Method for lifting roof girders and purlines at the same time

A technology for purlins and roof beams is applied in the field of hoisting roof beams and purlins at the same time, achieving the effects of high construction difficulty, high safety risk and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

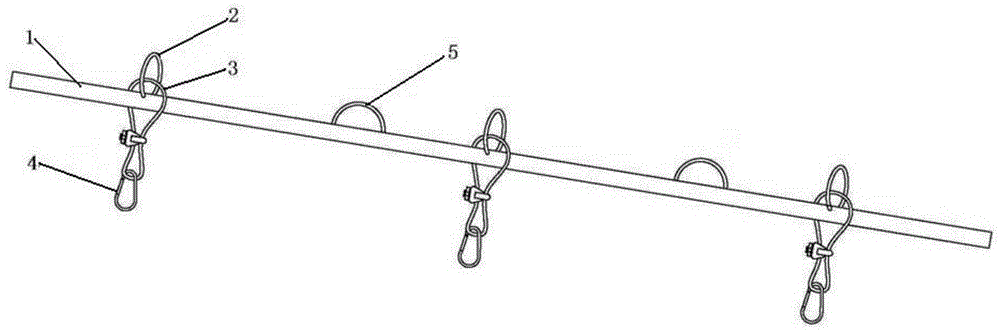

[0029] Use two auxiliary steel pipes to hoist the purlins at the same time. The auxiliary steel pipes are composed of steel pipes 1, steel rings 2, steel rings 3, lifting rings 4, and lifting points 5. The steel rings 2 are welded on the steel pipes 1. The number of steel rings and the purlins required to be installed The number of steel rings 2 is the same, the distance between the steel rings 2 is the same as the distance between the roof beam purlins, the steel ring 3 is sleeved on the steel pipe 1 through the steel ring 2, and the lifting ring 4 is sleeved under the steel ring 3, The lifting points 5 are semicircular structures welded on the steel pipe 1 with steel bars, and the number is three. The steel ring 2 is made of steel bars with a thickness of 6 mm. The traveler 3 is made of steel bars with a thickness of 5 mm.

[0030] When installing purlins, assemble the purlins that need to be installed on the ground, and use two auxiliary steel pipes as supports. 5. Instal...

Embodiment 2

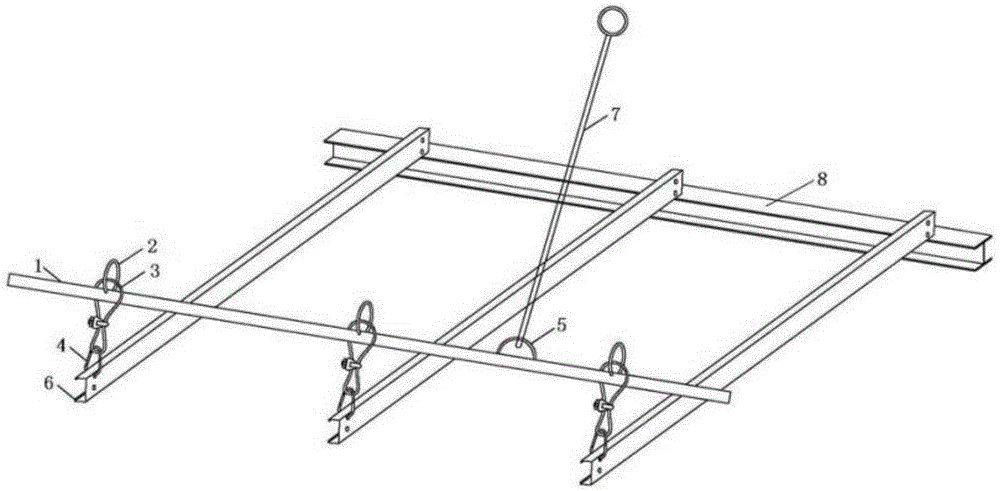

[0032] A purlin and a roof beam are simultaneously hoisted by an auxiliary steel pipe. The auxiliary steel pipe is composed of steel pipe 1, steel ring 2, steel ring 3, lifting ring 4 and lifting point 5. The steel ring 2 is welded on the steel pipe 1. The number of steel rings It is the same as the number of purlins required to be installed, the distance between the steel rings 2 is the same as the distance between the purlin brackets of the roof beam, the steel ring 3 passes through the steel ring 2 and is sleeved on the steel pipe 1, and the lifting ring 4 is sleeved on the steel pipe 1. Below the traveler 3, the lifting point 5 is a semicircular structure welded on the steel pipe 1 with steel bars, and the number is three. The steel ring 2 is made of steel bars with a thickness of 6 mm. The traveler 3 is made of steel bars with a thickness of 5 mm.

[0033] During installation, the purlins and roof beams that need to be installed are assembled on the ground according to the...

Embodiment 3

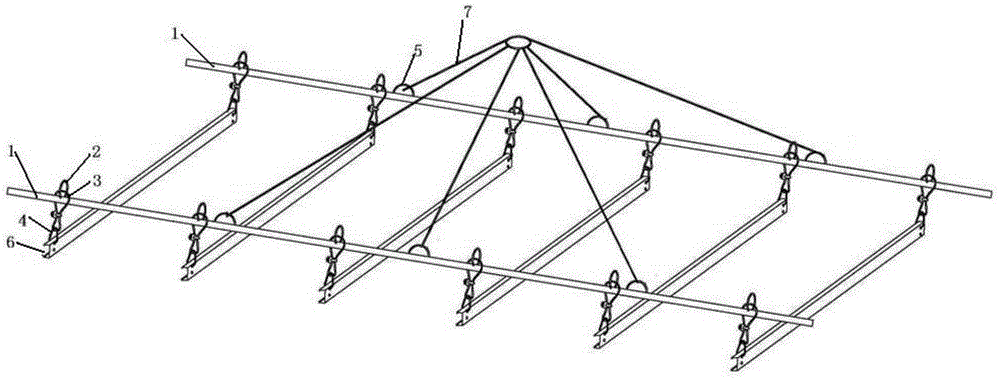

[0035] Use an auxiliary steel pipe to hoist the purlins and two roof beams at the same time. The auxiliary steel pipe is composed of steel pipe 1, steel ring 2, steel ring 3, lifting ring 4 and lifting point 5. The steel ring 2 is welded on the steel pipe 1. The number of steel rings It is the same as the number of purlins required to be installed, the distance between the steel rings 2 is the same as the distance between the purlin brackets of the roof beam, the steel ring 3 passes through the steel ring 2 and is sleeved on the steel pipe 1, and the lifting ring 4 is sleeved on the steel pipe 1. Below the traveler 3, the lifting point 5 is a semicircular structure welded on the steel pipe 1 with steel bars, and the number is three. The steel ring 2 is made of steel bars with a thickness of 6 mm. The traveler 3 is made of steel bars with a thickness of 5 mm.

[0036] During installation, the purlins and roof beams that need to be installed are assembled on the ground accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com