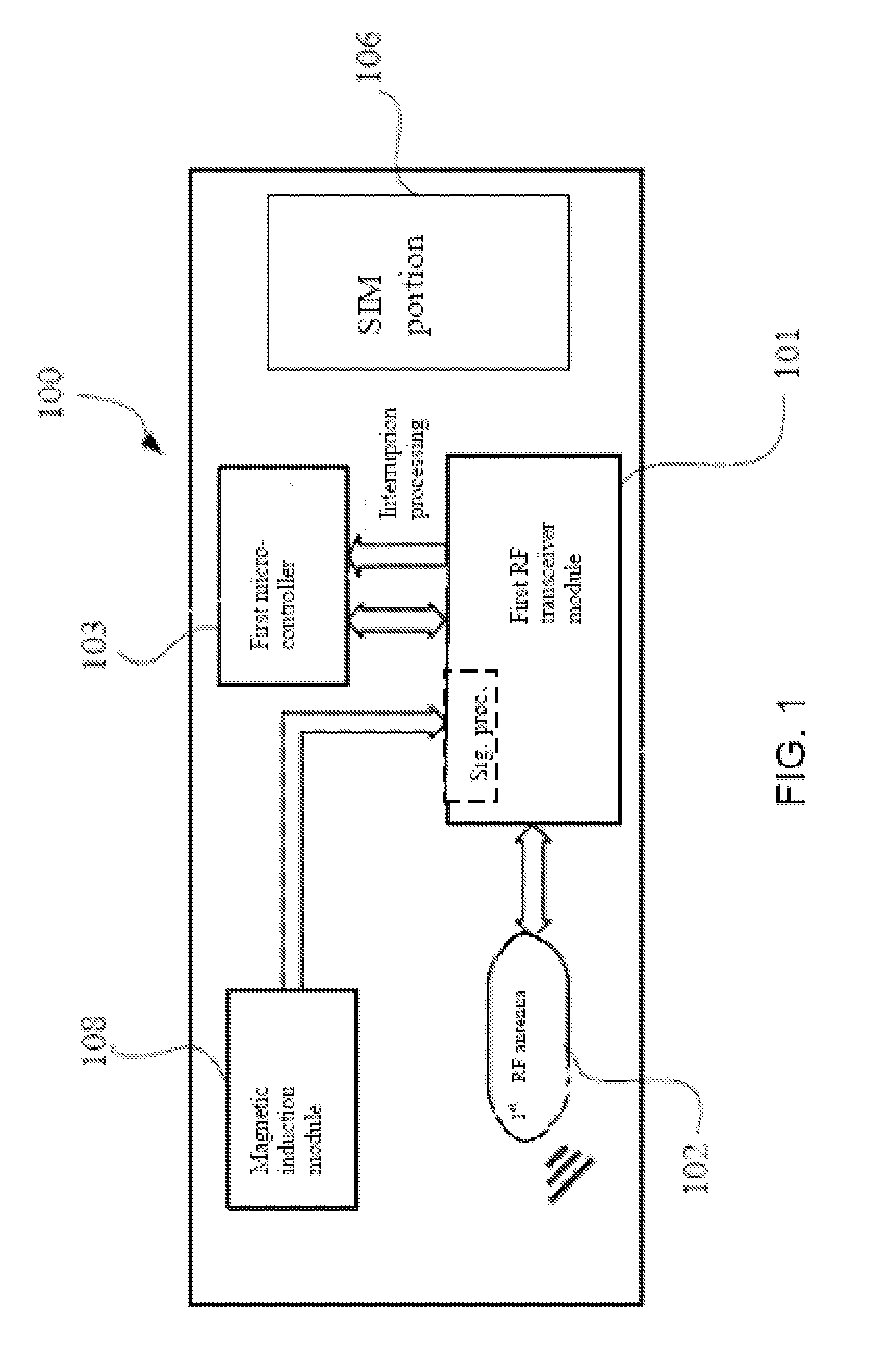

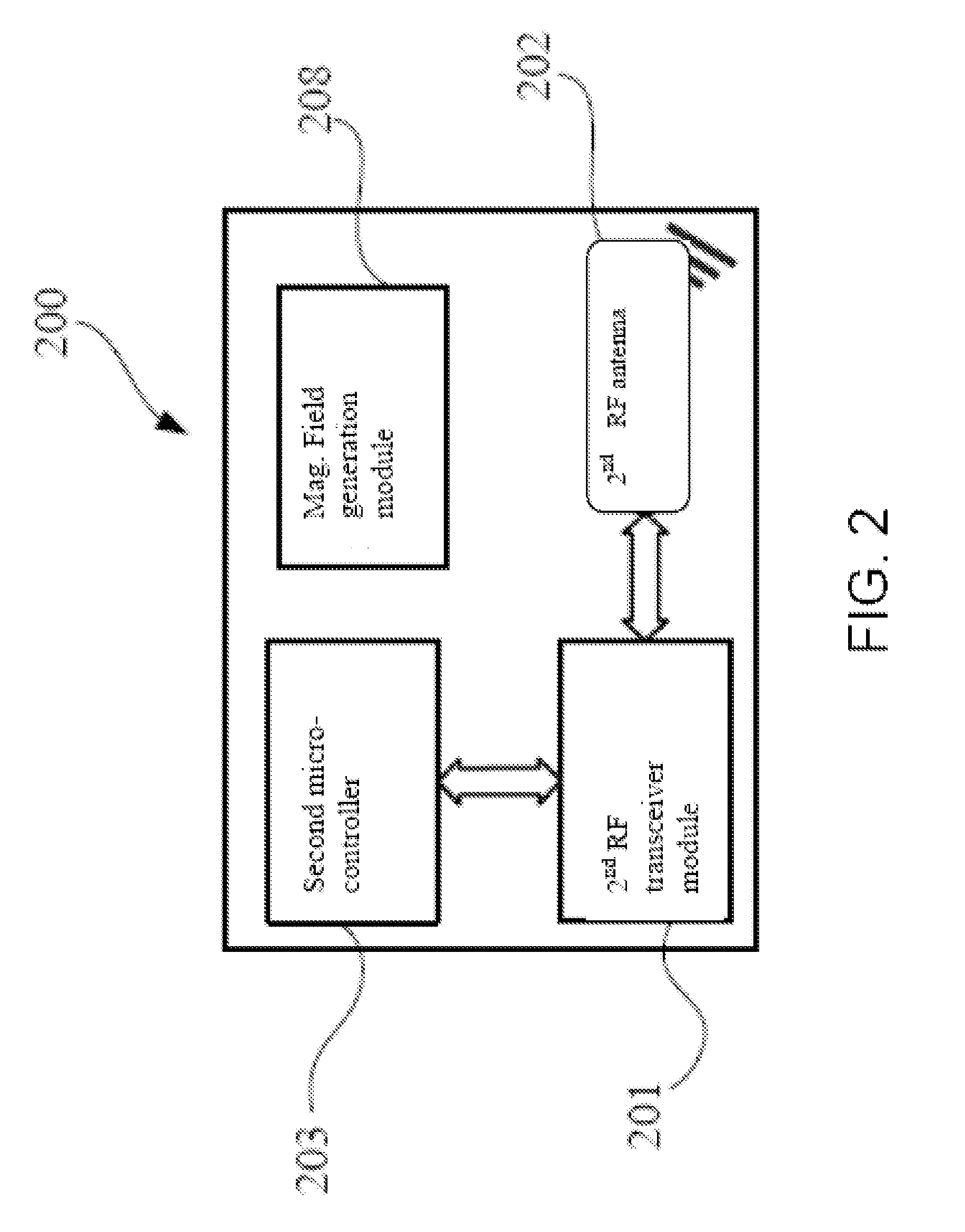

RF sim card, card reader, and communication method

ActiveUS20110165862A1Increased RF communication rangeReduced shieldingUnauthorised/fraudulent call preventionEavesdropping prevention circuitsTransceiverEngineering

A radio frequency (RF) device includes an RF transceiver, an RF antenna, and a magnetic signal detector. The RF is selected to be in the very high frequency (VHF), ultrahigh frequency (UHF), or super high frequency (SHF) bands such that the shielding effect is reduced and the RF device can be configured as a SIM card disposed inside a cellular phone with an increased RF communication range. The magnetic signal detector is used to sense a magnetic field signal from an RF reader, which includes an RF transceiver, an RF antenna, and a magnetic signal transmitter. The longer communication range afforded by the VHF, UHF, or SHF bands is reduced by the sensing of the magnetic field, thereby providing a communication range control, while the RF device and the RF reader exchange information through the RF channel with improved security as a result of the range control.

Owner:NATIONZ TECH INC

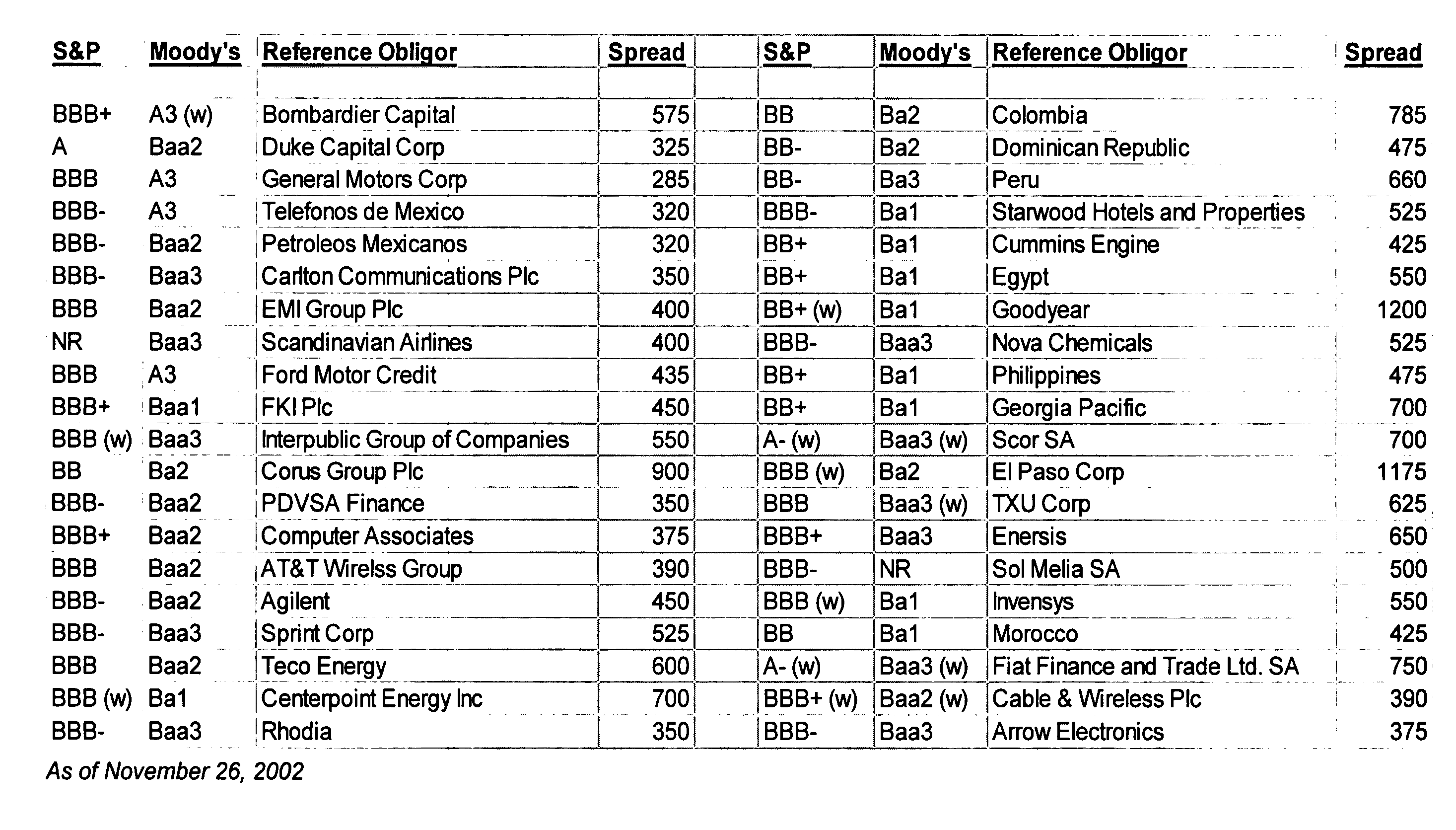

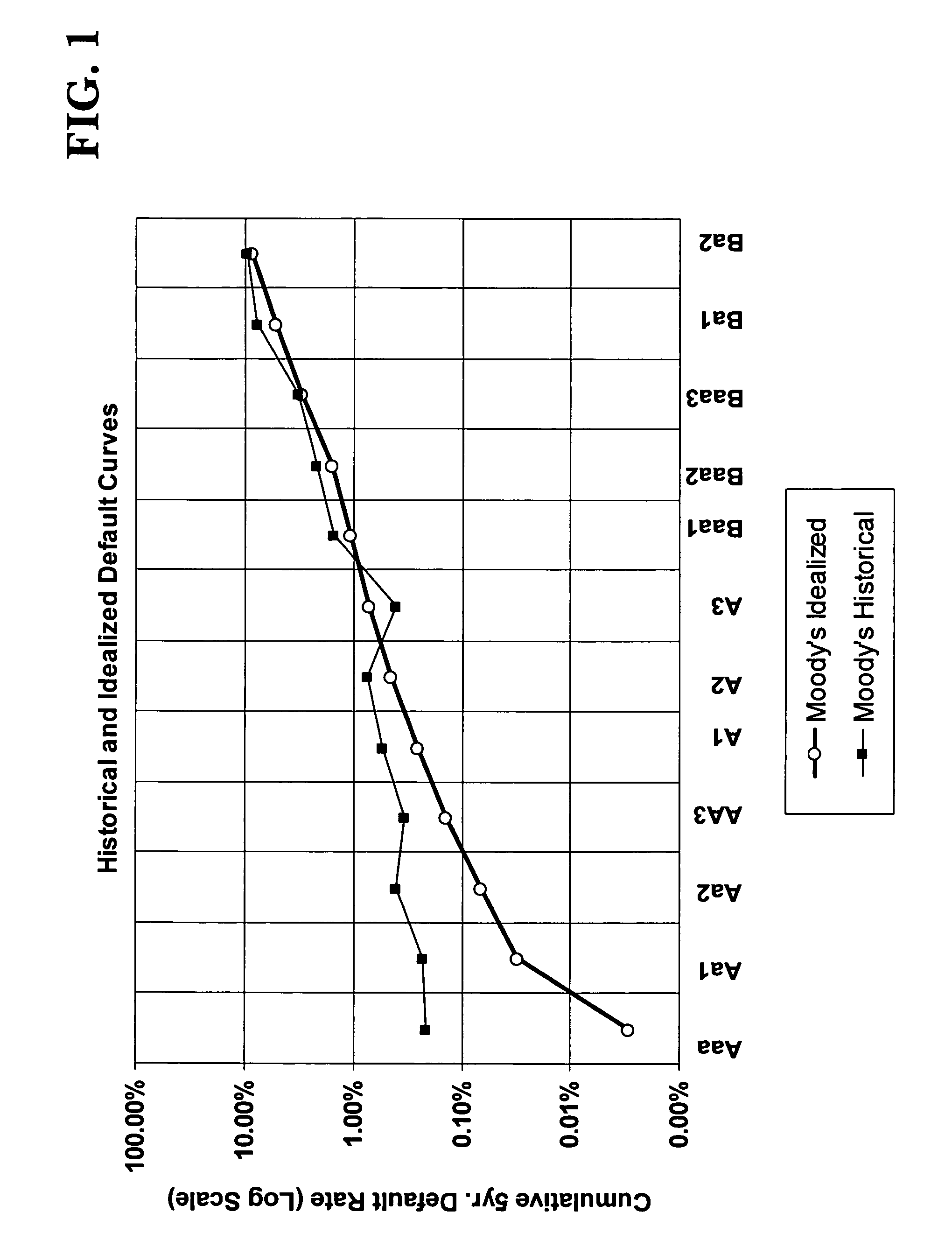

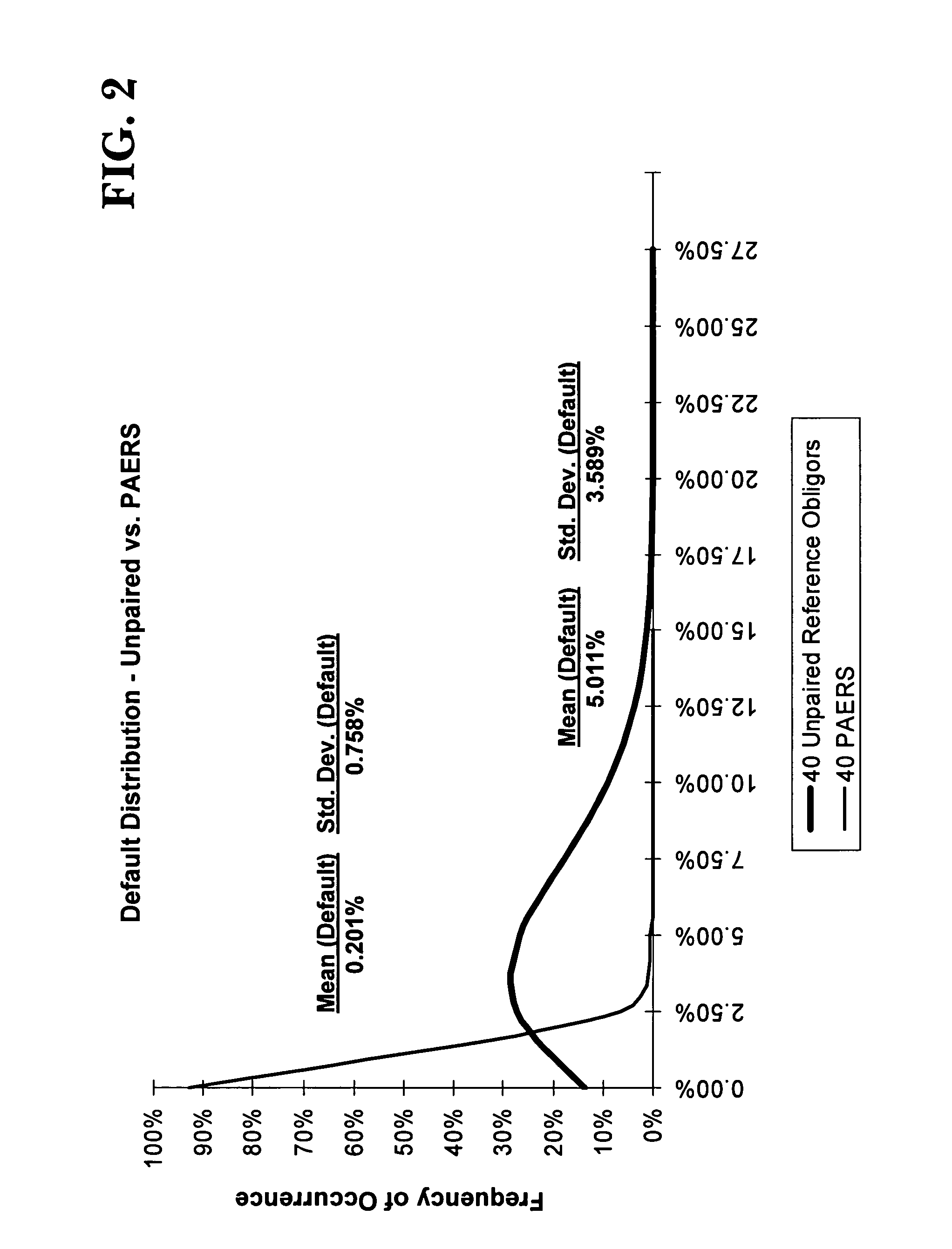

Hybrid securities having protection against event risk using uncorrelated last-to-default baskets

InactiveUS20050044029A1Reduce probabilityObtained inexpensivelyFinanceOffice automationData miningEvent risk

Hybrid securities defined as last-to-default credit default swaps over multiple name baskets and having protection against event risk. In the preferred embodiment, the hybrid security is defined as a second-to-default credit default swap over a two-name basket, wherein the underlying reference obligors in the basket are uncorrelated or substantially uncorrelated. A portfolio of second-to-default swaps over two-name baskets is provided, wherein the portfolio is defined in a manner that further reduces default risk through enhanced diversification achieved by recombining underlying reference obligors in different second-to-default baskets. A structured investment in a portfolio of underlying second-to-default swaps over two-name baskets is provided using a collateralized debt obligation (CDO) structure.

Owner:BABCOCK & BROWN

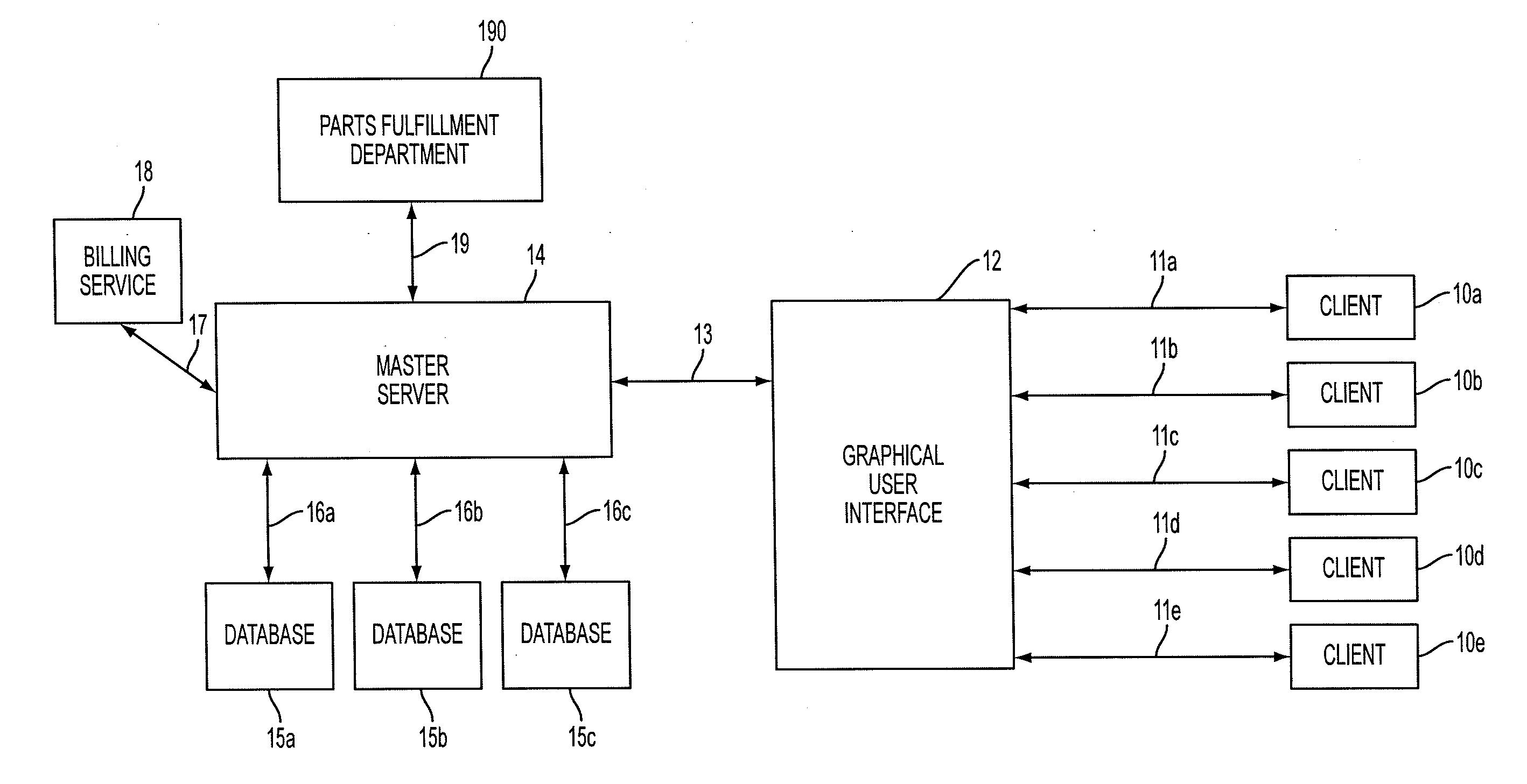

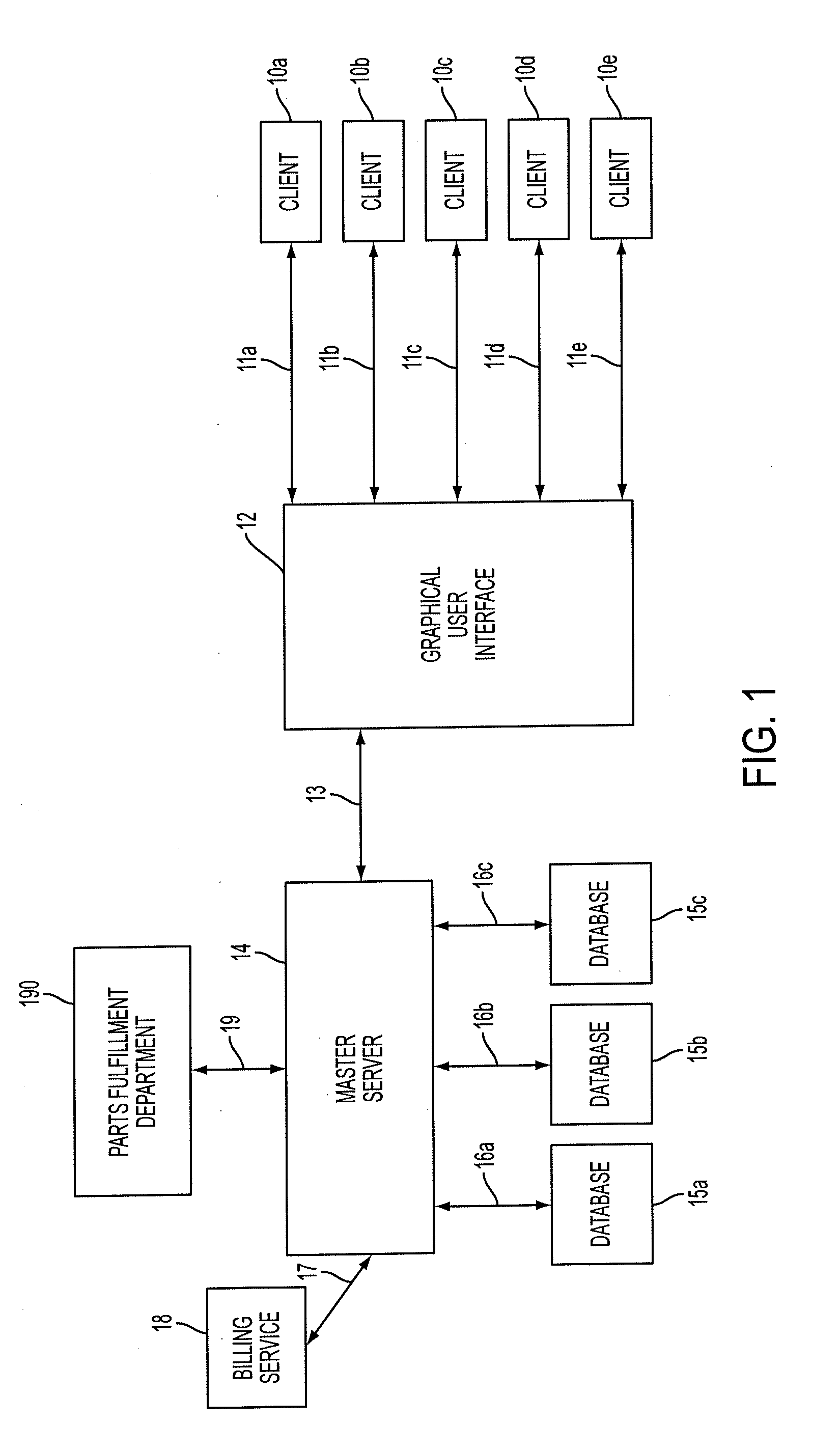

Method for generating vehicle repair estimate reports based on predictive estimating

InactiveUS20140279169A1Accurate vehicle repair estimateHigh security riskBuying/selling/leasing transactionsGraphicsRelevant information

Consumer safety of repaired vehicles can be improved by providing systems and methods for generating vehicle repair estimate reports based on predictive estimating and transmitting these reports to clients. A master server serviced by a vehicle manufacturer generates a vehicle repair estimate report based on predictive estimating and transmits this report to a client via a web-based graphical user interface. Also, a master server serviced by a vehicle manufacturer generates a vehicle repair estimate report based on predictive estimating and transmits this report to a client via a vehicle repair claims management user interface. The vehicle repair estimate report based on predictive estimating may comprise repair packages and repair information relating to recommended replacement parts and quantities thereof, the part numbers for the suggested replacement parts, the price estimate for the suggested replacement parts, manufacturer-recommended repair instructions, and other relevant information.

Owner:TOYOTA MOTOR SALES USA

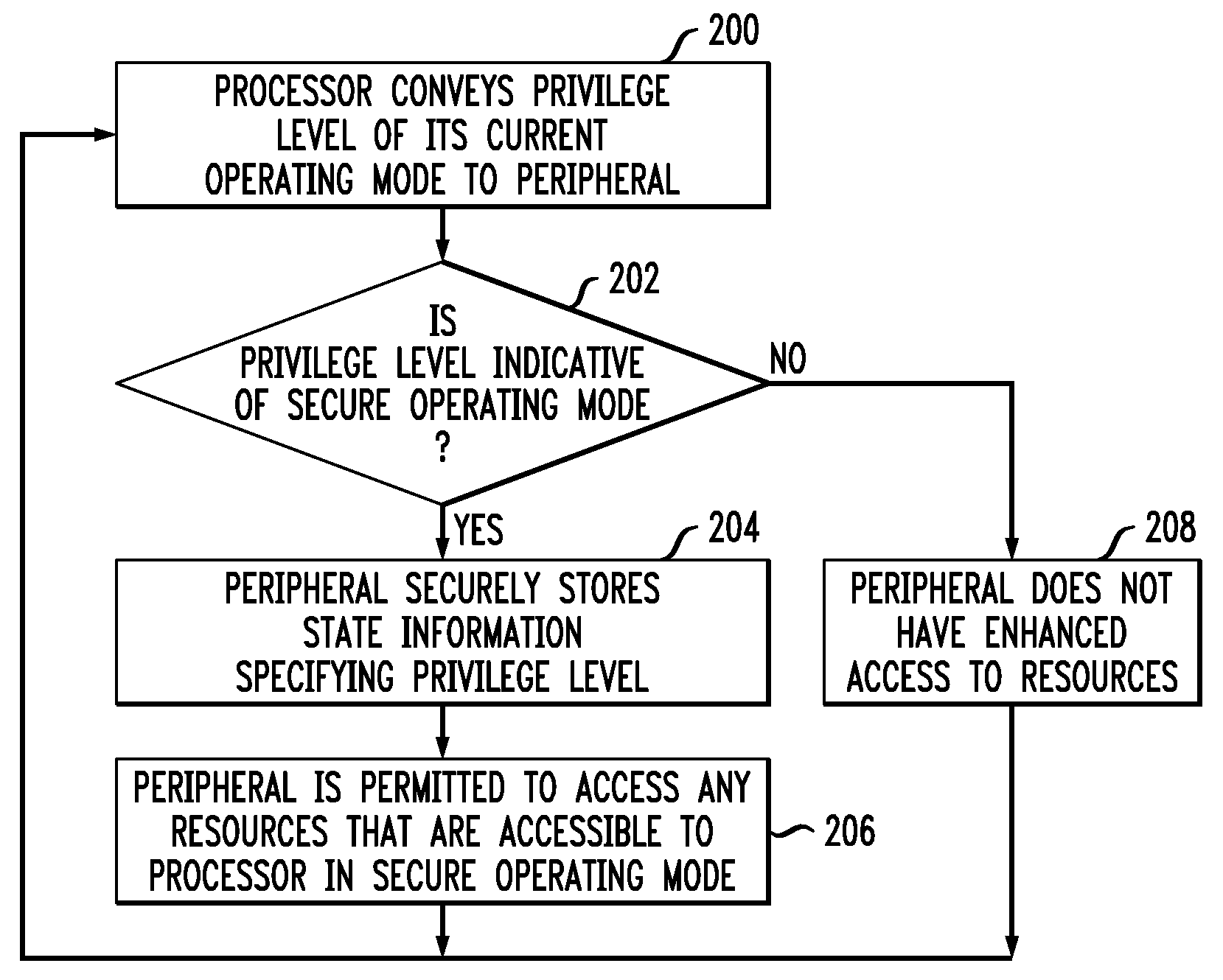

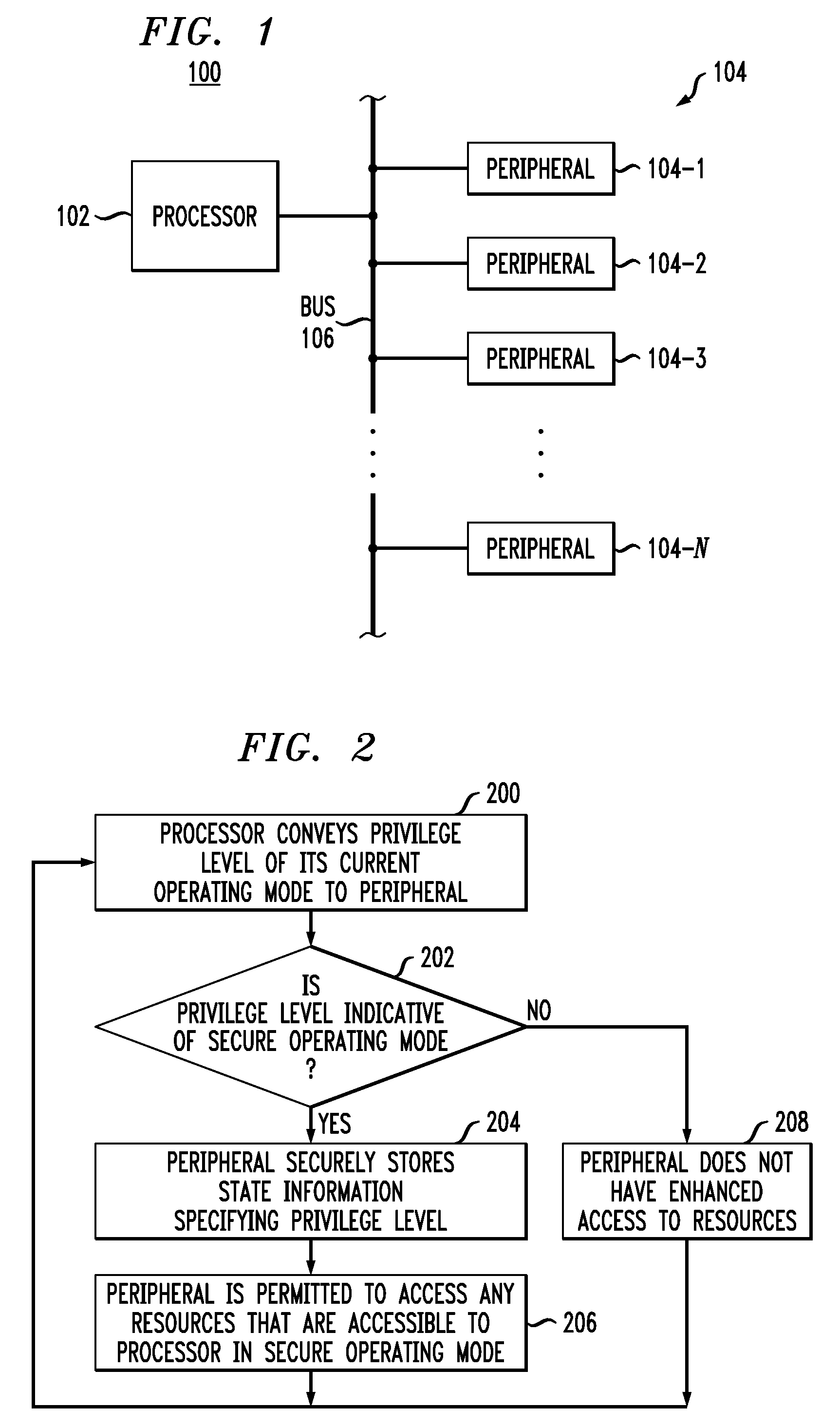

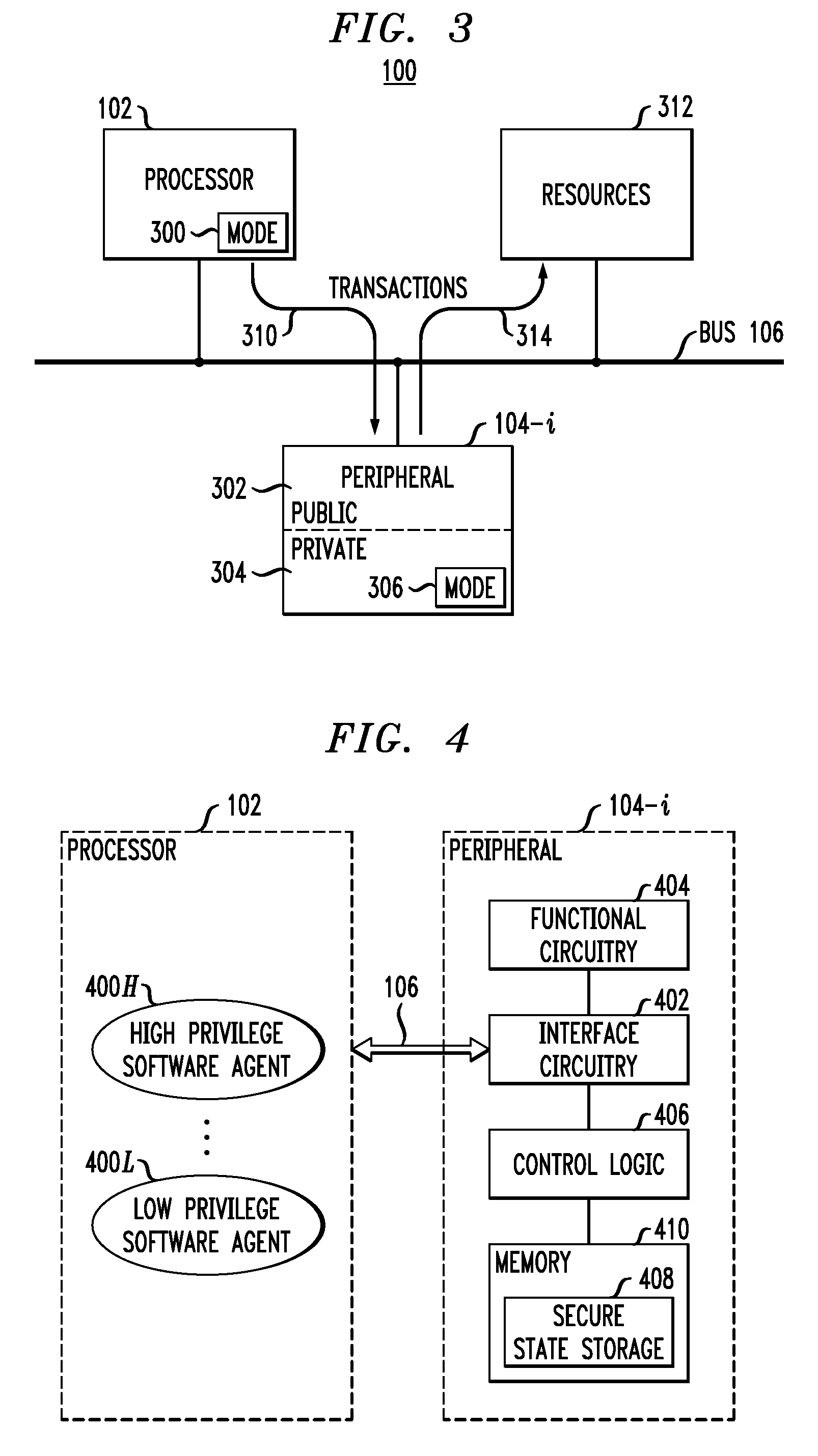

Method and Apparatus for Delegation of Secure Operating Mode Access Privilege from Processor to Peripheral

ActiveUS20090138623A1Improve securityHigh security riskDigital data processing detailsAnalogue secracy/subscription systemsHandling systemSafe operation

In a processing system comprising a processor and a plurality of peripherals coupled to the processor, access privileges of a secure operating mode of the processor are delegated to at least a given one of the peripherals. The given peripheral is configured to store, in a secure portion of that peripheral, state information indicative of the processor being in a secure operating mode. The given peripheral is further configured to utilize the stored state information to allow the given peripheral to access at least one resource that is accessible to the processor in the secure operating mode but is not otherwise accessible to the given peripheral. The processing system may comprise, for example, a system on a chip, wherein the processor and peripherals are combined into a single integrated circuit.

Owner:ALCATEL-LUCENT USA INC

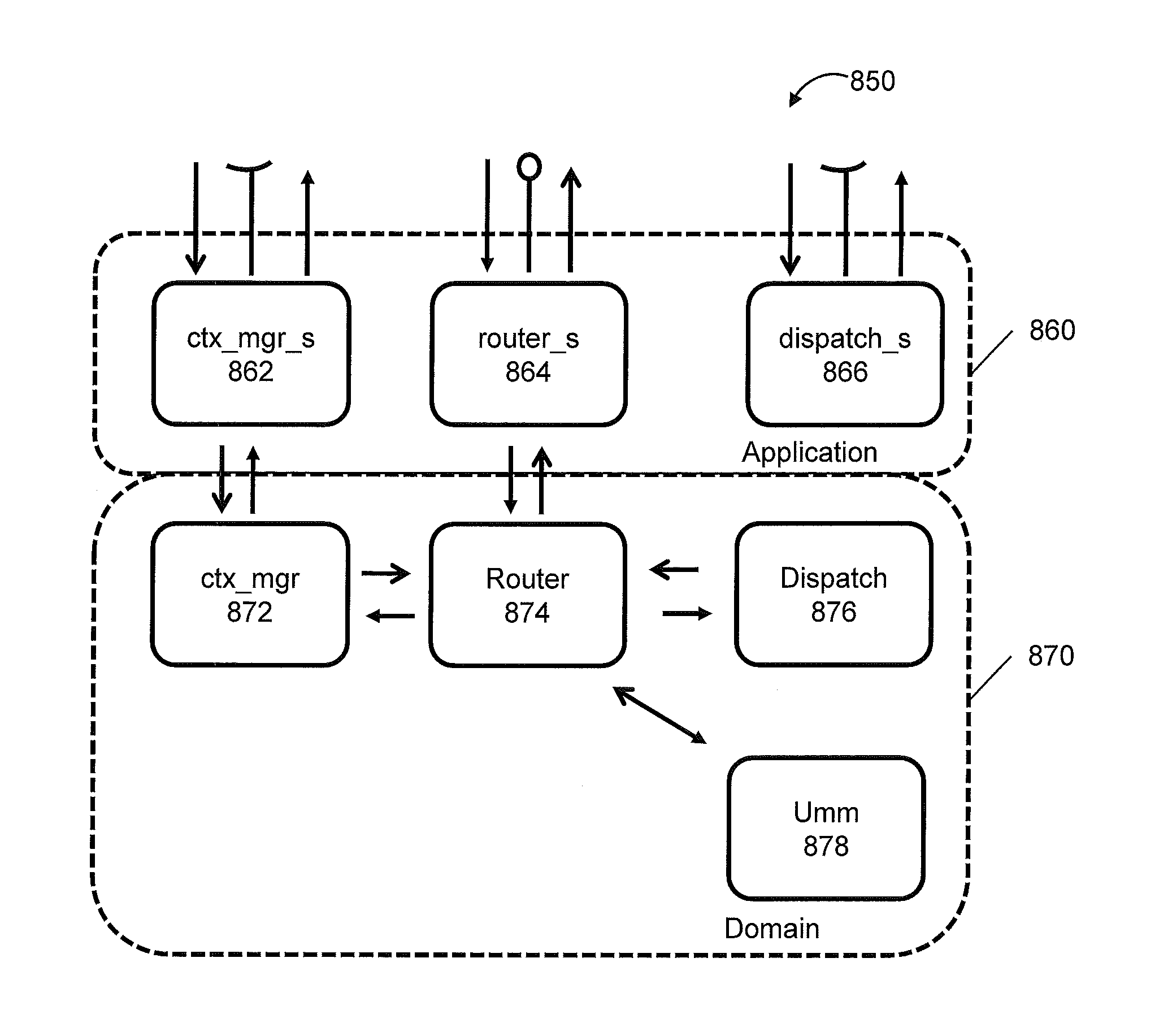

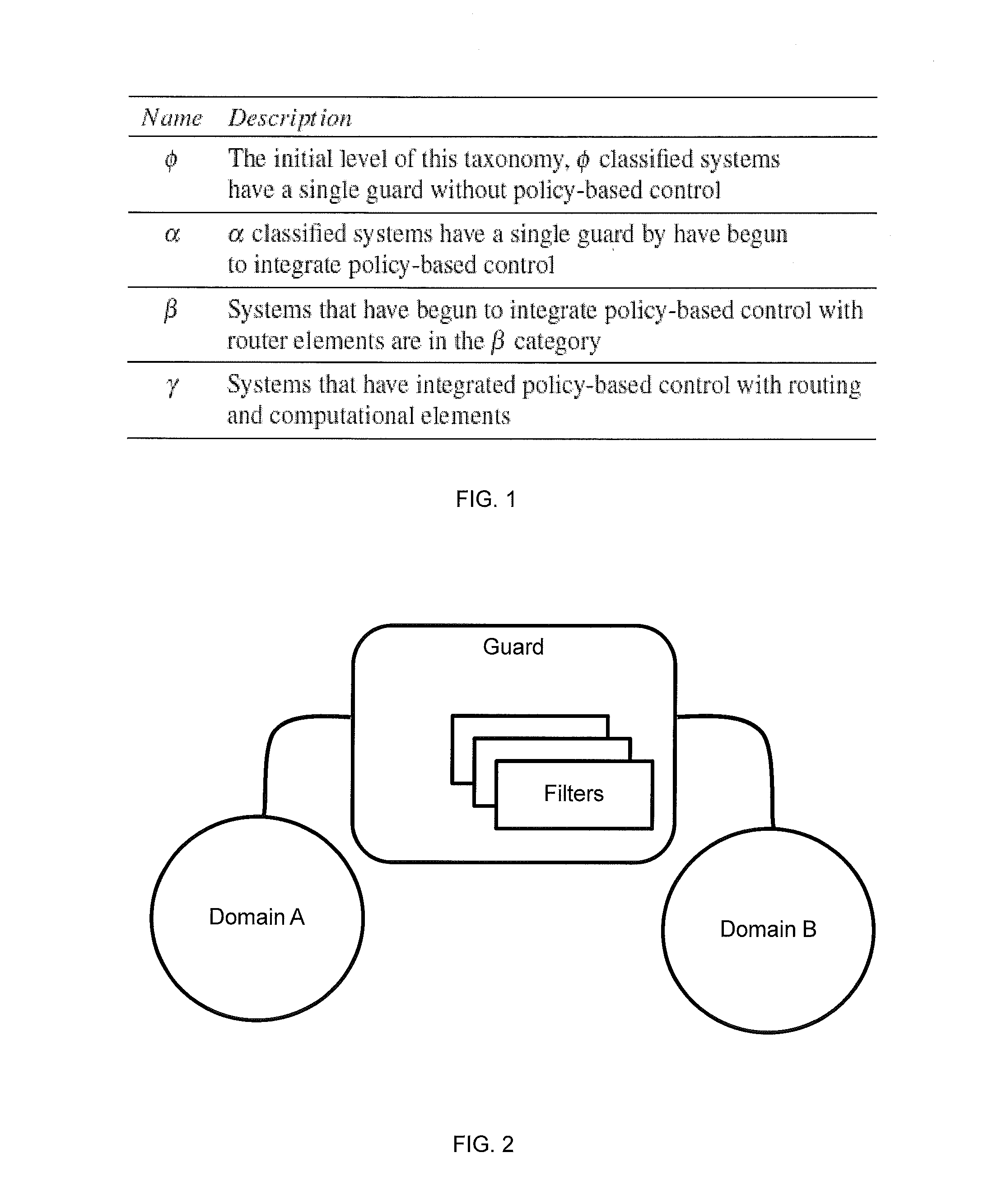

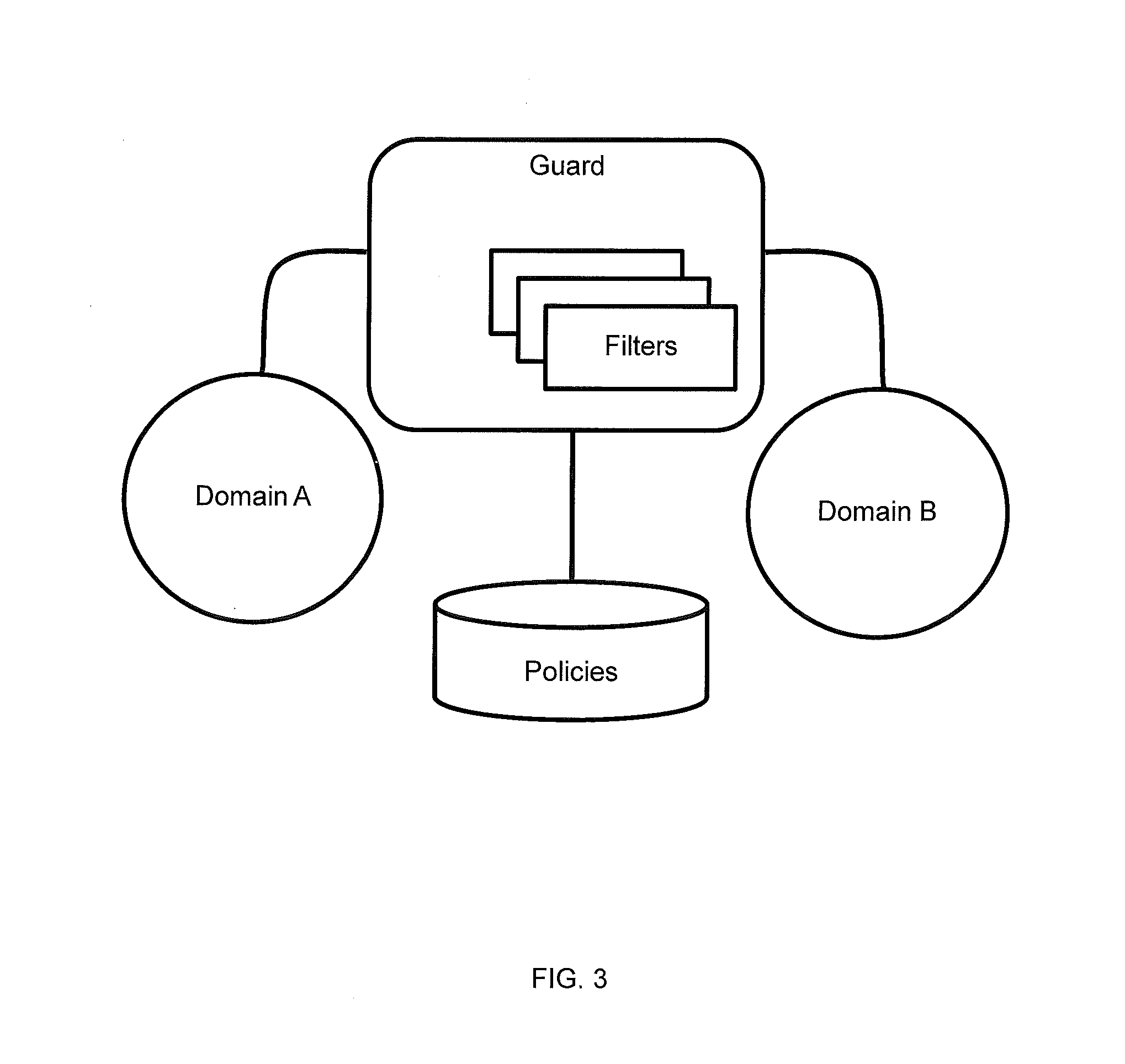

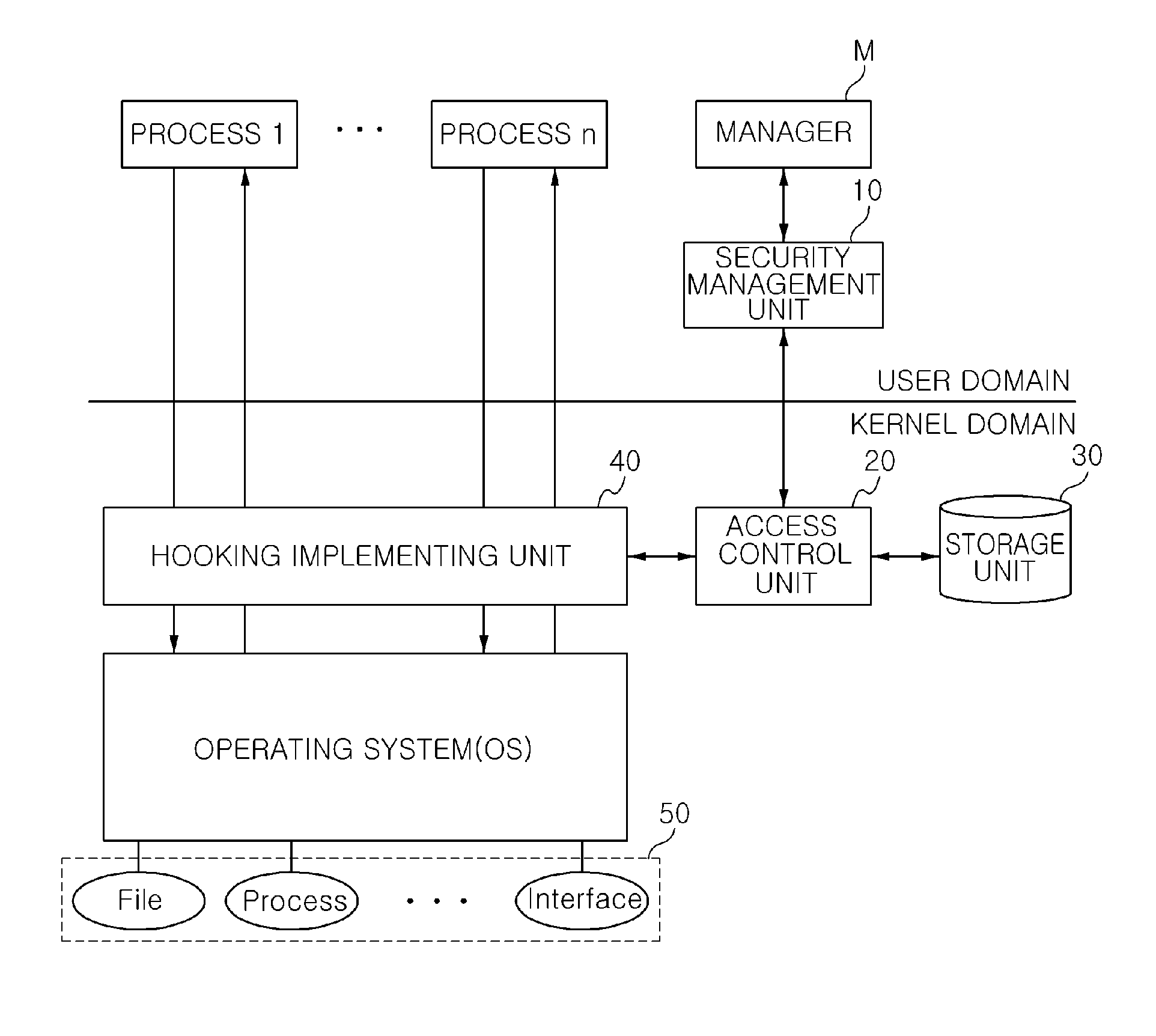

System and methods for usage management in multi-level security networks

ActiveUS9270701B1Efficient content managementHigh security riskTransmissionSpecial data processing applicationsSecurity domainInformation-centric networking

A system and methods for transferring information between two or more incompatible security domains or levels of classification by embedding policy-centric content management components into an information-centric network. Specifically, overlay architectures enable cloud computing for multi-level security environments.

Owner:STC UNM

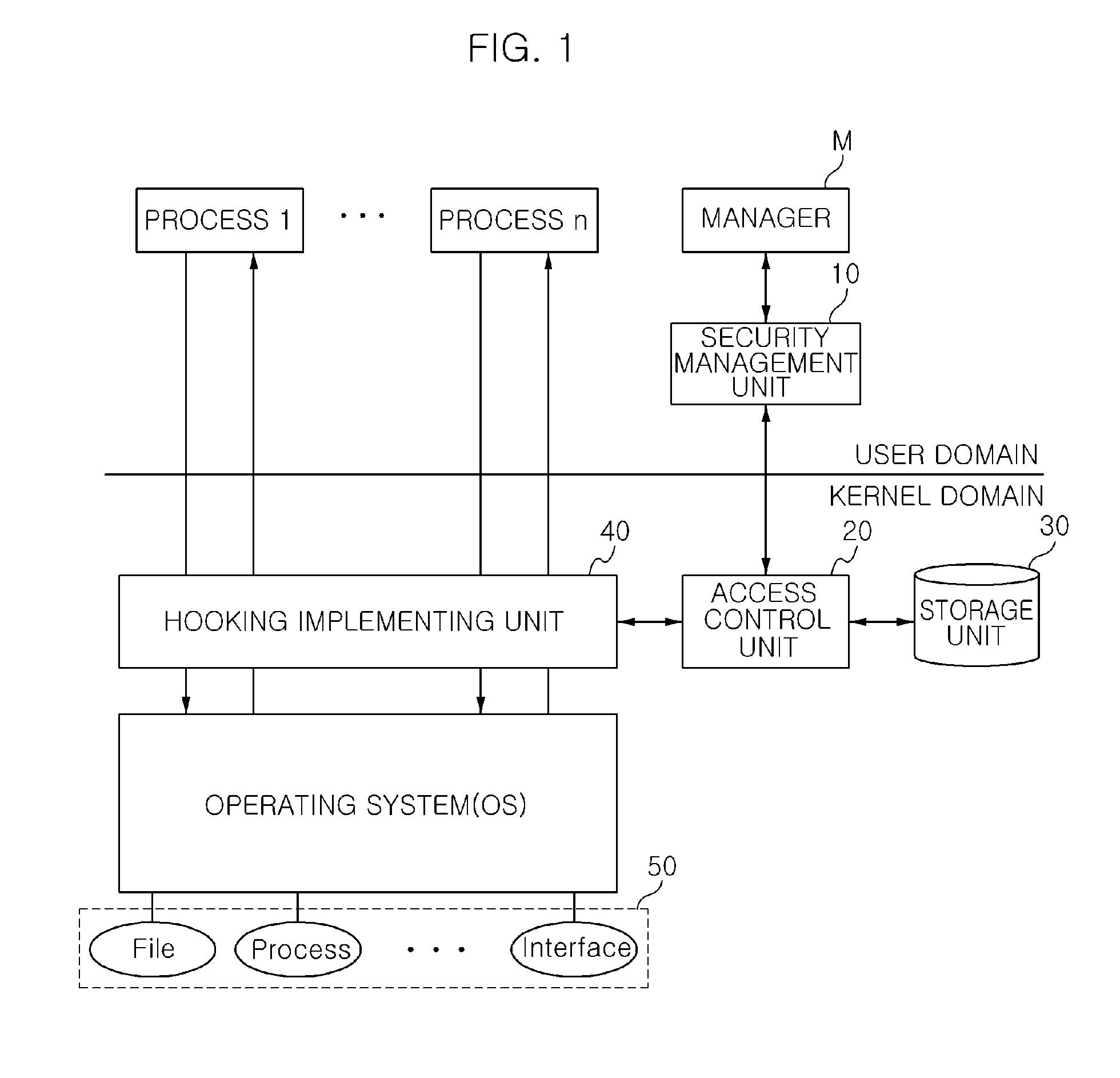

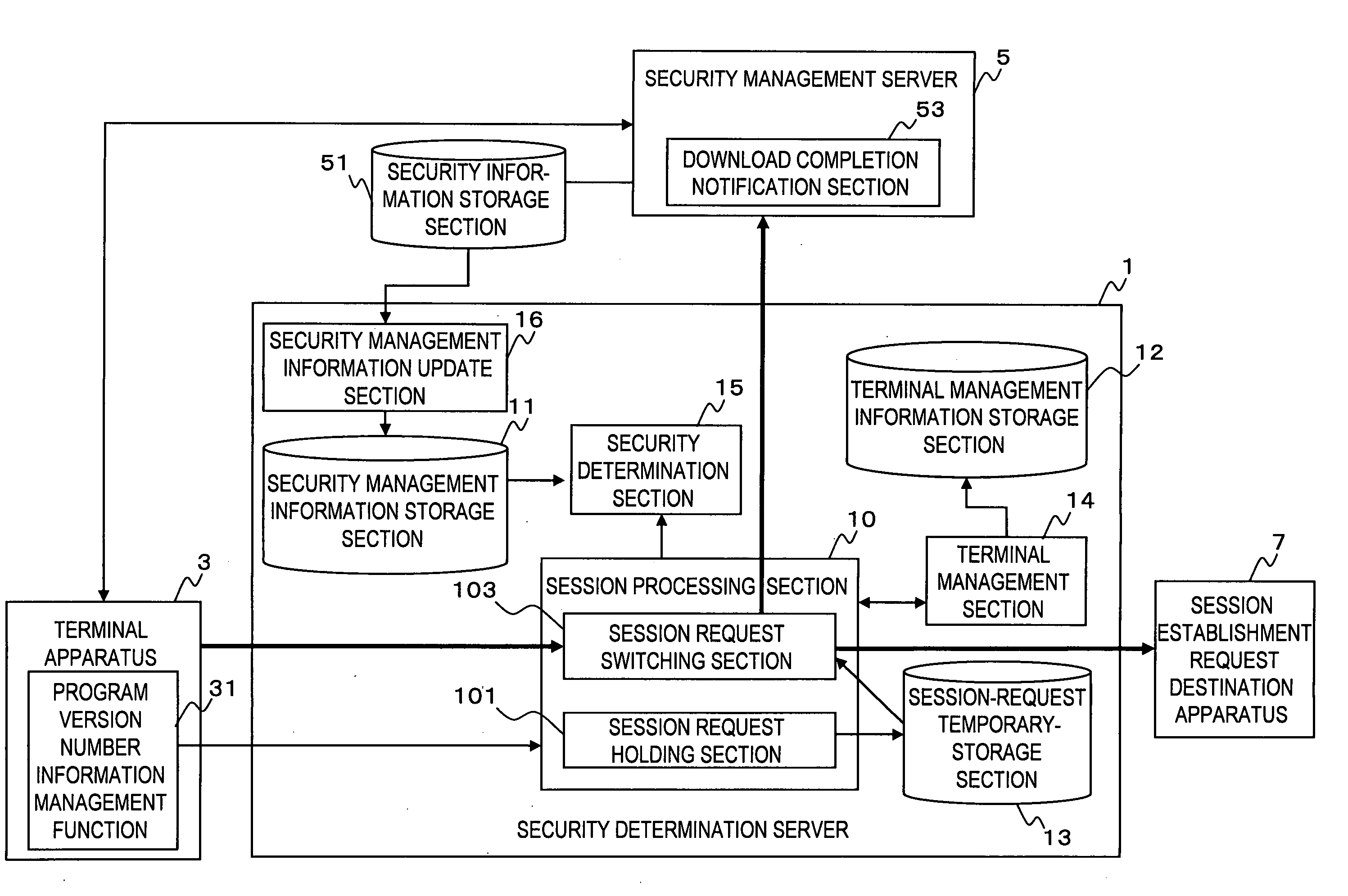

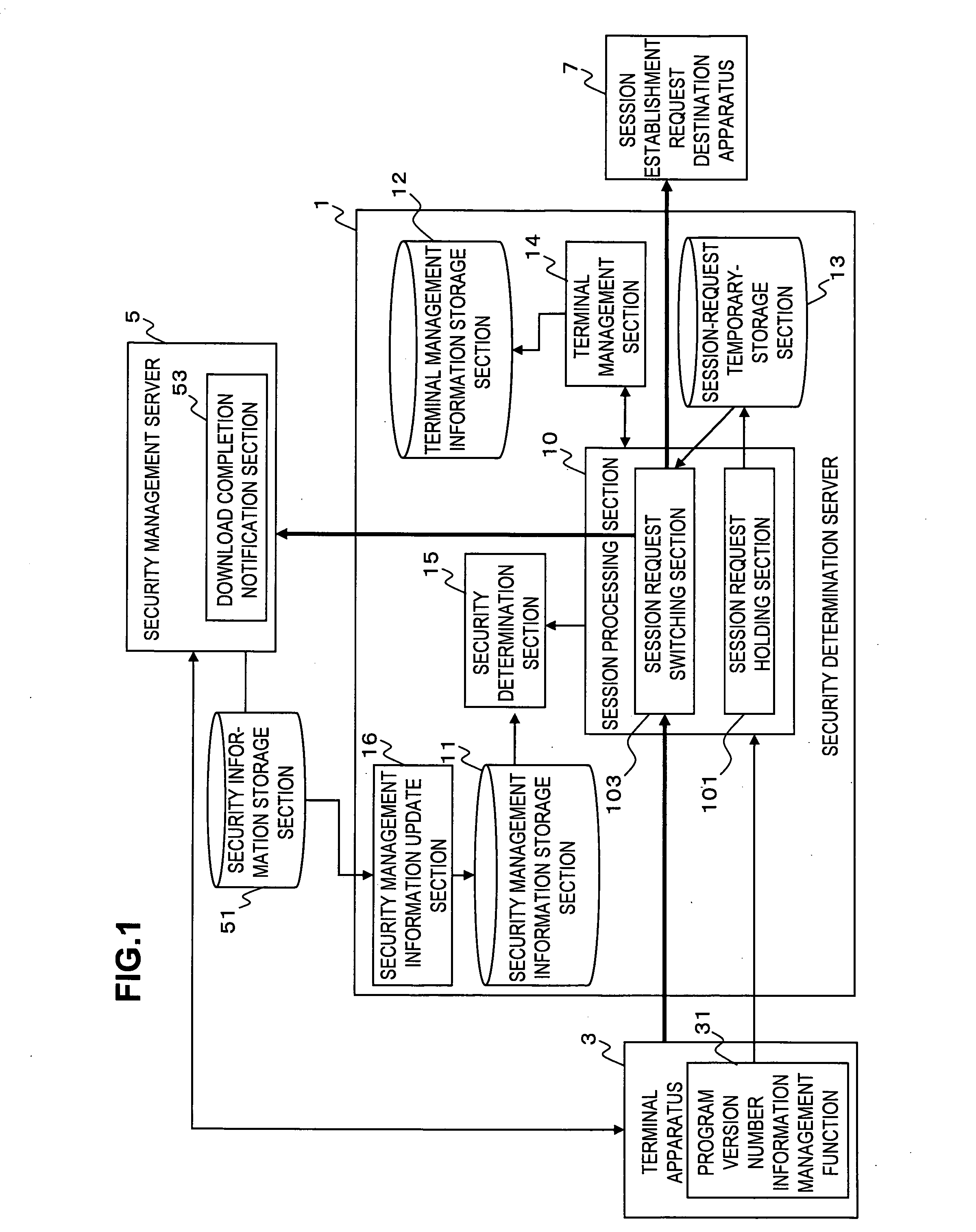

Apparatus and method for security managing of information terminal

InactiveUS20100100929A1High security riskImprove securityDigital data processing detailsUser identity/authority verificationComputer terminalSecurity policy

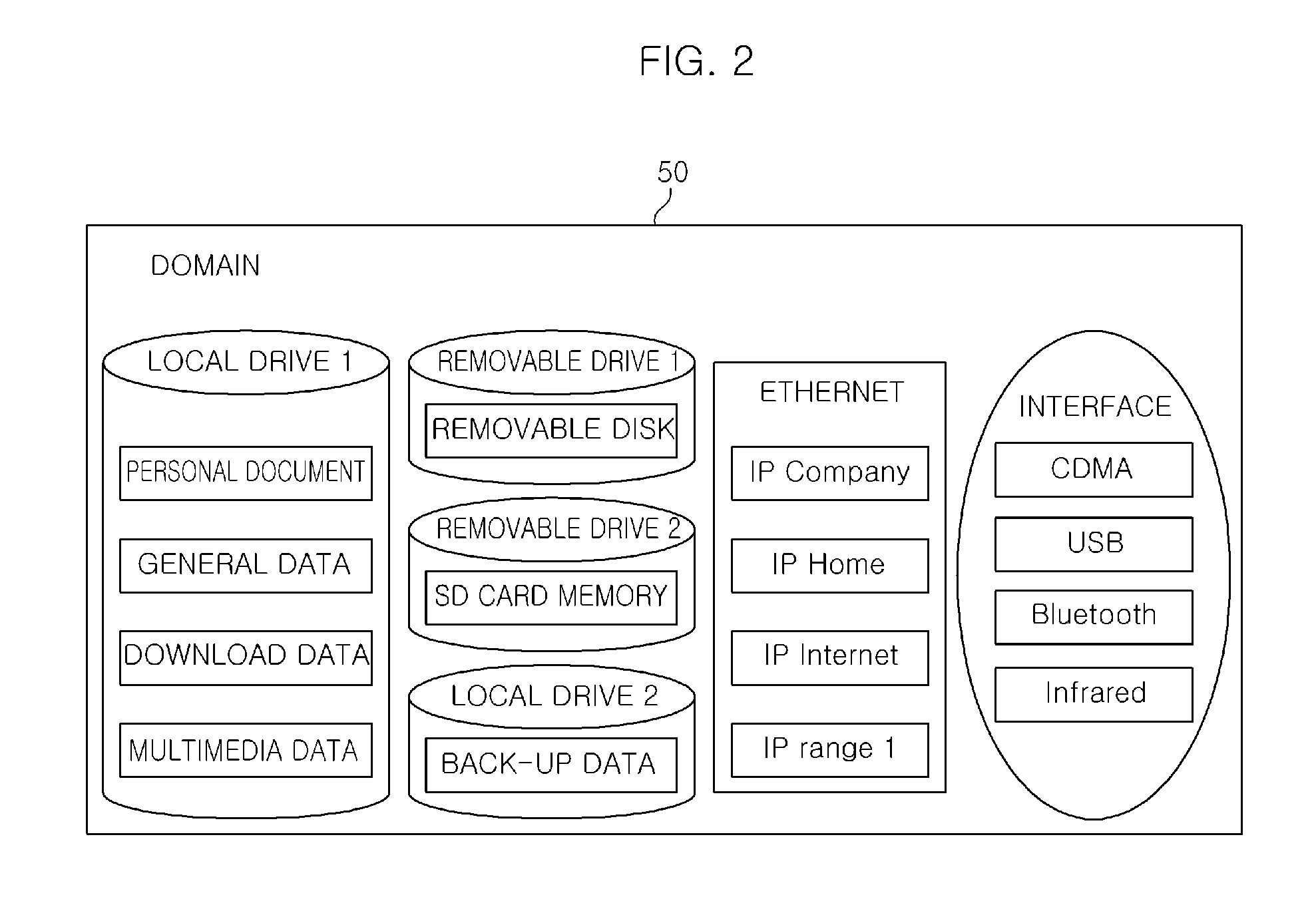

Provided is an apparatus and a method for security managing of an information terminal. The provided classifies a plurality of information providing means into a plurality of domains including at least one information providing means and when a user process accesses any one domain and then attempts to access another domain, controls the access to said another domain by verifying whether or not the access of the user process to said another domain is allowed. According to the provided, security threats are monitored for each domain which an execution process accesses by simply constructing domain classification information of an entire system without specifically establishing a security policy of an information providing device, such that it is possible to protect a terminal from a multi-domain access process having high security risk. Accordingly, it is advantageous to increase security for the terminal from various security threats.

Owner:ELECTRONICS & TELECOMM RES INST

Reducing risks associated with recertification of dormant accounts

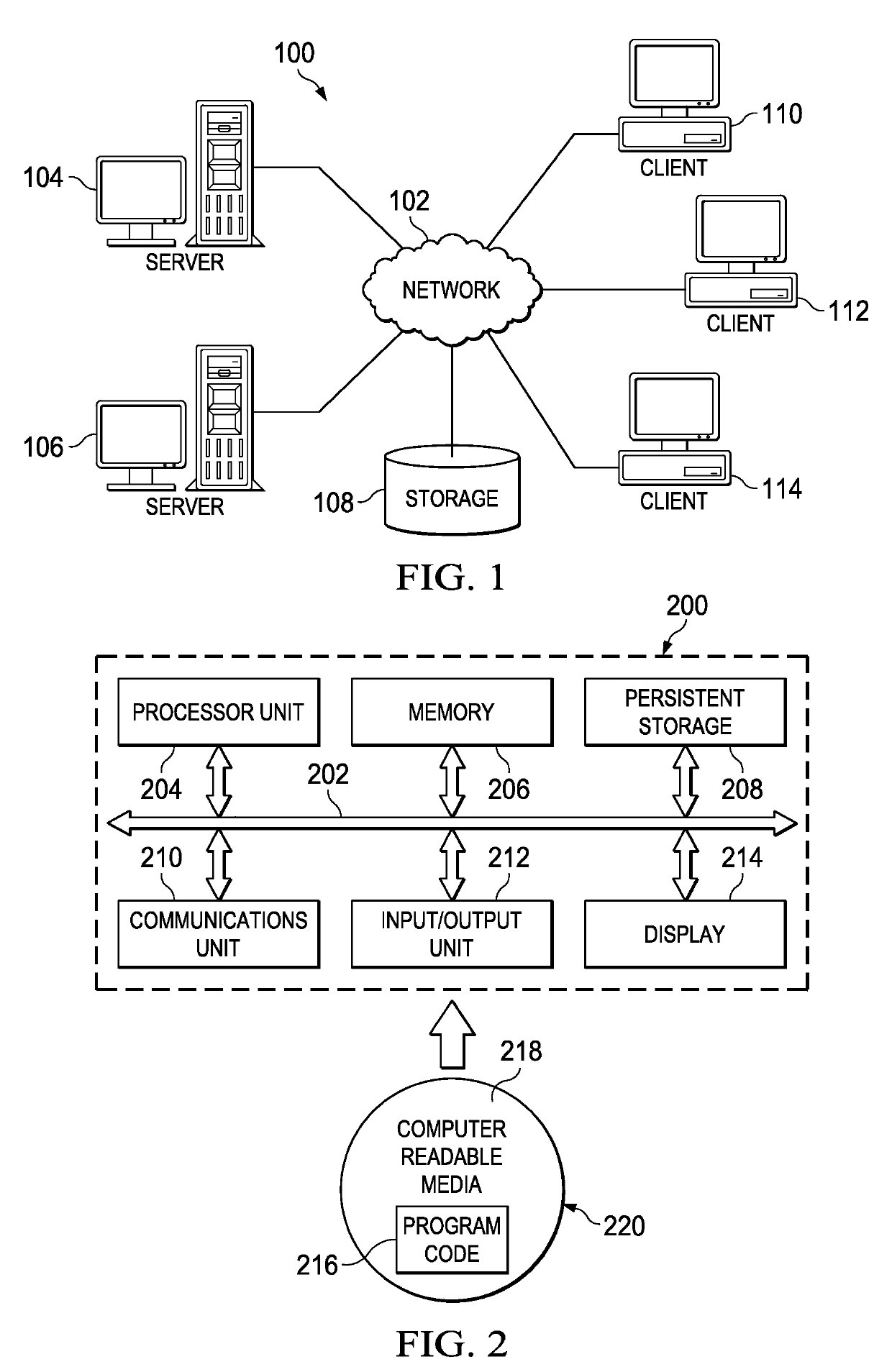

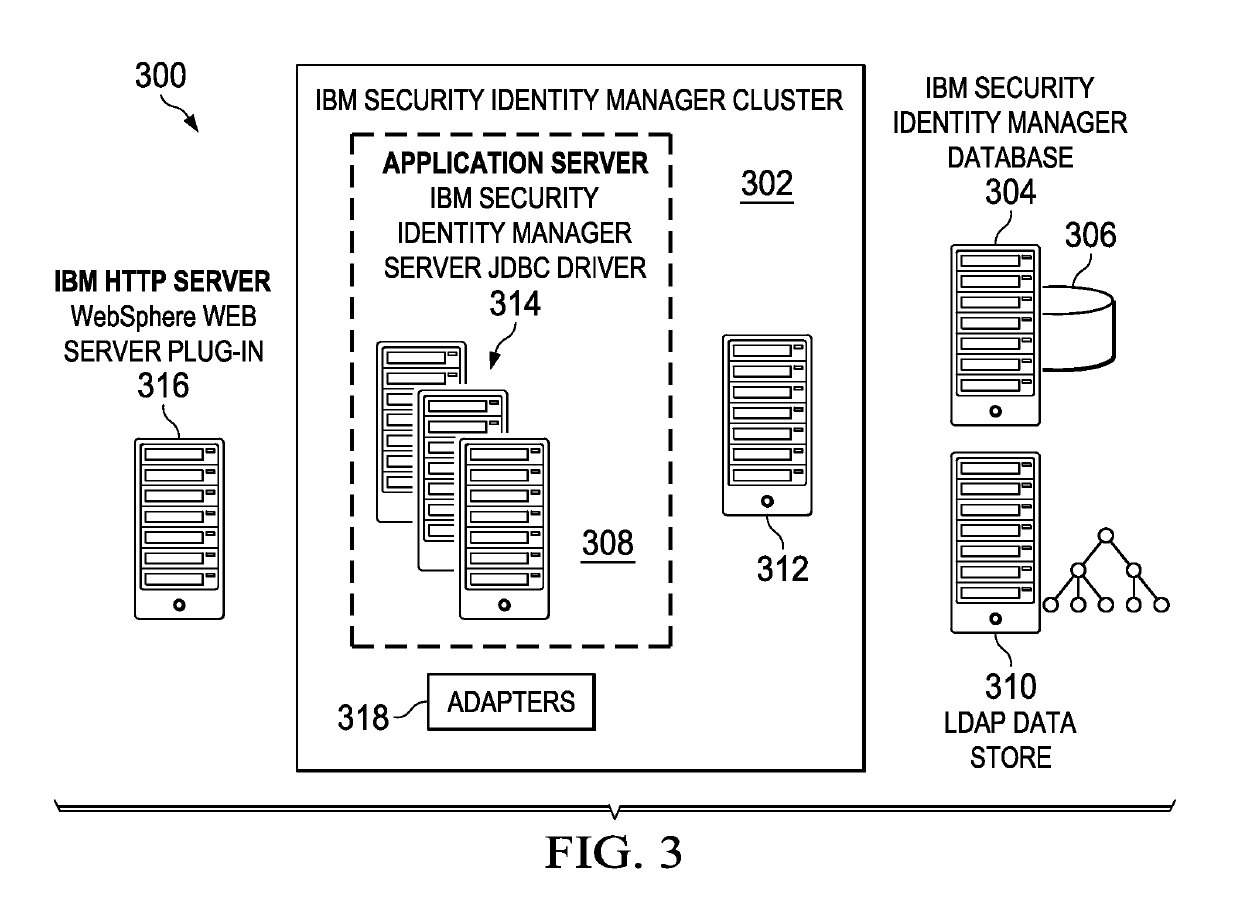

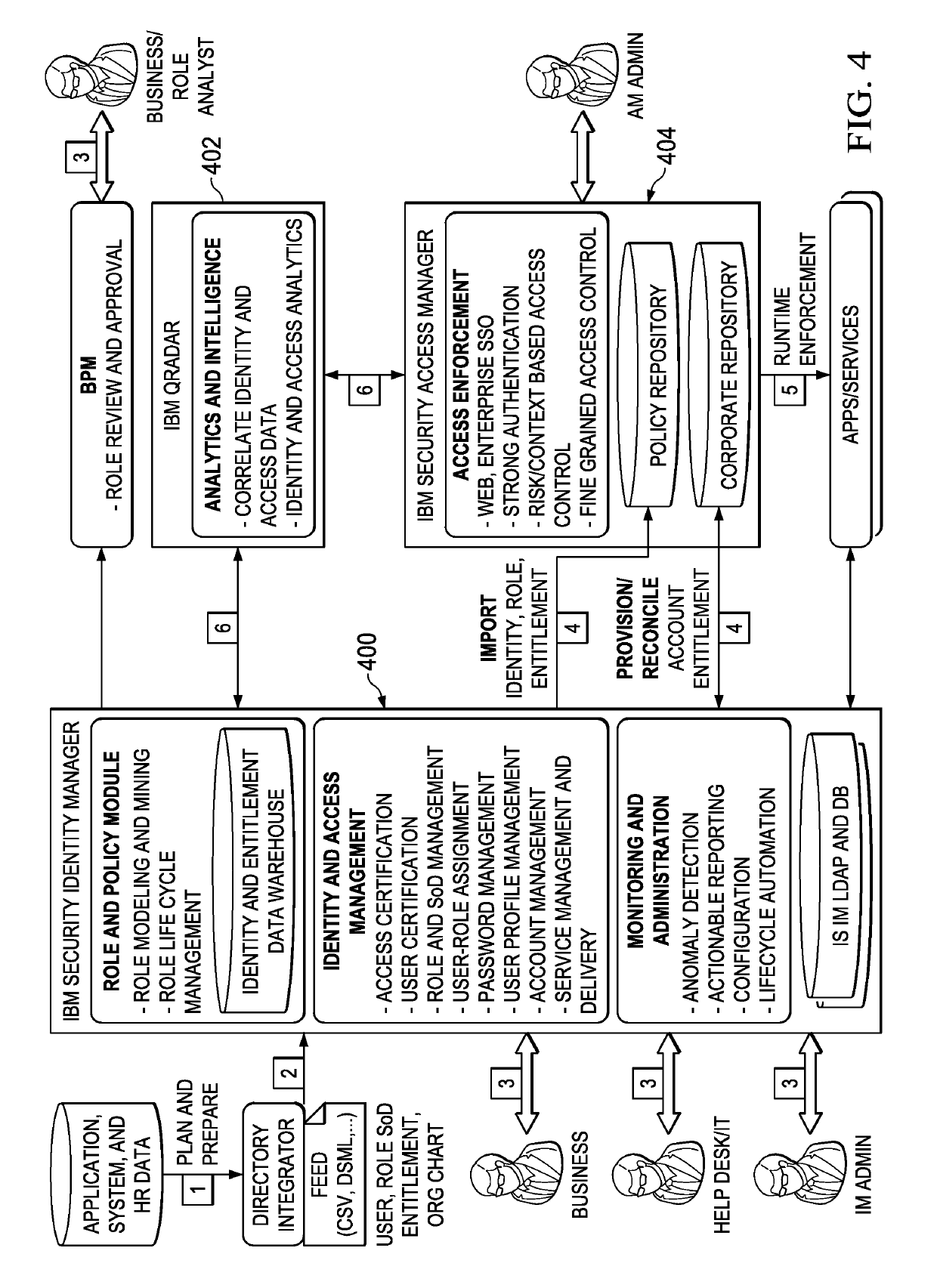

ActiveUS10440029B2High security riskTransmissionSpecial data processing applicationsIdentity management systemDatabase

An identity management system is augmented to provide for automated suspension of all dormant accounts before launching a re-certification campaign (pass). In one implementation, prior to receiving a recertification notice from the system, the affected user's account is already suspended and thus cannot be accessed. Once the recertification succeeds, however, the account is restored. Preferably, the technique is exposed to an IAM system administrator through a simple interface, e.g., a one-click “suspend and re-certify” button in an administrative menu. When the administrator initiates the re-certification process, he or she may select the button for a particular account or user.

Owner:IBM CORP

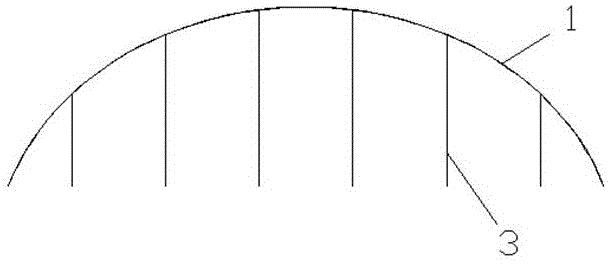

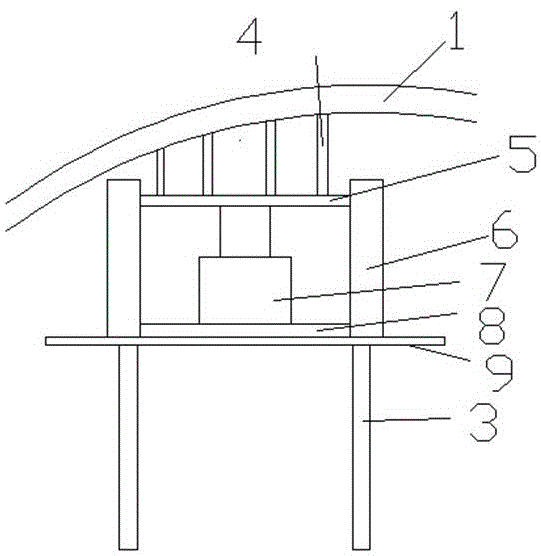

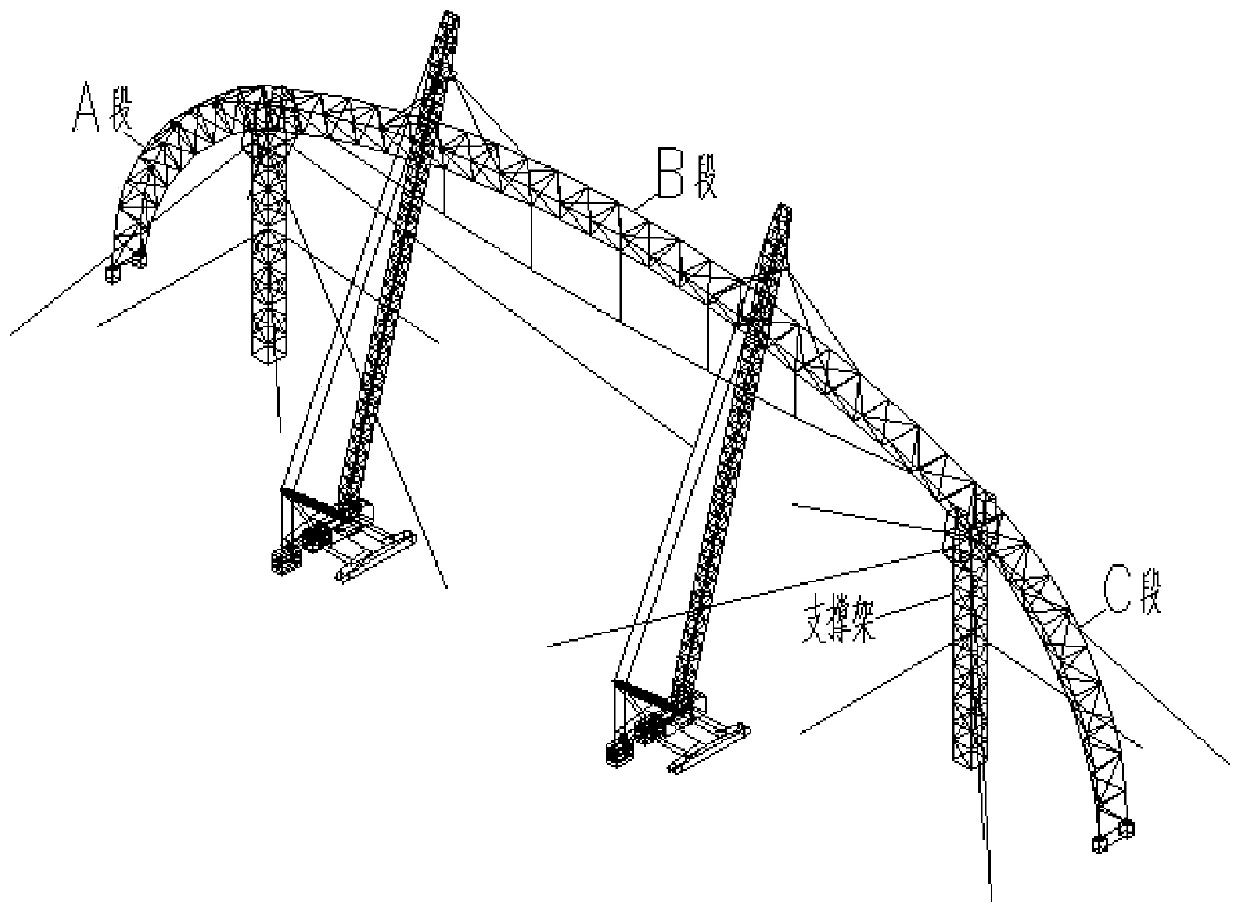

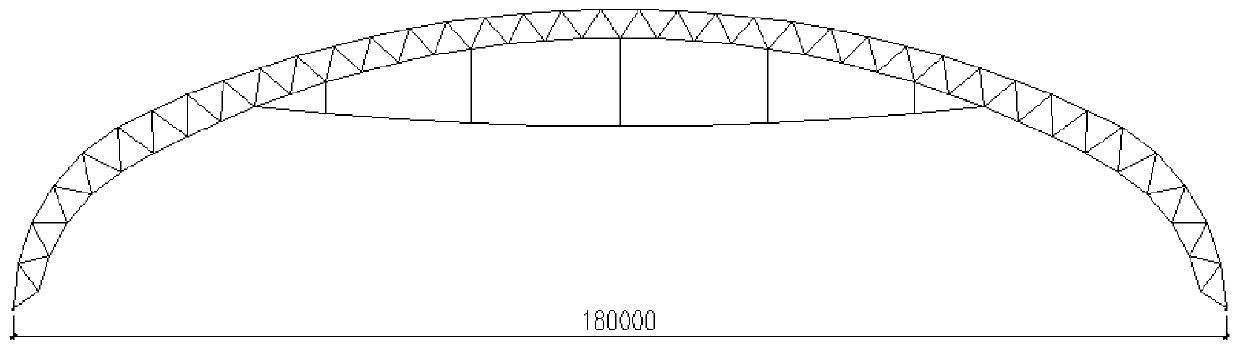

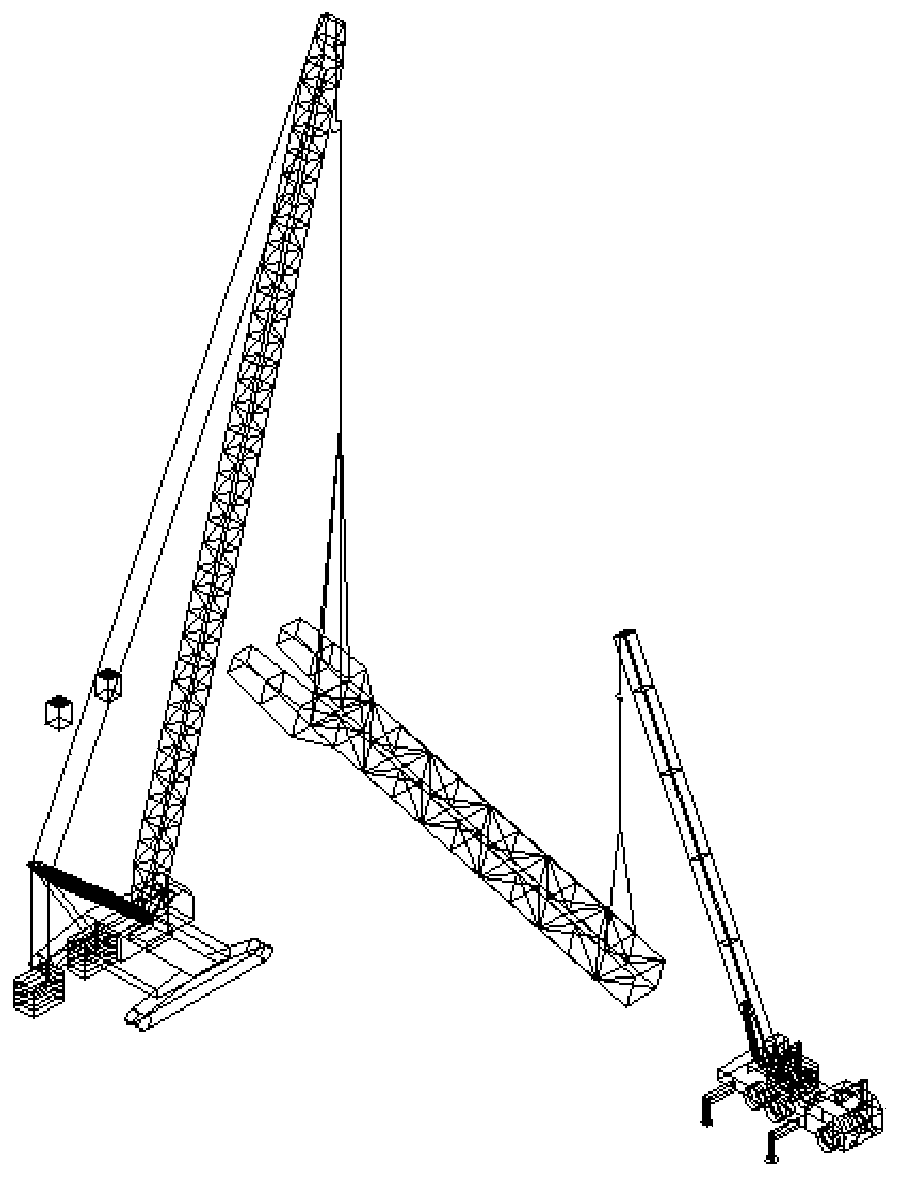

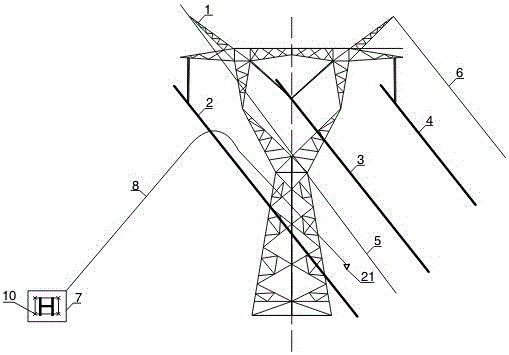

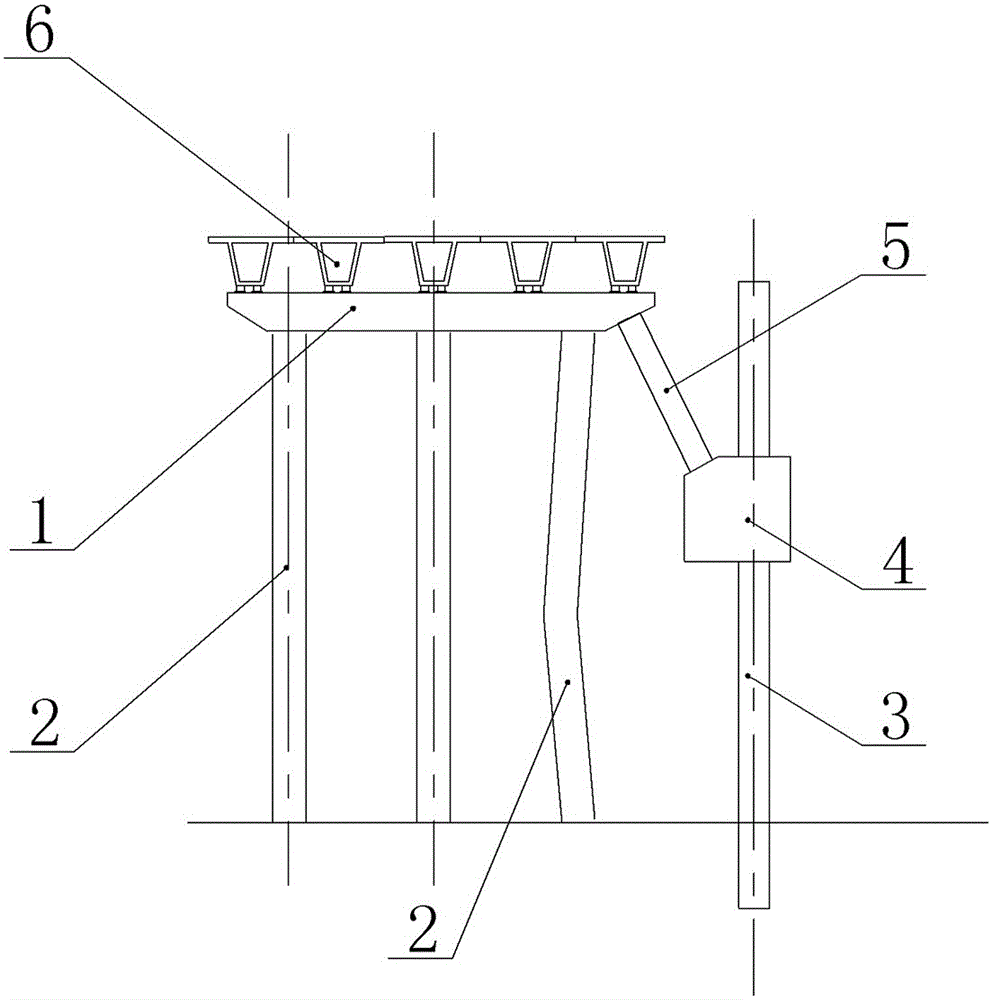

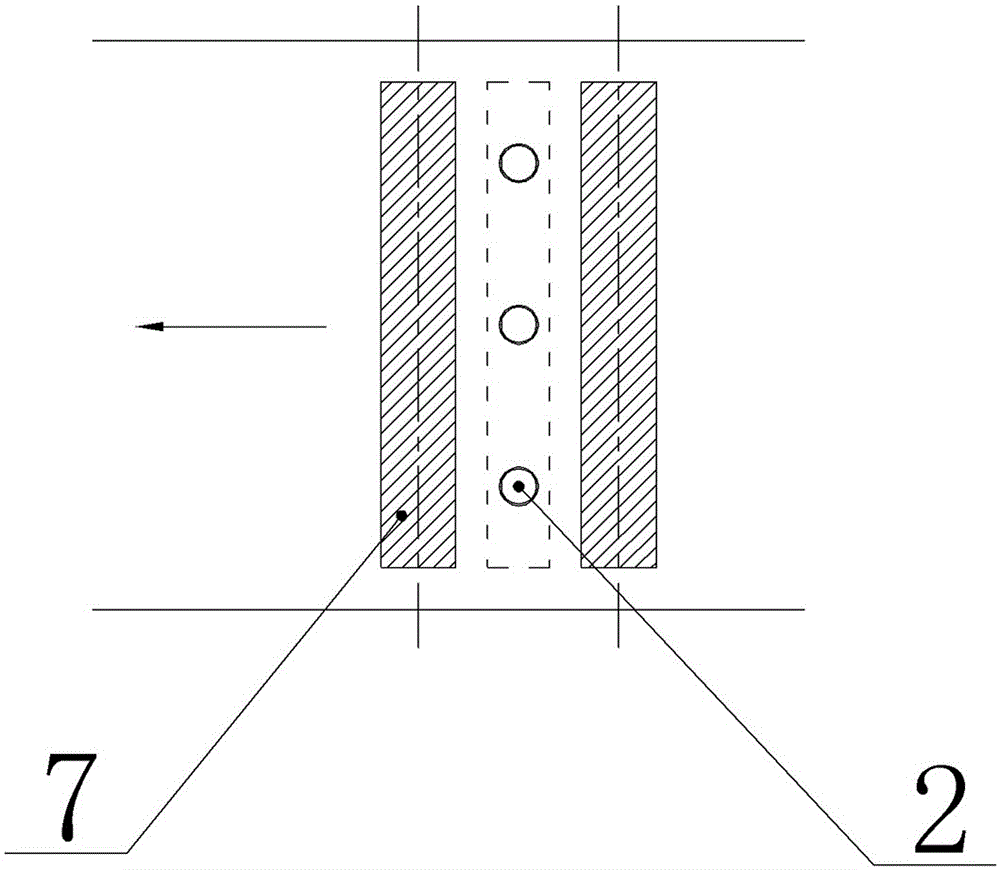

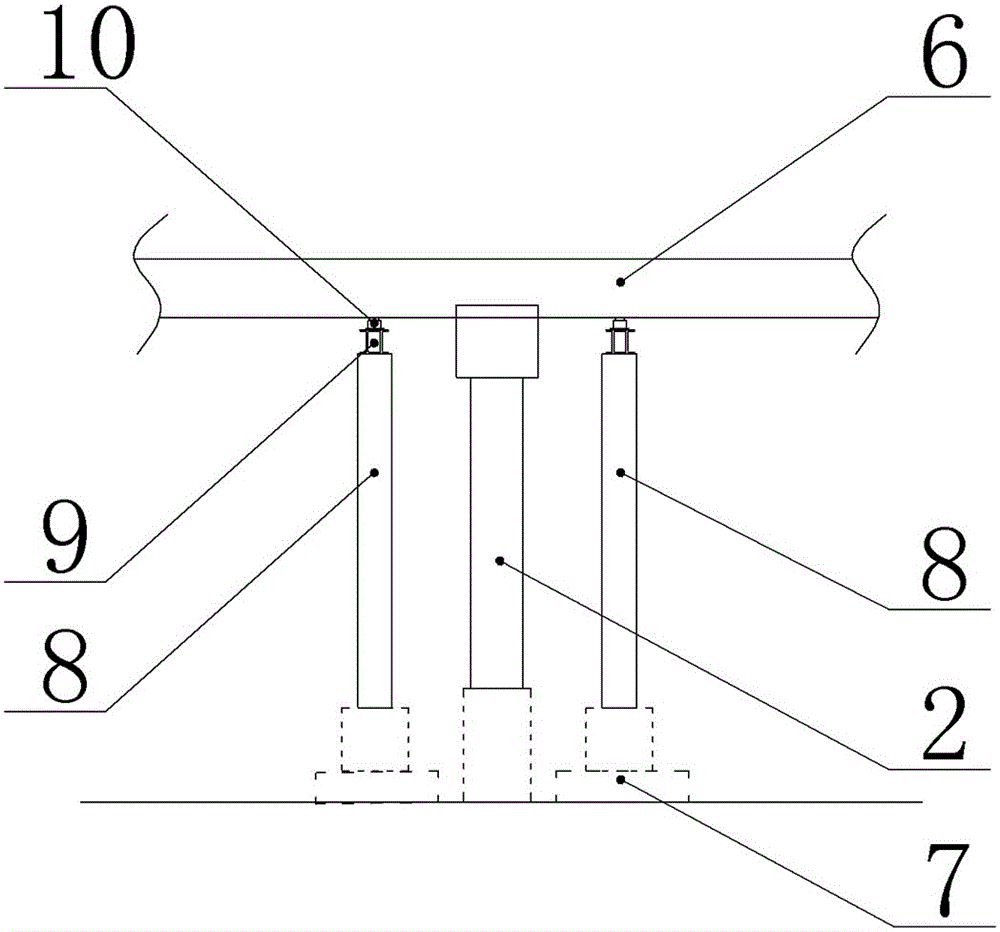

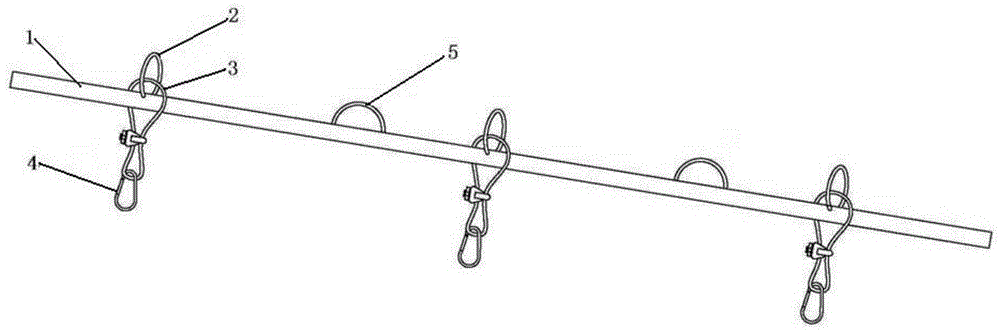

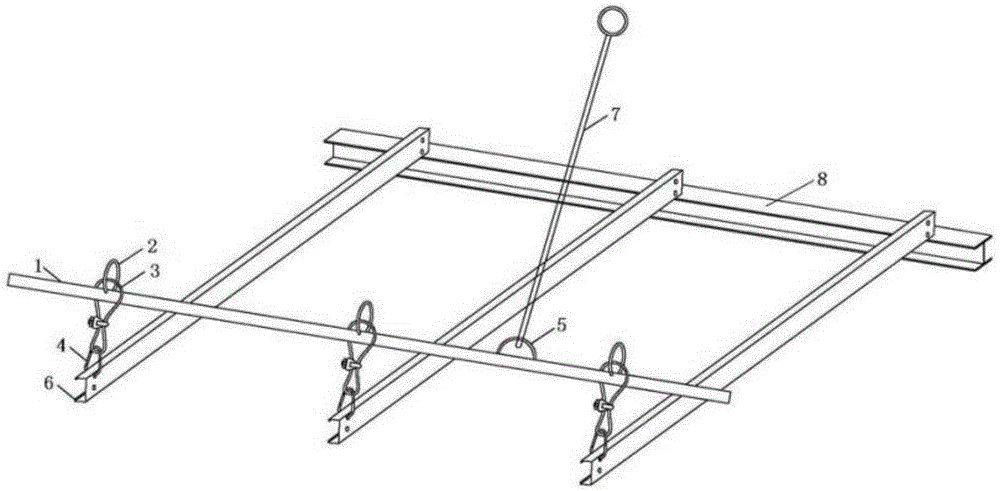

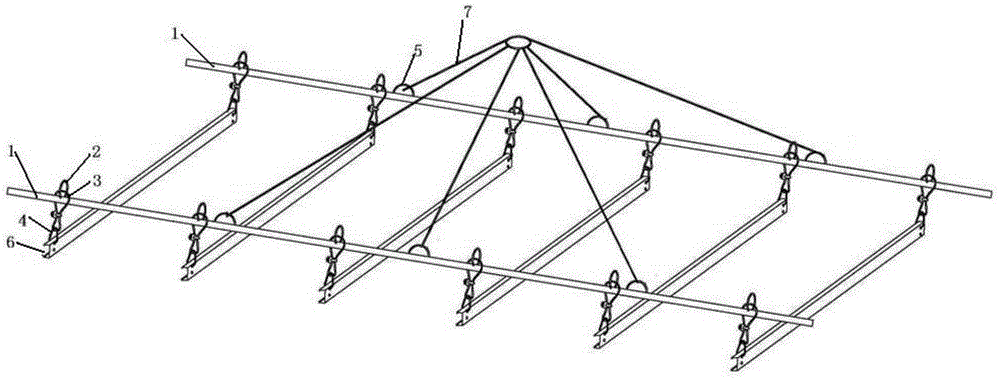

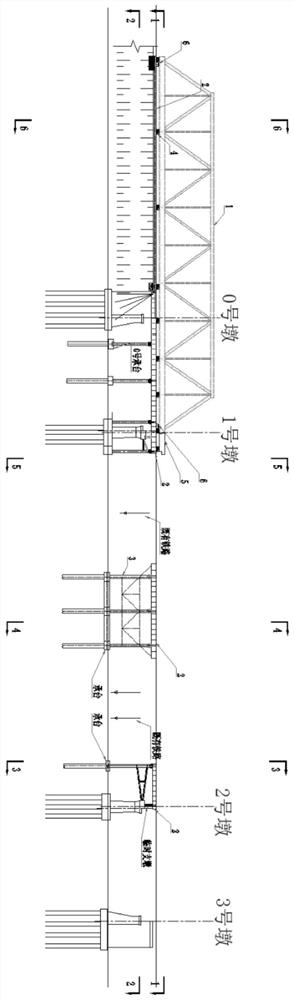

Hoisting construction method for oversized span steel truss of roof of stadium grandstand

ActiveCN106836498AHigh security riskHigh cost of technologyBuilding roofsBuilding material handlingPurlinButt joint

The invention discloses a hoisting construction method for an oversized span steel truss of a roof of a stadium grandstand. The hoisting construction method comprises the following steps that A construction preparation work is conducted; B temporary supporting frames are mounted; C test hoisting is conducted; D trusses are symmetrically hoisted from two ends to the inner side in a sectioning mode; E concrete is poured into main truss arch feet; F purlins are mounted; G preliminary acceptance and supplement brushing of anti-corrosion and fireproof paint are conducted; H the temporary supporting frames are unloaded; J inspection and acceptance are conducted; and M the temporary supporting frames are dismounted. According to calculation of the hoisting weight and the length of hoisting parts, the large span steel truss is sectioned and assembled on the ground firstly, and then aerial butt joint hoisting is conducted, so that the construction period can be effectively saved, and mounting cost can be effectively reduced. The sectioned steel trusses adopt the temporary supporting frames to conduct temporary support, unloading supporting seats on the top of the supporting frames are welded to the steel trusses, and the load of a mounted main truss is borne by the temporary supporting frames, so that mounting safety of the steel truss is guaranteed, and compared with whole audience supporting frame erecting, cost is greatly saved.

Owner:河南靖扬建设工程有限公司

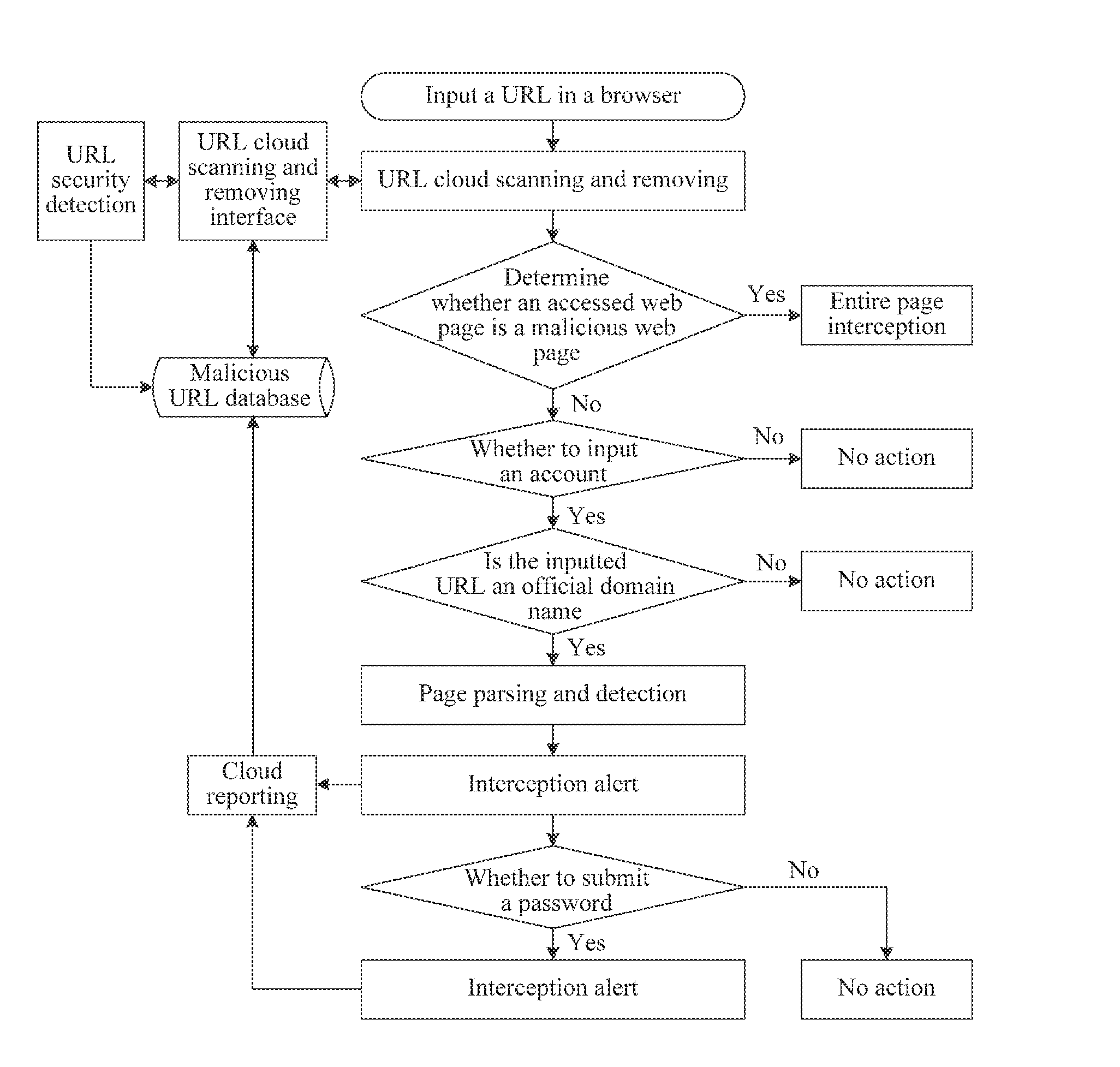

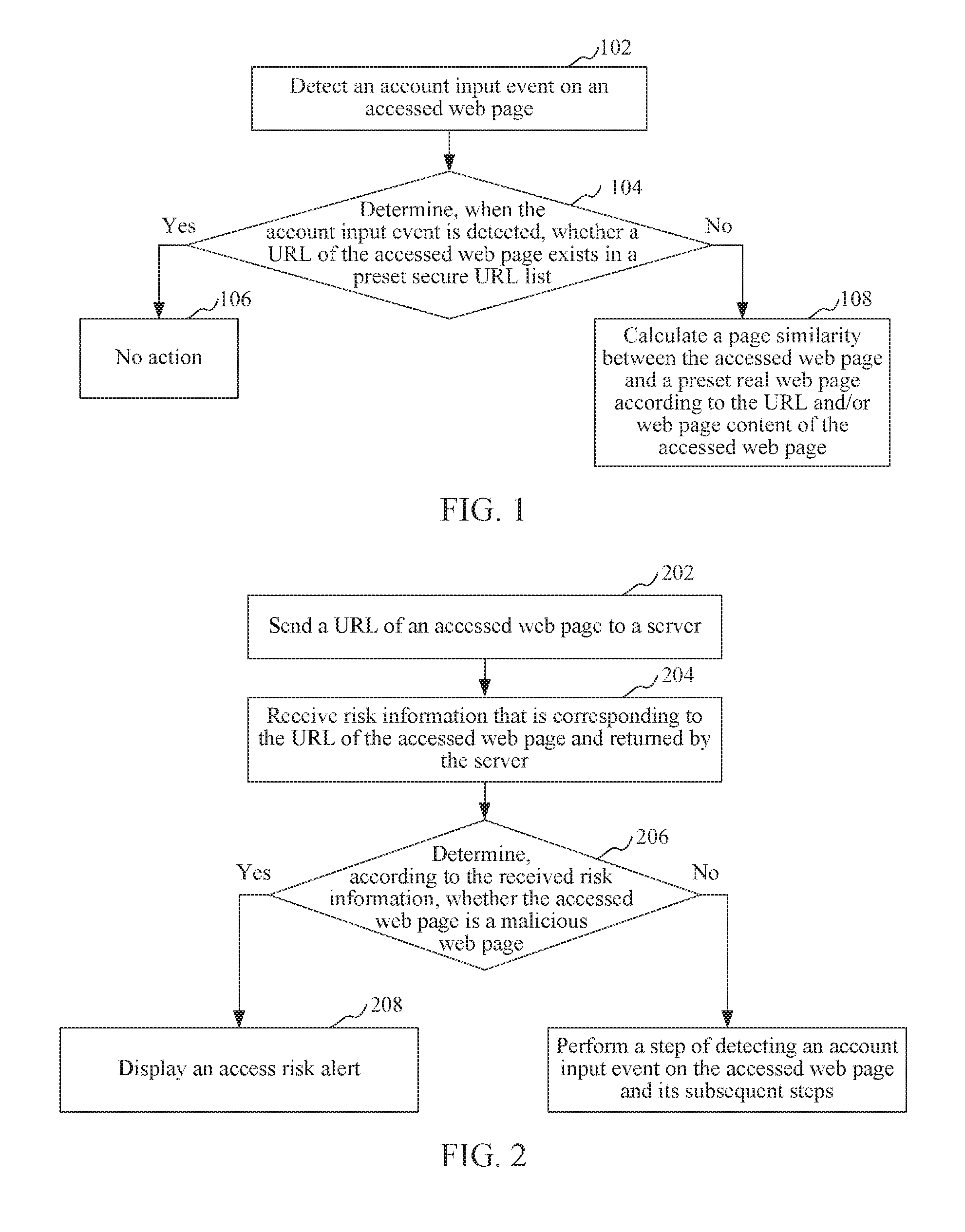

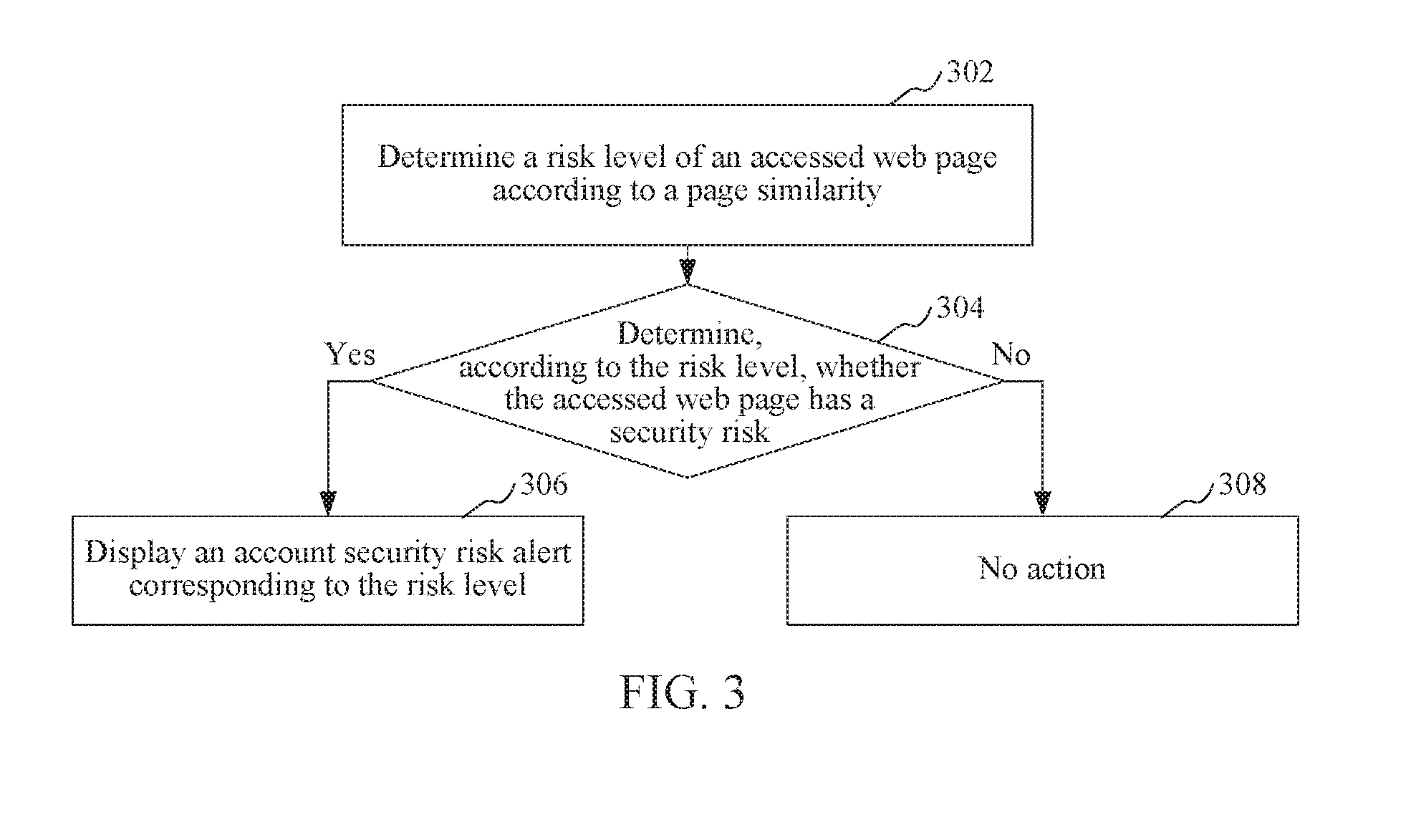

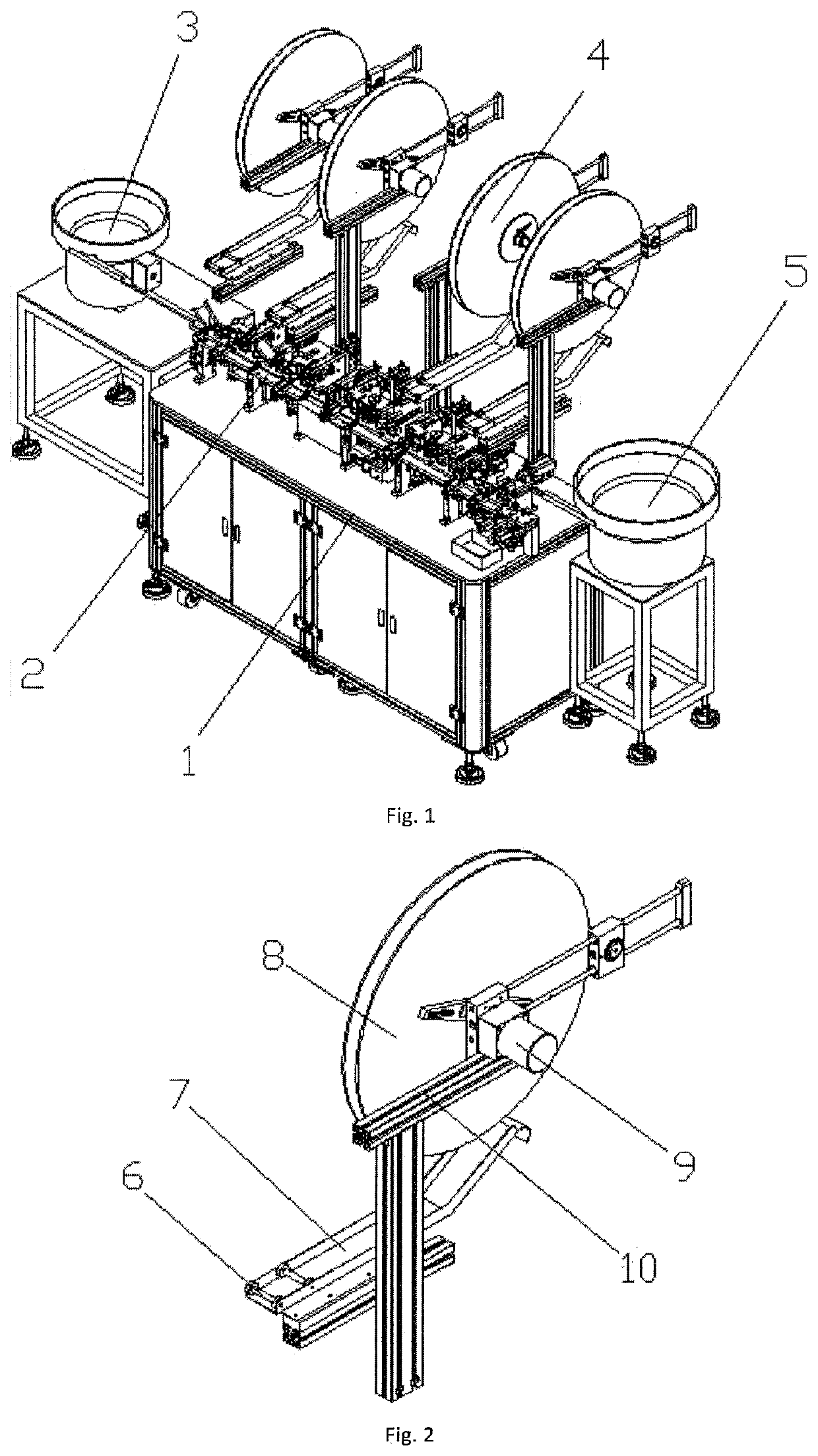

Method and system for security protection of account information

ActiveUS20160294867A1Effectively protect securityHigh similarityPlatform integrity maintainanceTransmissionInternet privacyPassword

A method for security protection of account information is provided, where the method includes: detecting an account input event on an accessed web page; determining, when the account input event is detected, whether a URL of the accessed web page exists in a preset secure URL list; calculating, if the URL of the accessed web page does not exist in the secure URL list, a page similarity between the accessed web page and a preset real web page according to the URL and / or web page content of the accessed web page; and determining, according to the page similarity, whether the accessed web page has a security risk, and if yes, displaying an account security risk alert. The method preventing a user from being induced by a malicious website to input an account and a password. A system for security protection of account information is further provided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

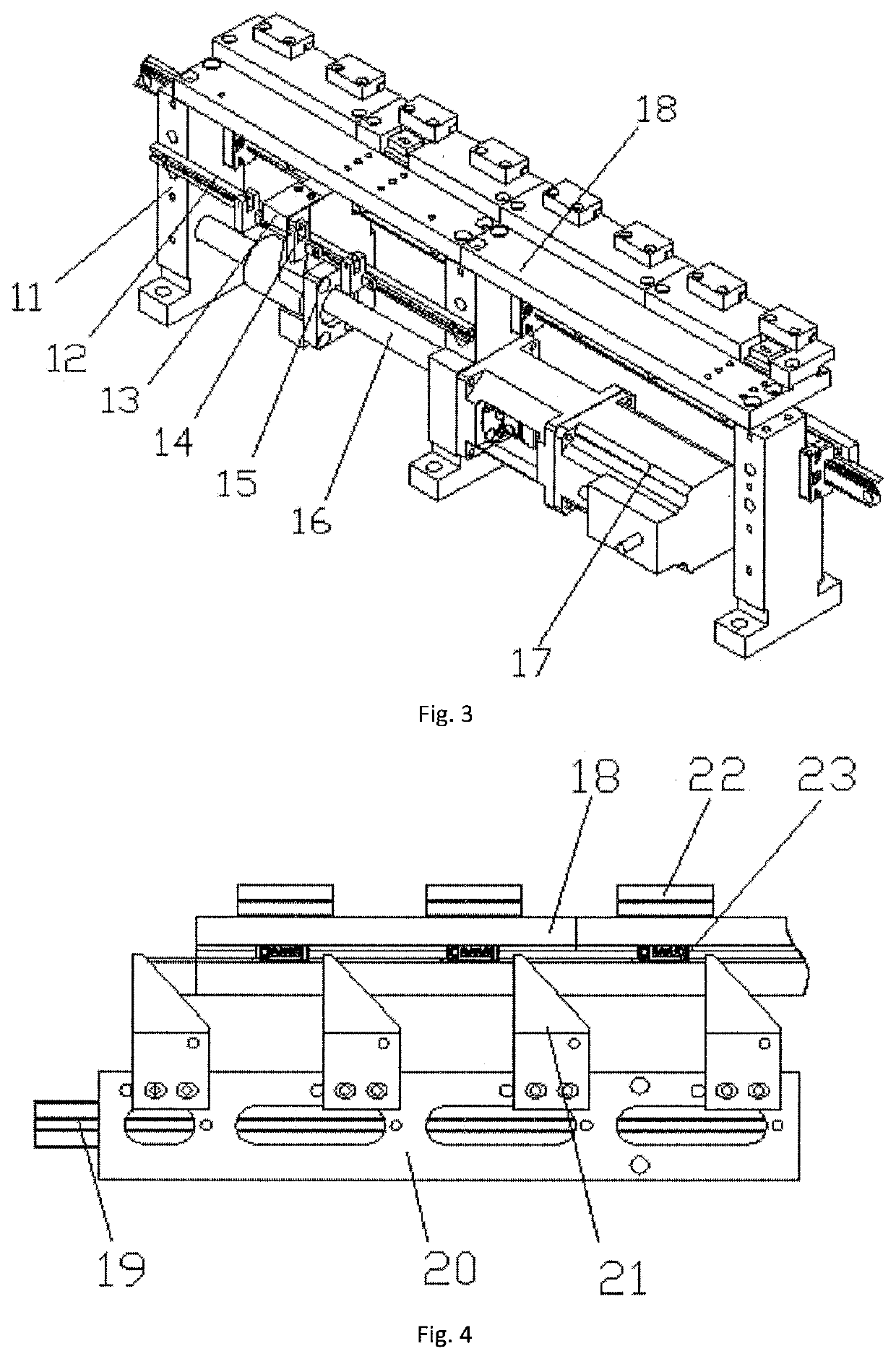

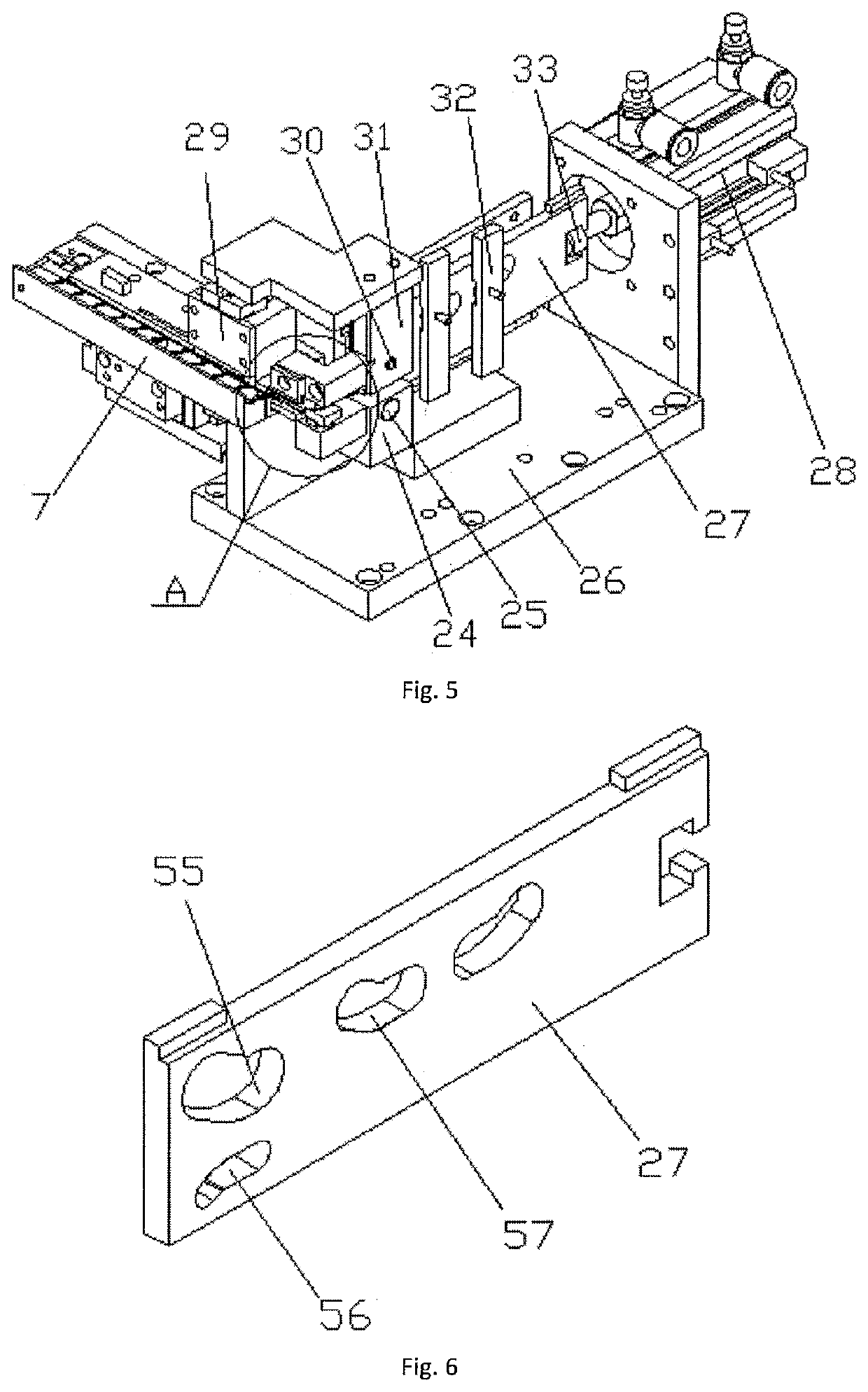

Automatic terminal fitting device for a four-pin electrical connector

ActiveUS20190341713A1Improve accuracyPrecise positioningContact member assembly/disassemblyCoupling device detailsElectricityElectrical connector

The present invention relates to an automatic terminal fitting device for four-pin electrical connector which may comprise a rack, power control box and conveying device provided on the rack. A rubber shell vibration disc, a terminal fitting mechanism, and a back cover vibration disc are provided on the rack along the transporting direction. The rubber shell vibration disc is connected to the front end of the conveying device by a rubber shell transportation rail. The terminal fitting mechanism is provided on the back side of the conveying device and engages with the terminal feeding device provided on the rack. The back cover vibration disc is provided on the back side of the conveying device, to the right side of the terminal fitting mechanism. And the terminal fitting mechanism may include four sets of terminal fitting devices sequentially provided on the back side of the conveying device. On the right side of the terminal fitting devices, a terminal strip bending device engaging with the conveying device is provided. The present invention effectively addresses the problems existing when fitting terminals manually during assembly, such as low production efficiency, high manpower consumption, intensive labor investment, relatively high potential safety hazard occurrence, and unsatisfactory connector defect rate.

Owner:DONGGUAN UNIV OF TECH

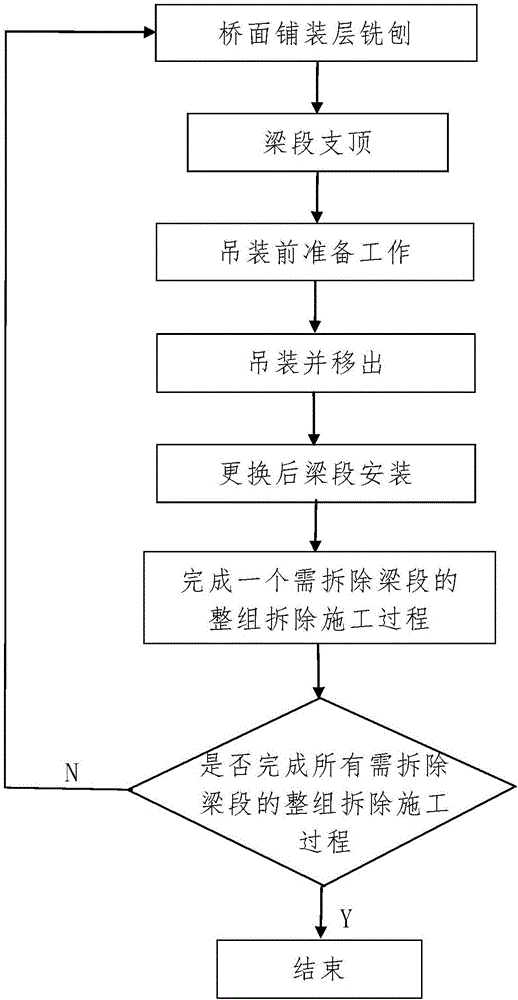

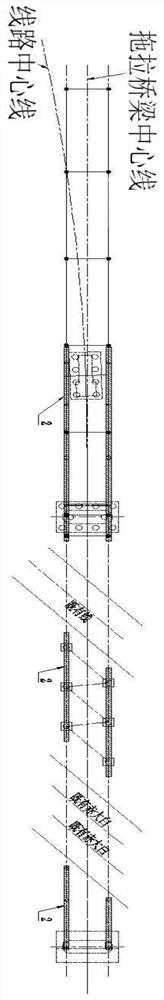

Full-set dismantling and installing construction method of bridge overpassing existing line

ActiveCN106149576ASimple stepsReasonable designBuilding repairsBridge erection/assemblyBuilding constructionEngineering

Owner:中铁二十局集团第三工程有限公司

RF SIM card, card reader, and communication method

ActiveUS8630584B2Reduced shieldingExpand communication rangeElectric signal transmission systemsNear-field transmissionTransceiverEngineering

A radio frequency (RF) device includes an RF transceiver, an RF antenna, and a magnetic signal detector. The RF is selected to be in the very high frequency (VHF), ultrahigh frequency (UHF), or super high frequency (SHF) bands such that the shielding effect is reduced and the RF device can be configured as a SIM card disposed inside a cellular phone with an increased RF communication range. The magnetic signal detector is used to sense a magnetic field signal from an RF reader, which includes an RF transceiver, an RF antenna, and a magnetic signal transmitter. The longer communication range afforded by the VHF, UHF, or SHF bands is reduced by the sensing of the magnetic field, thereby providing a communication range control, while the RF device and the RF reader exchange information through the RF channel with improved security as a result of the range control.

Owner:NATIONZ TECH INC

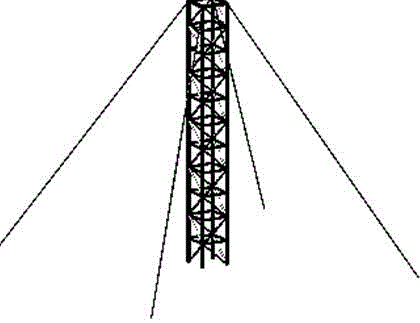

Construction method for ground cable hanging and aerial butt joint of ultra-large-span prestressed pipe truss

The invention discloses a construction method for ground cable hanging and aerial butt joint of an ultra-large-span prestressed pipe truss. The construction method is characterized in that the ultra-large-span prestressed pipe truss is divided into three sections A, B and C according to the characteristics of the ultra-large-span prestressed pipe truss structure, each section is assembled on the ground through a jig frame, and after the procedures of jig separation, transportation, overturning, hoisting and the like, the sections A and C are hoisted to a designed position at first; the sectionB is divided into a subsection B1 and a subjection B2 and spliced on the ground through a jig frame, after jig separation, the subsections B1 and B2 are sequentially hoisted to a ground support framefor aerial butt joint, a prestressed steel inhaul cable is hung, and the steel inhaul cable is primary tensioned according to a simulation checking result; and after primary tensioning, the section Bis hoisted to the designed position through two machines to be in aerial butt joint with the section A and the section C, after butt joint is finished, a connecting truss is installed, the steel inhaul cable is finally tensioned according to the simulation checking result, and the ultra-large-span prestressed pipe truss is installed. The construction method highlights the characteristics of highconstruction speed, low cost, low safety risk, high construction quality and the like in the operation process.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE +2

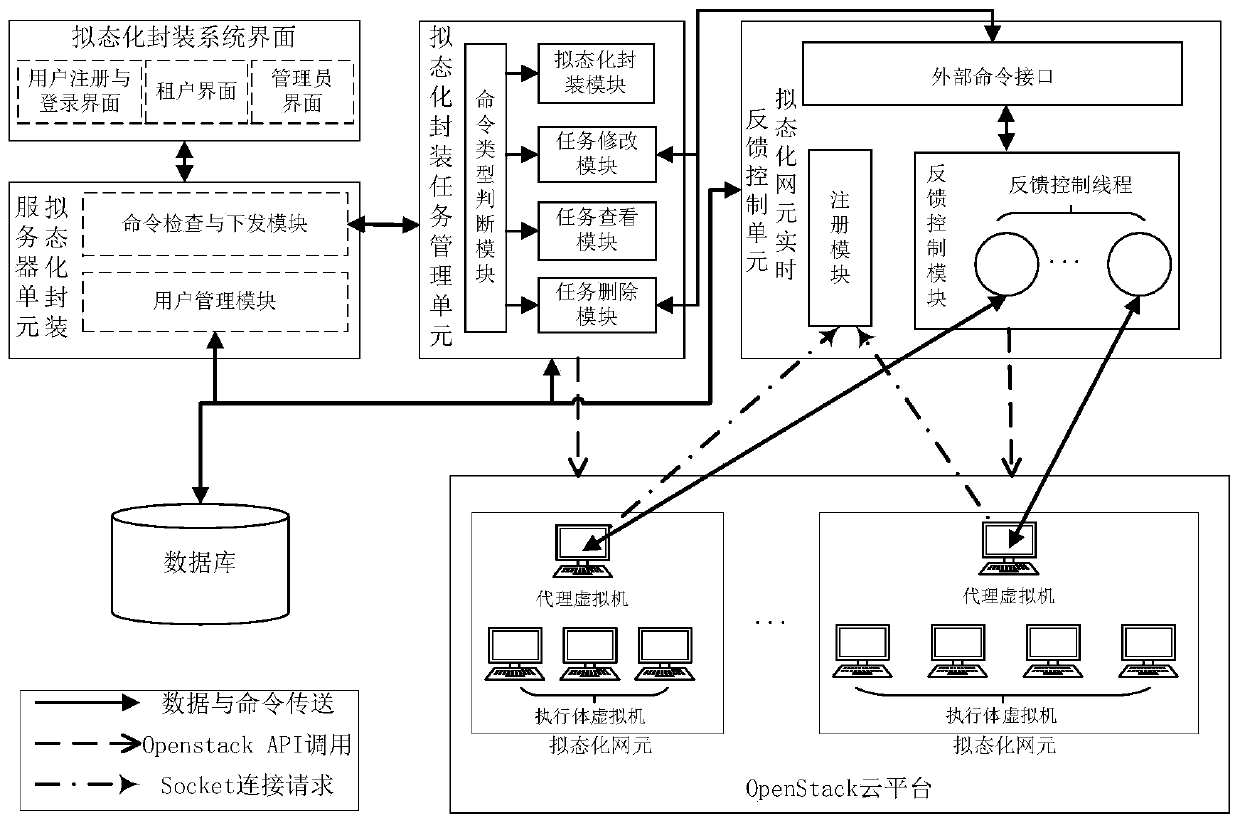

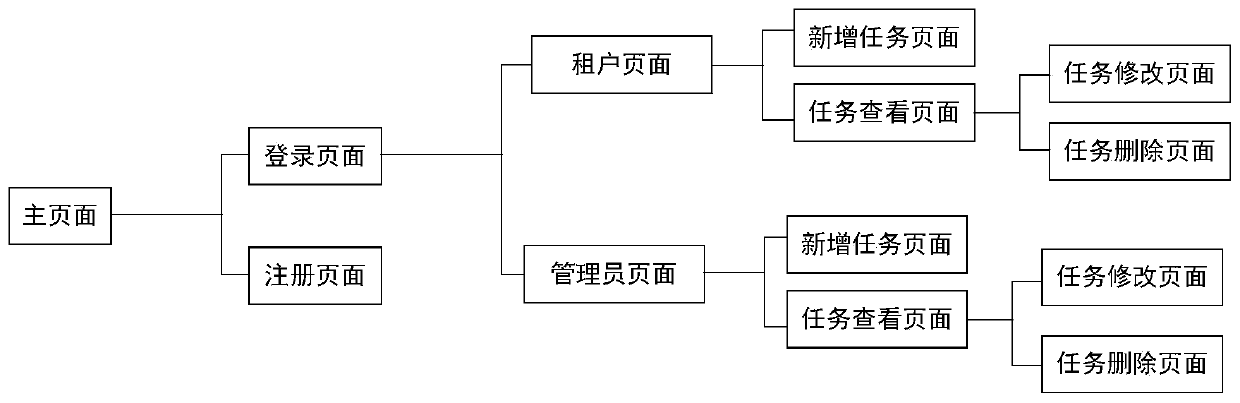

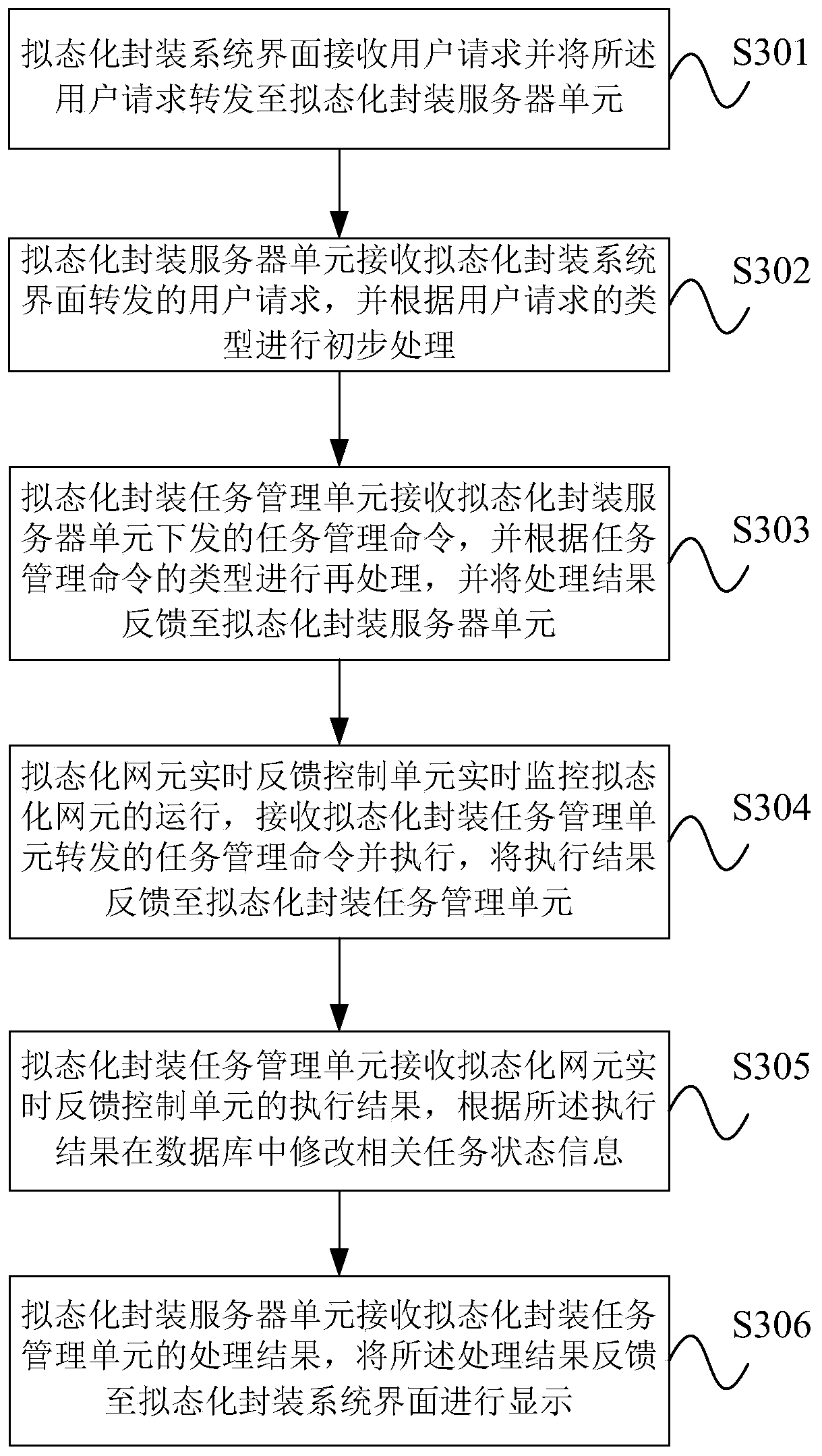

Mimicry application packaging and control system and method based on cloud platform

ActiveCN110764871AIncrease uncertaintyAvoid complexitySoftware simulation/interpretation/emulationControl systemFeedback control

The invention provides a mimicry application packaging and control system and method based on a cloud platform. The system comprises a mimicry packaging system interface for providing a graphical management entrance for a user; a mimicry encapsulation server unit which is responsible for receiving and preliminarily processing a user request from an interface and comprises user management, commandcheck and command issuing; a mimicry packaging task management unit which provides a mimicry packaging task management function and comprises task creation, task deletion, task running state check andcontrol condition modification in the task running process; and a mimicry network element real-time feedback control unit which is responsible for monitoring and managing the operation of the mimicrynetwork element in real time, including monitoring the online connection of the mimicry network element, collecting the operation exception information of the mimicry network element and making decisions such as detection of an exceptional virtual machine, scheduling of the exceptional virtual machine and control of the operation state of the mimicry network element.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU +1

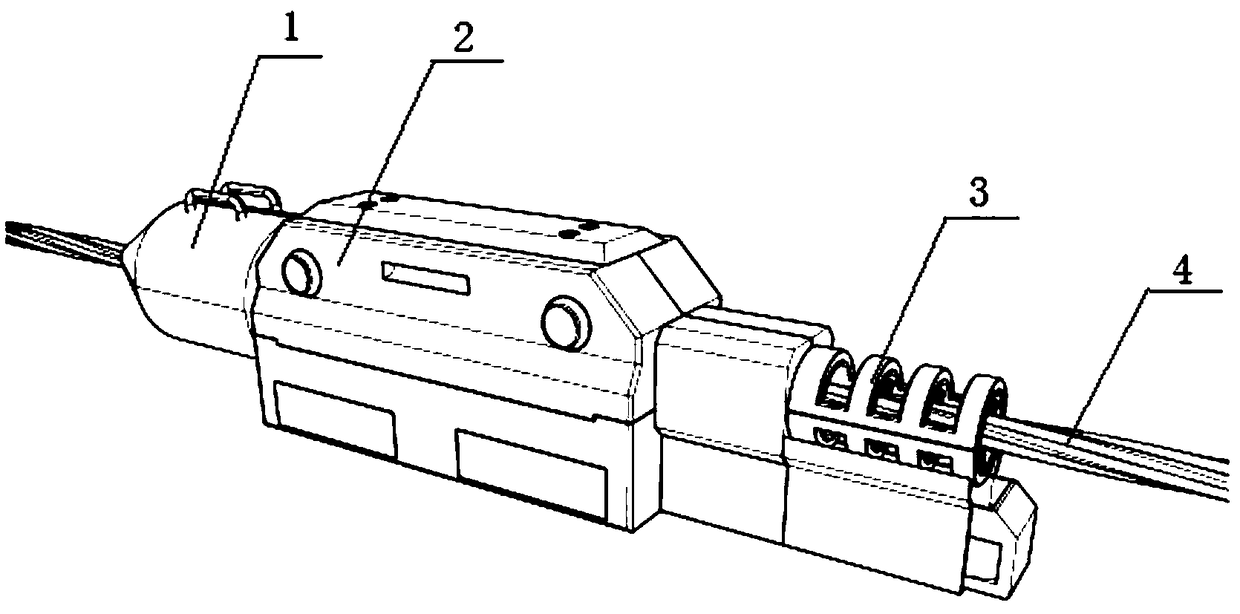

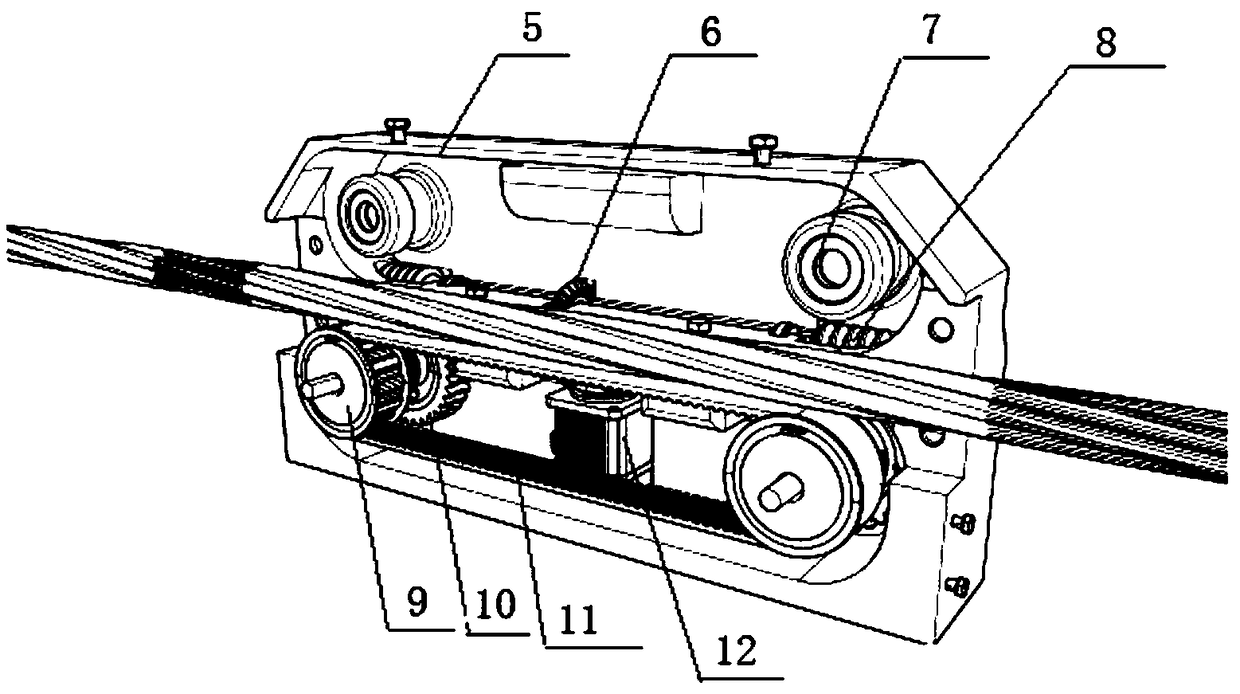

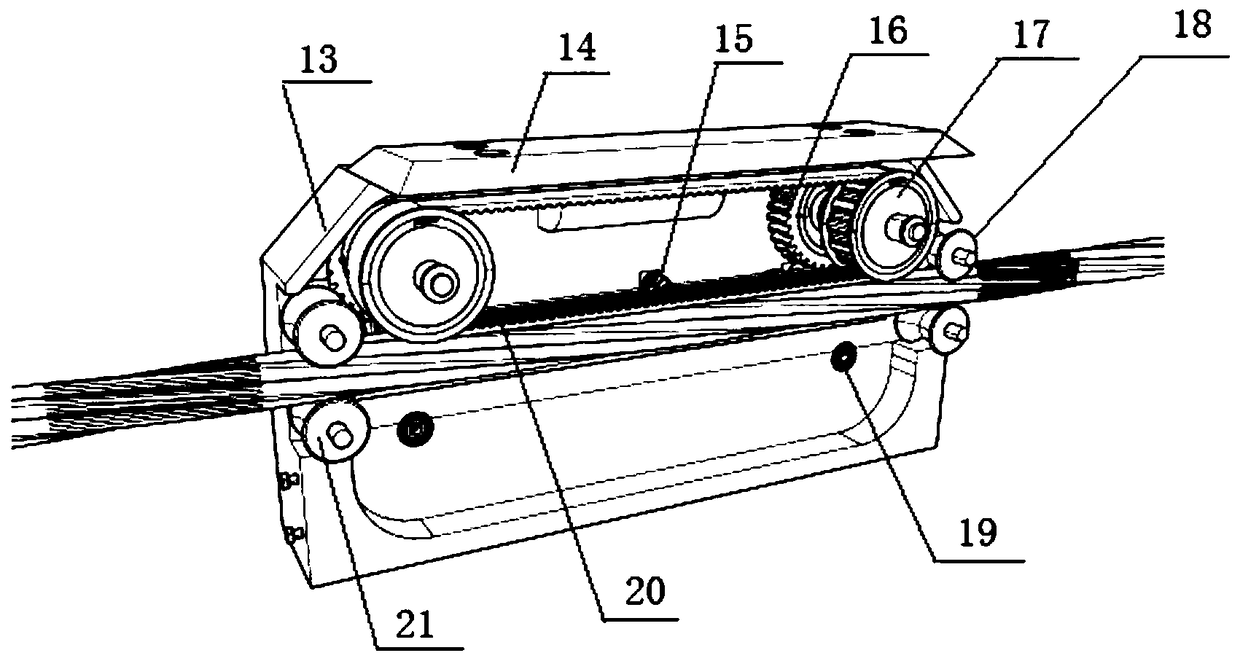

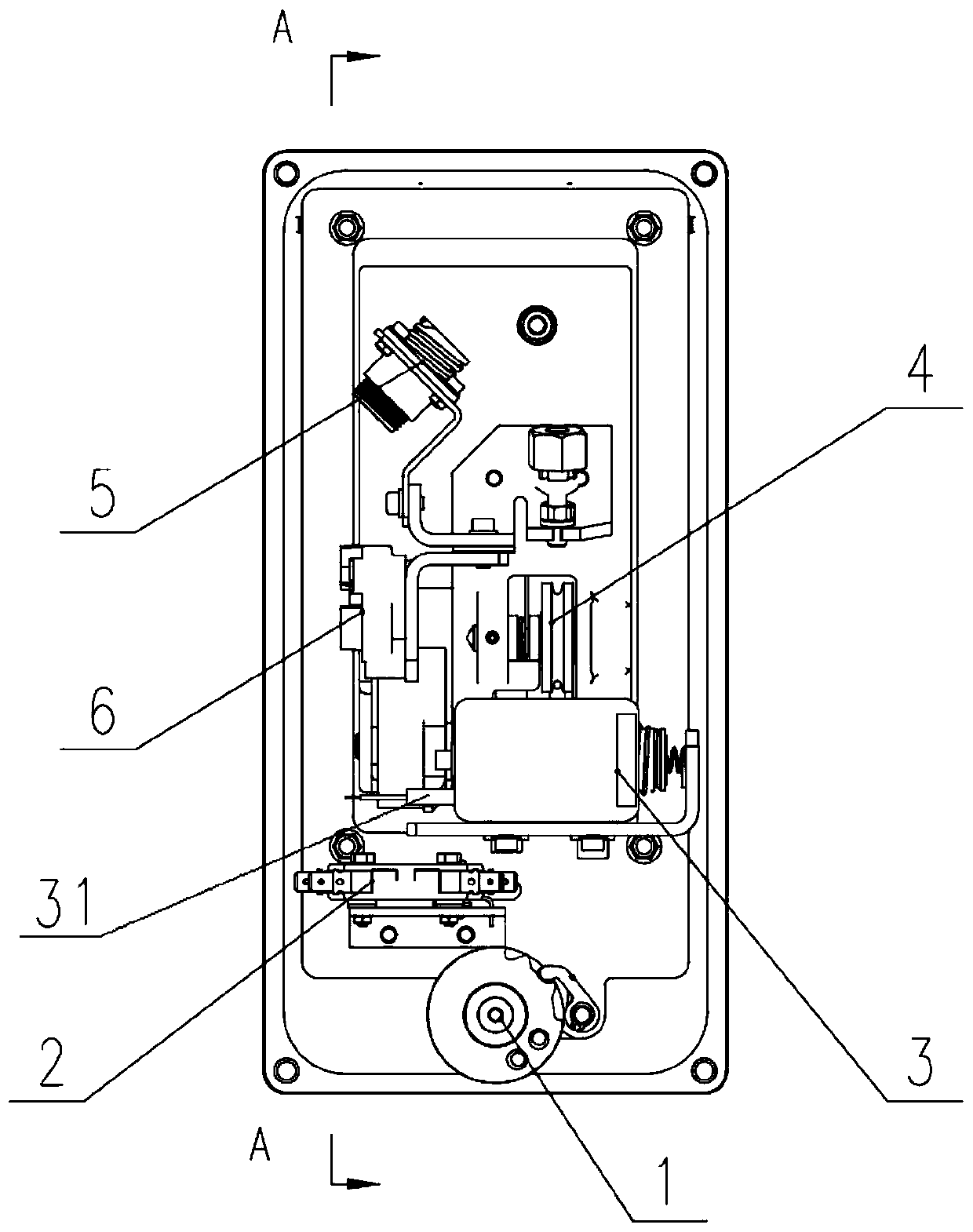

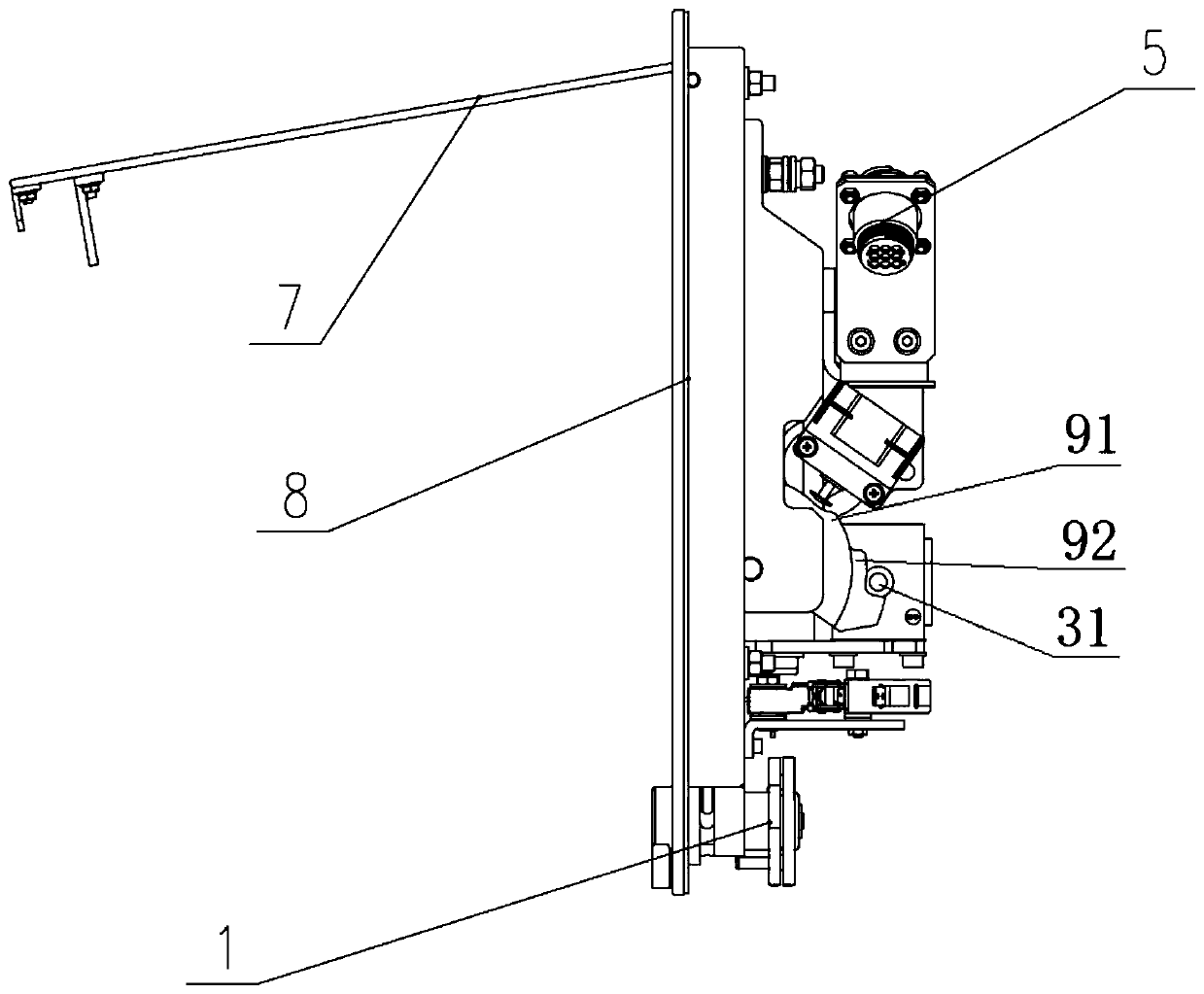

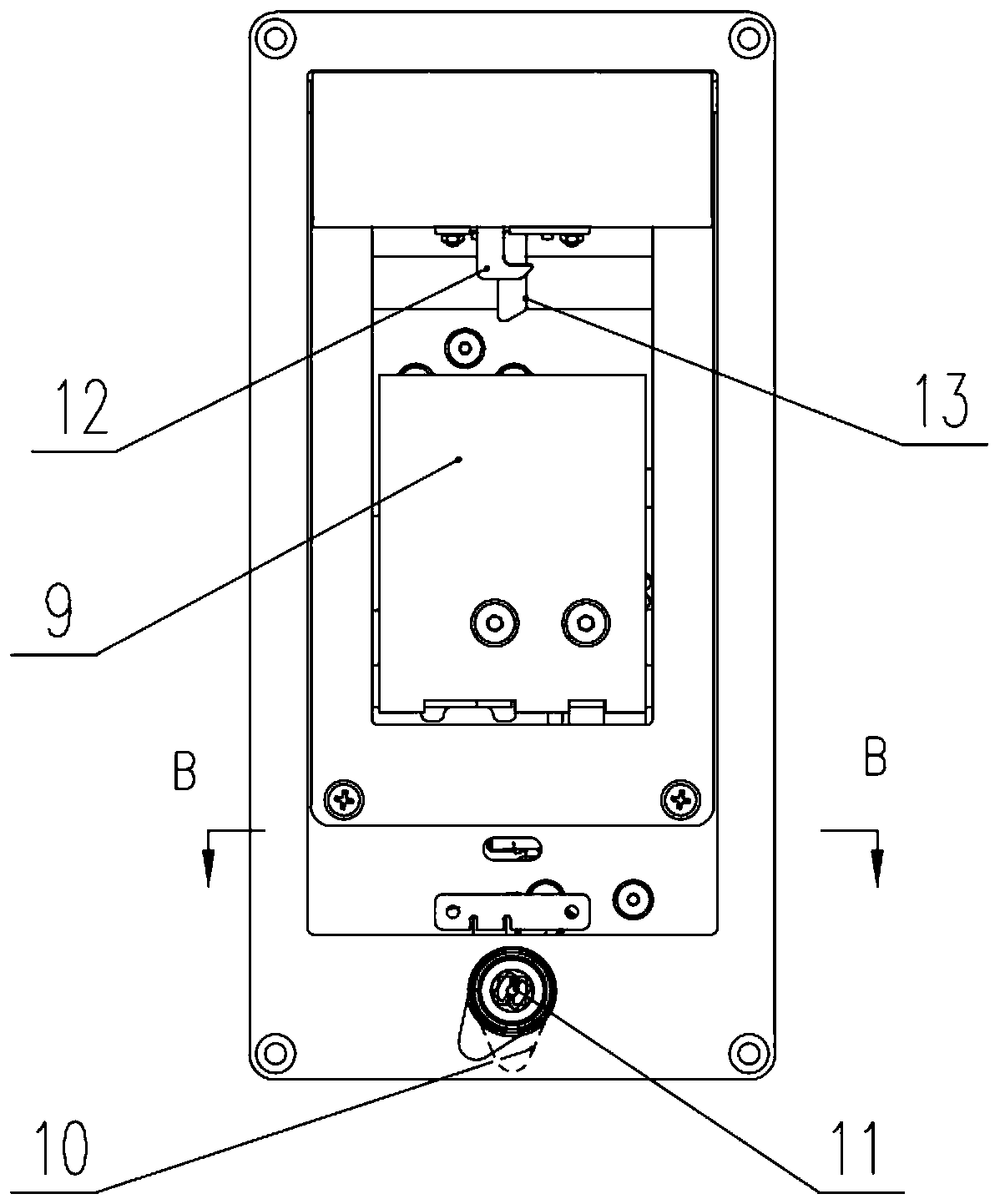

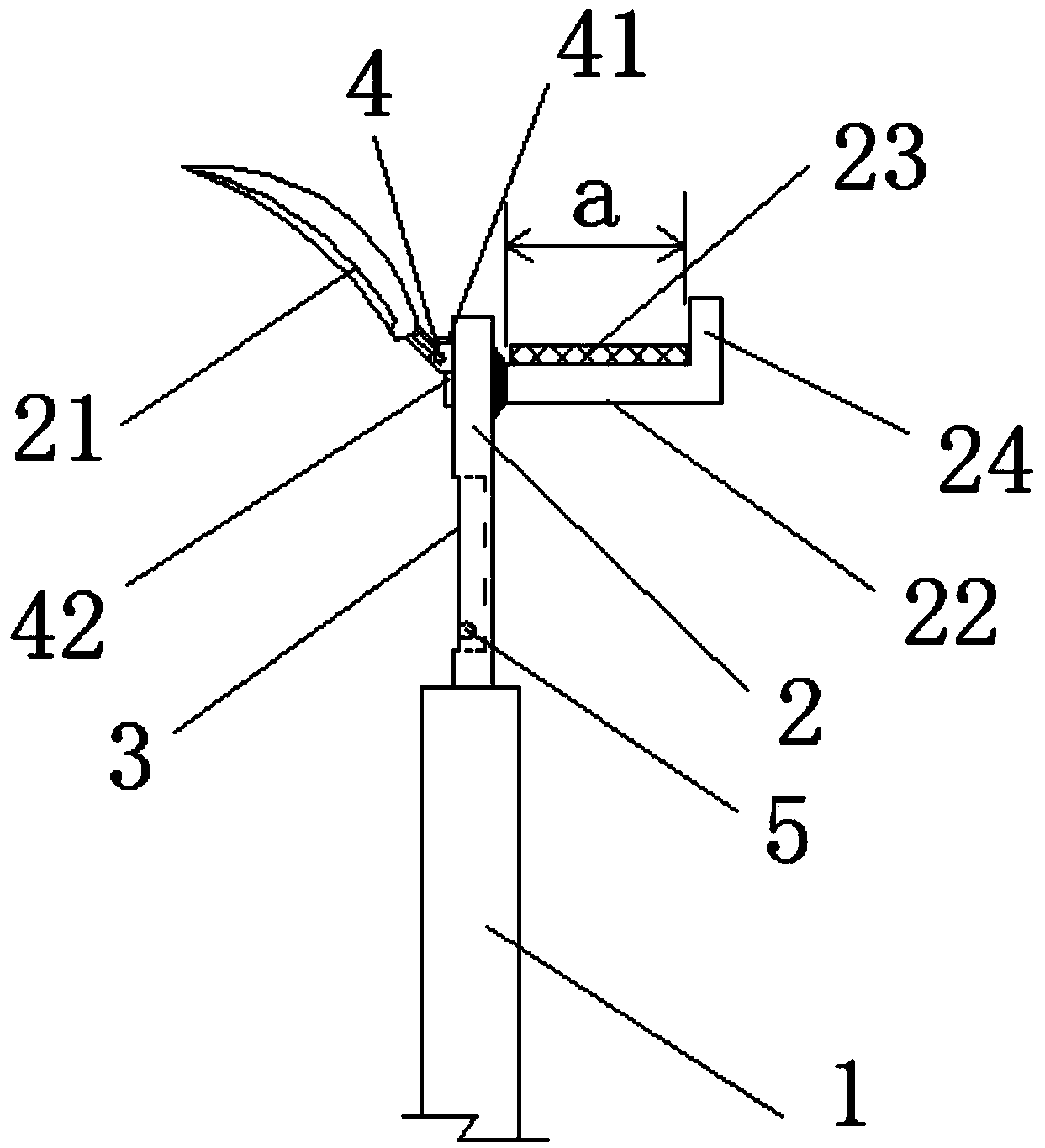

Integral aerial steel wire rope oil removing and lubricating device

ActiveCN108622803ASolve the problem of inconvenient oil removal and lubricationRealize automatic degreasingCleaning using toolsLoad-engaging elementsOperation modeLubrication

The invention relates to an integral aerial steel wire rope oil removing and lubricating device. The device comprises an oil removing mechanism, a cable walking mechanism and an oil coating mechanism;the oil removing mechanism and the oil coating mechanism are positioned on two sides of the cable walking mechanism; the oil removing mechanism comprises a brush, a brush base and an oil collecting tank; the brush and the brush base are of symmetric buckling structures; the oil collecting tank is positioned at the lower part of the brush; the cable waslking mechanism comprises a shell, a first walking wheel mechanism and a second walking wheel mechanism; the shell comprises a first shell and a second shell symmetrically mounted; the first walking wheel mechanism is mounted in the first shell;the second walking wheel mechanism is mounted in the second shell; the first walking wheel mechanism and the second walking wheel mechanism tightly hold a steel wire rope, and drive the oil removingmechanism and the oil coating mechanism to walk; and the oil coating mechanism is an oil cylinder mounted in an opposite buckling manner. The device is compact in structure and less in occupied space,can realize efficient and convenient lubrication of the crane steel wire rope, and changes a traditional operation mode with low manual coating efficiency and high safety risk.

Owner:TIANJIN UNIV OF SCI & TECH

Primary blasting well forming method for middle guide well

InactiveCN108374661AVarious construction methodsHigh security riskBlastingShaft sinkingDetonatorSludge

The invention relates to the field of tunnel engineering, and discloses a primary blasting well forming method for a middle guide well. The method includes the steps: (1) performing measuring and positioning to determine the wellhead position of a vertical well; (2) mechanically digging a wellhead of the vertical well; (3) reversely digging the bottom of the vertical well upwards; (4) according toa blasting design lofting blast hole position of the middle guide well: performing lofting to form 2m*2m middle guide well position of the vertical well by the aid of a total-station instrument, andlabeling the position of the blast hole position; (5) completely drilling a blast hole by a down-the-hole drill once; (6) plugging the bottom of the blast hole; (7) filling the blast hole with explosive; (8) plugging an upper opening of the blast hole with blast sludge after the blast hole is plugged by the explosive; (9) line connecting and explosion initiating, connecting starting detonators inthe blast holes in a clustering manner, and performing differential initiation of non-electric millisecond detonators. The method has the advantages that construction safety is improved, potential safety hazards are reduced, and life safety of construction staff is guaranteed.

Owner:浙江省隧道工程集团有限公司

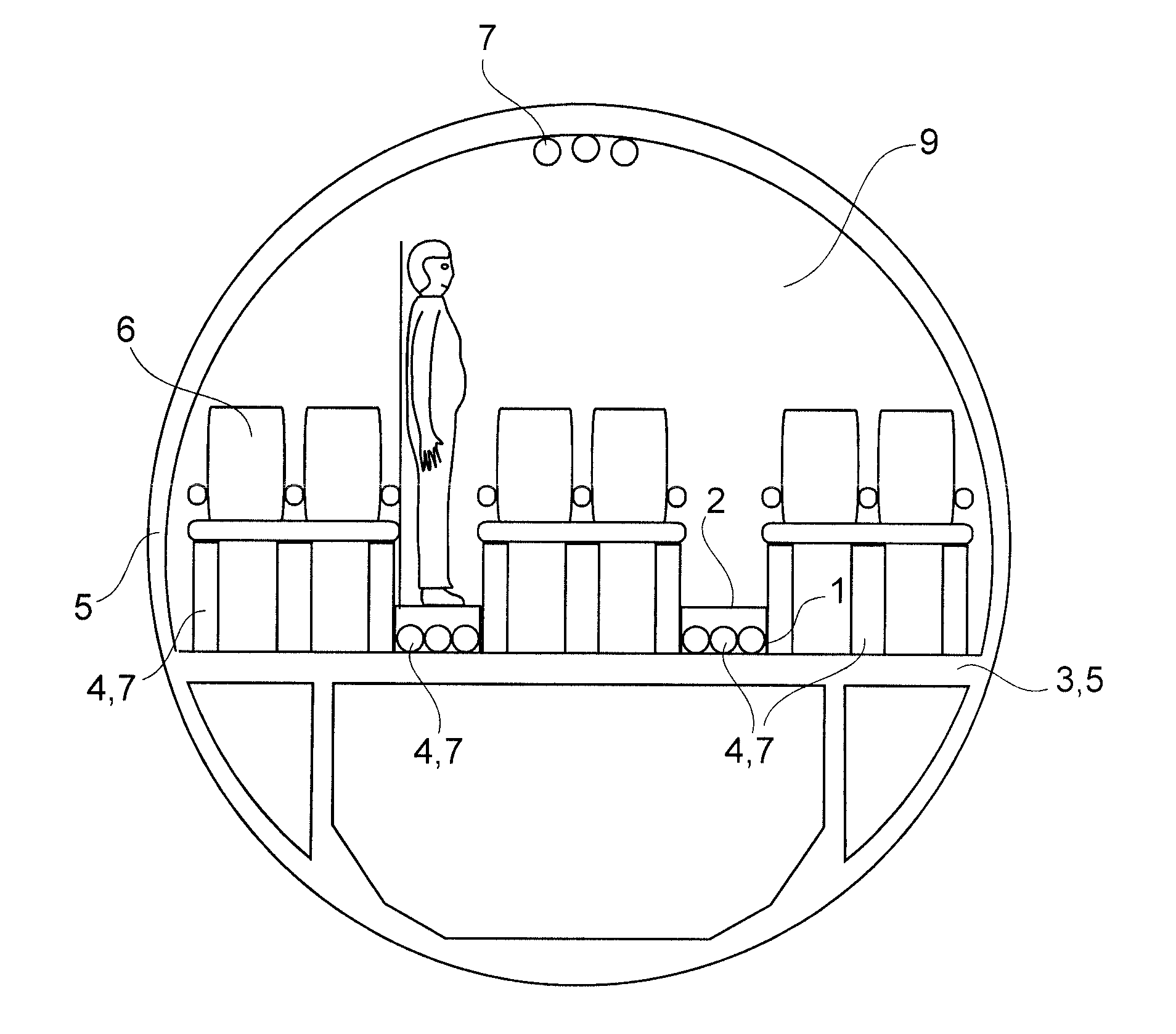

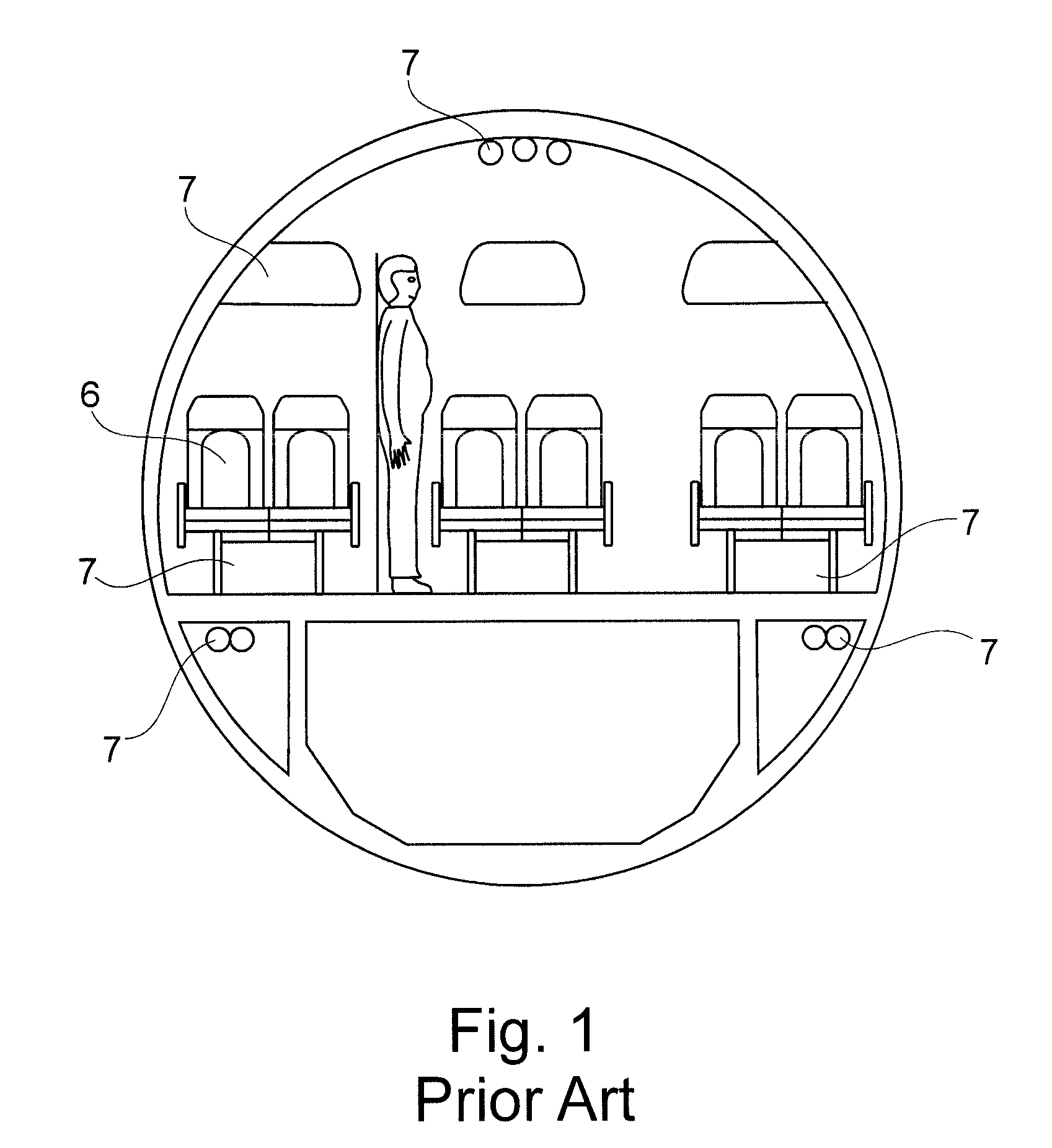

Under-floor system for an aircraft

InactiveUS20100116934A1Improve protectionEasy accessSeating arrangementsAir-treatment apparatus arrangementsEngineeringStructuring element

The present invention relates to an under-floor system for providing a functional space for an aircraft. The under-floor system comprises a support-member structure and a cover element. The support-member structure is designed such that the support-member structure can be fastened to an aircraft structure element. The cover element can be fastened to the support-member structure such that the cover element is spaced apart from, for example, the aircraft floor. By means of spacing the cover element apart from the aircraft floor, the functional space can be provided.

Owner:AIRBUS OPERATIONS GMBH

Vehicle door emergency unlocking control method and vehicle door system

ActiveCN111335755ASafe evacuationImprove securityElectrical locking circuitsAccident situation locksEmergency exitSignaling system

The invention discloses a vehicle door emergency unlocking control method and a vehicle door system. The method comprises the steps that firstly, a protection cover plate of an emergency exit device is opened when a handle needs to be operated, or the handle of the emergency exit device is operated at a small angle which cannot unlock a vehicle door after the protection cover plate is opened; if the vehicle is in a fault power loss condition, the handle of the emergency exit device is released by a handle control structure, and the handle is allowed to be operated; if not, a vehicle door evacuation request loop is activated, and an evacuation request signal is sent to a train signal system by the vehicle door evacuation request loop; and after receiving the evacuation request signal, the train signal system controls the train to stop in a safe area so as to activate a zero-speed train line signal and controls the train door to forbid unlocking of the train line signal to be invalid, sothat the handle is controlled to be released by the handle control structure to allow the handle to operate. According to the method, the safety of whether the vehicle door can be manually opened ornot is improved, and therefore safe evacuation of passengers is better guaranteed.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

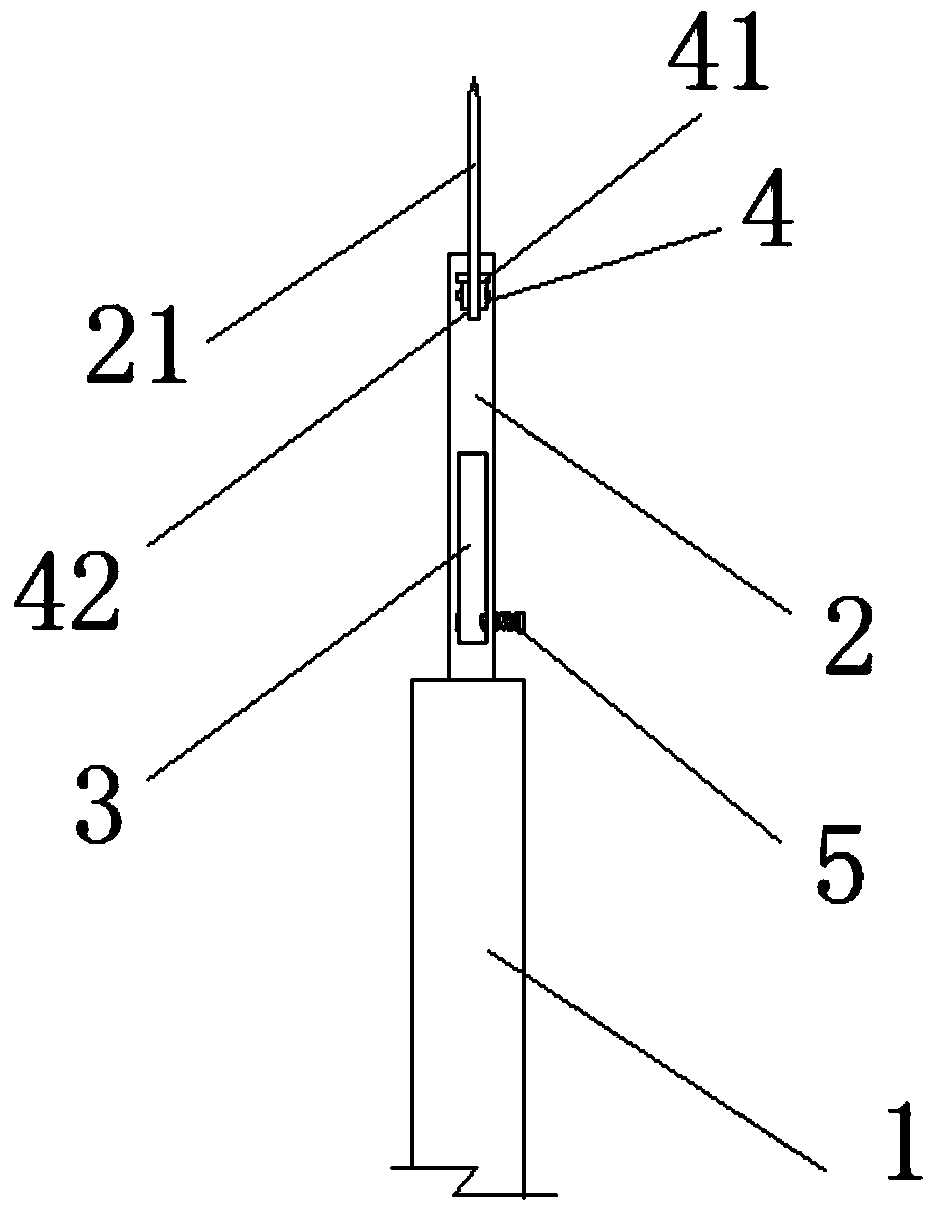

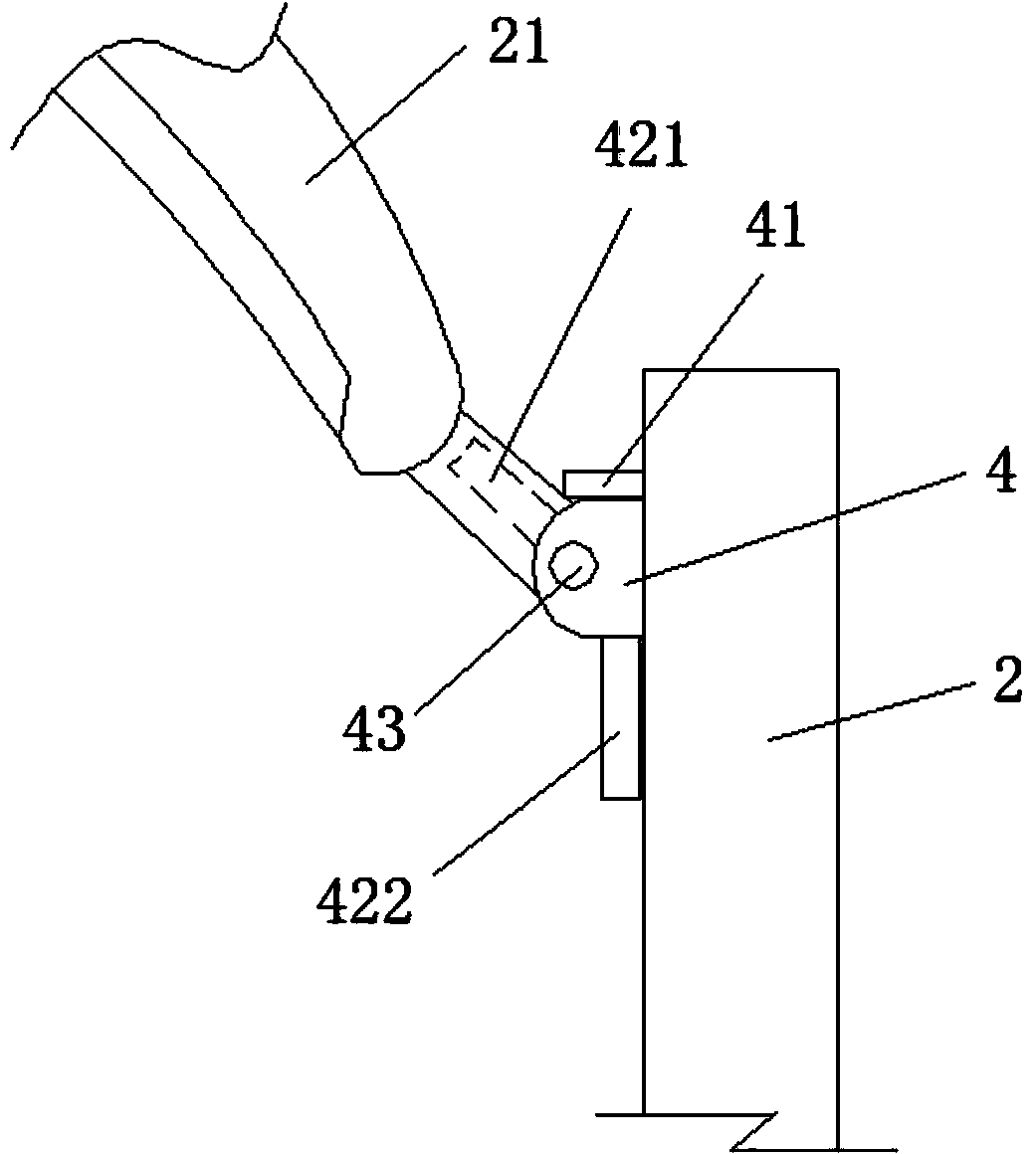

Insulating operating rod having trimming function

ActiveCN104037650AImprove the safety of useEnsure safetyApparatus for overhead lines/cablesElectricityEngineering

The invention discloses an insulating operating rod having a pruning function. The insulating operating rod having the pruning function comprises an insulating operating rod; an operating head is connected to the front end of the insulating operating rod; a semilunar hooked knife and a hanging hook component are arranged on the operating head; a downward lateral side of the hooked knife is provided with a knife edge; the hanging hook component is a solid galvanized steel bar; a tail end of the hanging hook component is connected with the operating head in a full welding mode; a middle section of the hanging hook component is perpendicular to the insulating operating rod; the upper surface of the middle section of the hanging hook component is provided with a buffering cushion layer; a head of the hanging hook component bent upward to form into a positioning hook; the insulating operating rod is connected with the operating head through a connecting head; a position on the operating head, which is arranged under the hanging hook component, is provided with a fan. The insulating operating rod having the pruning function has the advantages of allowing branch pruning with electricity, guaranteeing operation and maintenance personnel security, effectively hanging a falling type fuse, avoiding the falling type fuse falling off from the insulating operating rod during operation, reducing damage to personnel on the rod and the ground, shortening the first-aid repair time, avoiding unnecessary work delay and improving the utilization safety.

Owner:STATE GRID CORP OF CHINA +2

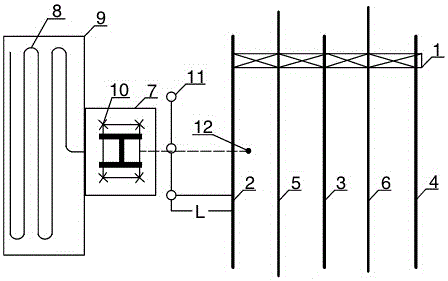

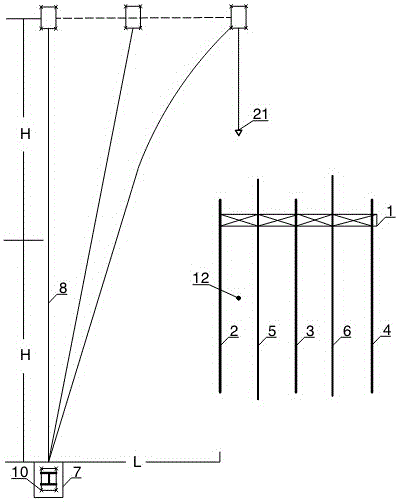

Transmission line unmanned aerial vehicle and electric lifting device combined live working method

ActiveCN105958376AImprove securityPreserve strengthApparatus for overhead lines/cablesEquipotentialSimulation

The present invention belongs to the technical field of electric lifting machine and live line operation and particularly relates to a transmission line unmanned aerial vehicle and electric lifting device combined live working method. An unmanned aerial vehicle is used to suspend an insulation rope to a conductive wire, a semi-static rope is dragged through the insulation rope to suspend the semi-static rope to the conductive wire, an equipotential electrician operates a small fly people machine to enter a strong electric field and reach a live line to carry out defective elimination operation. The method comprises the steps of setting the unmanned aerial vehicle and the insulation rope, checking the unmanned aerial vehicle, throwing the rope through the unmanned aerial vehicle, dragging the semi-static rope, installing the semi-static rope, installing the small fly people machine and a buffer self-locking device, carrying out equipotential electrician checking and connection, lifting the equipotential electrician by the small fly people machine and completing potential transfer, hanging a hard insulation ladder head and carrying out translocation, entering into equipotential to hang an extension rope to eliminate a defect, and exiting the equipotential. An operator is lifting by using the small fly people machine to reach a live line defective position, climbing an iron tower and a soft ladder to enter and leave the strong electric field is not needed, the safety risk is small, the working efficiency is high, and the operation is simple.

Owner:国网甘肃省电力公司超高压公司

Rapid repair method for three-stand-column structure bridge with damaged lateral stand columns and undamaged beam and slab structure

ActiveCN105155431APromote progressEnsure stabilityBridge erection/assemblyBridge strengtheningCounter pressureRepair method

The invention belongs to the technical field of traffic and municipal engineering, and discloses a rapid repair method for a three-stand-column structure bridge with damaged lateral stand columns and an undamaged beam and slab structure. For the three-stand-column structure bridge, when the stand columns on one or two sides are damaged, and the upper beam and slab structure is not damaged, the damaged stand columns and a capping beam on the lower portion of a beam and slab are directly replaced or repaired without dismantling the bridge beam and slab, and through temporarily supporting the capping beam, integrally jacking box girders, removing the damaged stand columns and the capping beam in a chiseling mode and pouring new stand columns and a new capping beam, conversion of a stress system is completed finally. According to the technical scheme, through counter-pressure unloading and temporary support erecting, the capping beam is primarily fixed, the stableness of the stress system of the whole bridge is ensured, then through designing an integral jacking system of the box girders, the new stand columns and the new capping beam are built and erected, and therefore stabilization and replacement of the whole stress system are completed. The scientific and reasonable construction scheme is made to ensure smooth progressing of projects.

Owner:HENAN HIGHWAY ENG GROUP

Physical antibacterial wet tissue

ActiveCN106860029AIncreased durabilityAvoid drug resistanceCosmetic preparationsToilet preparationsNanoparticleMedicine

The invention relates to a physical antibacterial wet tissue. The physical antibacterial wet tissue comprises a wet tissue body and wet tissue liquid, and is characterized in that the wet tissue body is made of an antimicrobial membrane or nanoparticle nonwoven cloth with positive charges; the antimicrobial membrane or the nanoparticle is formed by chemical bond combination ; the wet tissue liquid selects RO (reverse osmosis) pure water, a surfactant, a skin moisturizing agent, a skin conditioning agent and other additives; then, ozone with concentration of 0.1 to 1.0mg / L is introduced into the wet tissue liquid; finally, the wet tissue liquid is added into the wet tissue body according to a certain weight ratio, and then the wet tissue body is sealed and packaged, so as to obtain the physical antibacterial wet tissue. The physical antibacterial wet tissue is a wet tissue with zero separation of preservative, is soft to skin, is free from irritation and allergy, and is especially suitable for allergic skins, tender skins and the like.

Owner:SUZHOU BORAGE DAILY CHEM

Physical antibacterial wet wipe

InactiveCN106726636AAntibacterial effect exceedsNon-irritatingCosmetic preparationsPhysical treatmentIrritationPreservative

The invention provides a physical antibacterial wet wipe. The physical antibacterial wet wipe comprises a wet wipe body and wet wipe liquid, wherein the wet wipe body is a non-woven fabric bonded with macromolecular quaternary ammonium salt; the wet wipe liquid is prepared from RO (Reverse Osmosis) purified water, a surfactant, an emollient, a humectant, a skin conditioning agent and other additives; ozone with the concentration of 0.1mg / L to 1.0mg / L is introduced into the wet wipe liquid; finally, the wet wipe liquid is added into the wet wipe body according to a certain weight ratio and the wet wipe body is sealed and packaged to form the physical antibacterial wet wipe. The product belongs to a wet wipe with zero preservative separation; the physical antibacterial wet wipe is soft to skins, has no irritation and no allergies and is especially suitable for sensitive skins, tender skins and the like.

Owner:SUZHOU BORAGE DAILY CHEM

Method for lifting roof girders and purlines at the same time

ActiveCN104989109AEasy constructionSimple construction processAnimal housingBuilding material handlingArchitectural engineeringPipe

The invention relates to a method for lifting roof girders and purlines at the same time. According to the method, auxiliary steel pipes serve as supporting pieces, a plurality of purlines or purlines and roof girders are assembled into a whole on the ground, the angle of the position of a crane rope is adjusted, and the overall inclination of the purlines and the roof girders is made to be the same as the roof gradient; then, the purlines and roof girders are lifted to the corresponding position of the rood girders as a whole and mounted in sequence, and the auxiliary steel pipes are removed after mounting is completed. According to the method, three mounting schemes that the two auxiliary steel pipes are used at the same time, one auxiliary steel pipe and one roof girder are used, and one auxiliary steel pipe and two roof girders are used are provided, the angle and lifting schemes are adjusted flexibly according to the construction filed situation, construction can be carried out along with building projects, and engineering advance is promoted; meanwhile, the problems that a traditional mounting process is low in construction speed, poor in quality, high in risk and low in benefit are solved, the construction period is shortened, quality is promoted, and safety guarantee is enhanced.

Owner:ASIA DAIRY FAB

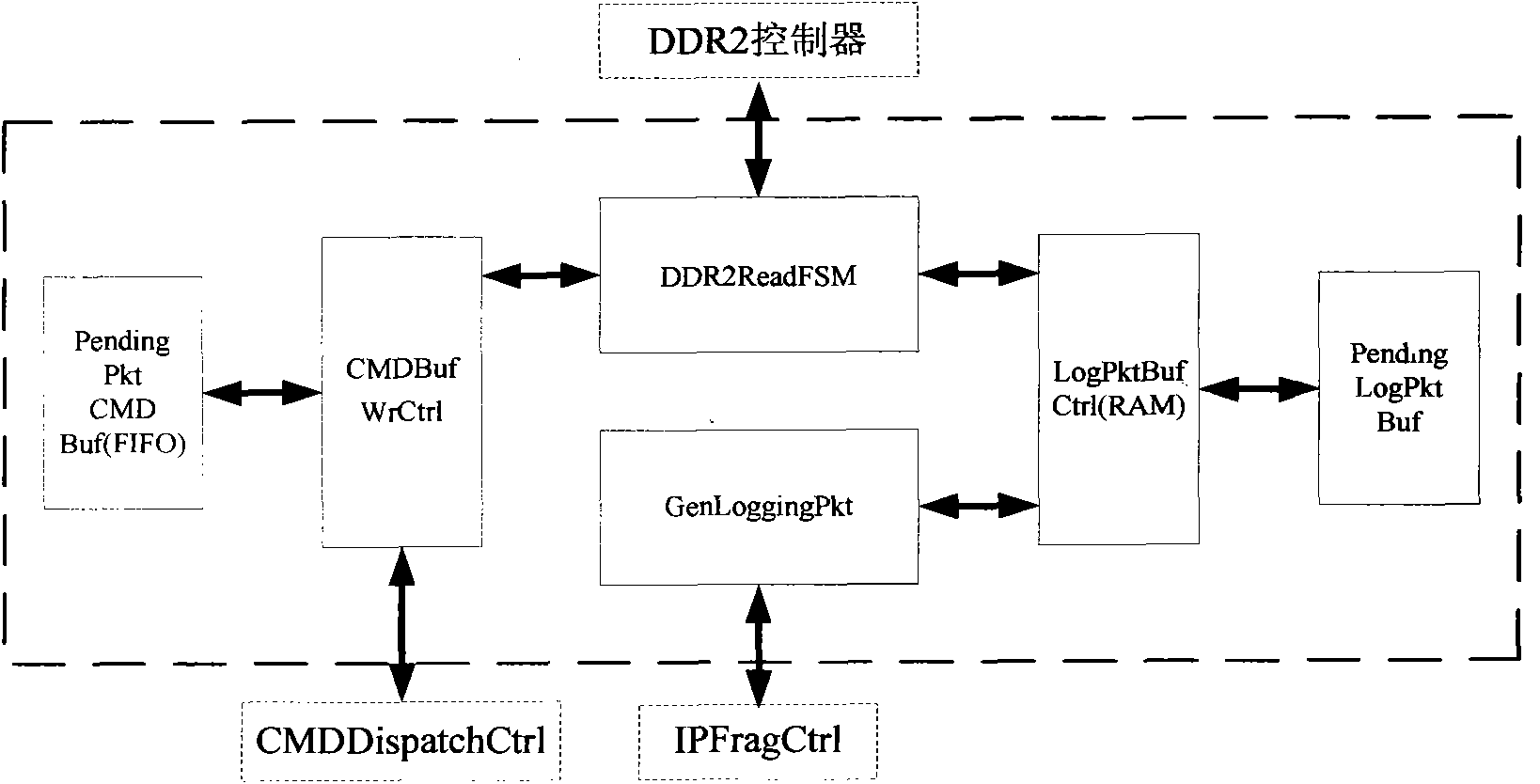

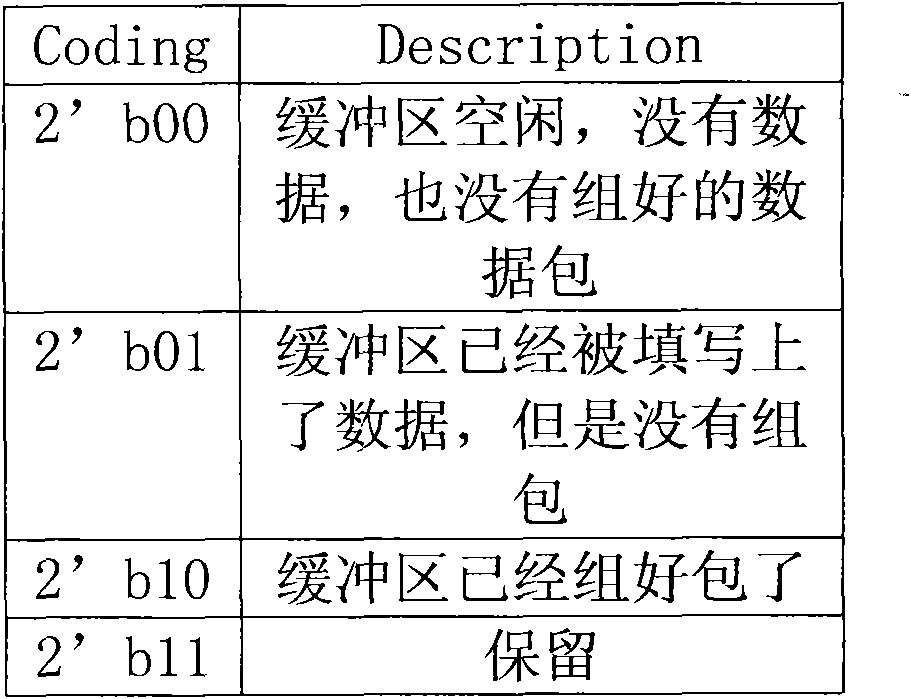

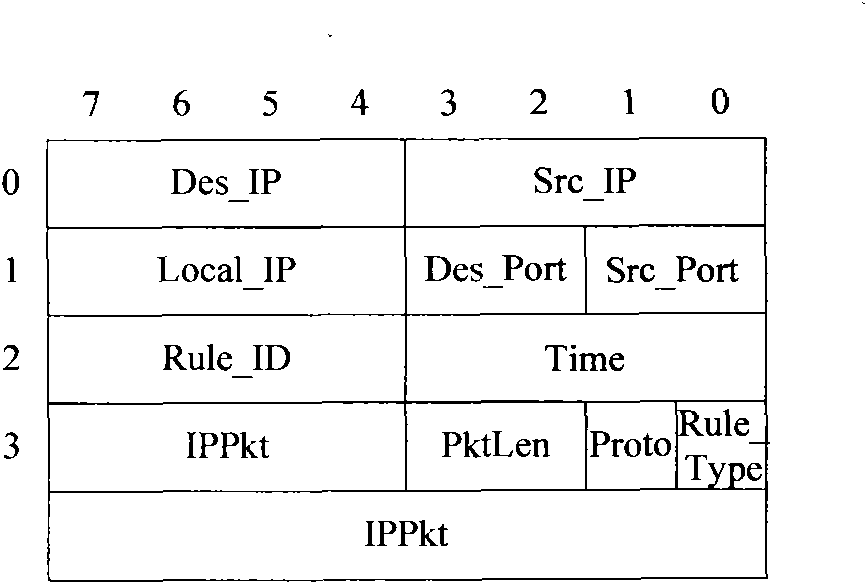

FPGA (Field Programmable Gate Array)-based network security log processing method and device

ActiveCN102098291AAvoid Cybersecurity RisksEnsure network securityData switching networksIp addressReal-time computing

The invention provides an FPGA (Field Programmable Gate Array)-based network security log processing method and device. The device comprises a network data storage, a user rule storage and a feature comparator. The method comprises the steps of: receiving packets sent by an external network, and temporarily storing the packets in the network data storage; detecting source and target IP addresses, source and target ports and protocols of the network packets, and monitoring the control bit of a message; for packets in accordance with set source and target IP addresses, set source and target ports and a set protocol, filtering results according to rules for hit packets, analyzing packet header information and filtering actions, and judging whether to send a log packet and determining the type of the log packet; and when a feature value is accorded with, grouping the packets taken from the network data storage, and sending the grouped packets to a mainframe memory to be stored, and analyzing data. By means of the method and the device provided by the invention, packet contents on the network can be monitored in time, network security risks can be prevented from increasing, and the network security is guaranteed.

Owner:曙光网络科技有限公司

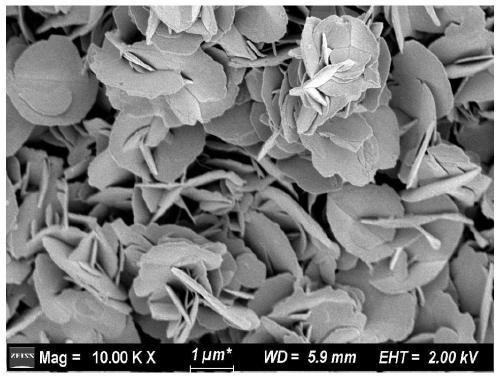

Method for one-step in-situ electro-deposition of layered double hydroxide coating on magnesium alloy surface

ActiveCN110484950AHigh security riskReduce security risksElectrolytic inorganic material coatingLayered double hydroxidesMaterials science

The invention provides a method for one-step in-situ electro-deposition of a layered double hydroxide coating on a magnesium alloy surface. The method includes the following steps that firstly, pretreatment is conducted and includes mechanical polishing and oil removing and grease removing, wherein oil removing includes acetone ultrasonic oil removing and alkaline oil removing; secondly, electro-deposition solution preparing and electro-deposition are conducted, wherein an electro-deposition solution of nitrate is prepared through distilled water, and electro-deposition is conducted in the above electro-deposition solution with a magnesium alloy being the work electrode and a platinum sheet being the counter electrode; and thirdly, the distilled water is used for flushing a sample obtainedthrough electro-deposition, the sample is dried in an oven or directly subjected to cold air blowing, and a magnesium alloy sample with an LDH film layer deposited is obtained. The method is achievedat the normal temperature and normal pressure, safety risks of production are lowered, the film forming speed is high compared with tens of hours or several tens of hours of a hydrothermal method, and LDH powder does not need to be prepared in advance or a pulse power source does not need to be used for deposition in multiple steps with various solutions.

Owner:CHINA WEST NORMAL UNIVERSITY

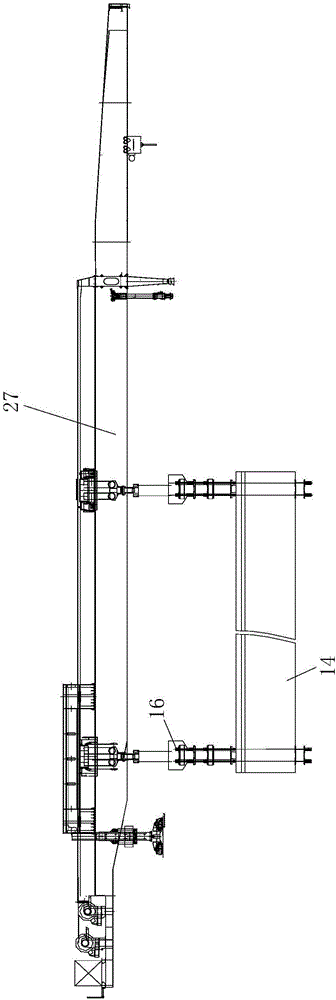

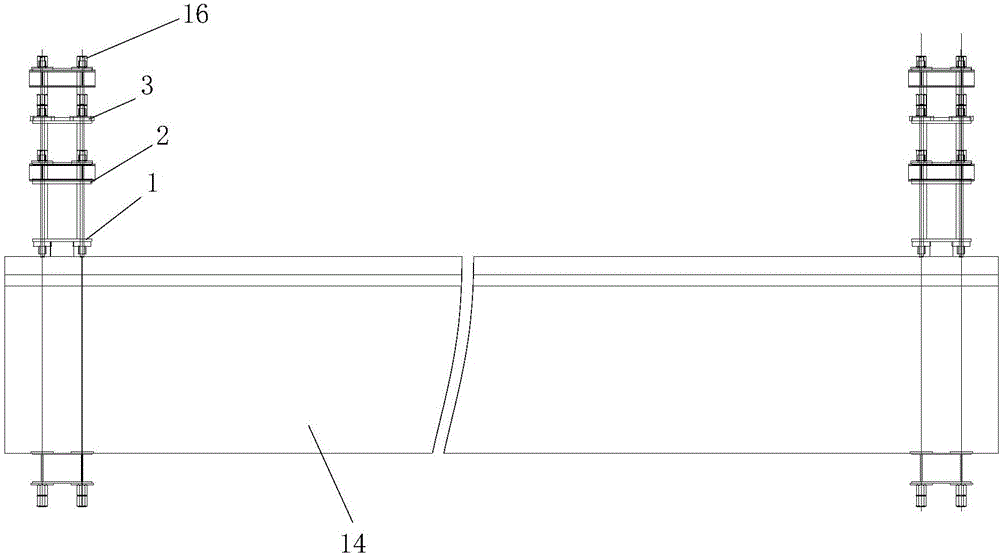

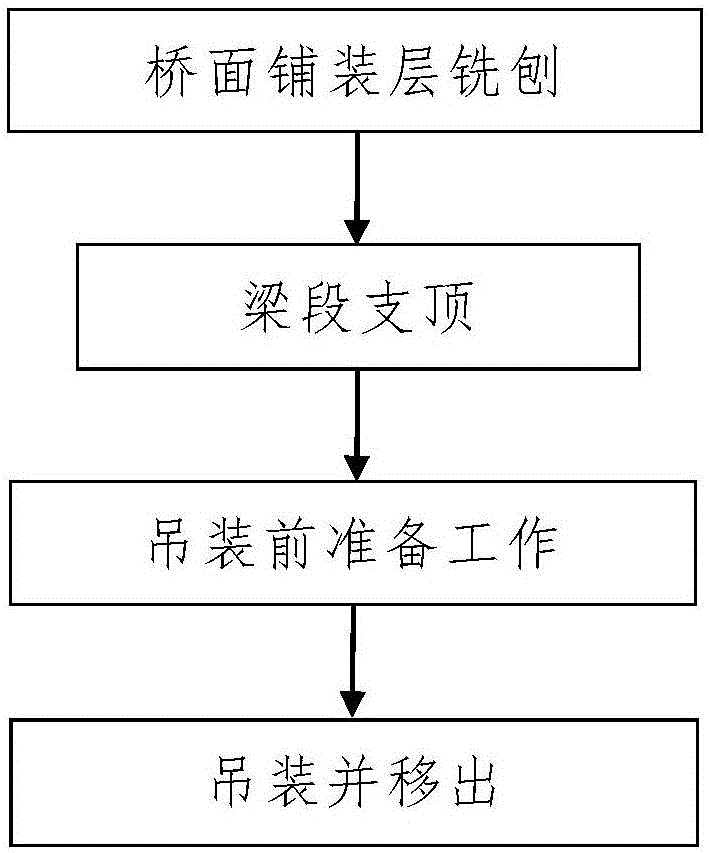

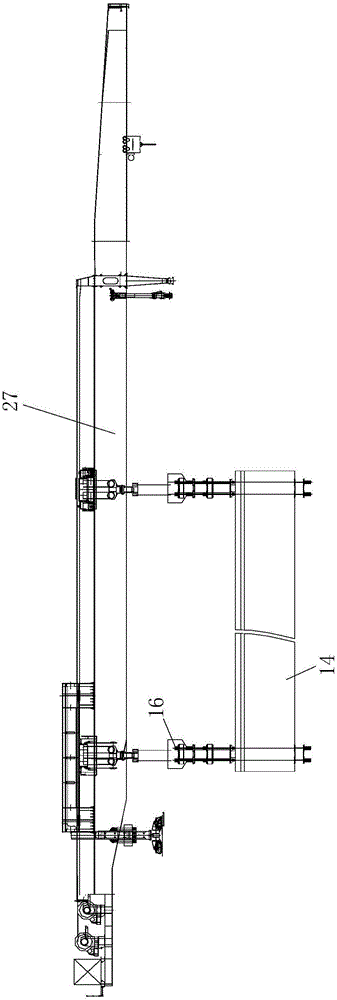

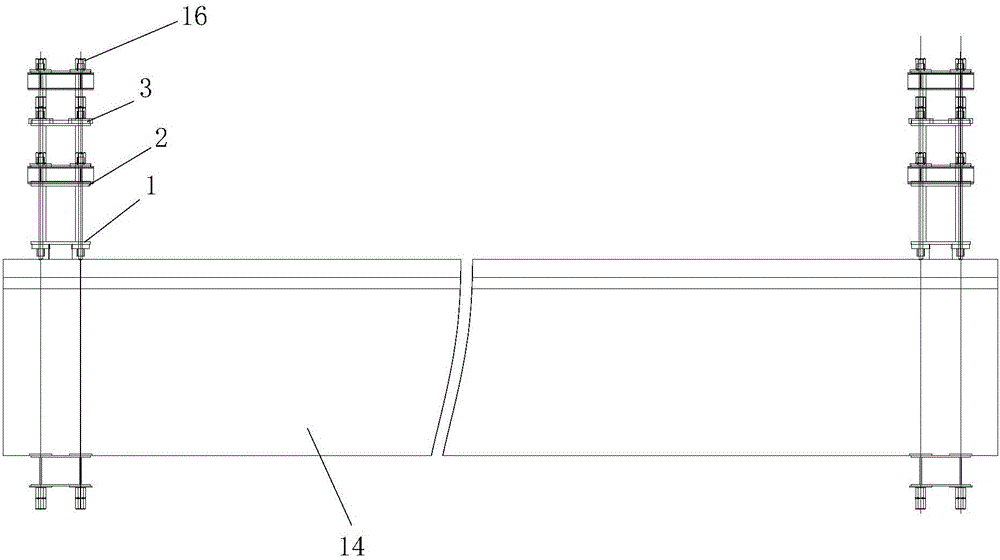

Crossing existing line bridge girder dismounting method

ActiveCN106284109ASimple stepsReasonable designBuilding repairsBridge strengtheningBridge deckRailway line

The invention discloses a crossing existing line bridge girder dismounting method. A dismounted bridge girder is a girder crossing an existing railway line and is formed by splicing a plurality of girder segments to be dismounted from front to back. During complete set dismounting construction of any segment to be dismounted, the process comprises the following steps that firstly, a bridge deck pavement is milled, specifically, the bridge deck pavement of the girder segment constructed currently is milled; secondly, the girder segment is jacked up, specifically, the girder segment constructed currently is horizontally jacked upwards through a vertical jacking device, so that the girder segment constructed currently is separated from two supporting piers; thirdly, preparation operation before hoisting is conducted; and fourthly, the girder segment constructed currently is horizontally hoisted upwards through a bridge girder erection machine and moved to the outer sides of the two supporting piers. The method is simple in step, reasonable in design, easy and convenient to construct and good in application effect, the complete set dismounting construction process of the crossing existing line bridge girder can be completed easily, conveniently and rapidly, and the construction process is safe and reliable, the construction period is short, and the method is economic and practical.

Owner:中铁二十局集团第三工程有限公司

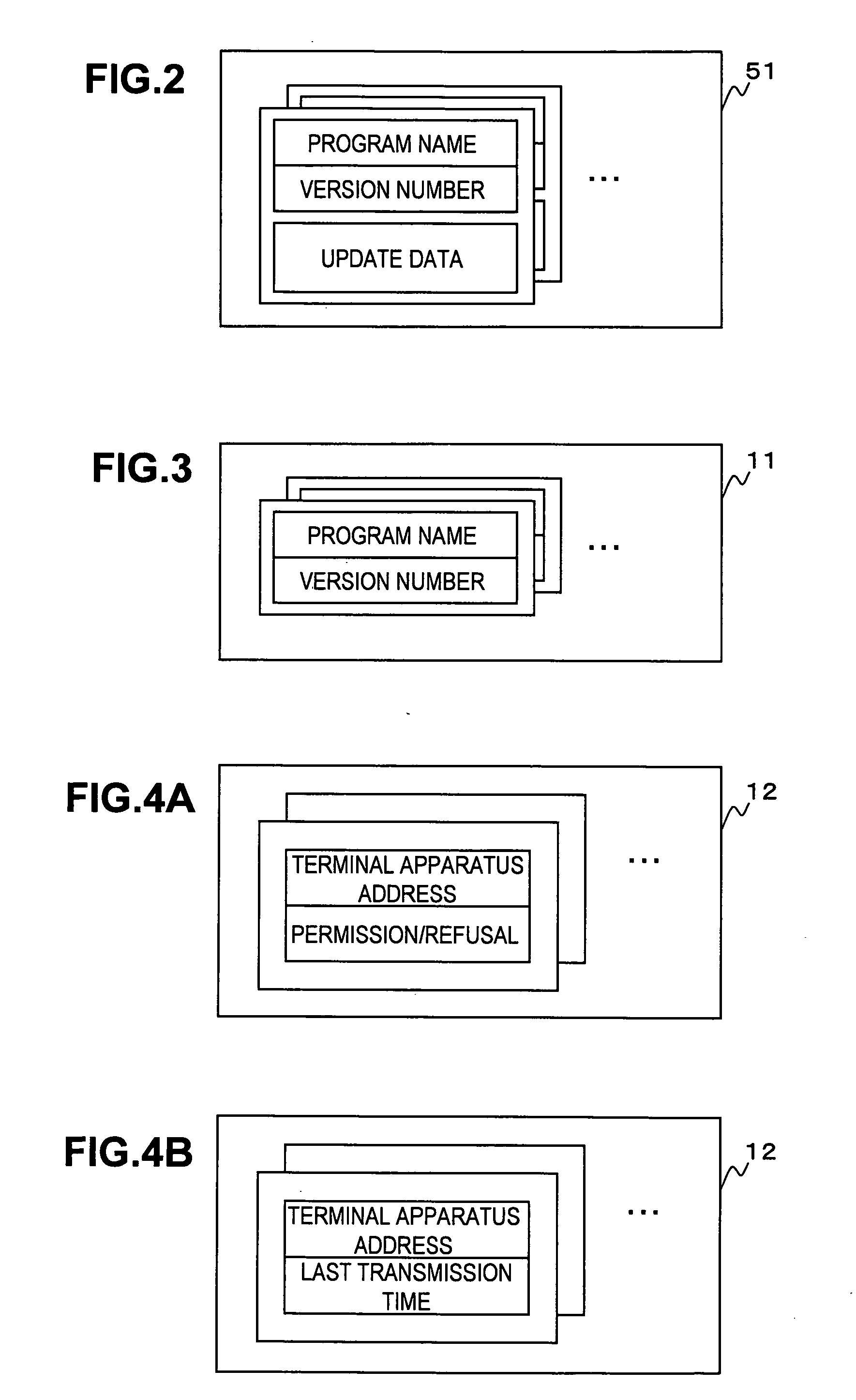

Terminal apparatus security management apparatus and method

InactiveUS20080072308A1Easy to getHigh security riskMultiple digital computer combinationsPlatform integrity maintainanceSecure stateTerminal equipment

A security management apparatus temporarily holds a session establishment request by a terminal apparatus 3 then determines permission or refusal of the session establishment request based on terminal management information. If permission is determined, the apparatus determines whether or not the security state of the source terminal apparatus is the latest one based on security management information. If it is determined not to be the latest one, then the apparatus sends out a session establishment request in which the terminal apparatus and a security information management apparatus are set as the source and the destination. After that, when update of the security of the terminal apparatus is notified, the held session establishment request by the terminal apparatus is sent out. On the other hand, if the security state is determined to be the latest one, the held session establishment request by the terminal apparatus is sent out.

Owner:FUJITSU LTD

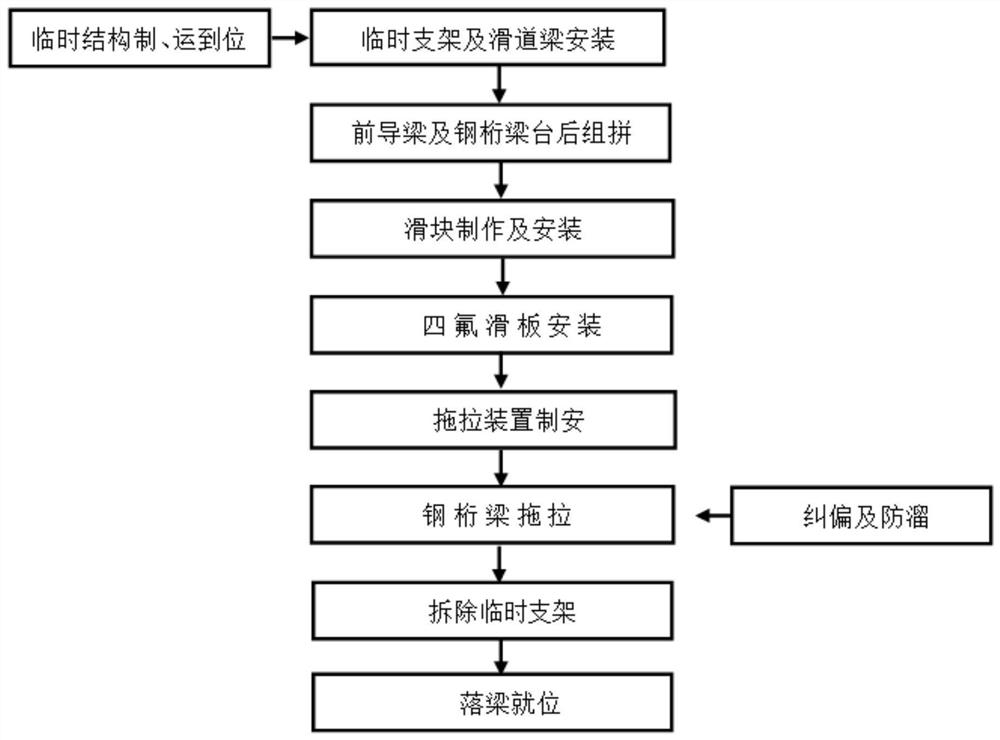

Single-line single-span railway steel truss girder dragging installation construction method and single-line single-span railway

InactiveCN112176867AImprove construction technologyShorten the construction periodTruss-type bridgeBridge erection/assemblyArchitectural engineeringJackscrew

The invention relates to a single-line single-span railway steel truss girder dragging installation construction method. The method comprises the following construction steps of S1, temporary supportand slide way girder installation, including behind-abutment roadbed section temporary support and slide way girder installation, inter-abutment temporary support and slide way girder installation, inter-pier temporary support and slide way girder installation and pier side temporary support and slide way girder installation; S2, front guide beam and steel truss girder behind-abutment assembling;S3, manufacturing and installing of a sliding block, including arrangement of the sliding block at a lower chord part between the large sections of the steel truss girder; S4, manufacturing and installing of a dragging device, including manufacturing and installing of a jack dragging horizontal counter-force seat, manufacturing and installing a rear anchoring device and penetrating and dragging ofa steel strand bundle; S5, dragging of a part of the steel truss girder; S6, dismounting of the temporary support, including dismounting of the sliding block and dismounting of the support; and S7, beam falling in place. The invention further relates to a single-line single-span railway obtained through the construction method. The construction method is advanced, engineering quality, safety andcontrollability are achieved, and the construction period is effectively shortened.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com